Patents

Literature

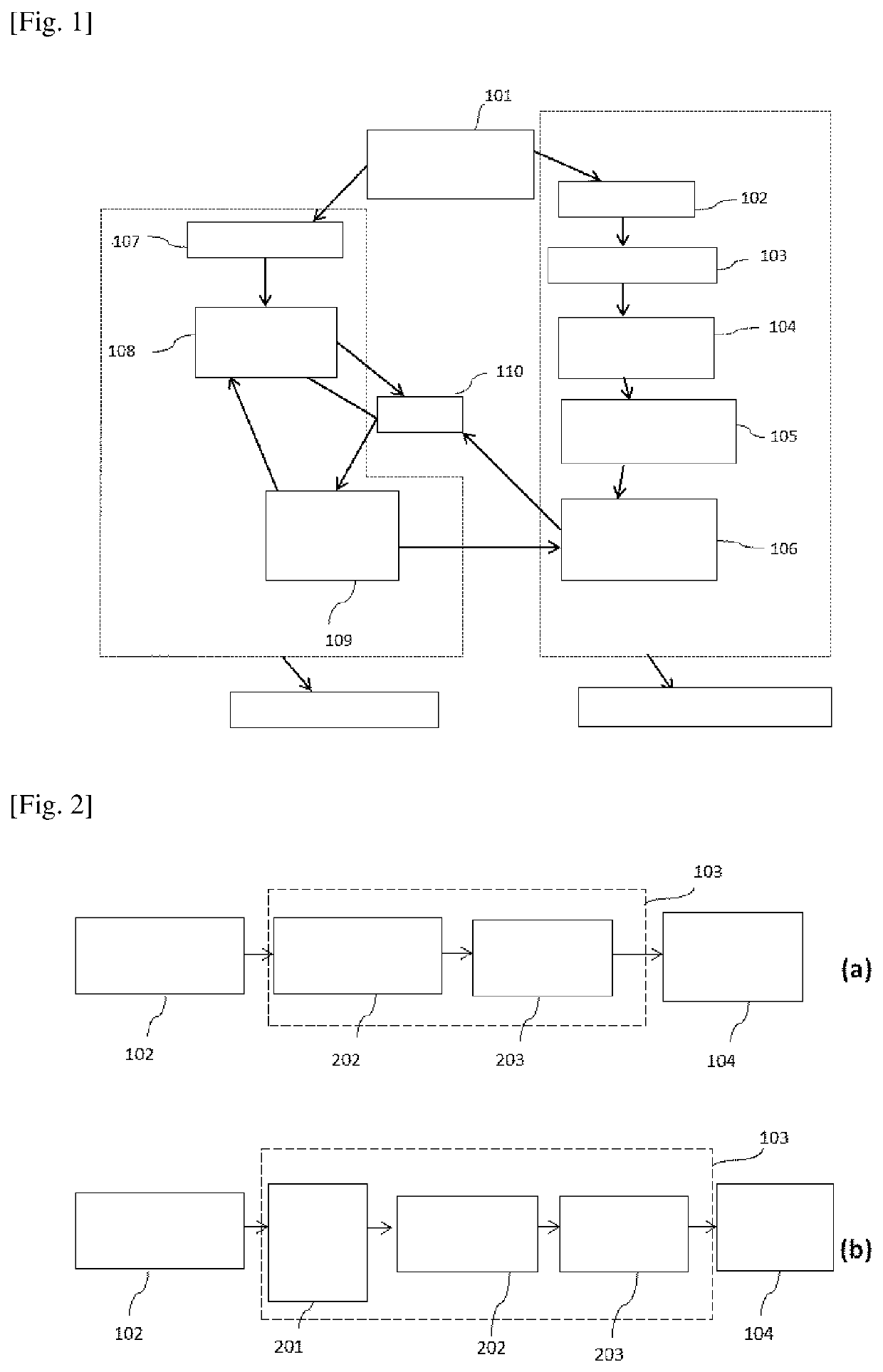

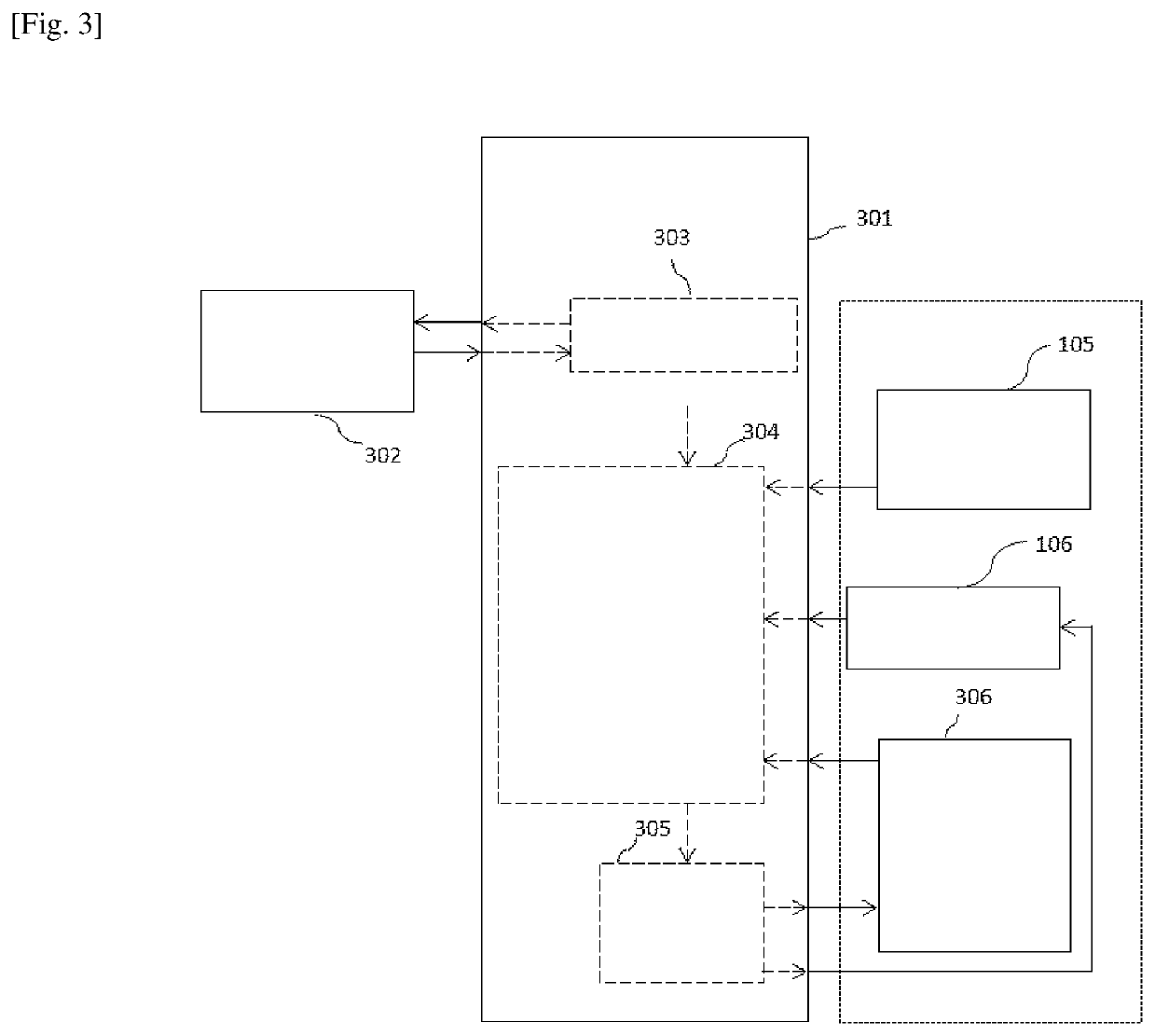

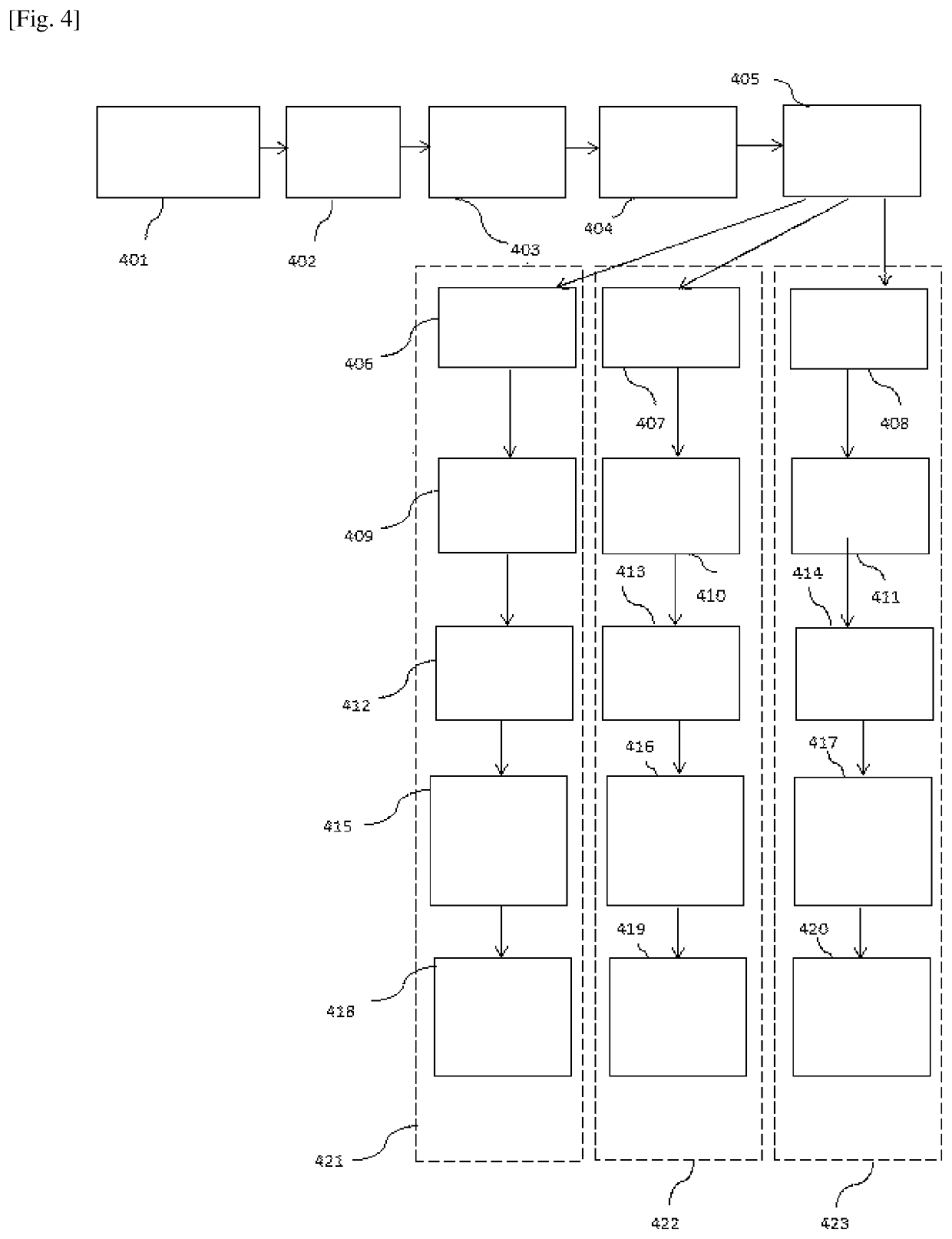

201 results about "Pulsed radiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

