Thin film filling method

A filling method and thin film technology, which is applied in coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of high leakage current path of devices, device failure, yield reduction, etc., and achieve the effect of good filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

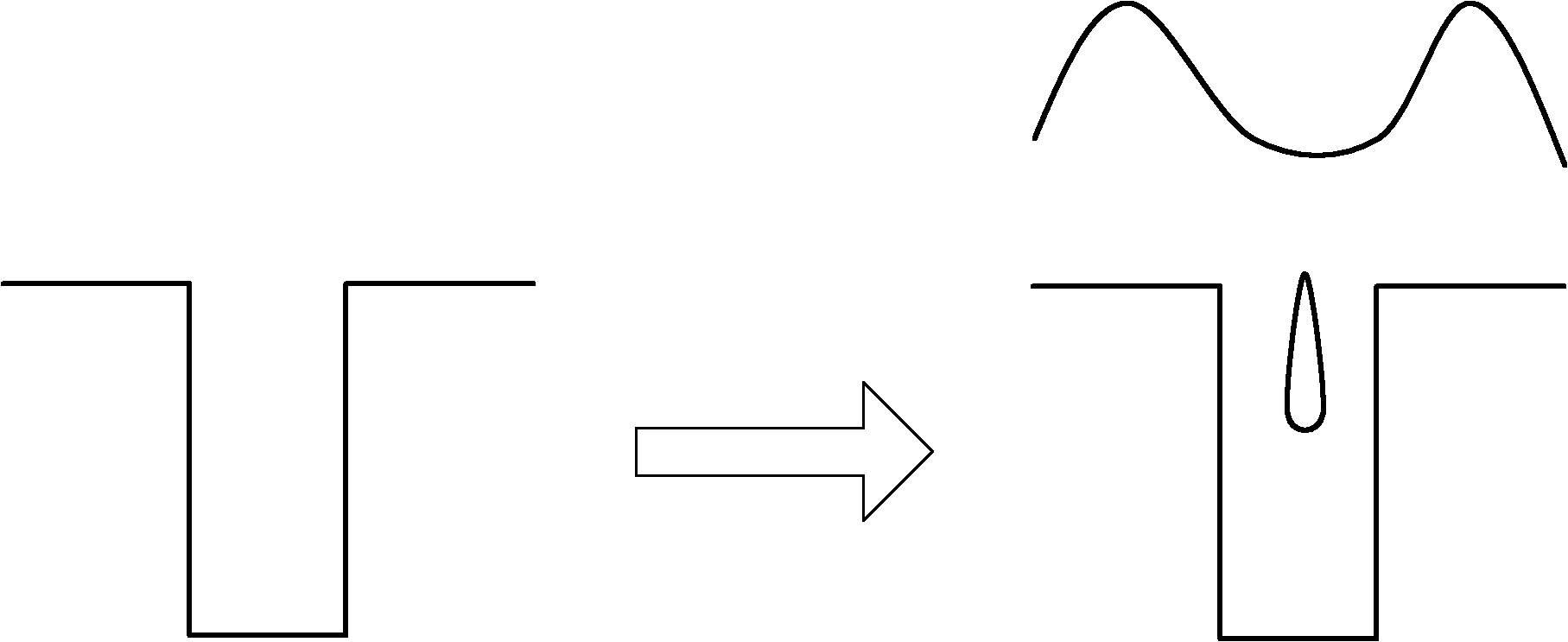

[0071] Such as Figure 4As shown in 401 in a, it is an STI structure formed on the surface of the substrate, which omits the pad oxide layer and nitride layer film grown in the furnace tube and the film oxide layer grown in the gap, and enters after heat treatment and annealing The HDP CVD chamber starts the first part of the deposition. For ease of description, this figure only shows an STI structure, and the formation of the STI structure and active region can refer to the existing conventional technology, which is not limited in the present invention. The semiconductor substrate may include any suitable semiconductor substrate material, specifically, but not limited to, silicon, germanium, silicon germanium, SOI (silicon on insulator), silicon carbide, gallium arsenide, or any III / V compound semiconductor, etc. .

