Film LED chip device based on compound low-resistance buffer structure and its making method

A technology of LED chip and buffer structure, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as cracking, structural changes, and failures, and achieve the effects of reducing wafer warping, reducing production costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

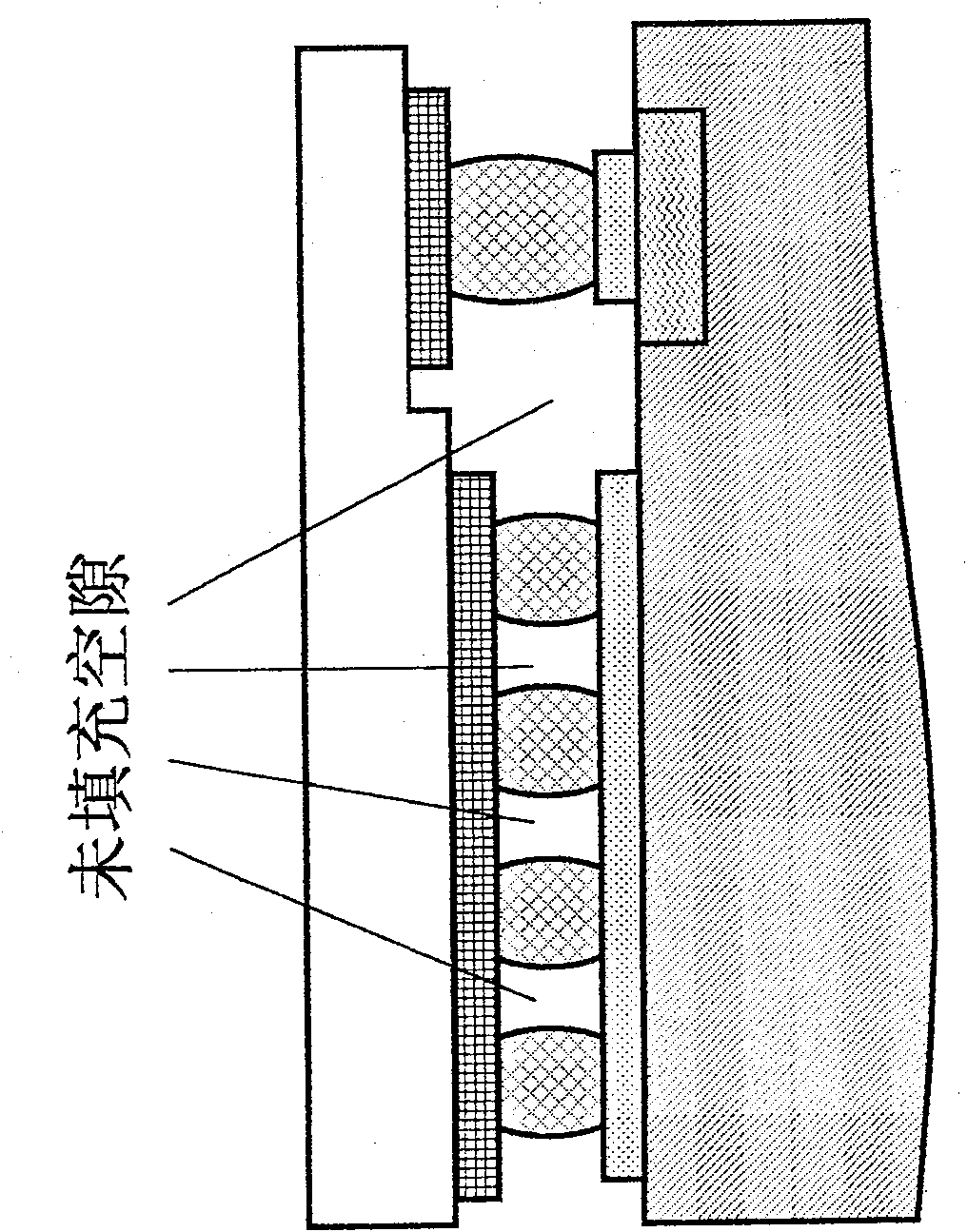

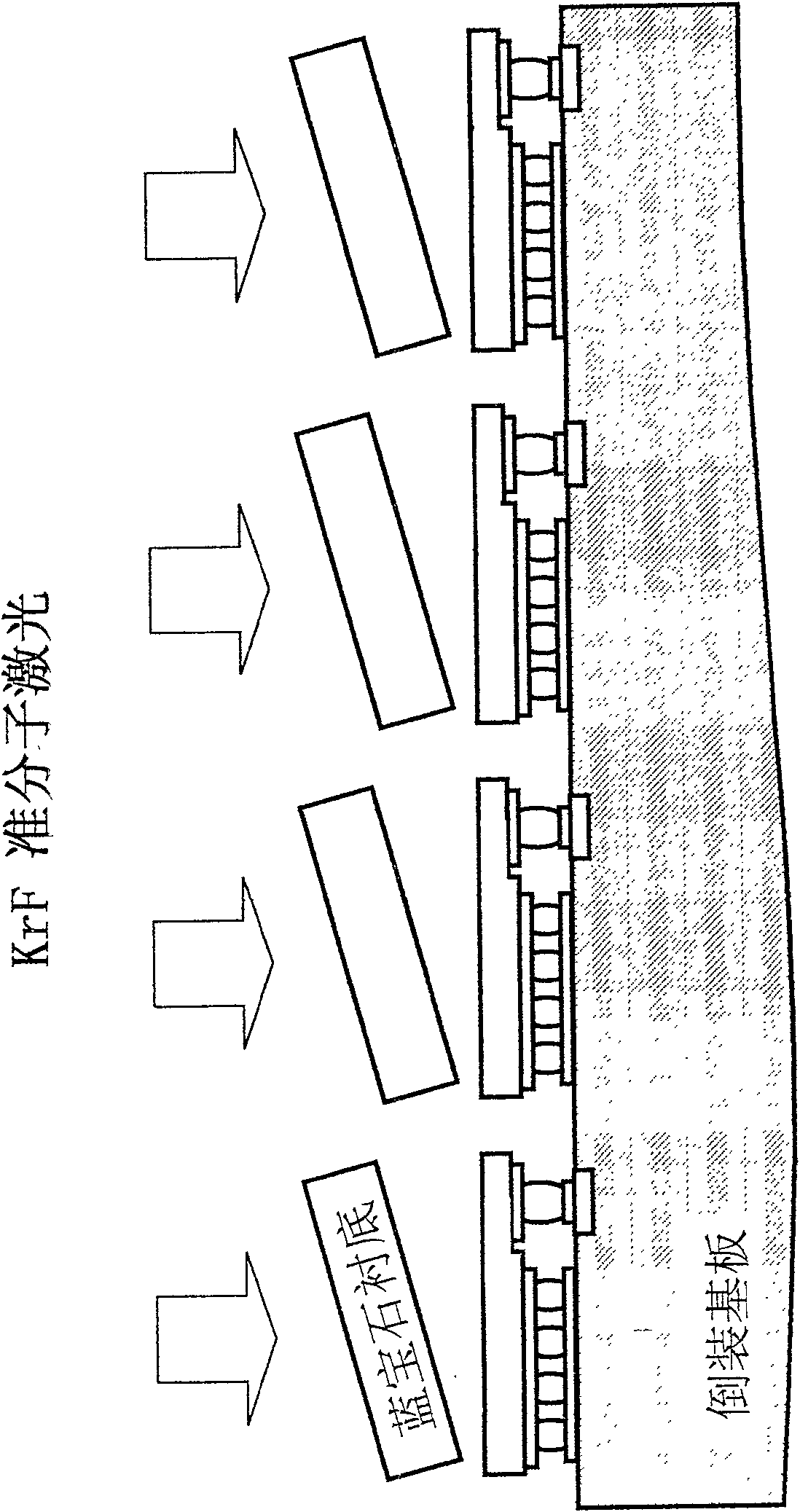

[0051] like Figure 4 A thin-film LED chip device based on a composite low-resistance buffer structure is shown in the figure. Epitaxial film 110; periodic grooves on the GaN-based epitaxial film 110, the periodic grooves are formed by sequentially removing the P-type semiconductor layer and the active layer at periodic intervals until the N-type semiconductor layer is exposed, and formed in the P-type semiconductor layer. The ohmic contact on the semiconductor layer and the metal reflection layer 120, the material of the metal reflection layer 120 is Ag or an alloy formed by a metal selected from Al, Ag, Ni, Au, Cu, Pd and Rh, and its thickness is 50 ~500nm; the multi-layer metal bonding layer 150 formed on the reflective metal layer; the N-electrode multi-layer metal bonding layer 150b formed on the N-type semiconductor layer; the passivation layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com