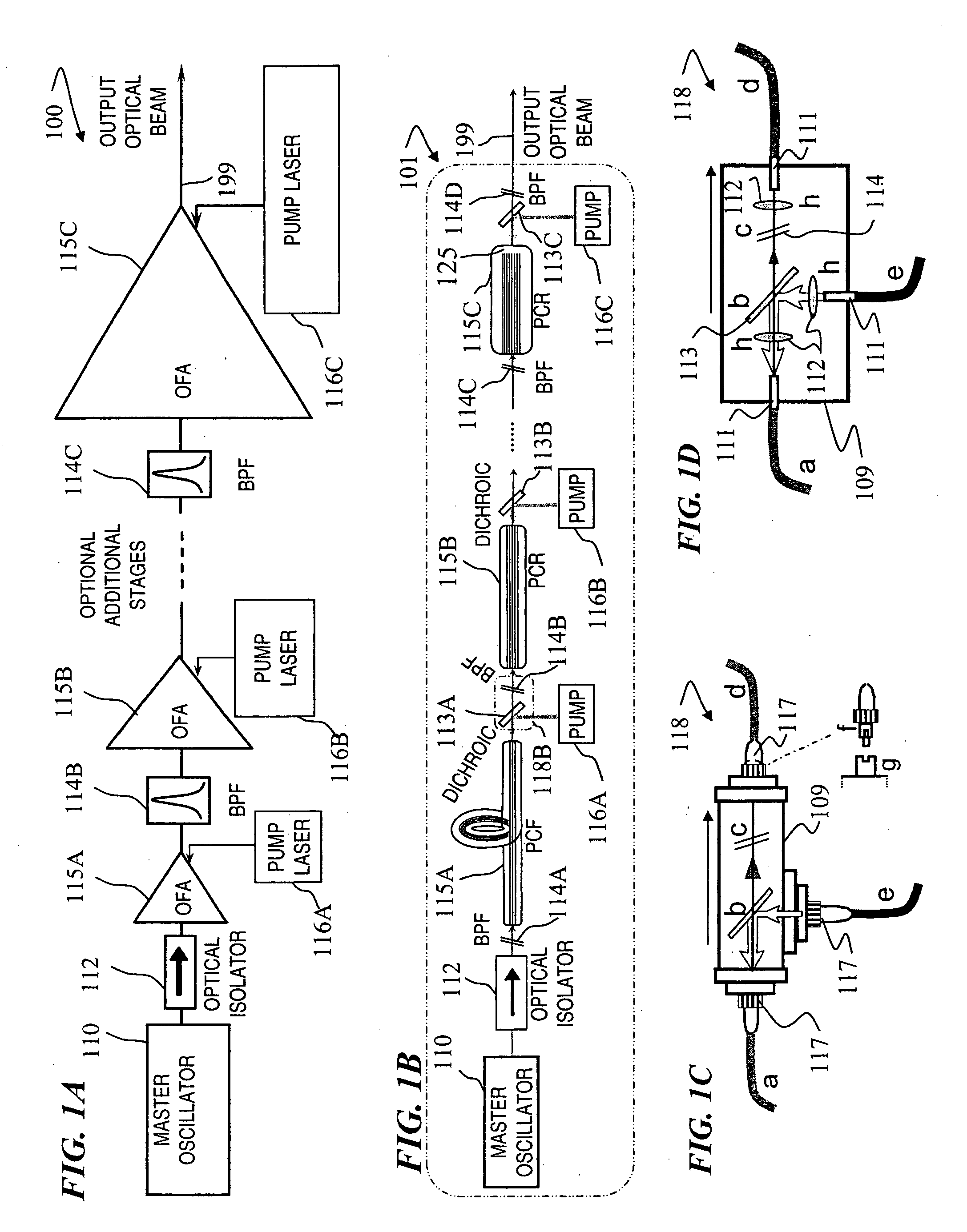

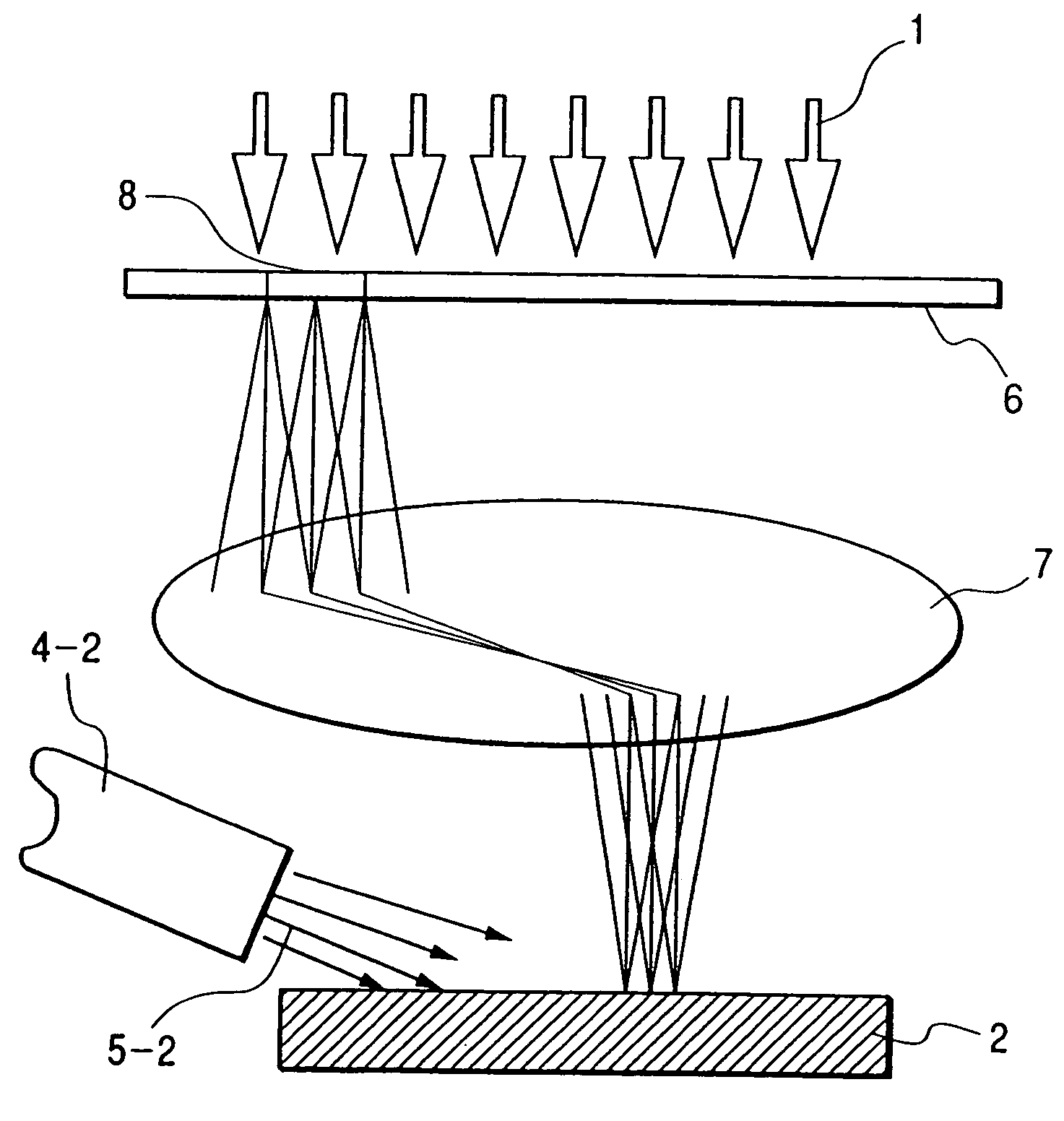

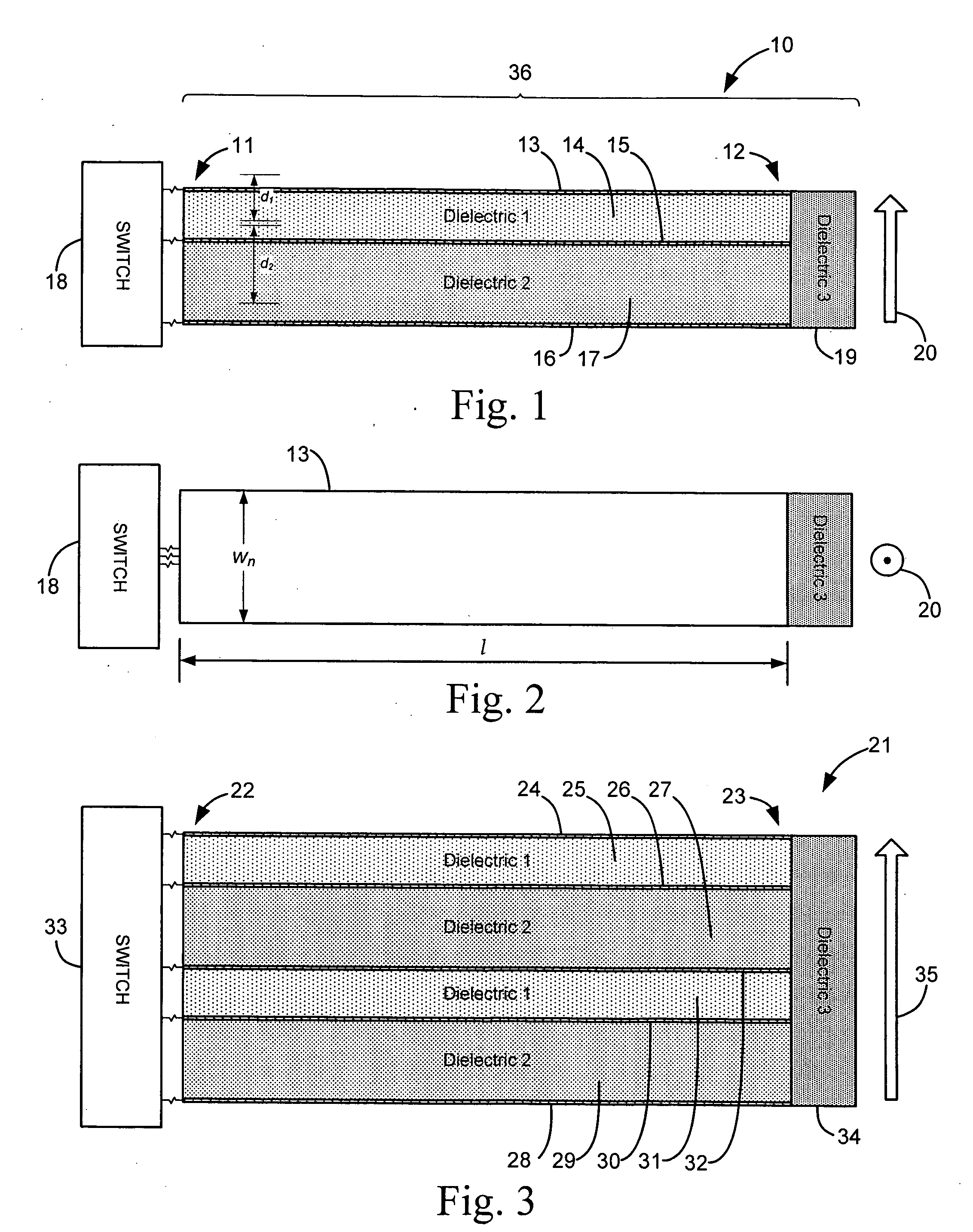

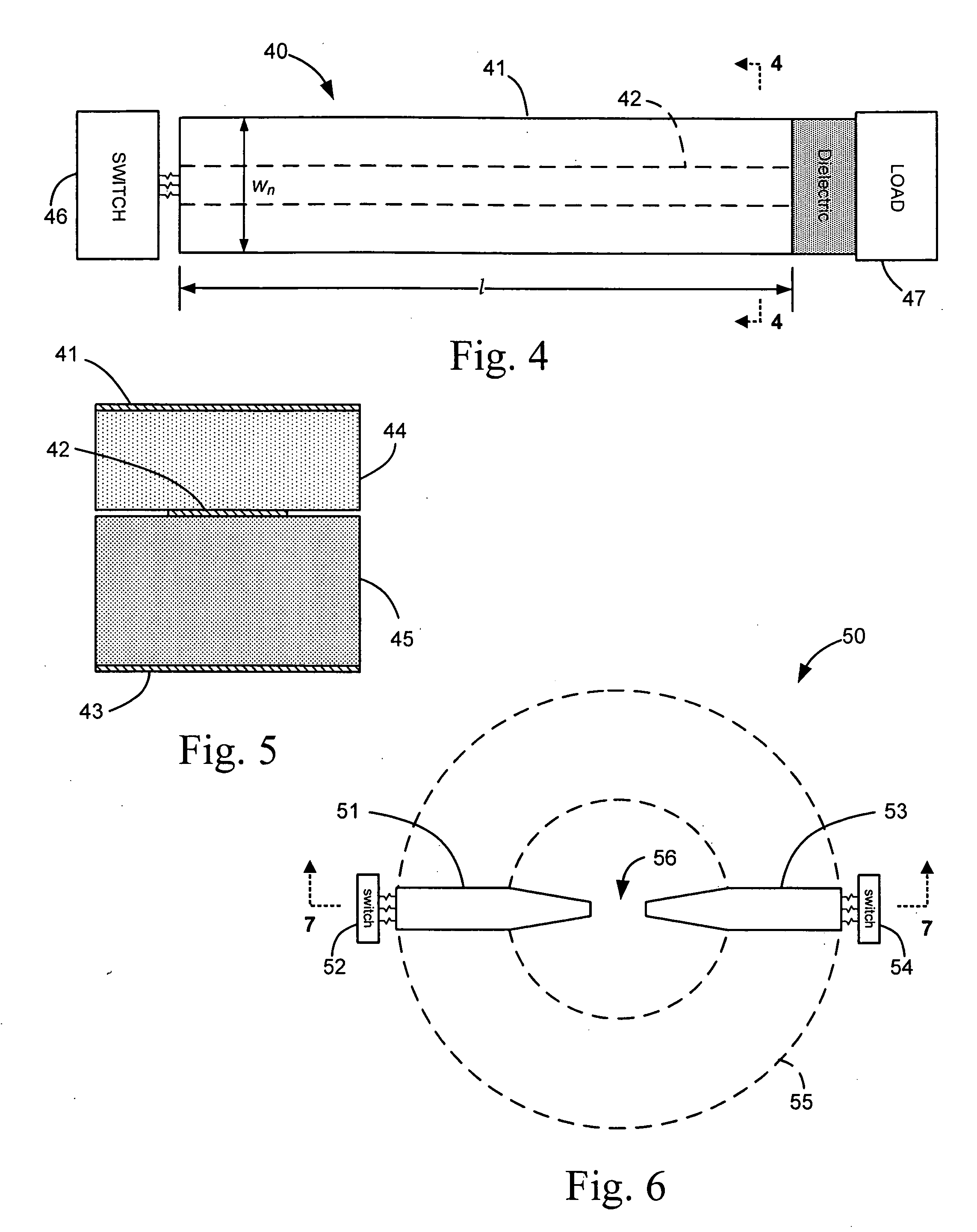

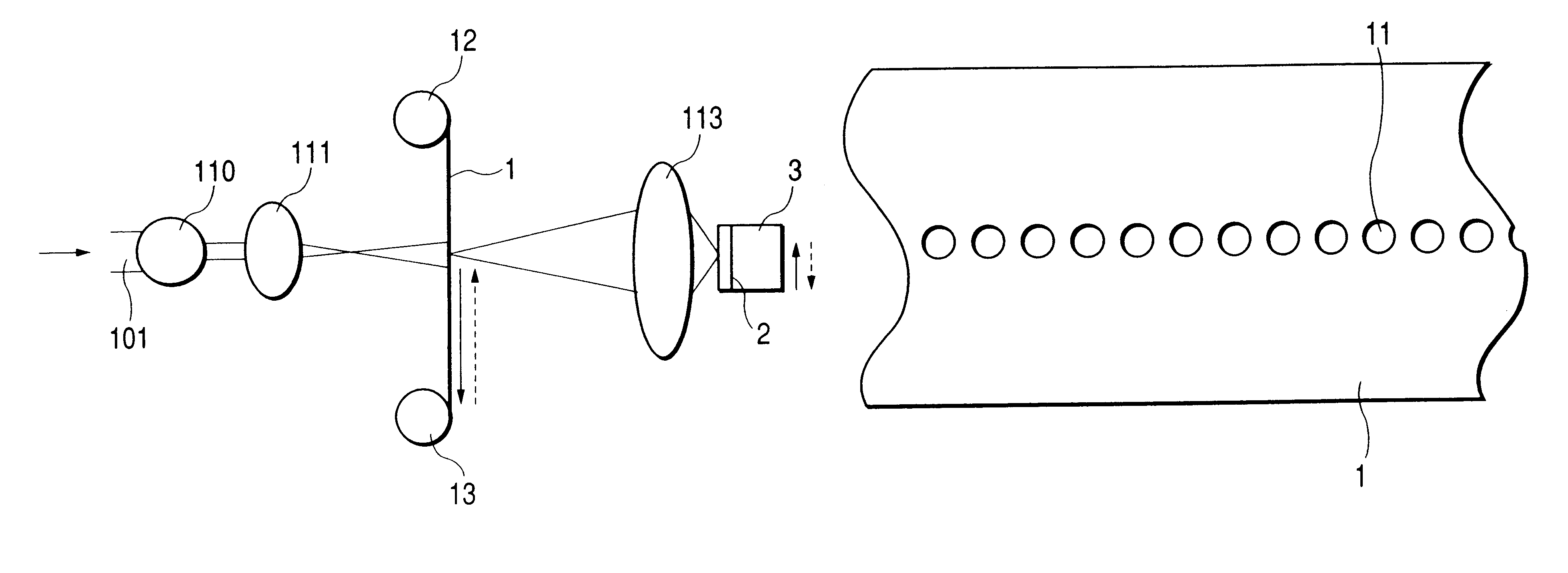

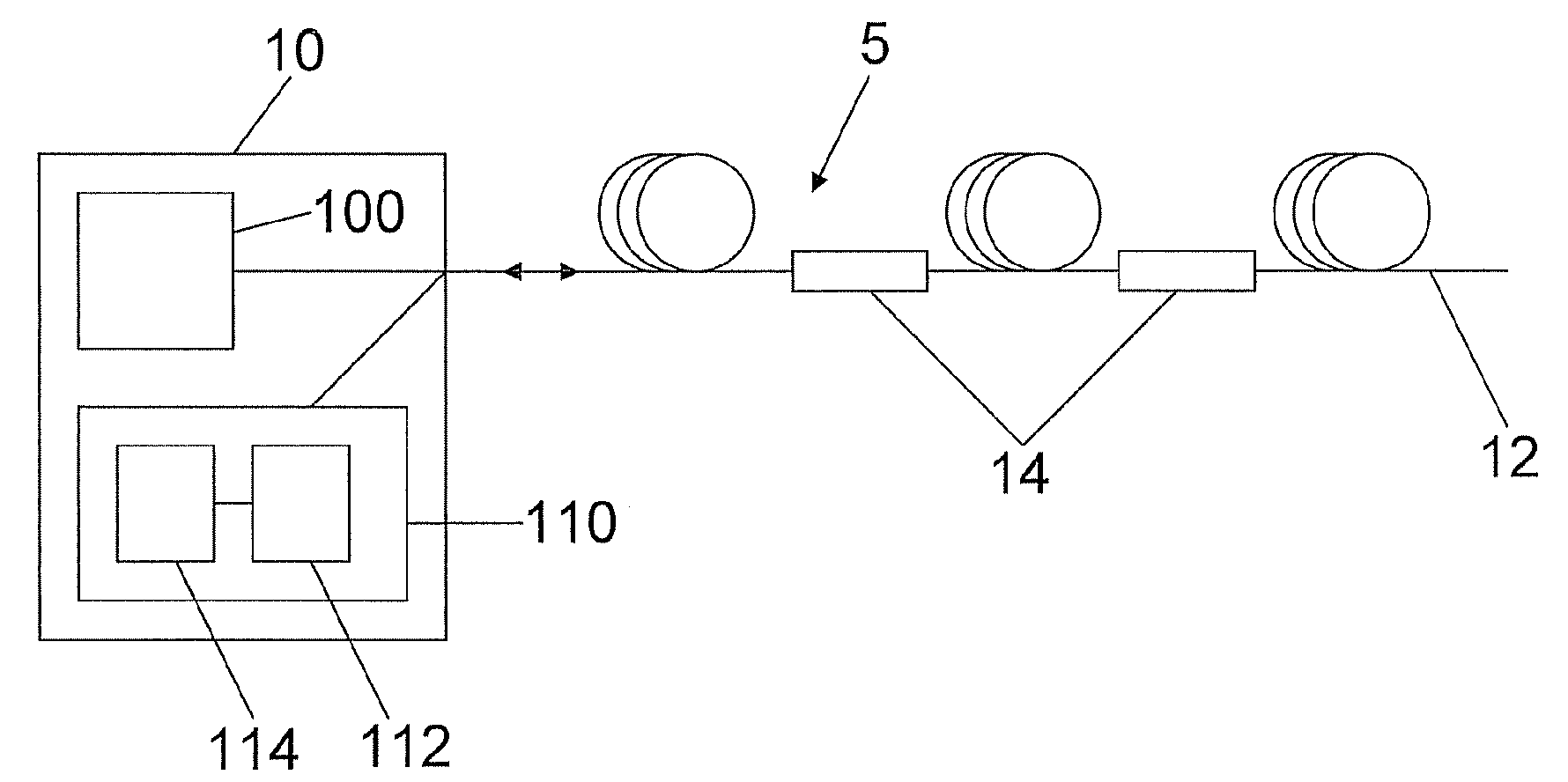

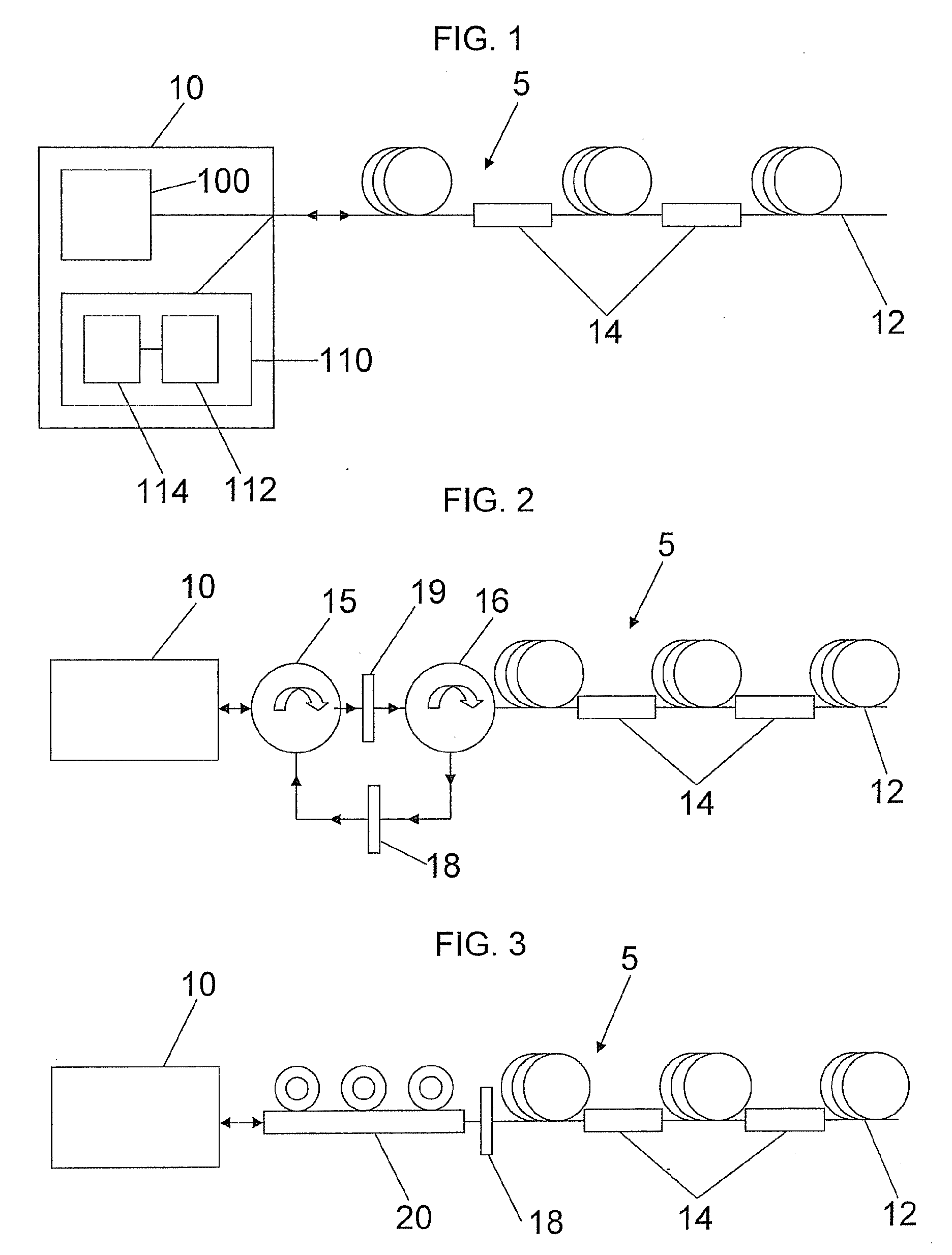

Fiber- or rod-based optical source featuring a large-core, rare-earth-doped photonic-crystal device for generation of high-power pulsed radiation and method

ActiveUS20070041083A1High peak powerHigh pulse energyGlass making apparatusOptical fibre with multilayer core/claddingRare earthEngineering

