Underground coal mine hydraulic sand fracturing system and method

A technology of sanding fracturing and water supply system, which is applied in the direction of earthwork drilling, wellbore/well components, and production fluids, etc. It can solve the problems that the sanding process cannot be fully used, and achieve a significant effect of fracturing and increase permeability and reduce consumption The effect of the amount and easy access to the coal seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

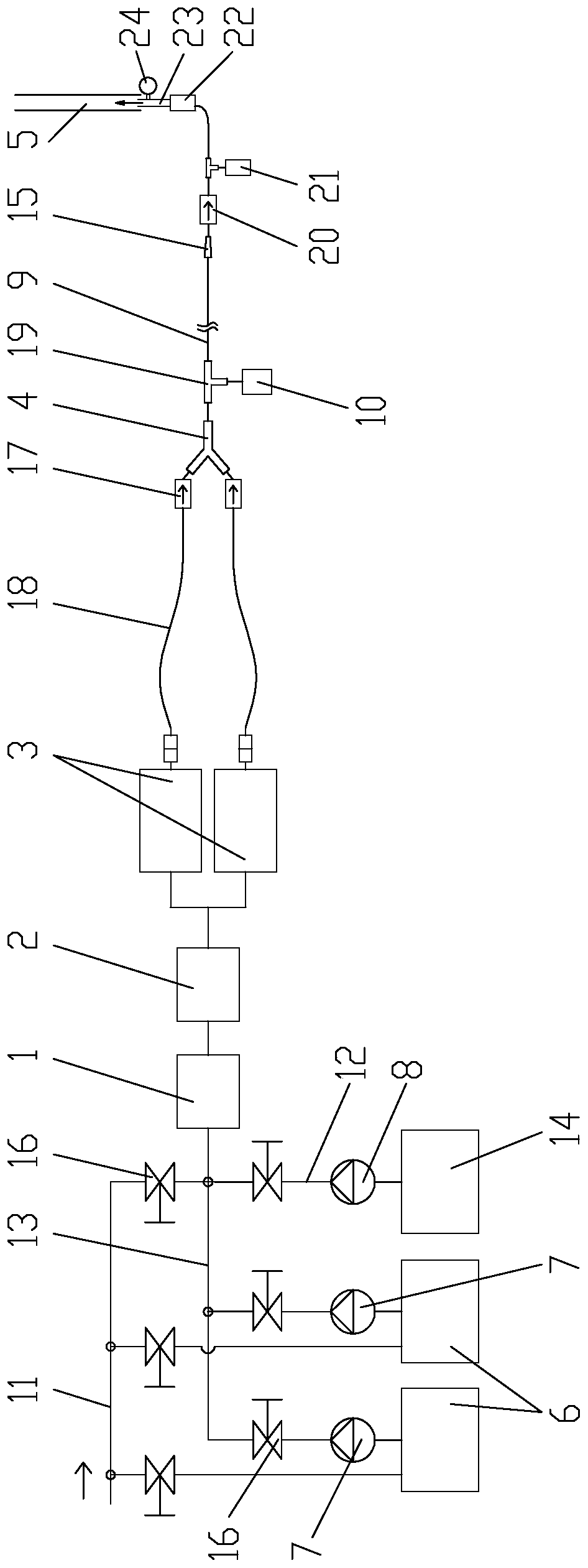

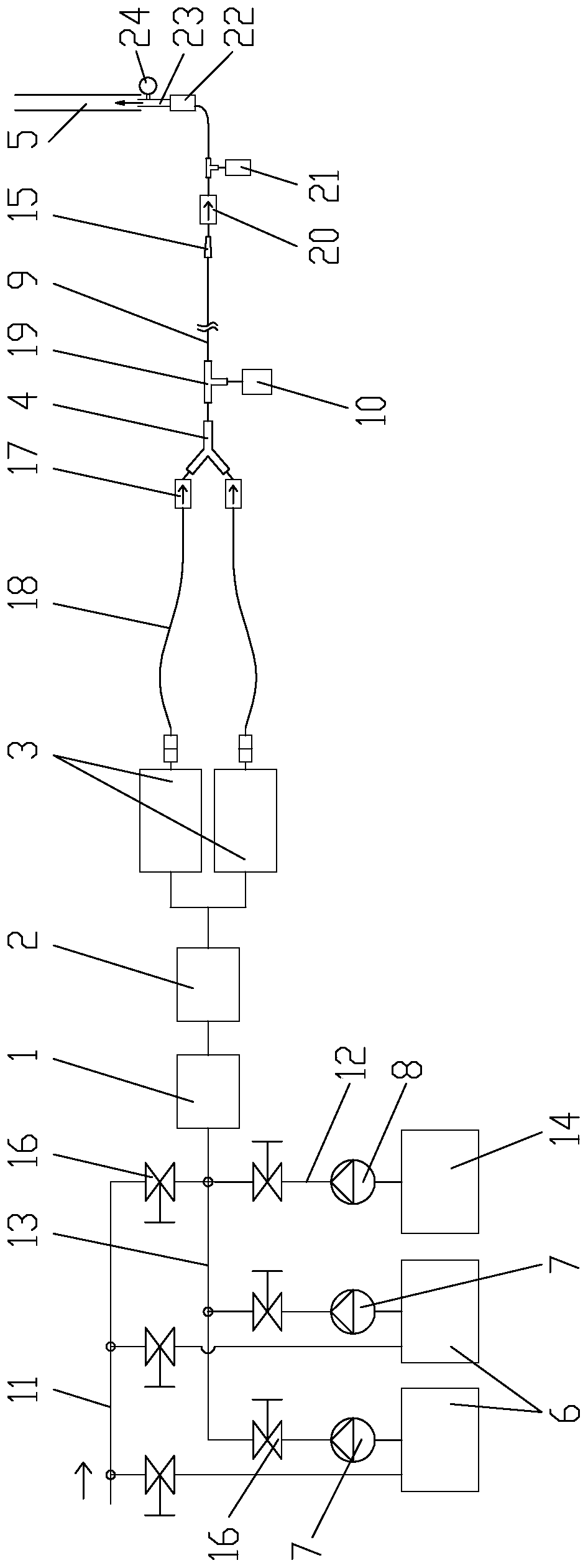

[0050] Example 1, see figure 1 , an underground coal mine hydraulic sand fracturing system, comprising a water supply system, a liquid distribution system, a sand mixing system, a fracturing system and a high-pressure manifold system; the water supply system has pipelines respectively connected to the liquid distribution system and the sand mixing system; The sand mixing system is composed of a sand mixing device 1 and a sand mixing booster device 2. The liquid inlet channel of the sand mixing device 1 is respectively connected with the outlet of the liquid distribution system and the corresponding water supply pipeline of the water supply system through a tee. The mixing of the sand mixing device 1 The liquid outlet port is connected to the inlet port of the supercharging device 2, and the sand mixing device 1 has a proppant adding port for adding proppant; the outlet port of the supercharging device 2 is connected to the fracturing system; the fracturing system consists of tw...

Embodiment 2

[0053] Example 2, combined with figure 1 , a hydraulic sand fracturing method, the method is implemented based on the hydraulic sand fracturing system of embodiment 1, comprising the following steps:

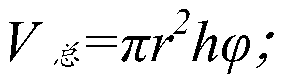

[0054] The first step, fracturing preparation: including hydraulic sand fracturing system layout, fracturing fluid preparation, proppant material preparation, and determining the amount of clean water V according to the fracturing method of clearing water first and then carrying sand in the fracturing fluid 清 , the amount of fracturing fluid V 压 and proppant dosage V 砂 ;

[0055] In the process of fracturing fluid preparation, the fracturing fluid is prepared from thickener, crosslinking agent, anti-swelling agent, gel breaker and water according to the following mass volume ratio and stirred and mixed evenly; the specific preparation ratio is thickened per 100L of water Agent 0.25g, crosslinking agent 0.25g, anti-swelling agent 1.5g, gel breaker 0.15g;

[0056] The proppant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com