Assembly for supplying lubrication to the bearings of a combustion engine of a motor vehicle

A technology for lubricants and bearings, which is applied in the field of components that supply lubricants to bearings, and can solve problems such as unavoidable high bearing loads and reduced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

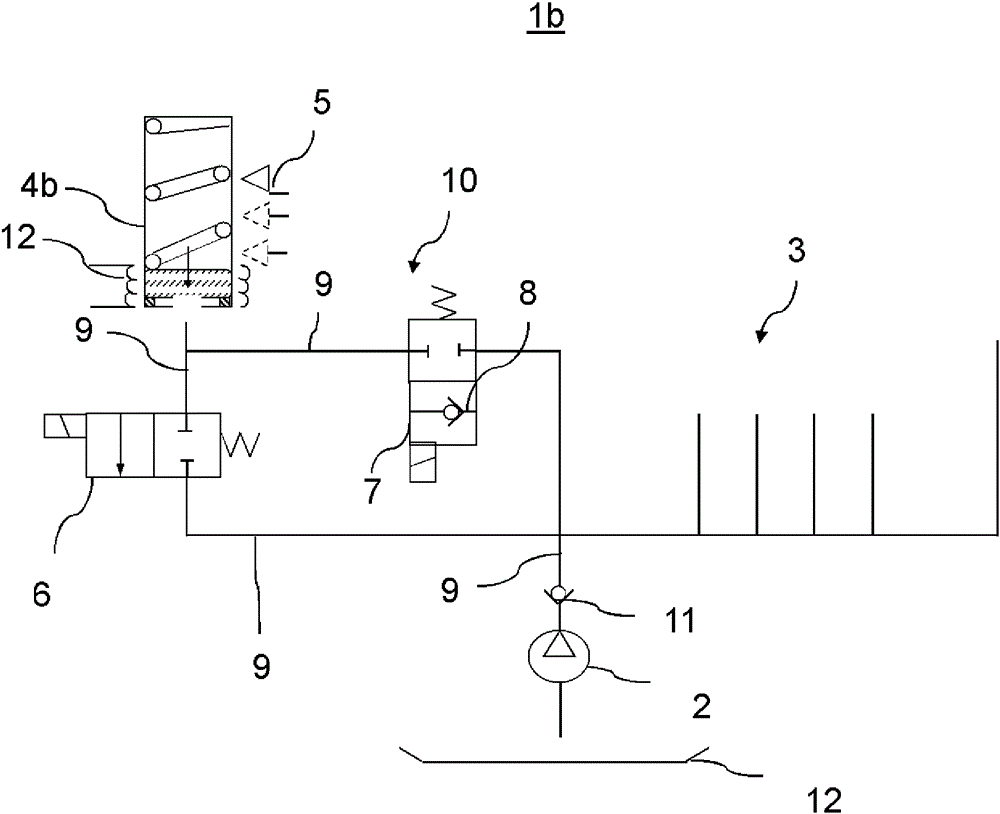

[0070] Figure 1A An assembly 1 for supplying lubricant to bearings of an internal combustion engine of a motor vehicle is shown very schematically. In FIG. 1 , for simplicity of illustration, only the oil opening 3 to the bearing of the internal combustion engine is shown, however, the internal combustion engine or the different bearings that are lubricated are not shown.

[0071] The bearing can be supplied with oil under pressure via the oil bore 3 in a conventional and per se known manner by the oil pressure pump 2 when the internal combustion engine is running after the engine has been started.

[0072] For this purpose, the oil pressure pump 2 is driven via a drive shaft (not shown) driven by the internal combustion engine. The oil pump 2 sucks oil from an oil sump (?lsumpf, sometimes called an oil sump) 12 . The oil sucked in by the oil pump 2 is then delivered to the internal combustion engine or the bearing for lubrication via the oil bore 3 . In addition, a check v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com