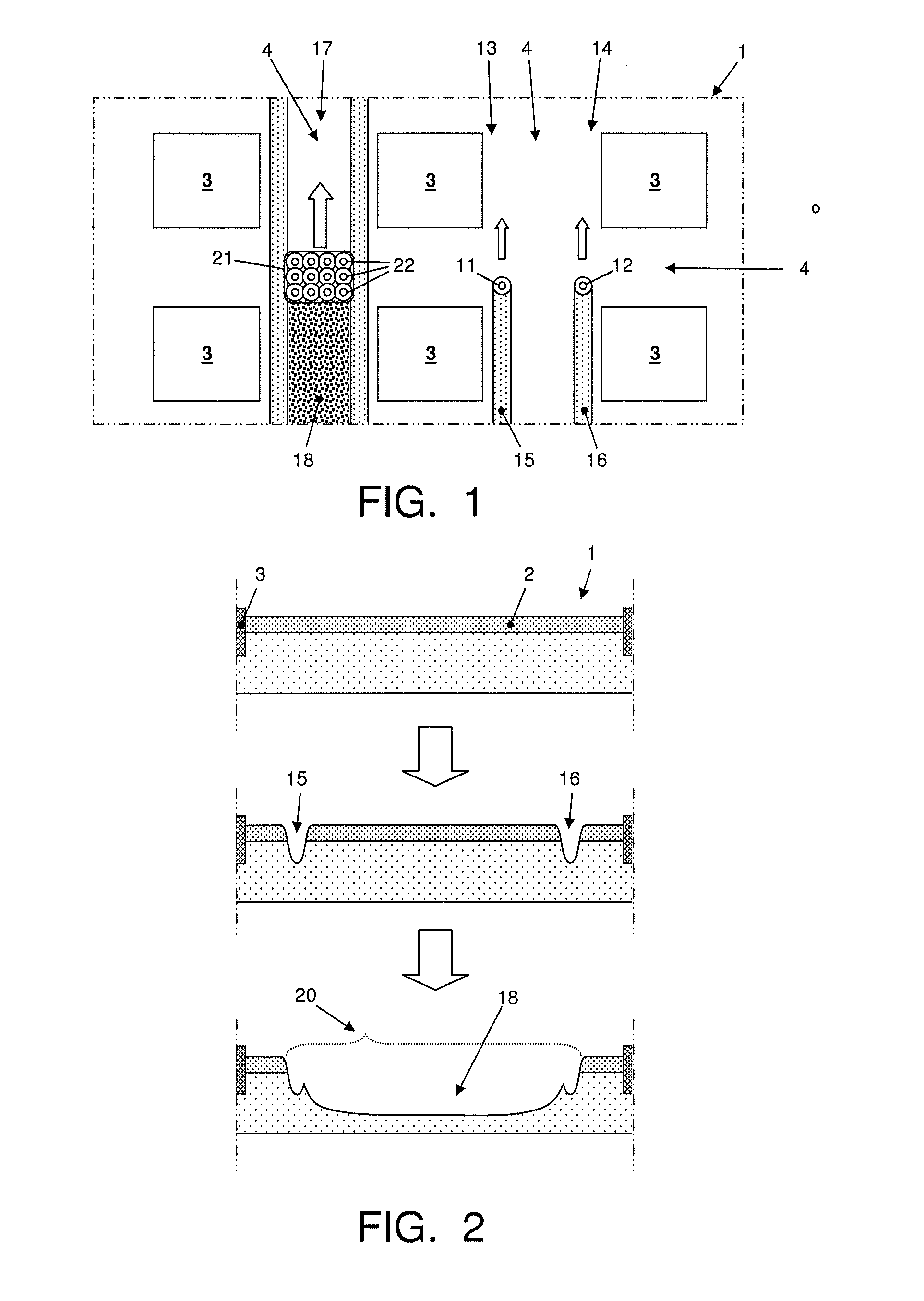

A method and apparatus use a photonic-crystal fiber having a very large core while maintaining a single transverse mode. In some fiber lasers and amplifiers having large cores problems exist related to energy being generated at multiple-modes (i.e., polygamy), and of mode hopping (i.e., promiscuity) due to limited control of energy levels and fluctuations. The problems of multiple-modes and mode hopping result from the use of large-diameter waveguides, and are addressed by the invention. This is especially true in lasers using large amounts of energy (i.e., lasers in the one-megawatt or more range). By using multiple small waveguides in parallel, large amounts of energy can be passed through a laser, but with better control such that the aforementioned problems can be reduced. An additional advantage is that the polarization of the light can be maintained better than by using a single fiber core.