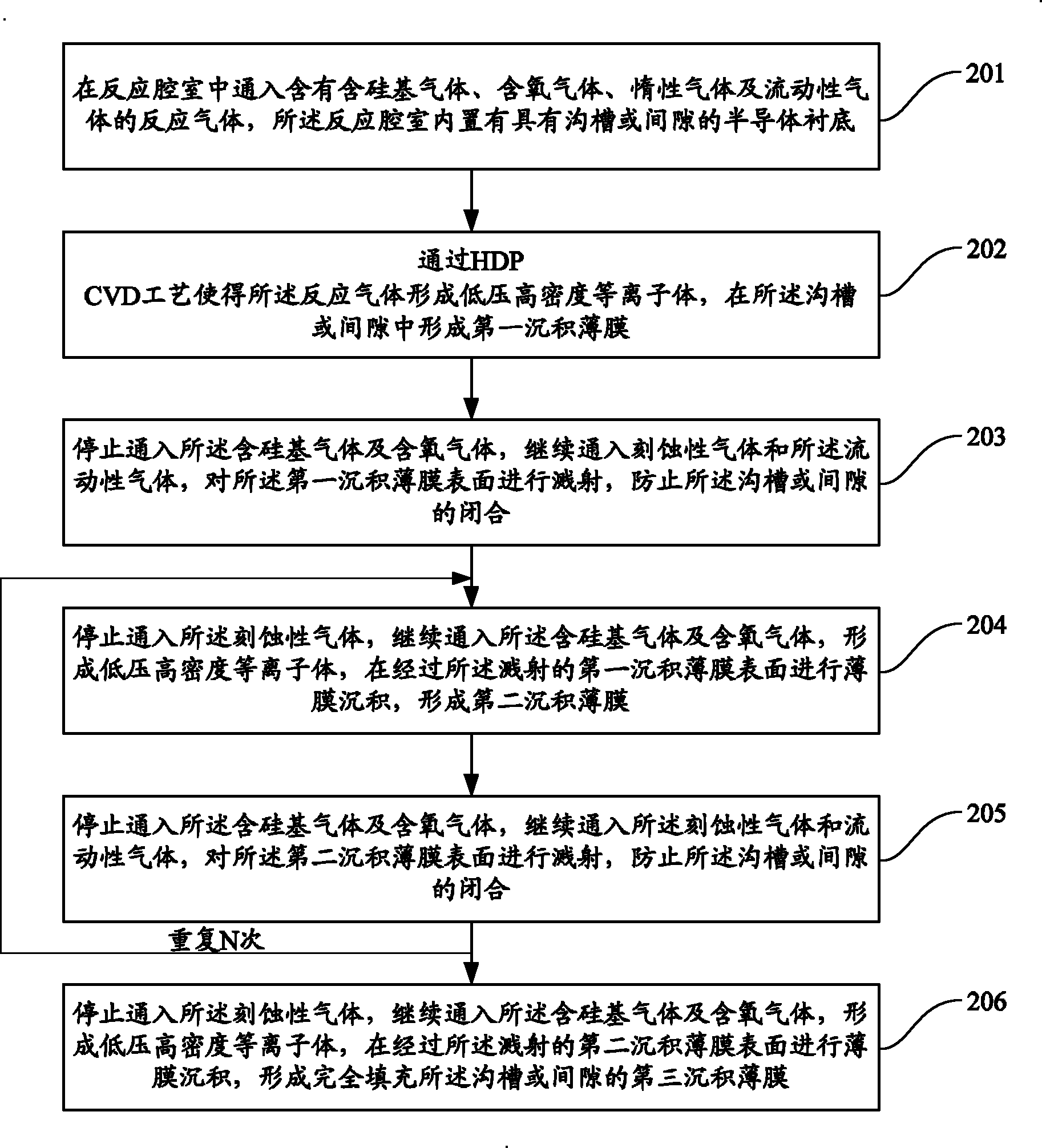

[0072] Figure 5 then shows the Figure 4 The process flow for thin film filling of the STI structure shown specifically includes the following steps:

[00...

Embodiment 2

[0082] Image 6 Another process flow for thin film filling of the STI structure is shown, which specifically includes the following steps:

[0083] Step 601, putting the semiconductor substrate with STI structure into the reaction chamber;

[0084] Step 602, injecting SiH into the reaction chamber 4 , O 2 , He and mobile dilution gas H 2 ;

[0085] Step 603, generating high-density plasma by inductive coupling, and performing ion bombardment under the action of bias power, so that the first deposited film is deposited on the STI and the surface of the substrate;

[0086] In this step, S / D has a lower value, so as to increase the deposition rate as much as possible, so that the film grows from bottom to top in the gap without closing the opening.

