Method and device for preparing and transferring printing plates

A printing plate and equipment technology, applied in the direction of printing plate preparation, printing, transportation and packaging, etc., to achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

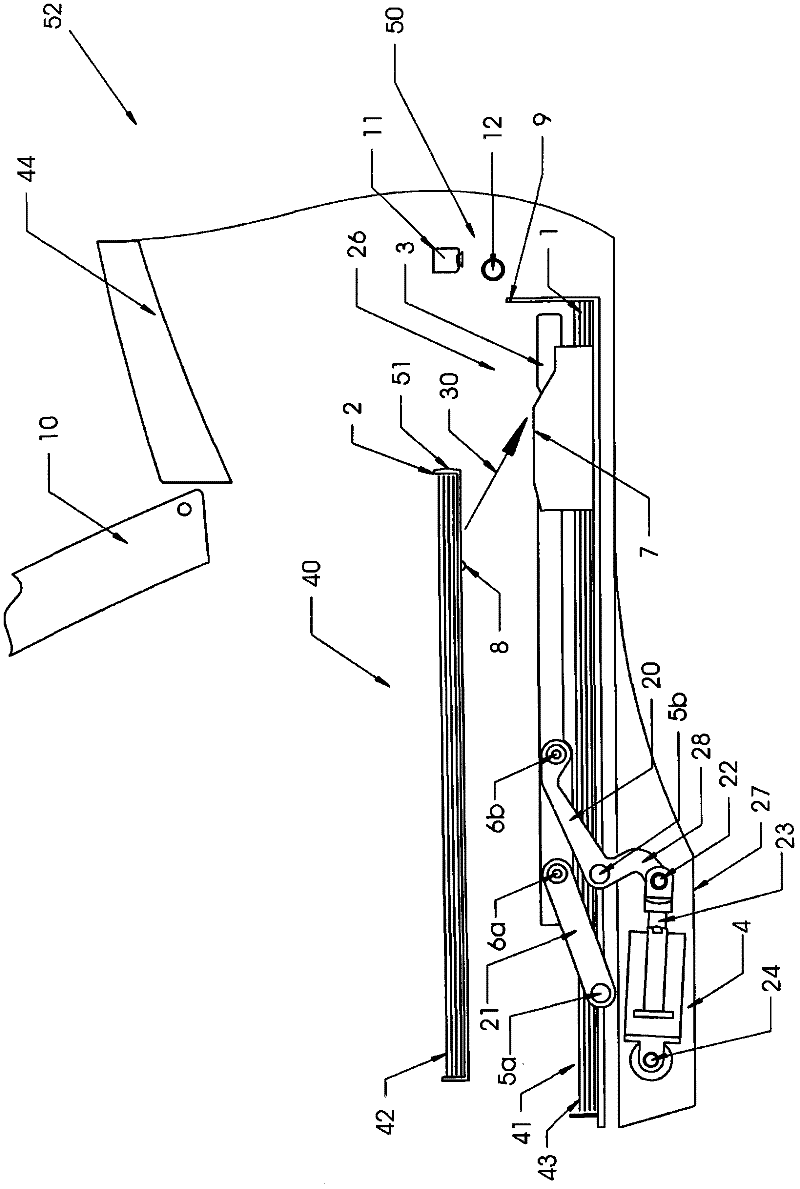

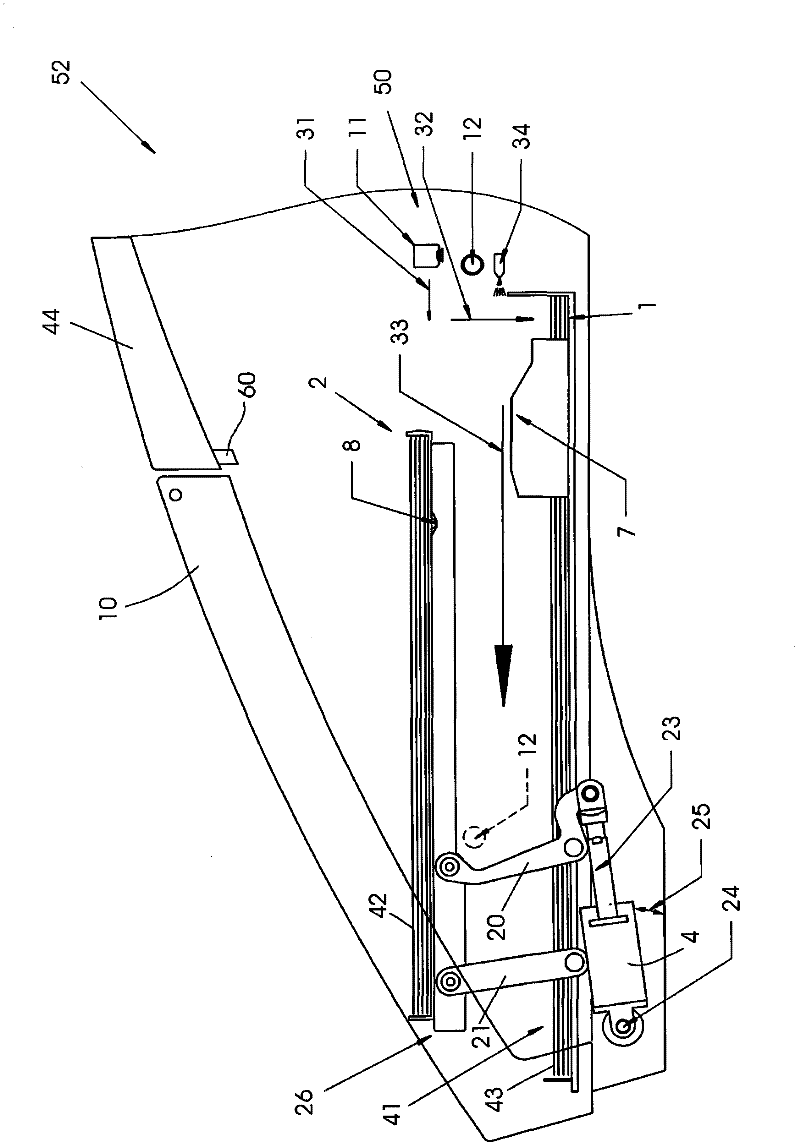

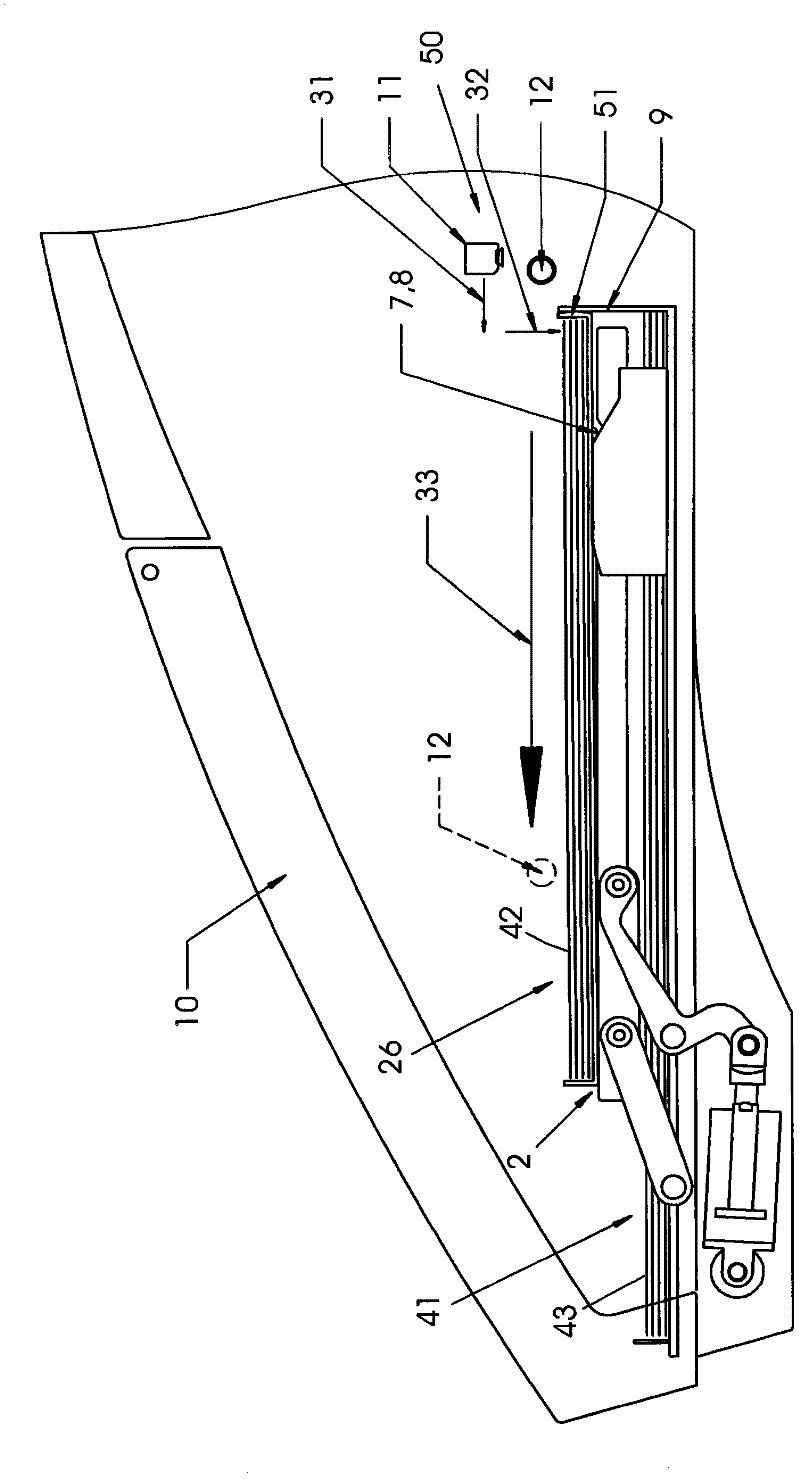

[0031] figure 1 A side cross-sectional view of the plate receiver 52 is shown. The printing plate receiver is here a component of a printing plate exposure machine (not shown here) which supplies the printing plates 42 , 43 via the printing plate receiver 52 . Such a plate receiver and a plate exposure machine are described in the unpublished German application DE 10 2009 052 144, to which reference is made with respect to the plate receiver and its positioning in the plate exposure machine.

[0032] The printing plate receiver 52 includes a cover element 44 which in turn includes the protective device 10 . The protective device 10 is pivotably arranged such that the printing plate stacks 40 , 41 and / or the pallet 2 with the printing plate stack 42 can be inserted into the printing plate receiving device 52 .

[0033] For receiving trays 2 , the plate receiver 52 includes the tray receiver 26 . The tray receiving device 26 is here in the lower front removal position, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com