Owner:LOCKHEED MARTIN CORP

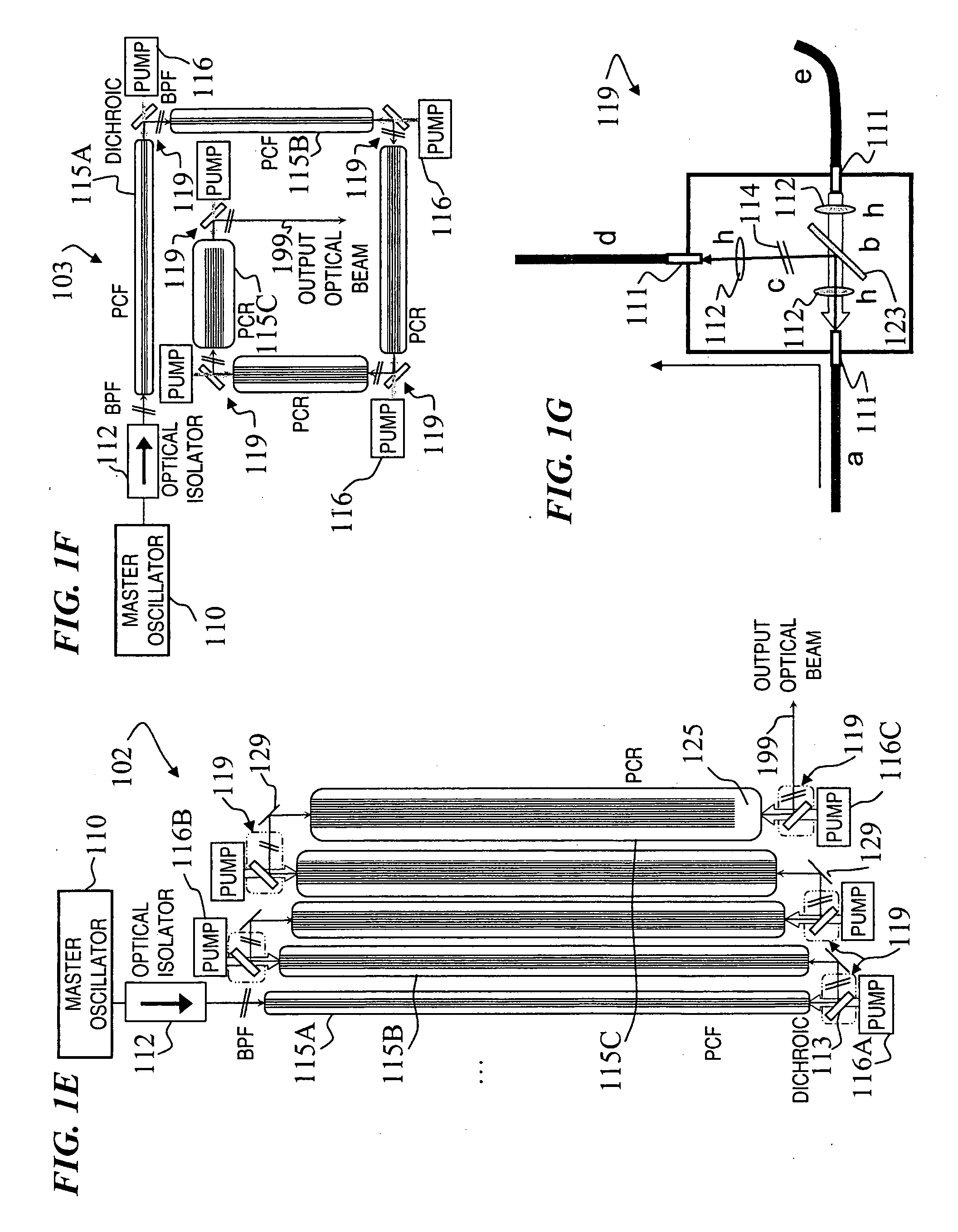

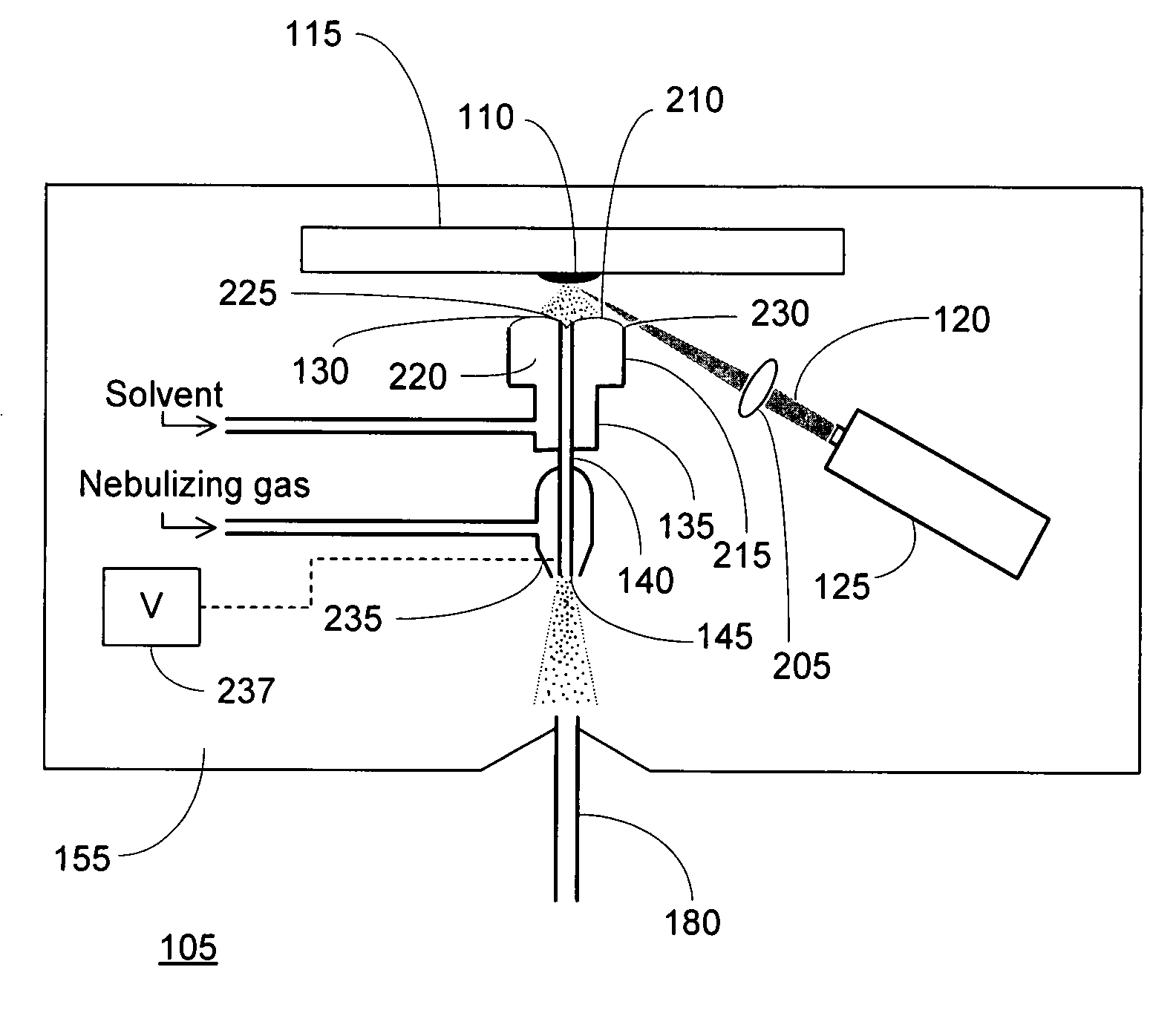

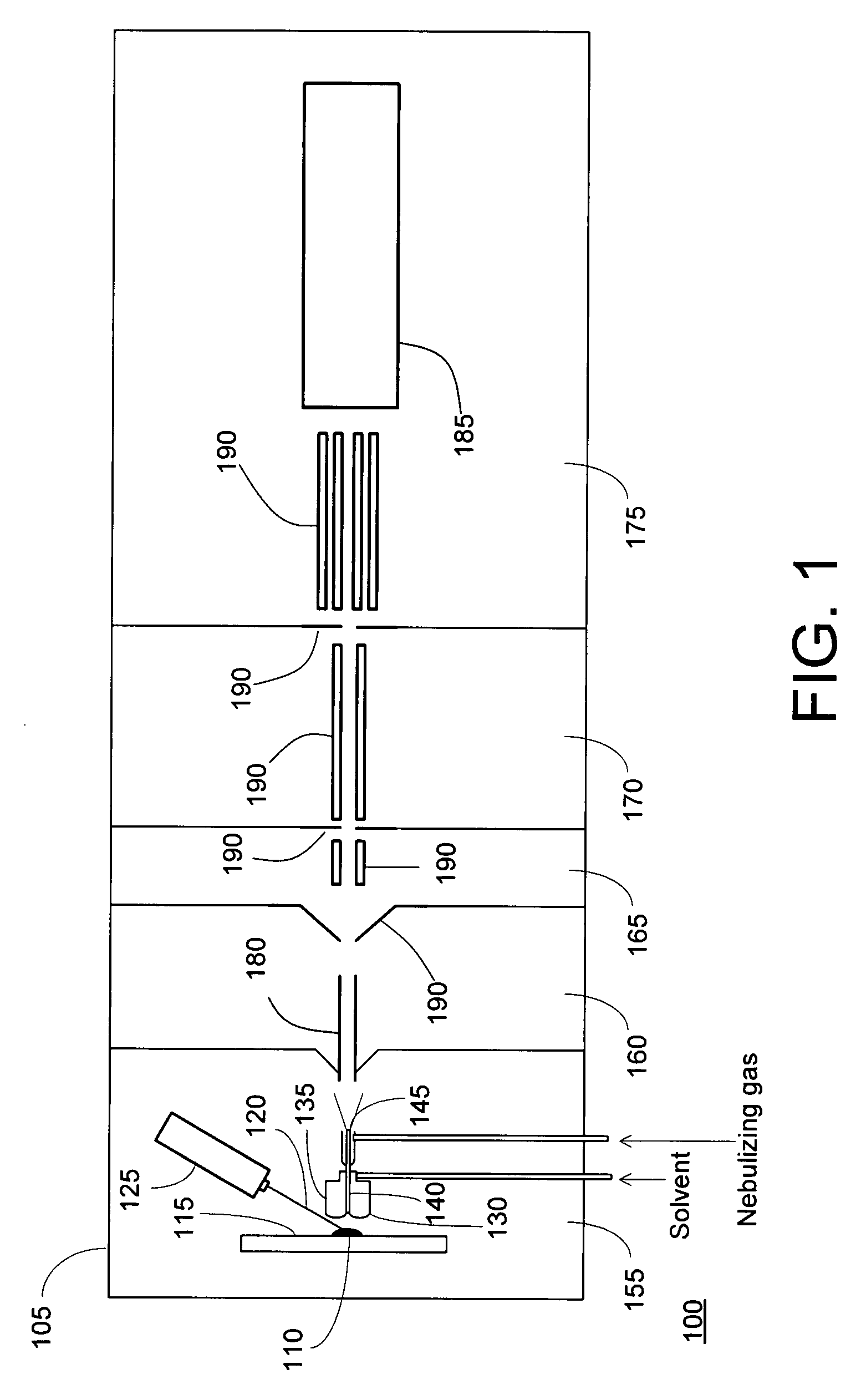

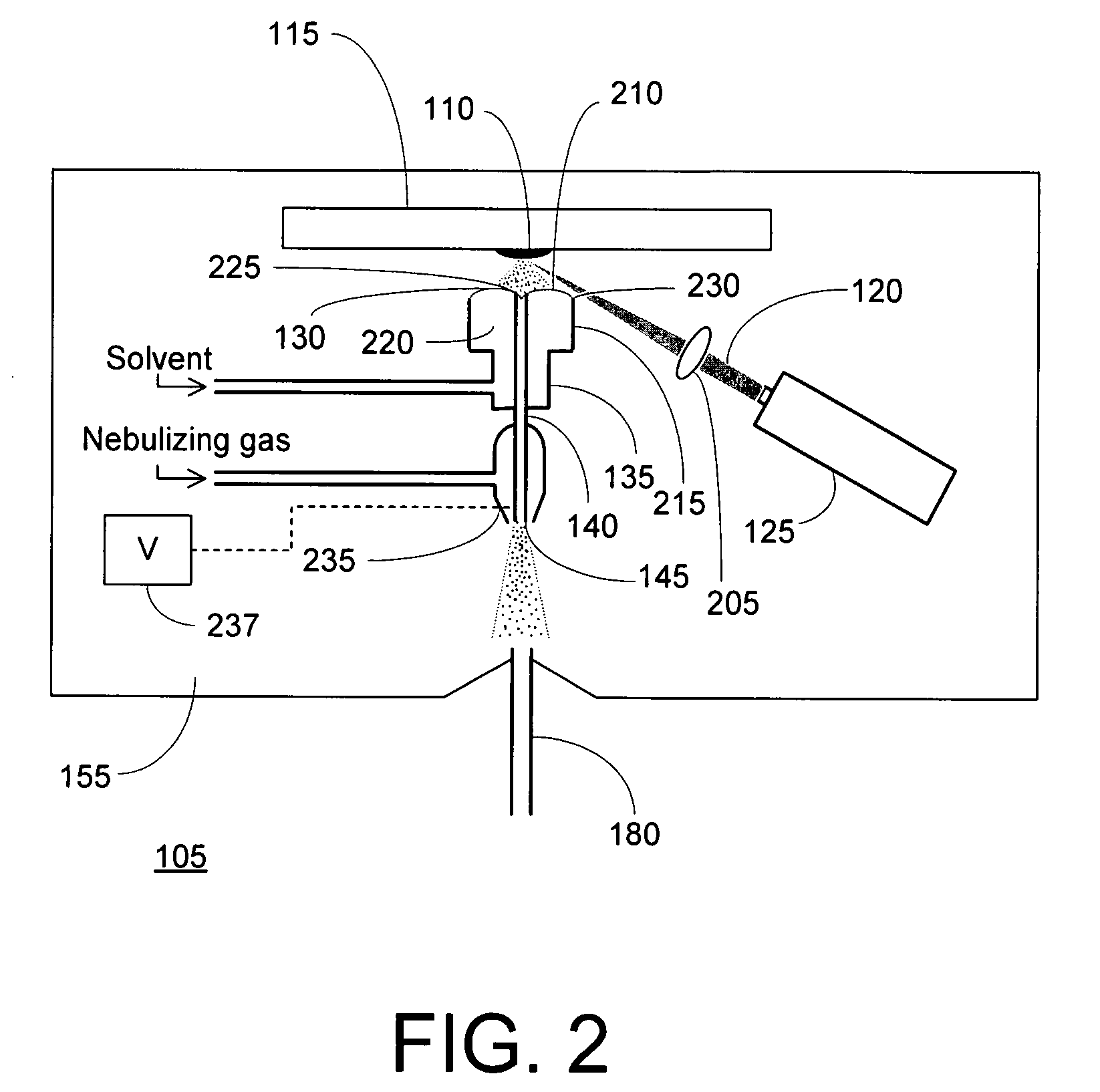

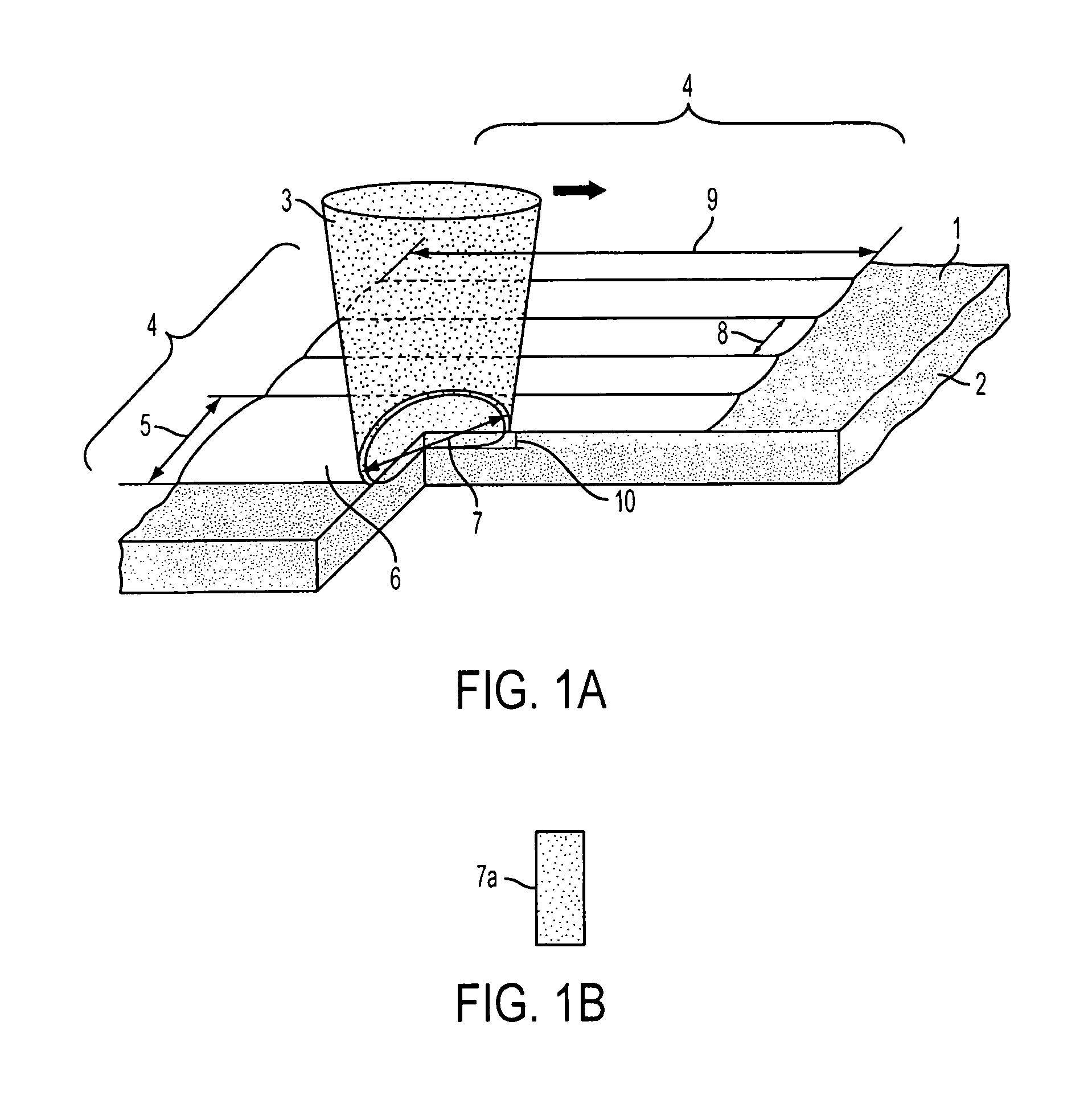

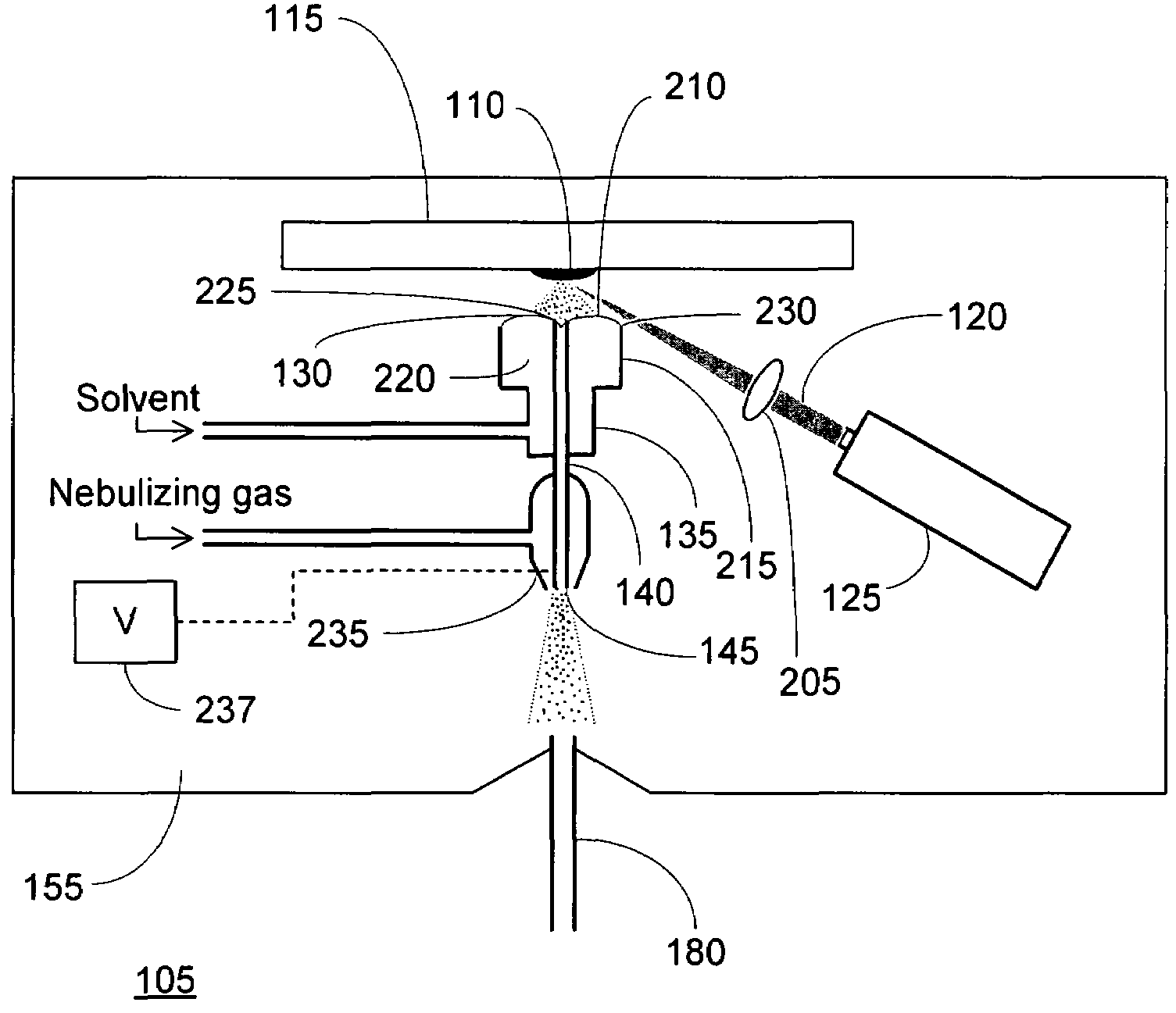

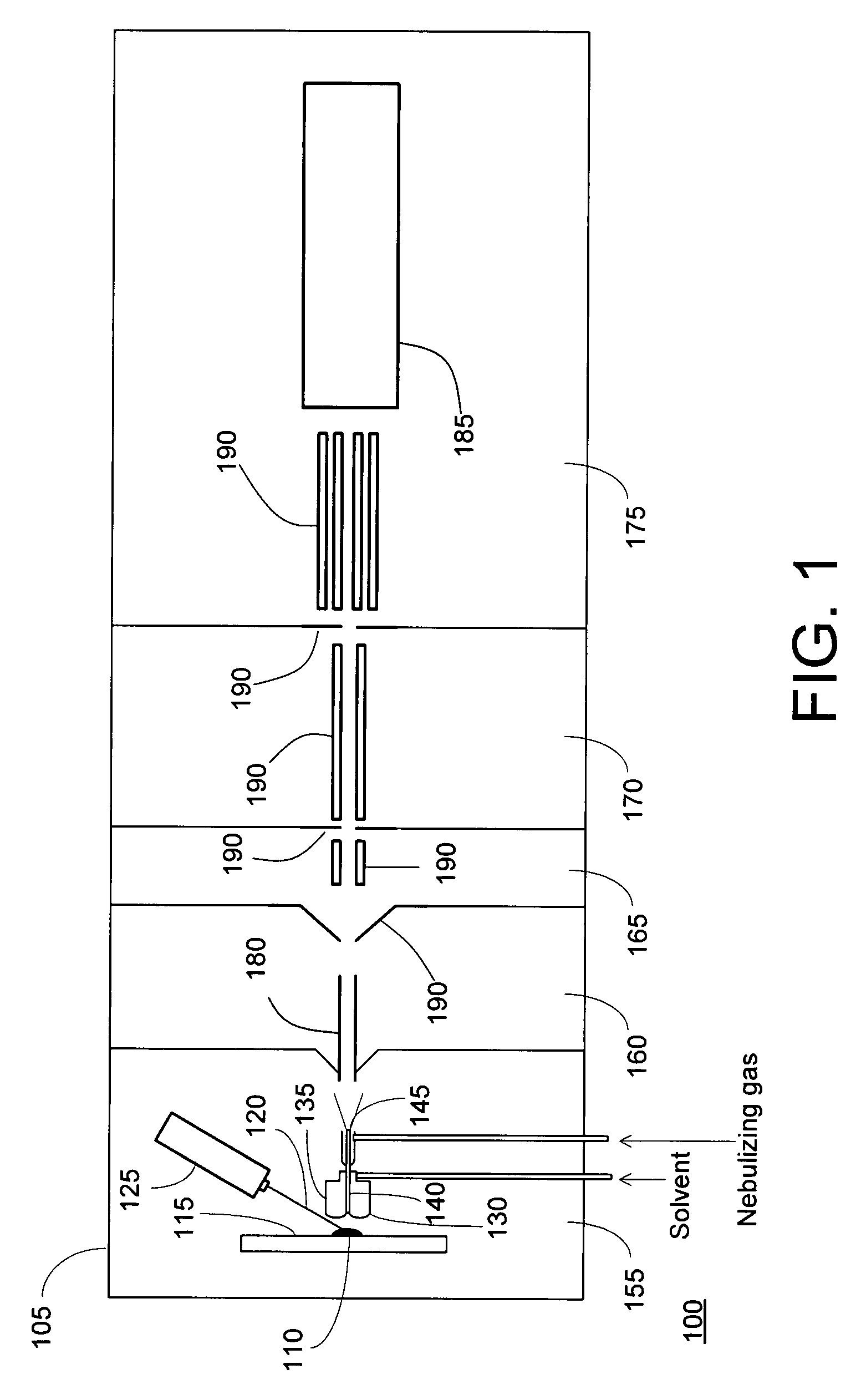

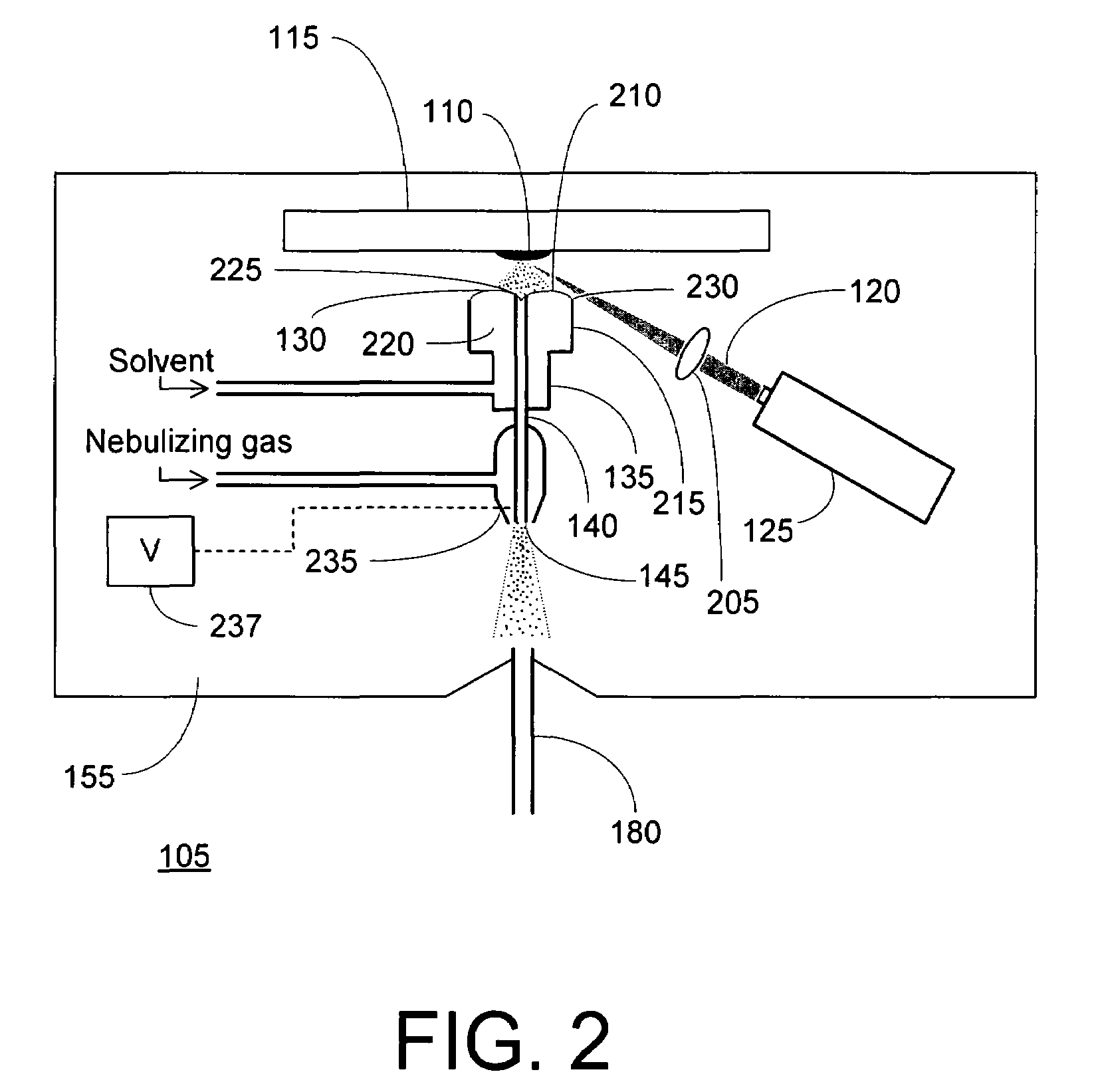

Laser desorption - electrospray ion (ESI) source for mass spectrometers

InactiveUS20080272294A1Minimize dilutionMaterial analysis by optical meansIon sources/gunsDesorptionElectrospray ionization

An ion source is disclosed for forming multiply-charged analyte ions from a solid sample. A beam of pulsed radiation is directed onto a portion of the sample to desorb analyte molecules. A retaining structure holding a solvent volume is positioned proximate the sample. Desorbed analyte molecules contact a free surface of the solvent and pass into solution. The solution is then conveyed through an outlet passageway to an electrospray apparatus, which introduces a spray of charged solvent droplets into an ionization chamber.