[0087] Step 604, stop feeding SiH 4 and O 2 , enter H 2 with NF 3 The physical and chemical etching process under the action;

[0088] The difference from Example 1 is that the etching gas in this example increases NF 3 , ...

no. 3 example

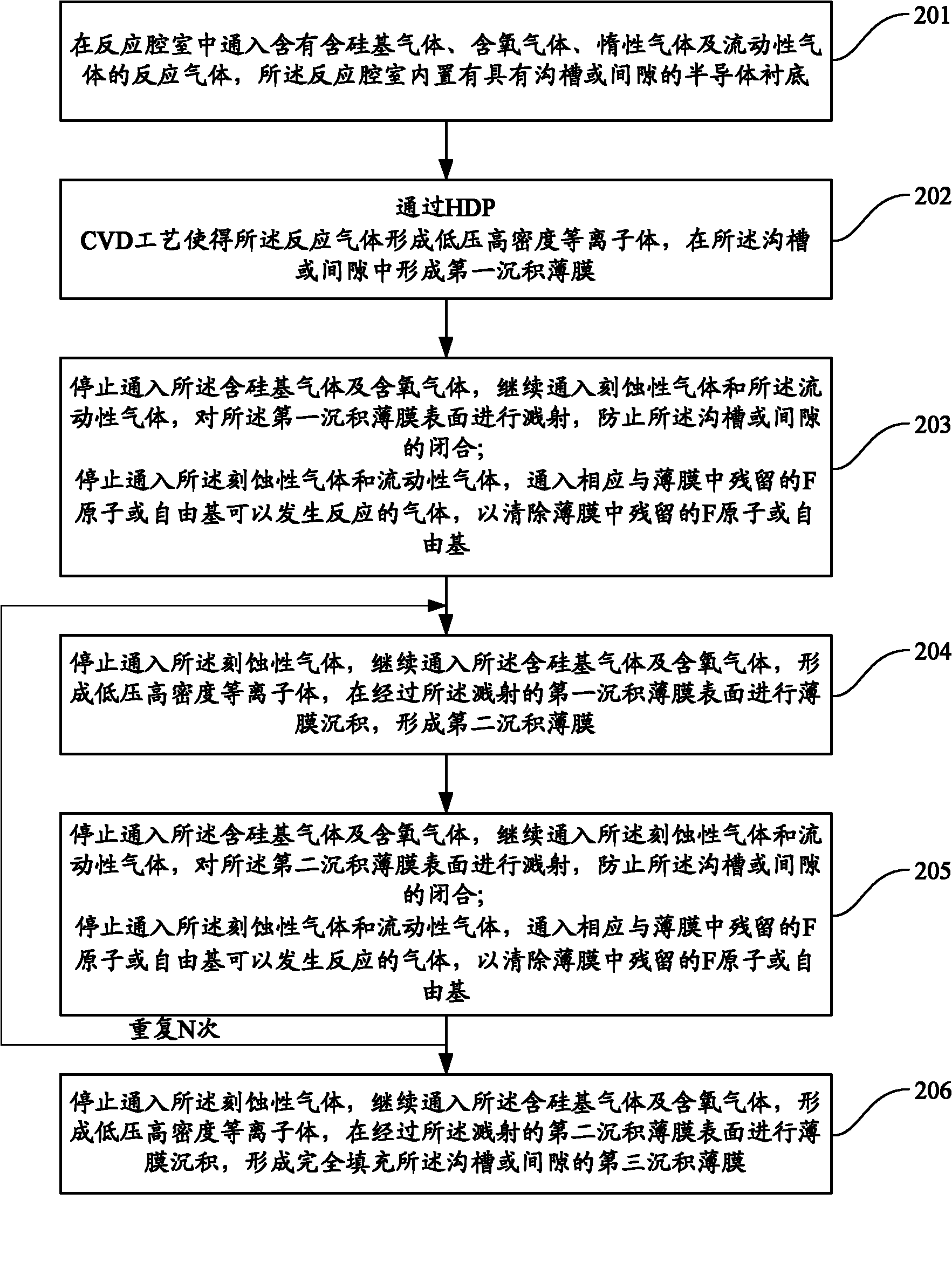

[0093] Figure 7 Another process flow for thin film filling of the STI structure is shown, which specifically includes the following steps:

[0094] Step 701, putting the semiconductor substrate with STI structure into the reaction chamber;

[0095] Step 702, injecting SiH into the reaction chamber 4 , O 2 , He and mobile dilution gas H 2 ;

[0096] Step 703, generating high-density plasma by inductive coupling, and performing ion bombardment under the action of bias power, so that the first deposited film is deposited on the STI and the surface of the substrate;

[0097] In this step, S / D has a lower value, so as to increase the deposition rate as much as possible, so that the film grows from bottom to top in the gap without closing the opening.

[0098] Step 704, stop feeding SiH 4 and O 2 , enter H 2 with NF 3 The physical and chemical etching process under the action;

[0099] The difference from Example 1 is that the etching gas in this example increases NF 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com