Owner:THERMO FINNIGAN

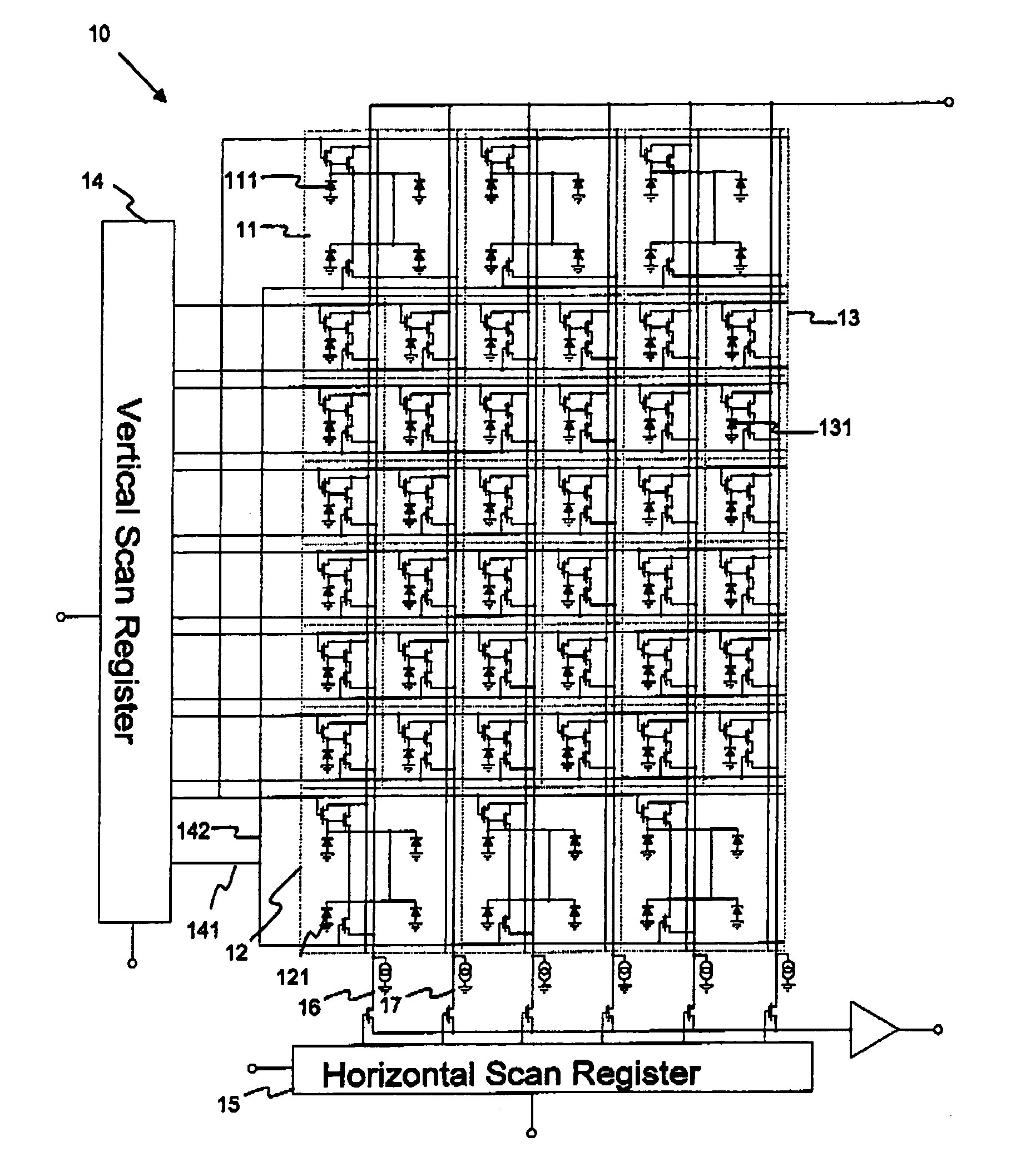

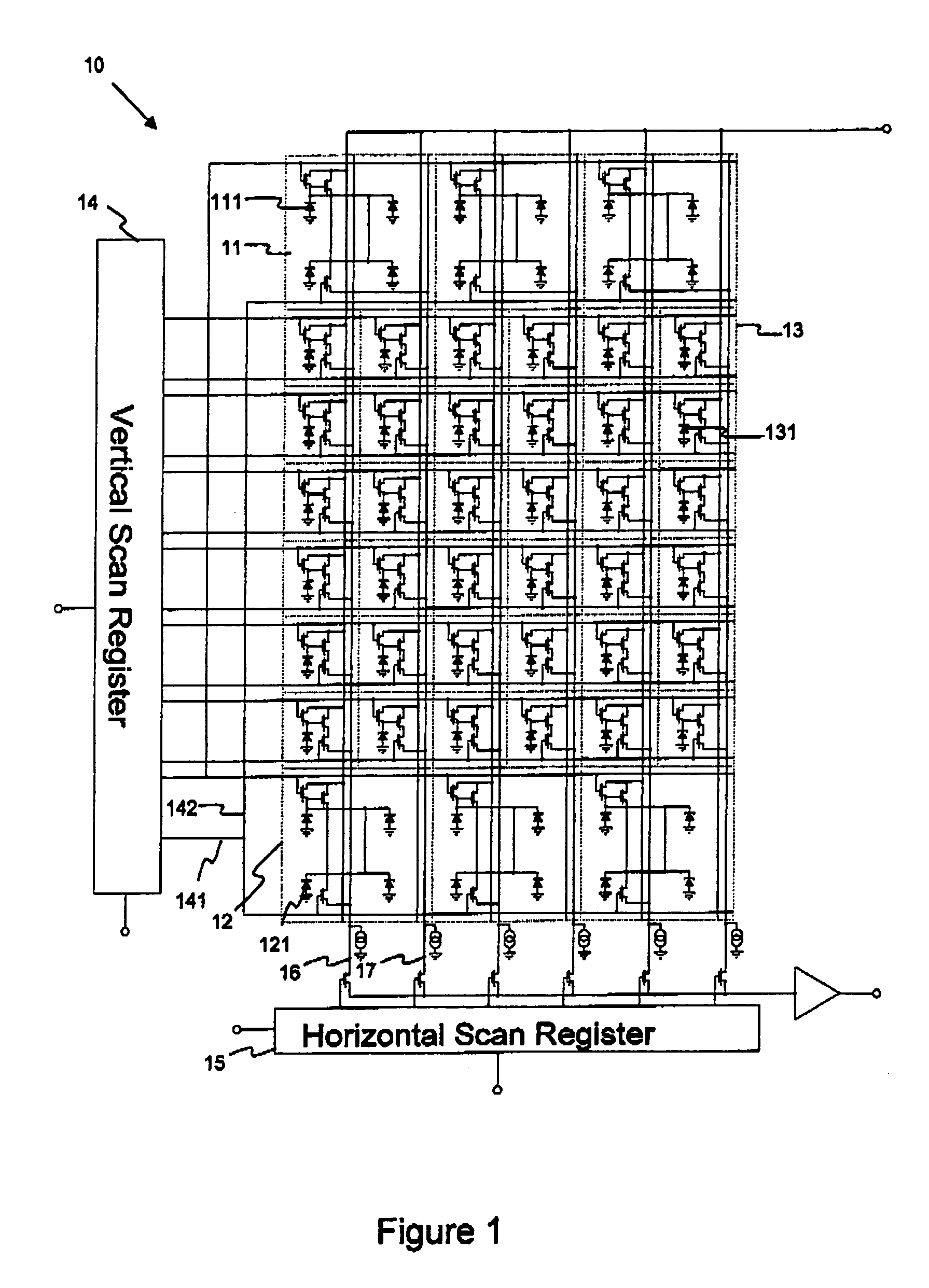

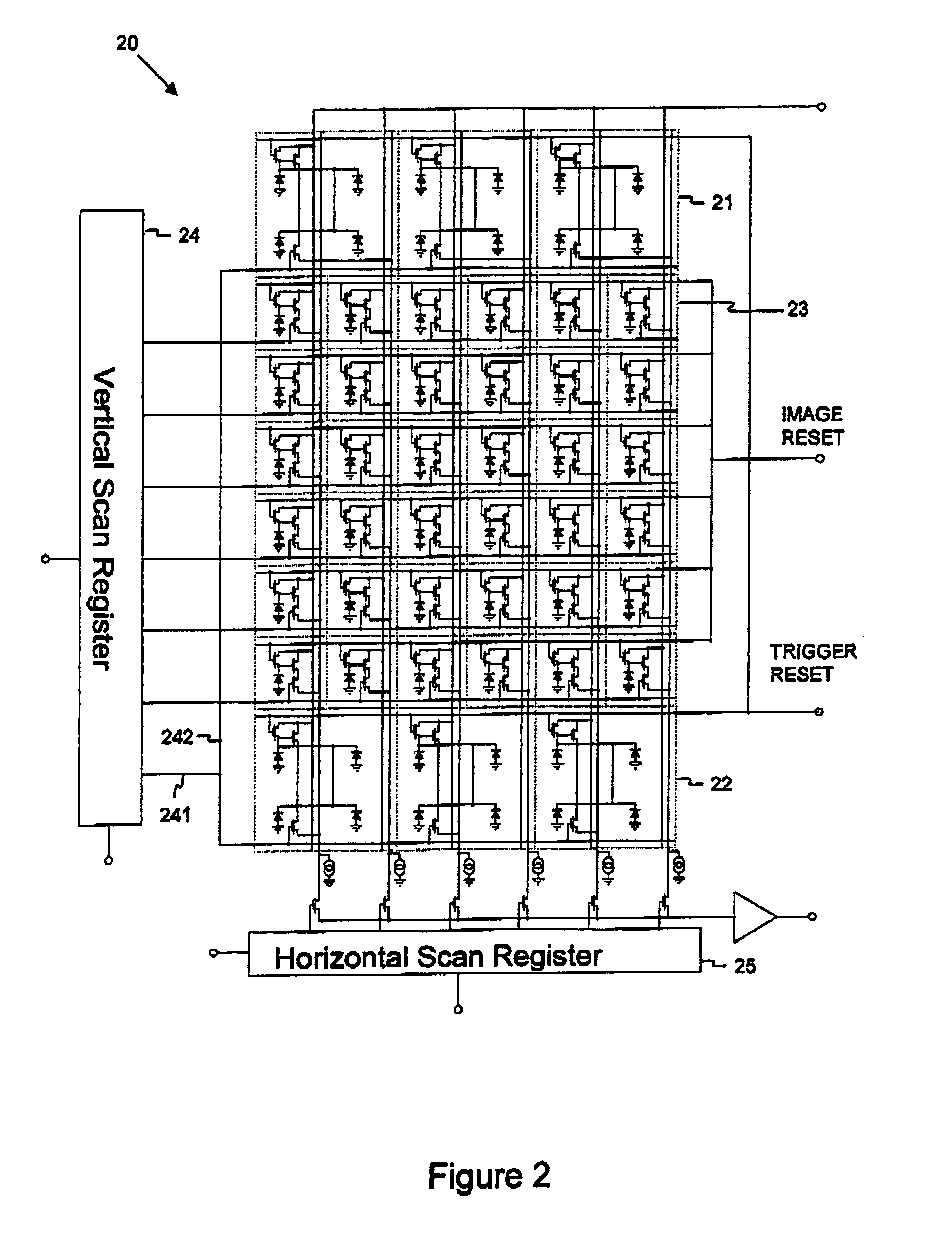

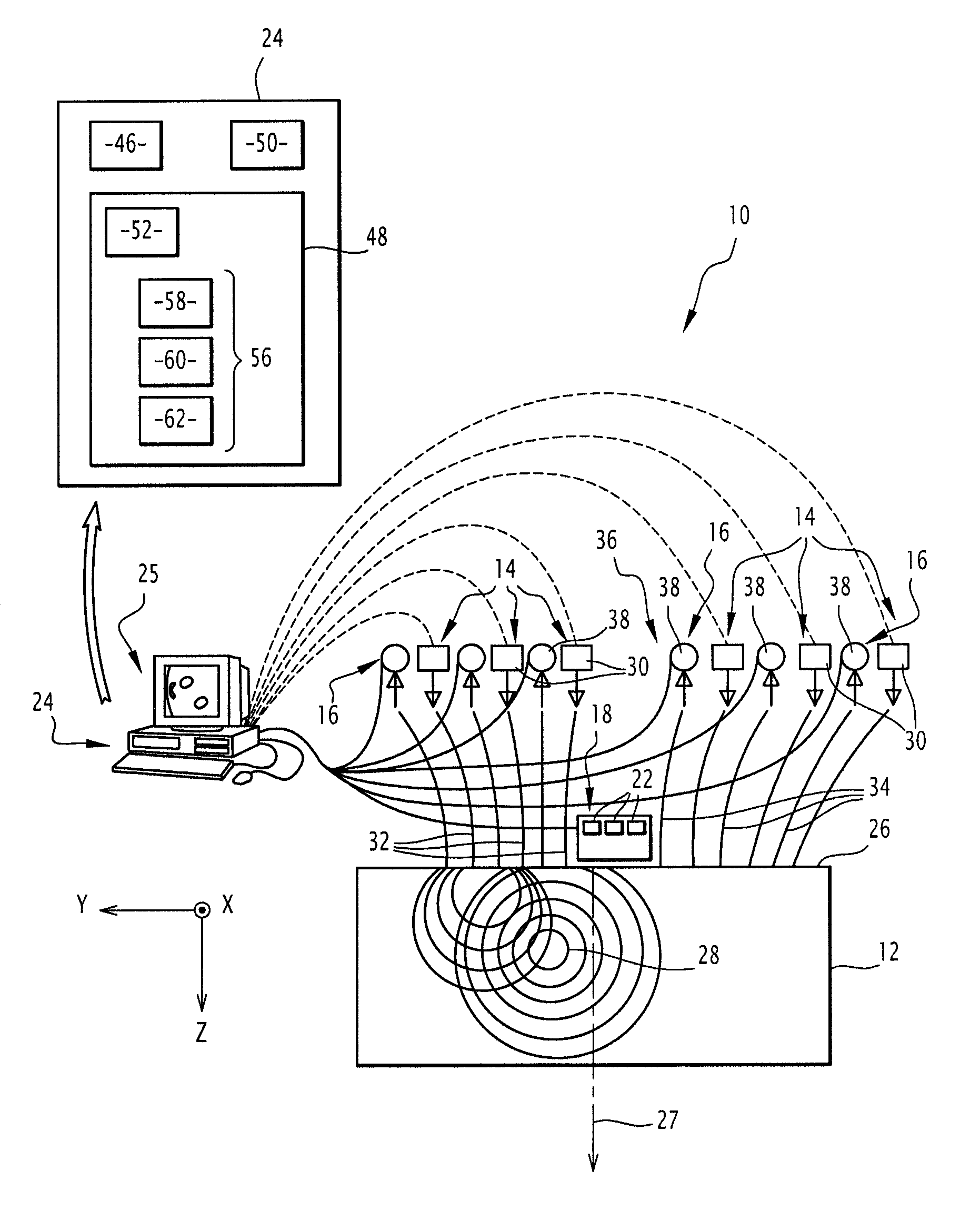

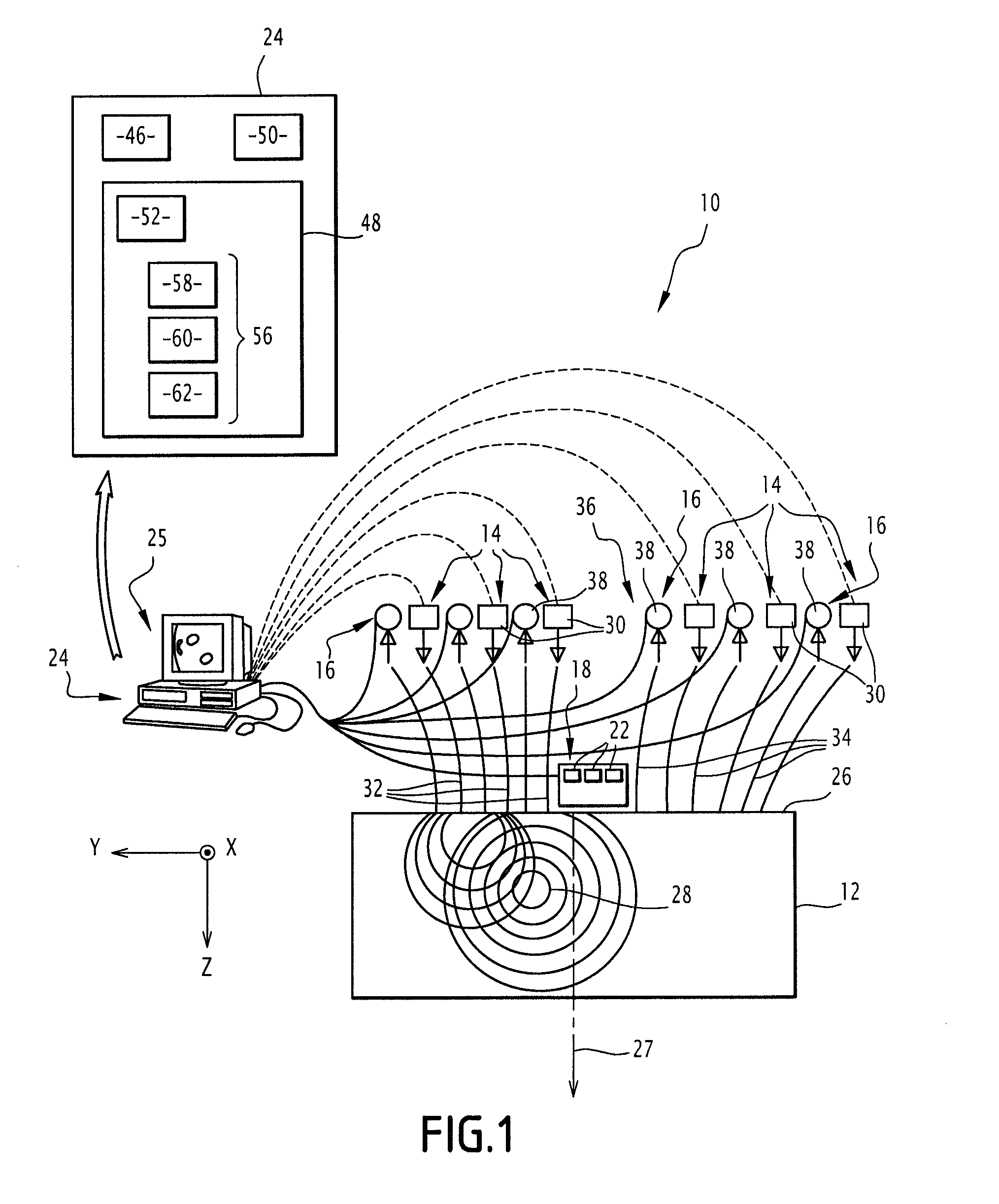

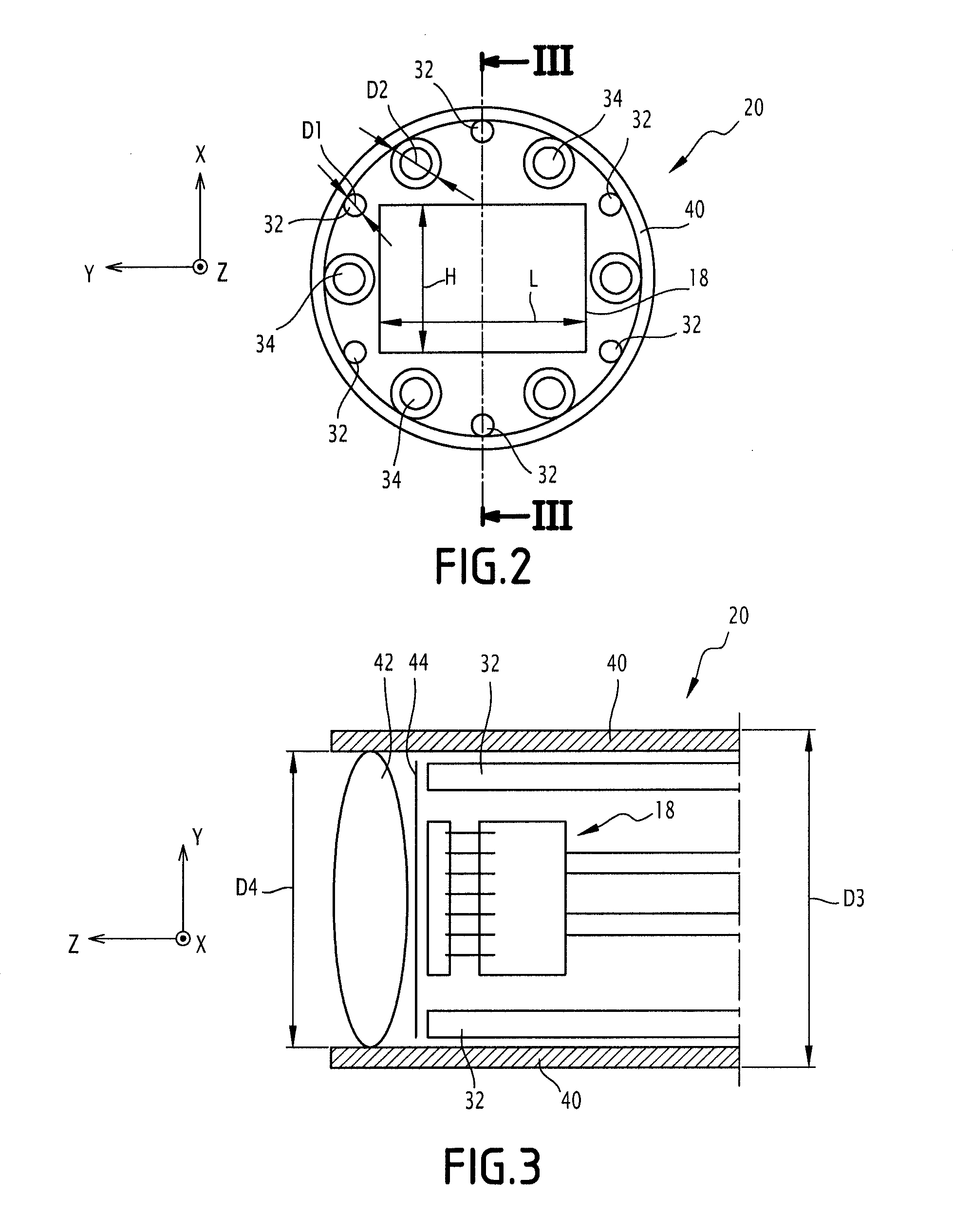

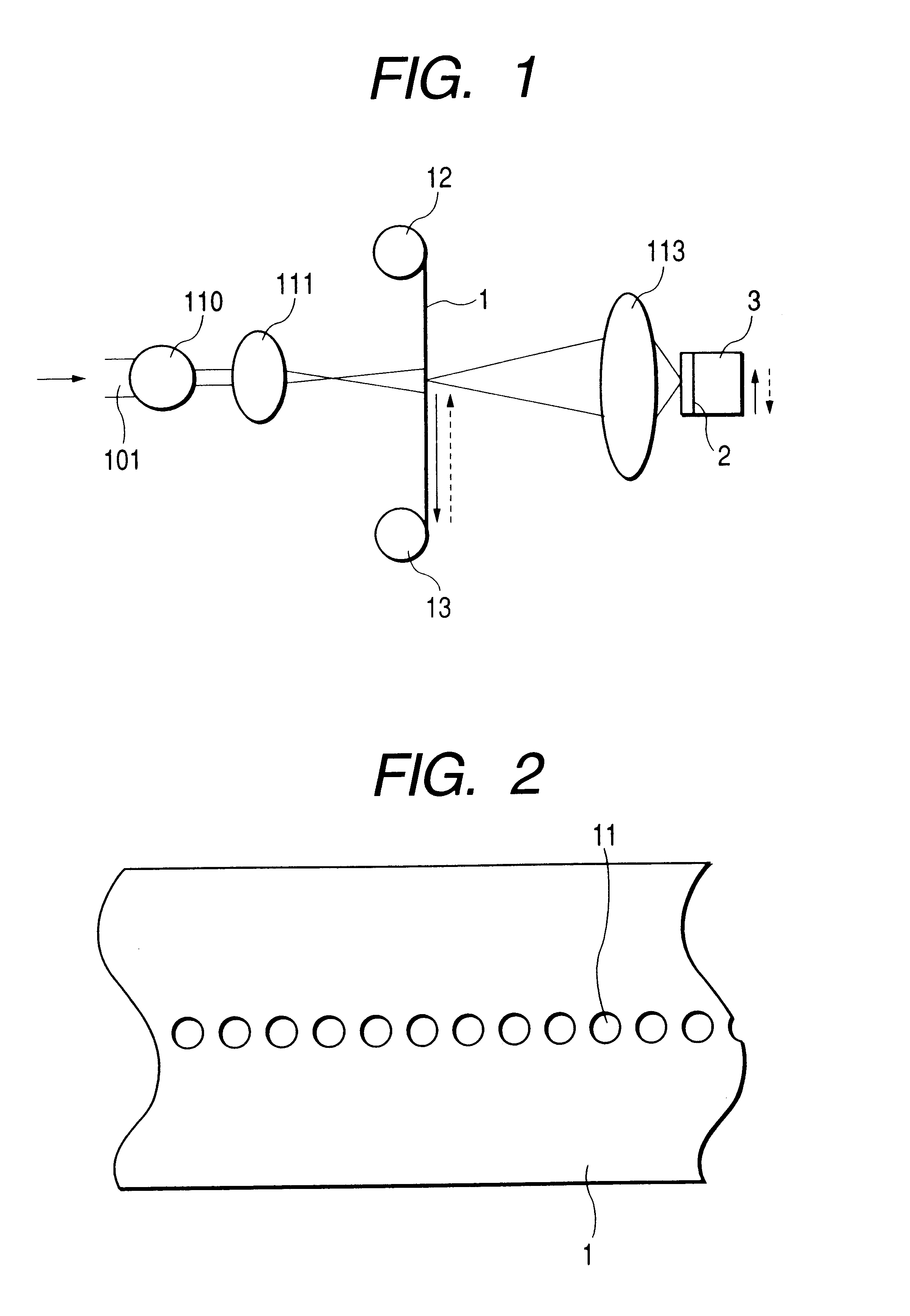

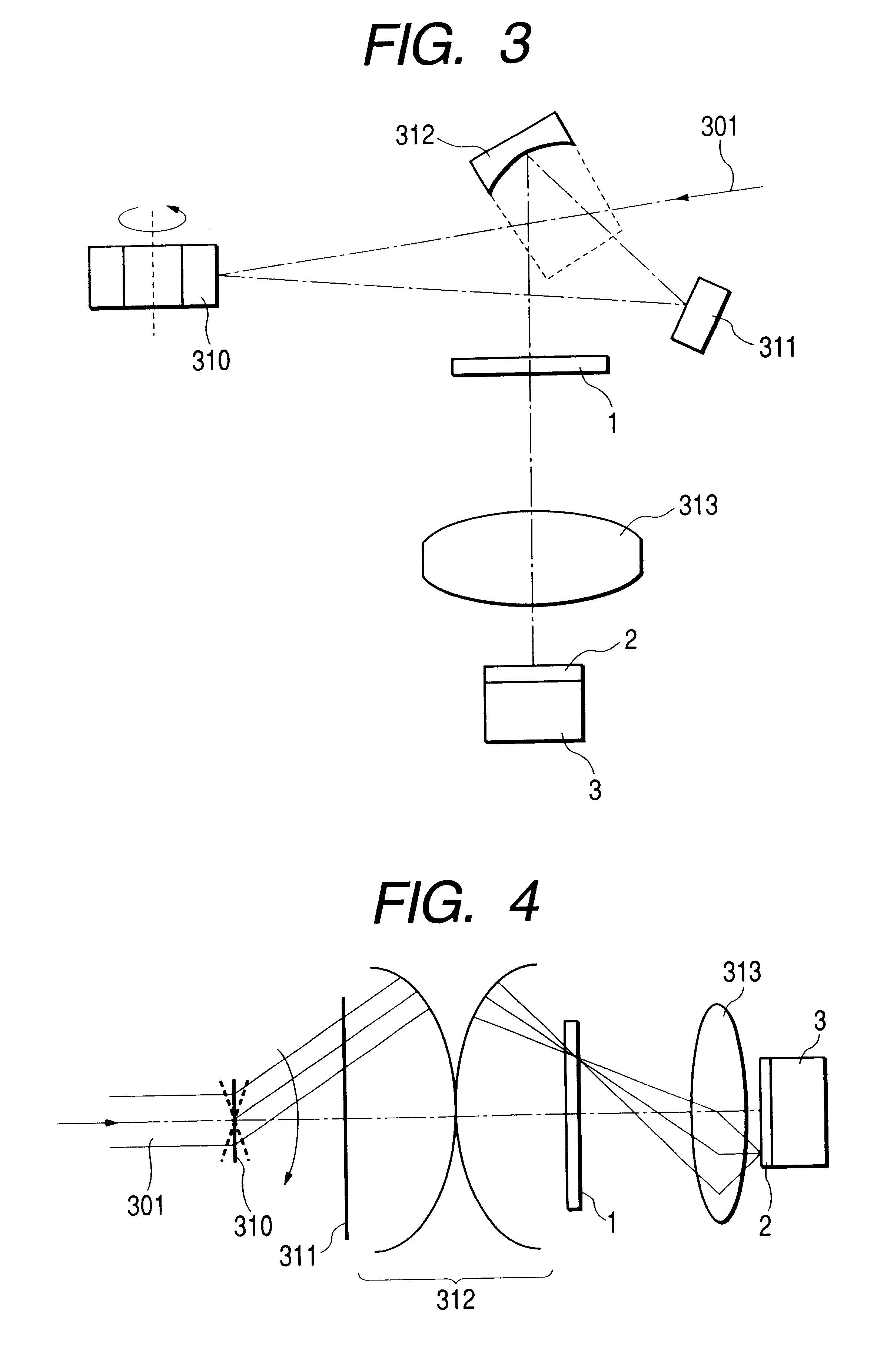

Sensor with trigger pixels for imaging of pulsed radiation

InactiveUS20070176109A1Television system detailsTelevision system scanning detailsX-rayRadiation sensor

A radiation sensor 10 includes an array of imaging pixels 13 electrically connectable to a readout port. At least one first peripheral row of trigger pixels 11 is located at a first edge of the array, the trigger pixels also being electrically connectable to the readout port but responding faster to x-rays than the imaging pixels. At least one second peripheral row of trigger pixels 12 may be located at a second edge of the array opposed to the first edge. Trigger pixels 11, 12 from the first and second peripheral rows may be addressable alternately in a predetermined pattern to detect a radiation signal for triggering the sensor. Various methods of clocking the sensor are also described. The sensor has particular applicability to intra-oral x-ray imaging.

Owner:E2V TECH (UK) LTD

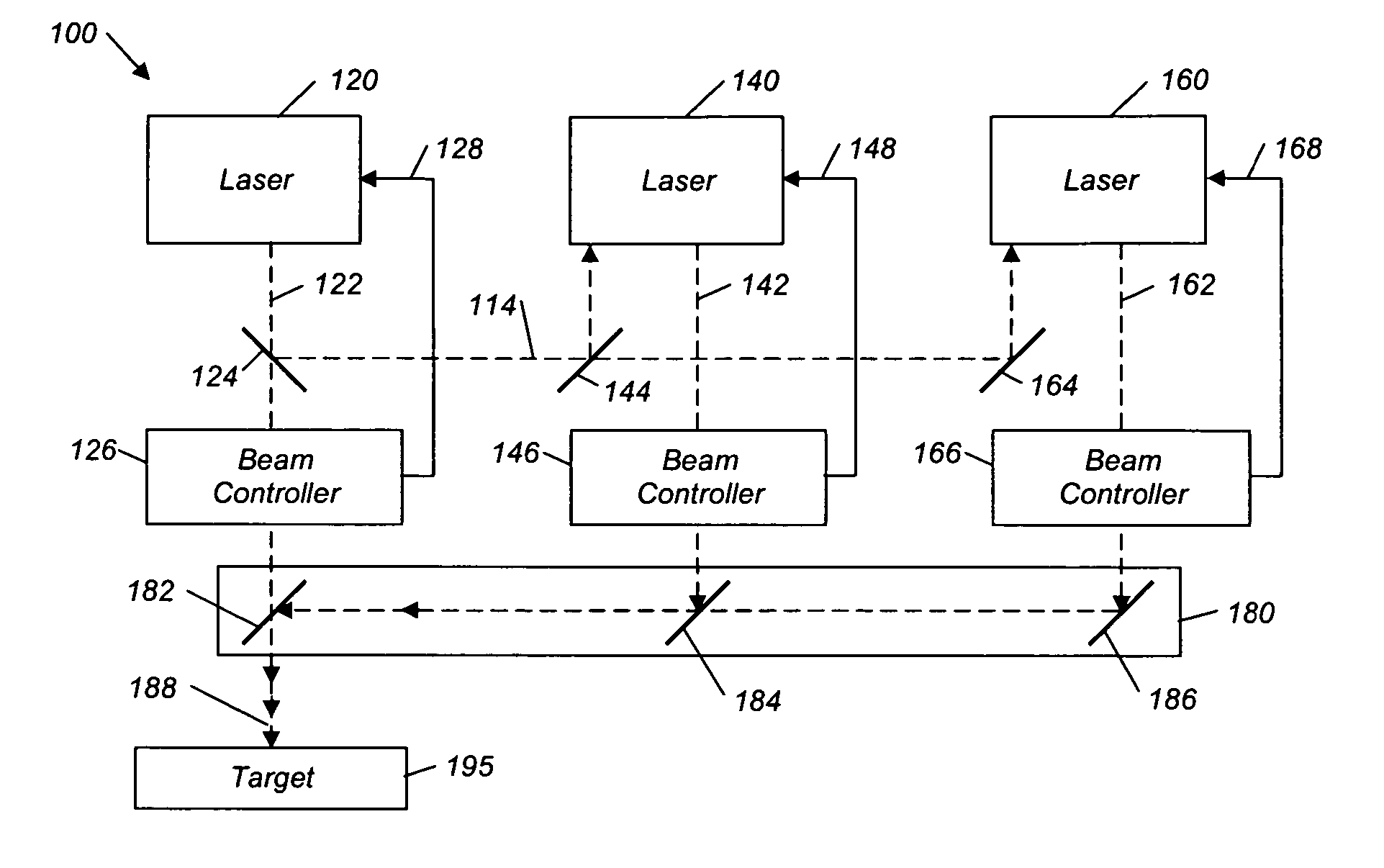

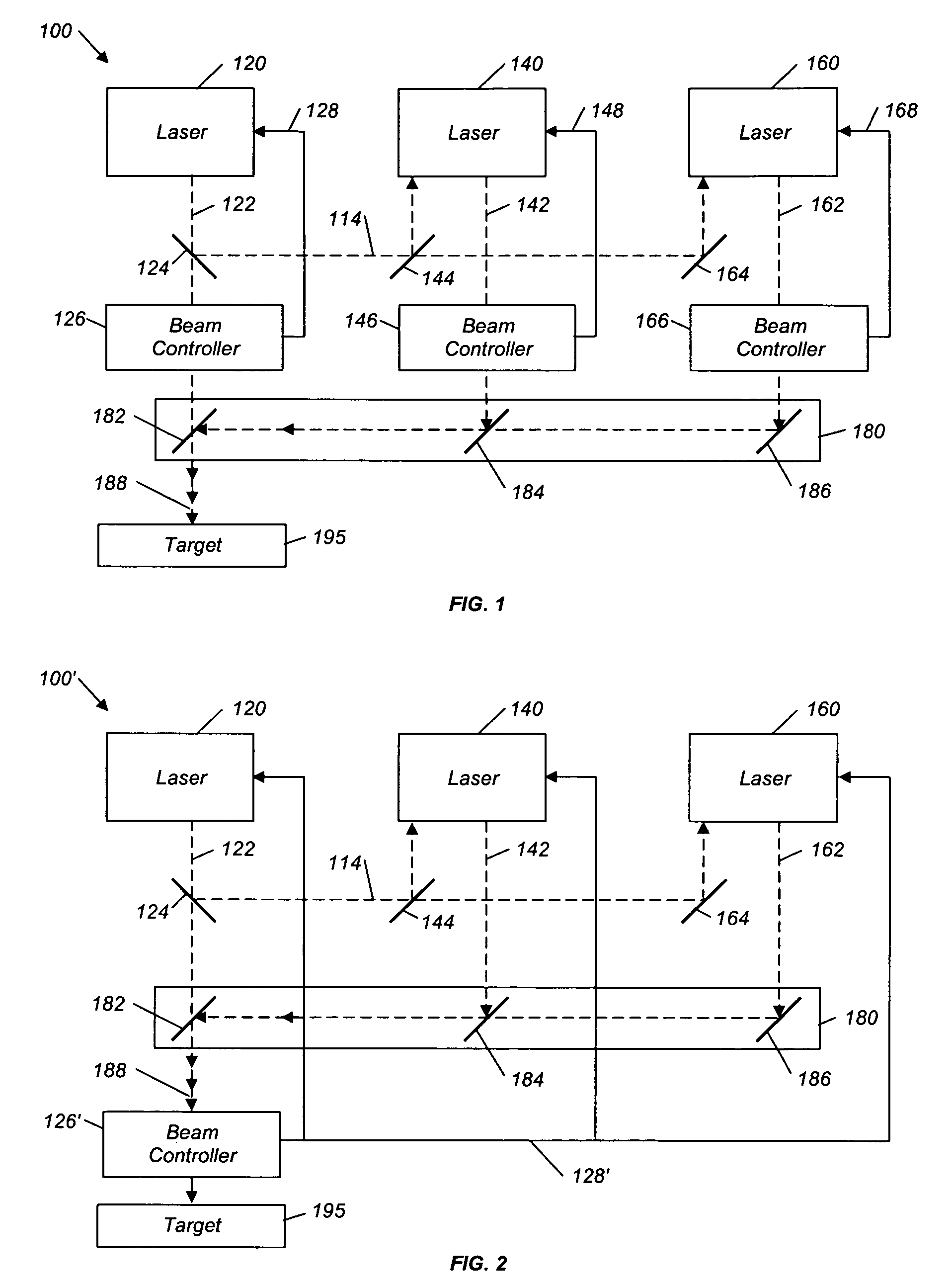

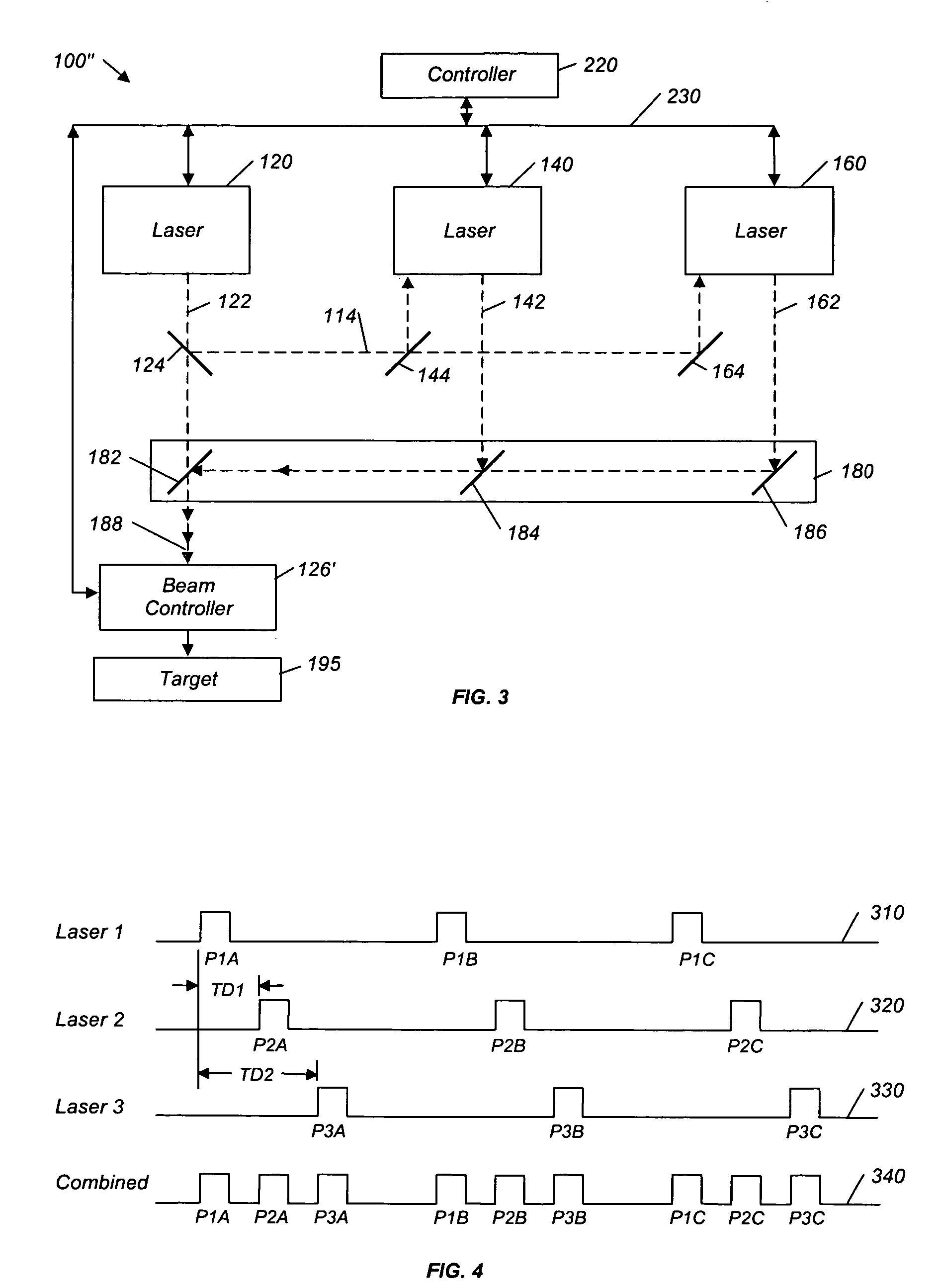

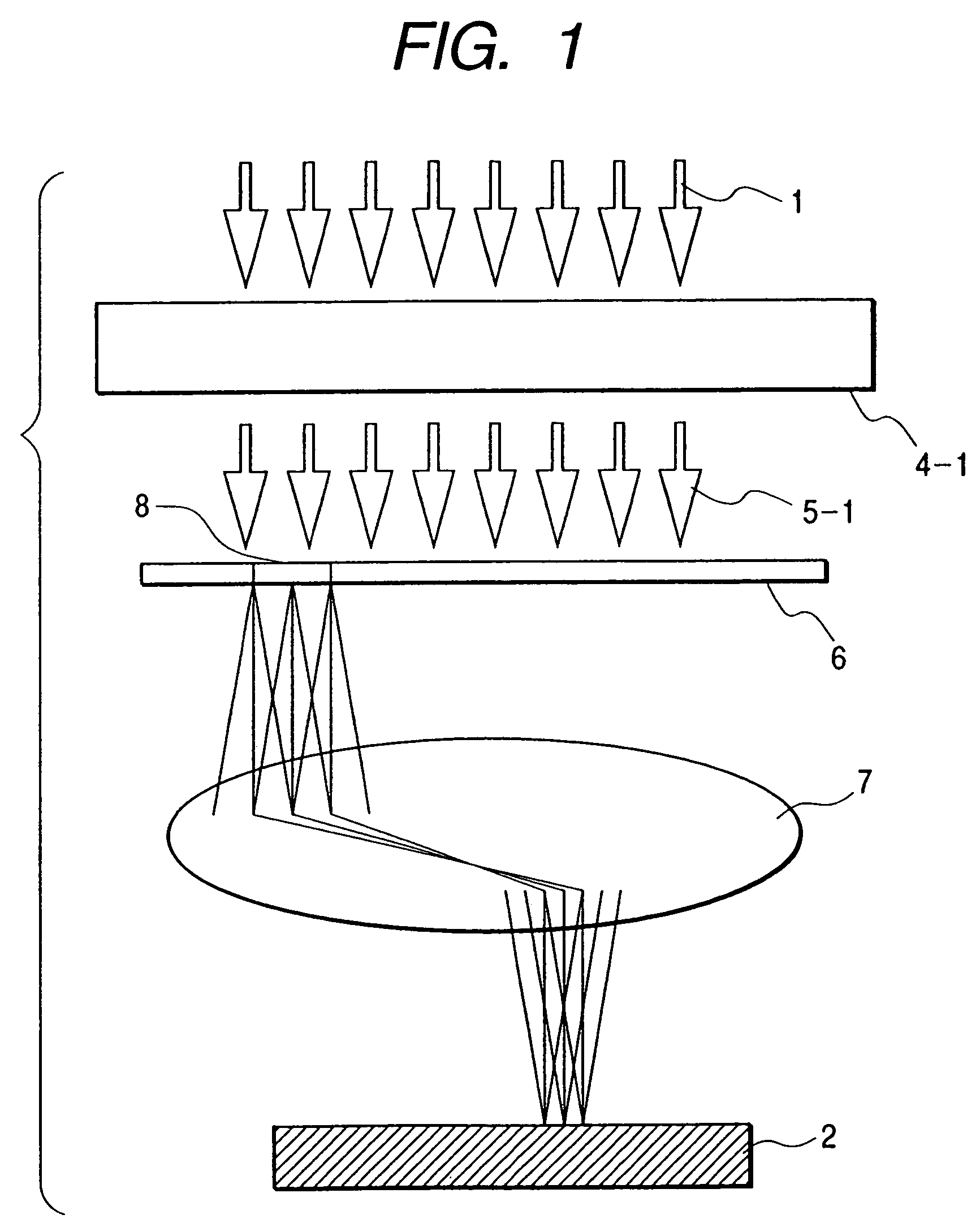

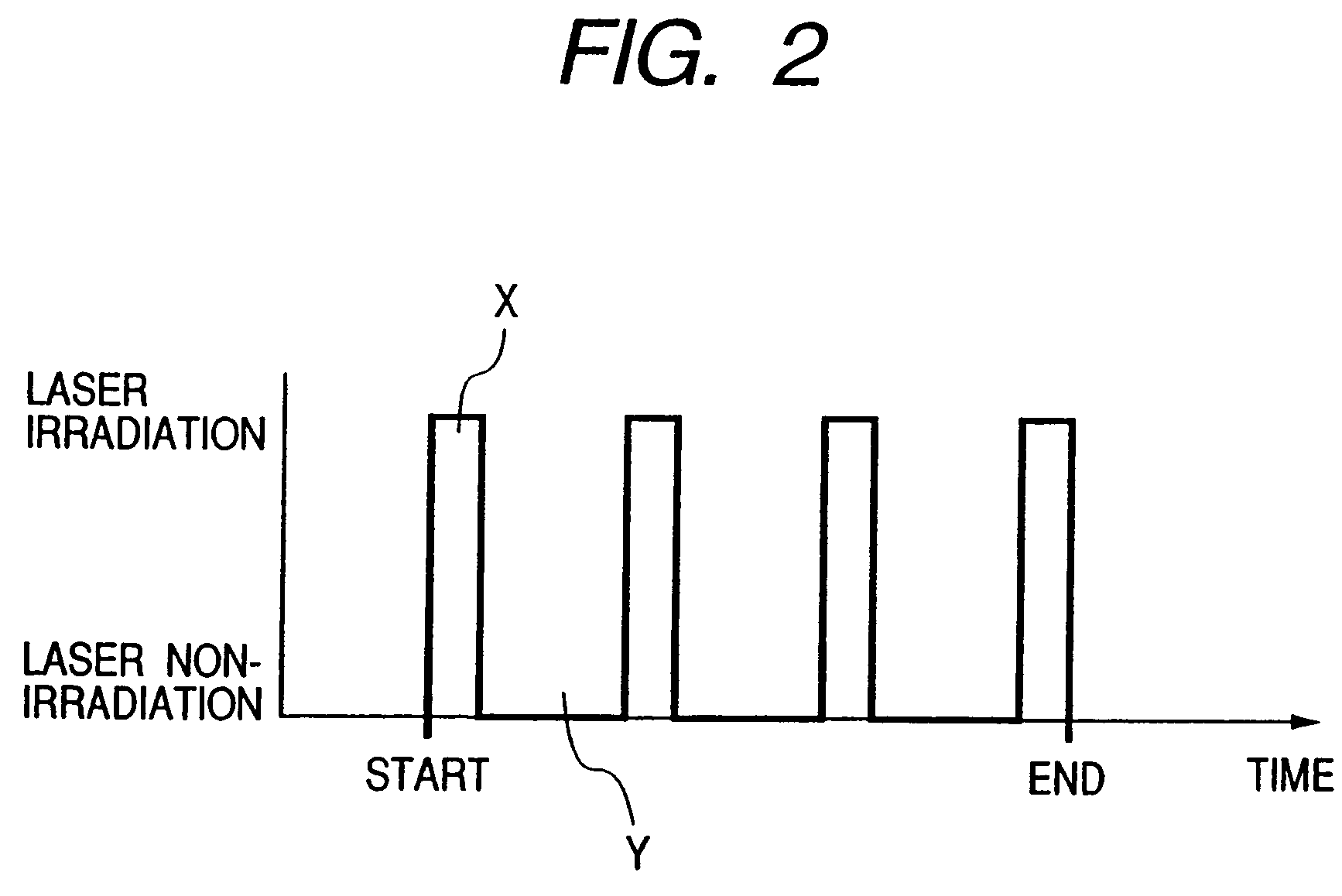

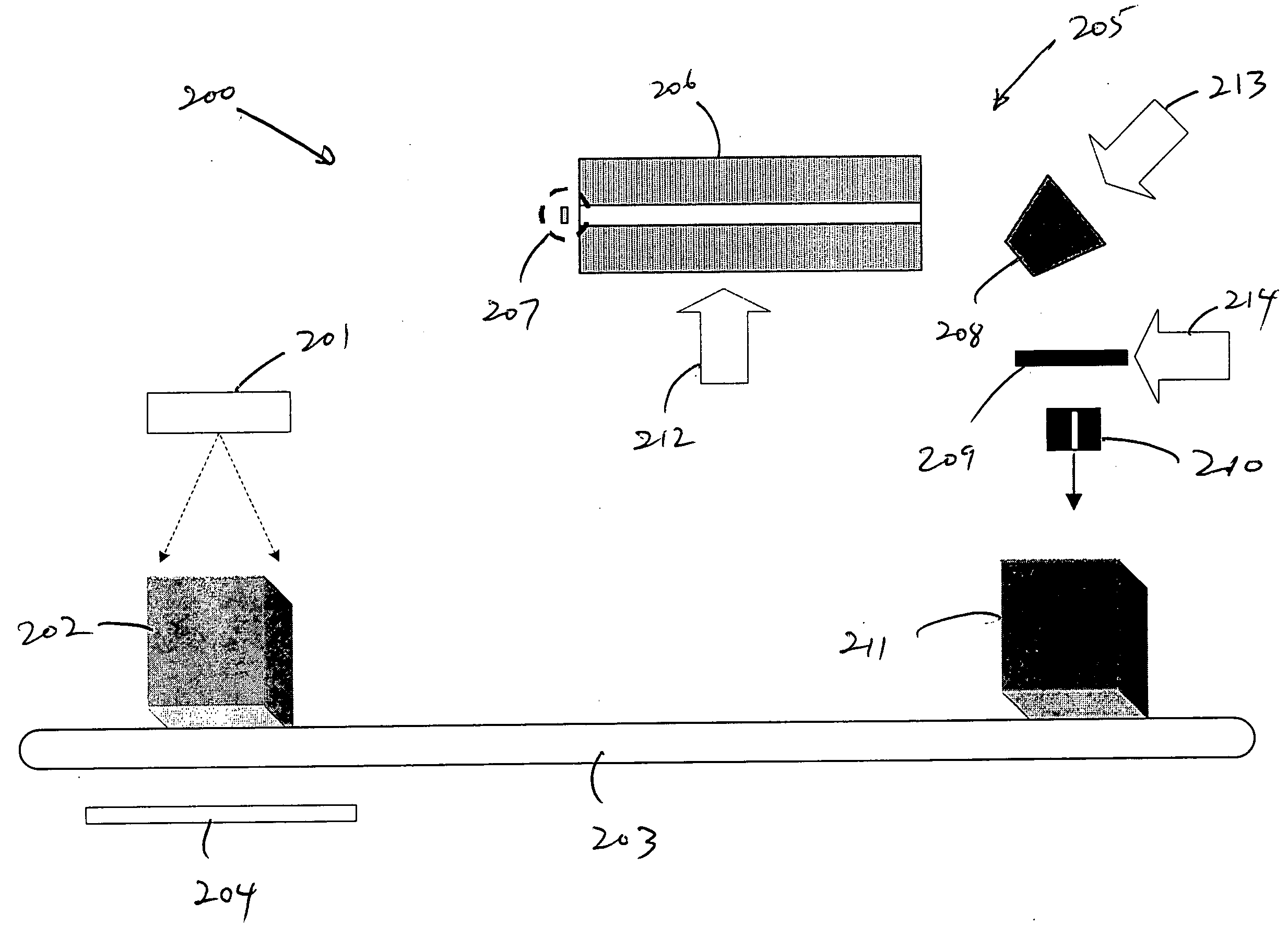

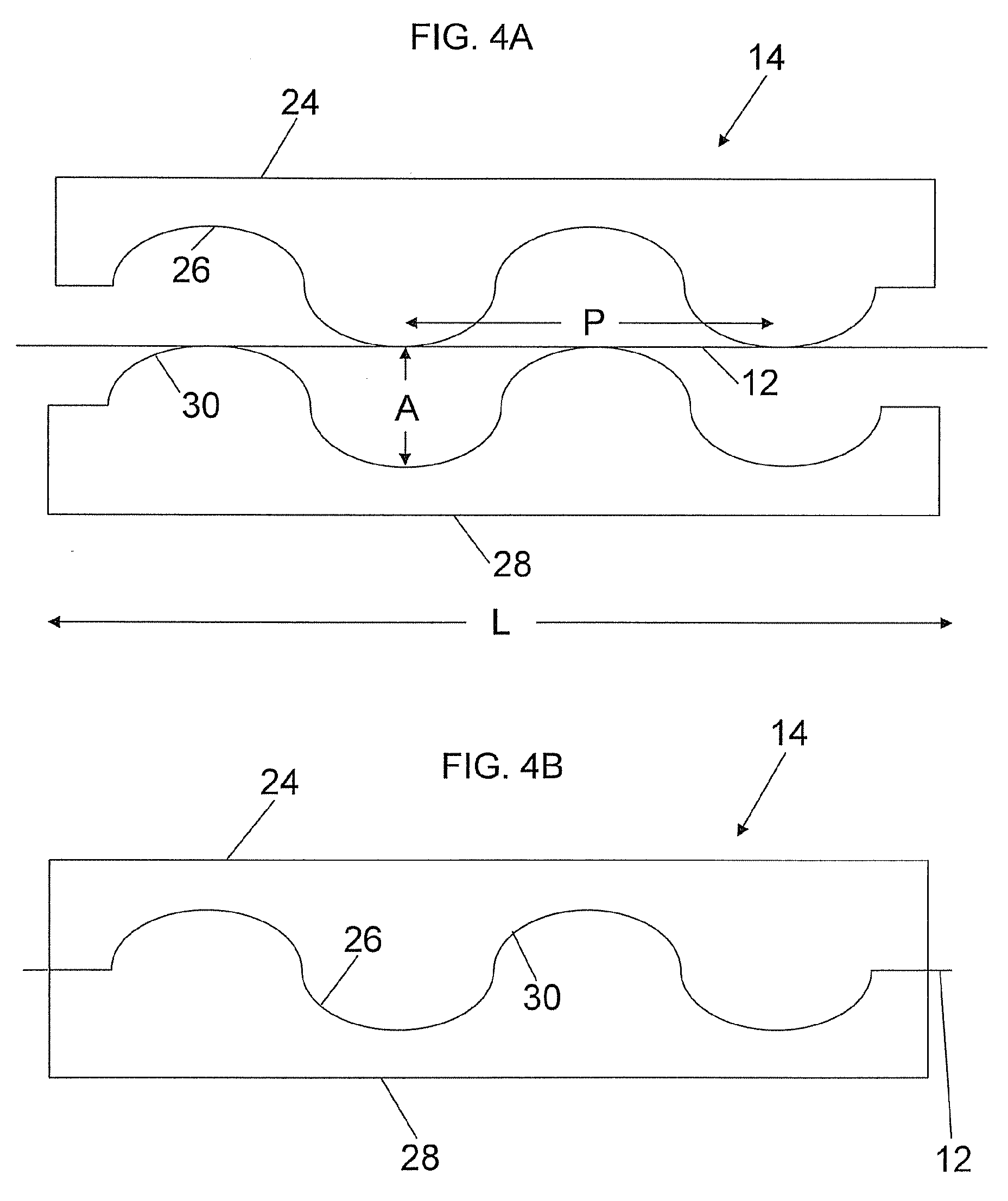

Method and apparatus to increase throughput of processes using pulsed radiation sources

ActiveUS20050247683A1Reduced strengthWelding/soldering/cutting articlesMetal working apparatusLithography processLithographic artist

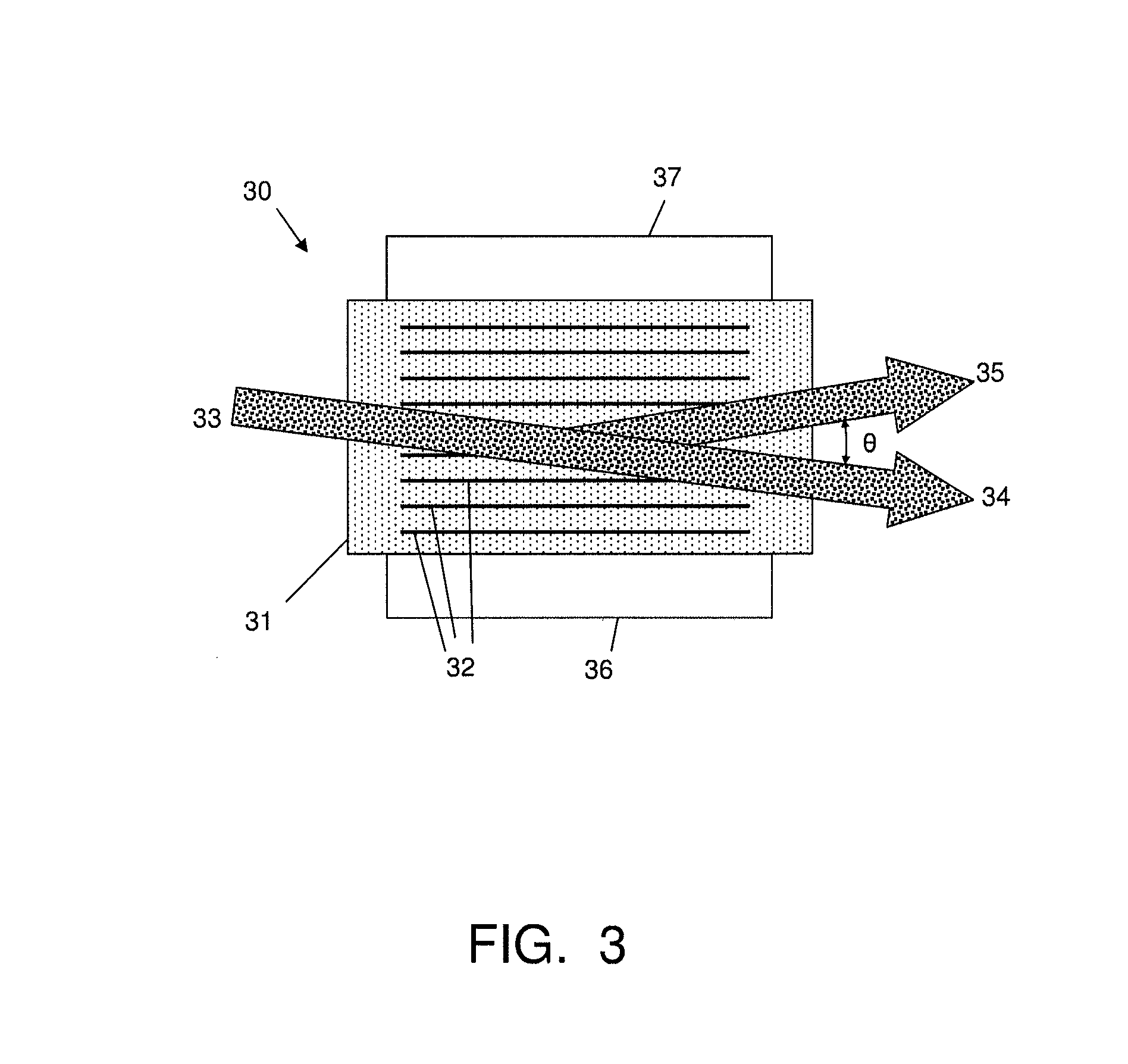

A material processing system and method is disclosed for processing materials such as amorphous silicon in an annealing processes and lithography processes on a silicon wafer, as well as ablation processes. A first laser generates periodic pulses of radiation along a beam path directed at the target material. Similarly, at least one additional laser generates periodic pulses. A beam aligner redirects the beam path of the at least one additional laser, such that the beam from the at least one additional laser is directed at the target along a path colinear with the first laser's beam path. As a result, all the lasers are directed at the target along the same combined beam path. The periodic pulses of the at least one additional laser are delayed relative to the first laser such that multiple pulses impinge on the target within a single pulse cycle of any given laser.

Owner:MICRON TECH INC

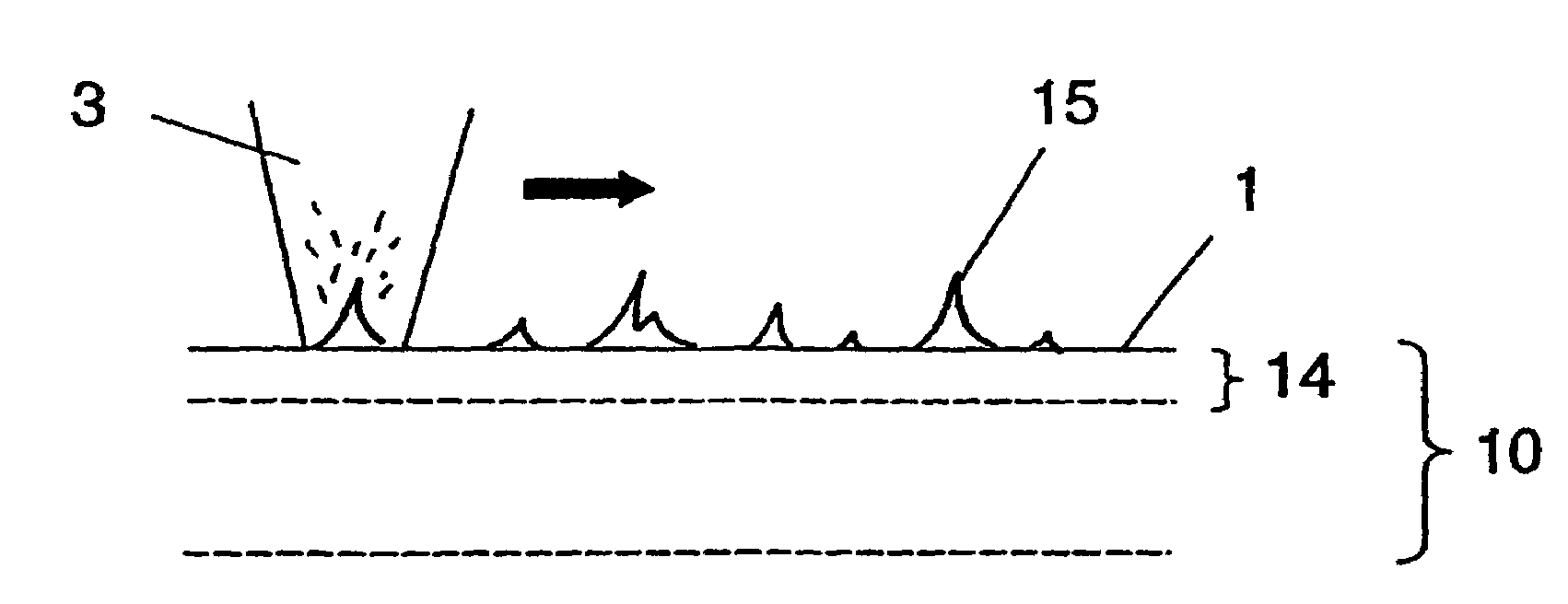

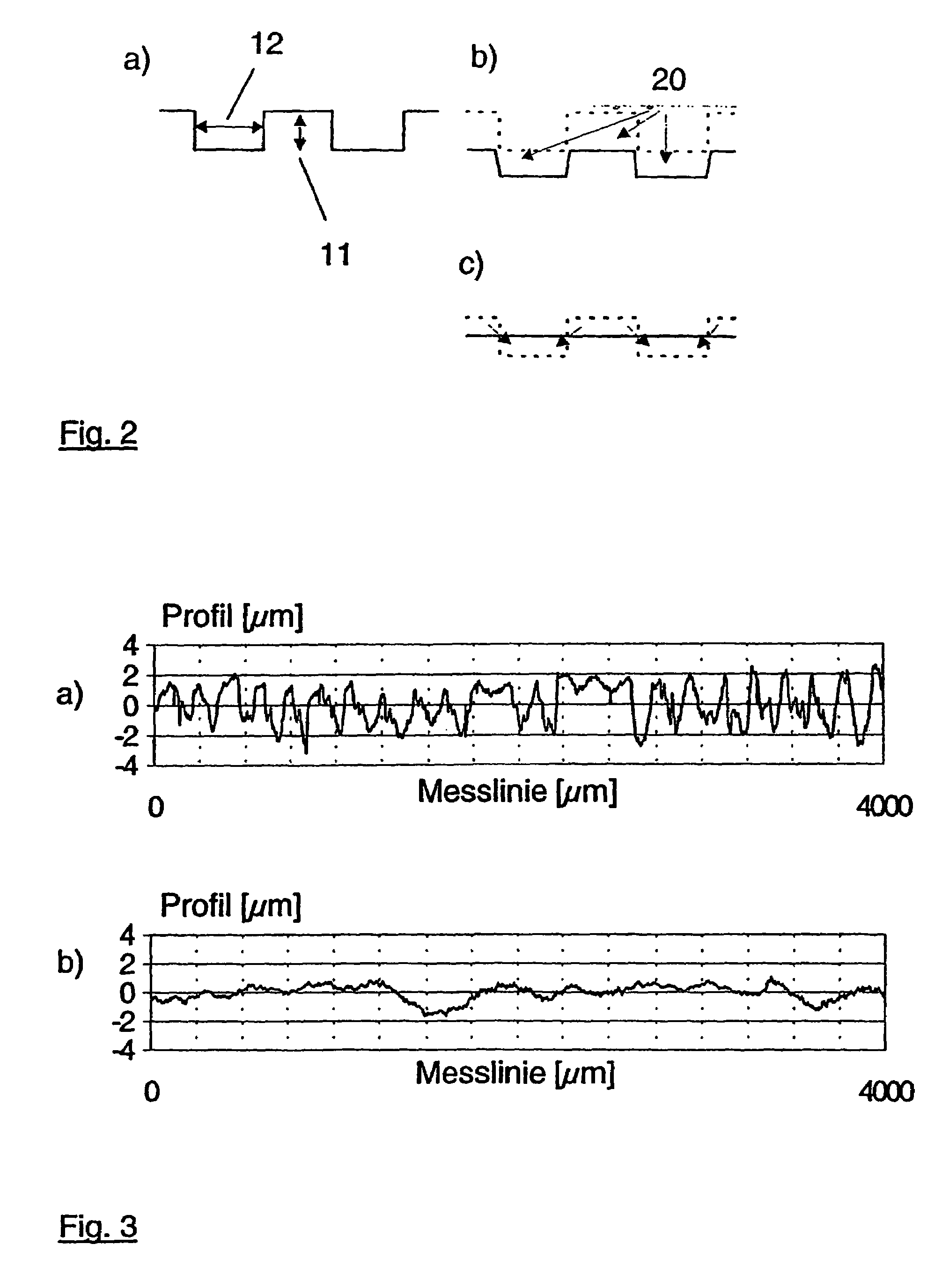

Method for smoothing and polishing surfaces by treating them with energetic radiation

InactiveUS7592563B2High glossQuick and inexpensiveElectron beam welding apparatusLaser beam welding apparatusMedicinePulse duration

The present invention relates to a method for smoothing and polishing surfaces by treating them with energetic radiation, in particular laser radiation, in which the to-be-smoothed surface is remelted in a first treatment step using said energetic radiation and employing first treatment parameters at least once down to a first remelting depth of approx. 5 to 100 μm, which is greater than a structural depth of the to-be-smoothed structures of said to-be-smoothed surface, wherein continuous radiation or pulsed radiation with a pulse duration of ≧100 μs is employed. The method makes it possible to automatically polish any three-dimensional surface fast and cost effective.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

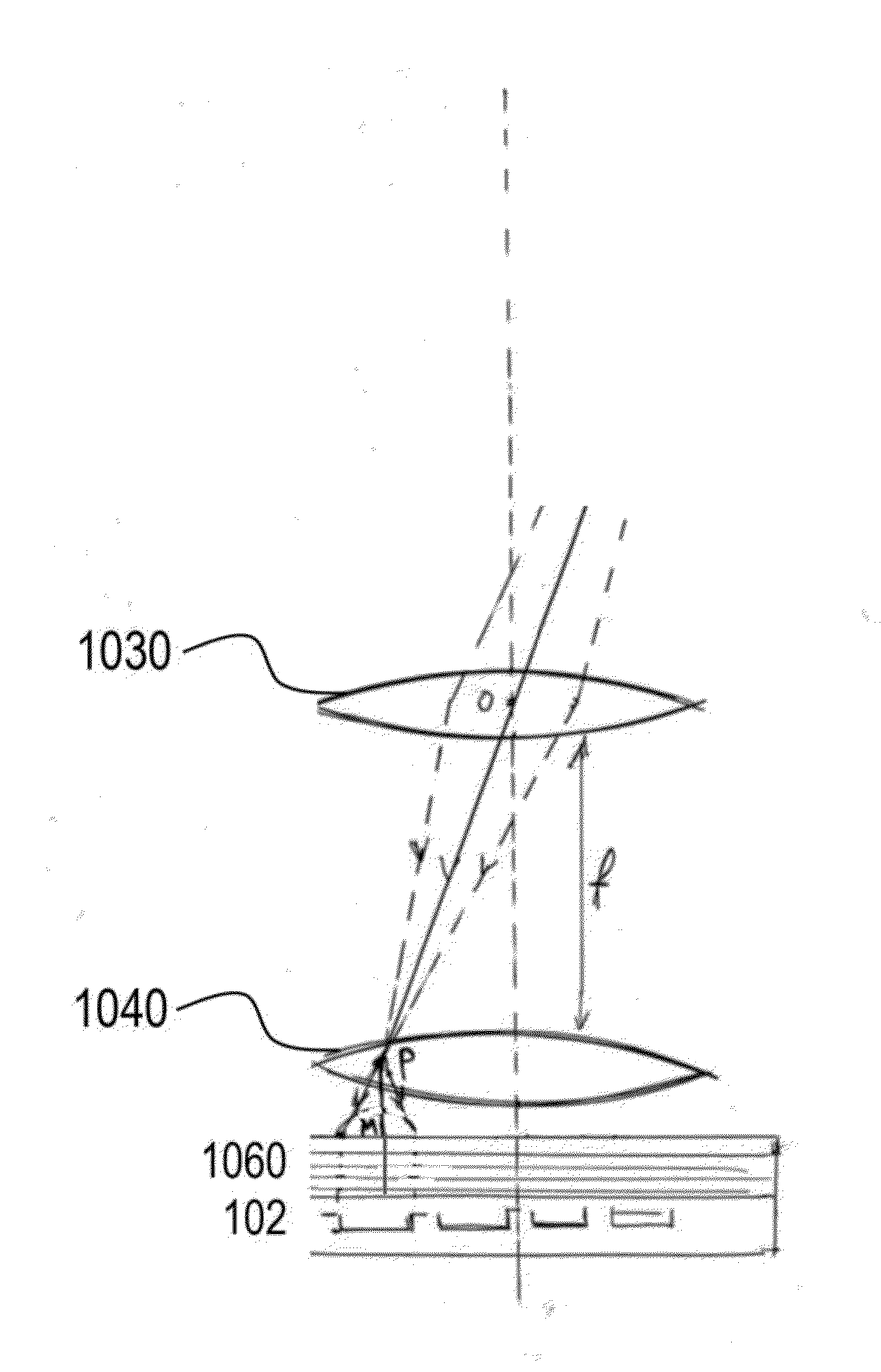

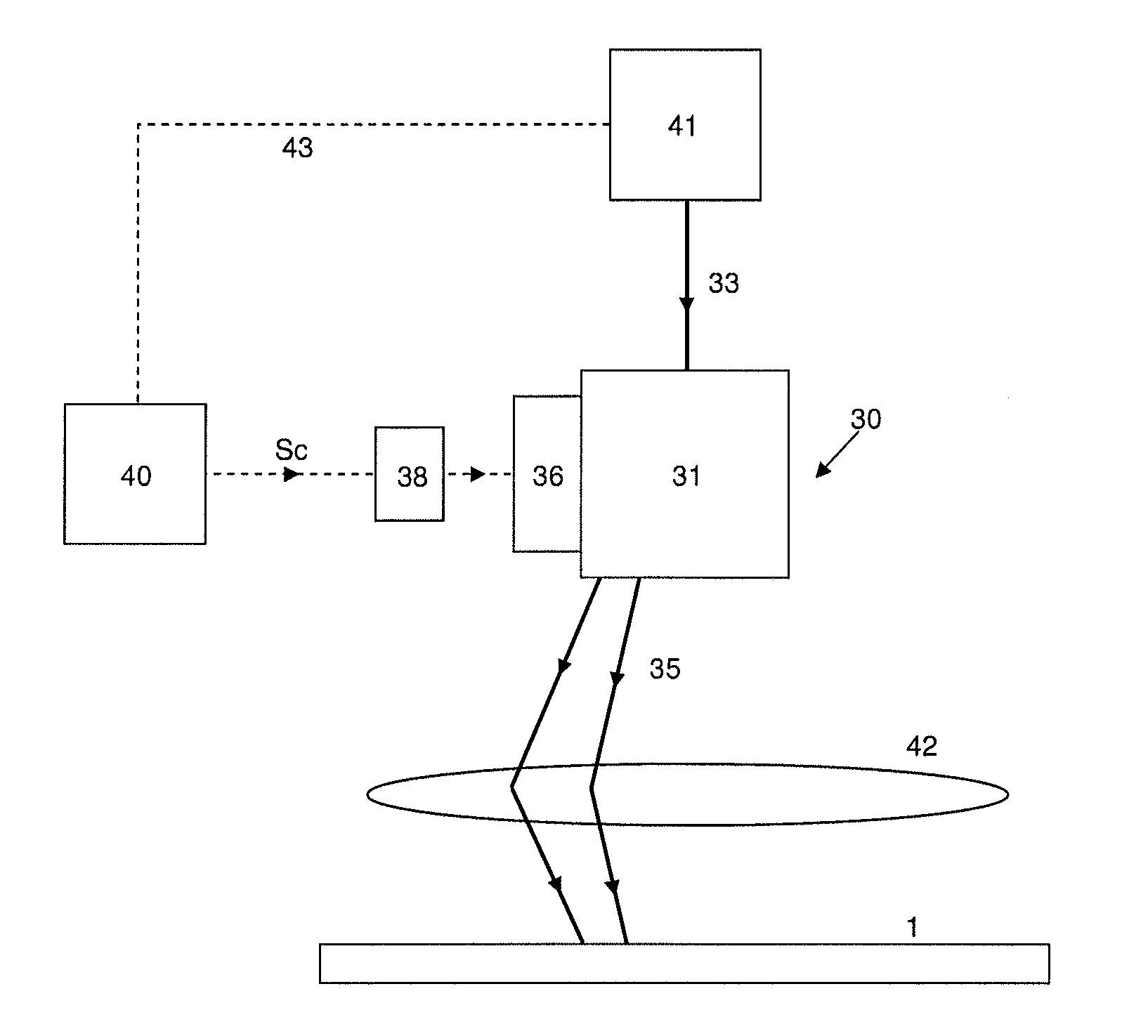

Surround sensing system with telecentric optics

ActiveUS10183541B2Reduce the amount requiredAccurate detectionUsing optical meansResilient suspensionsBandpass filteringAngle of incidence

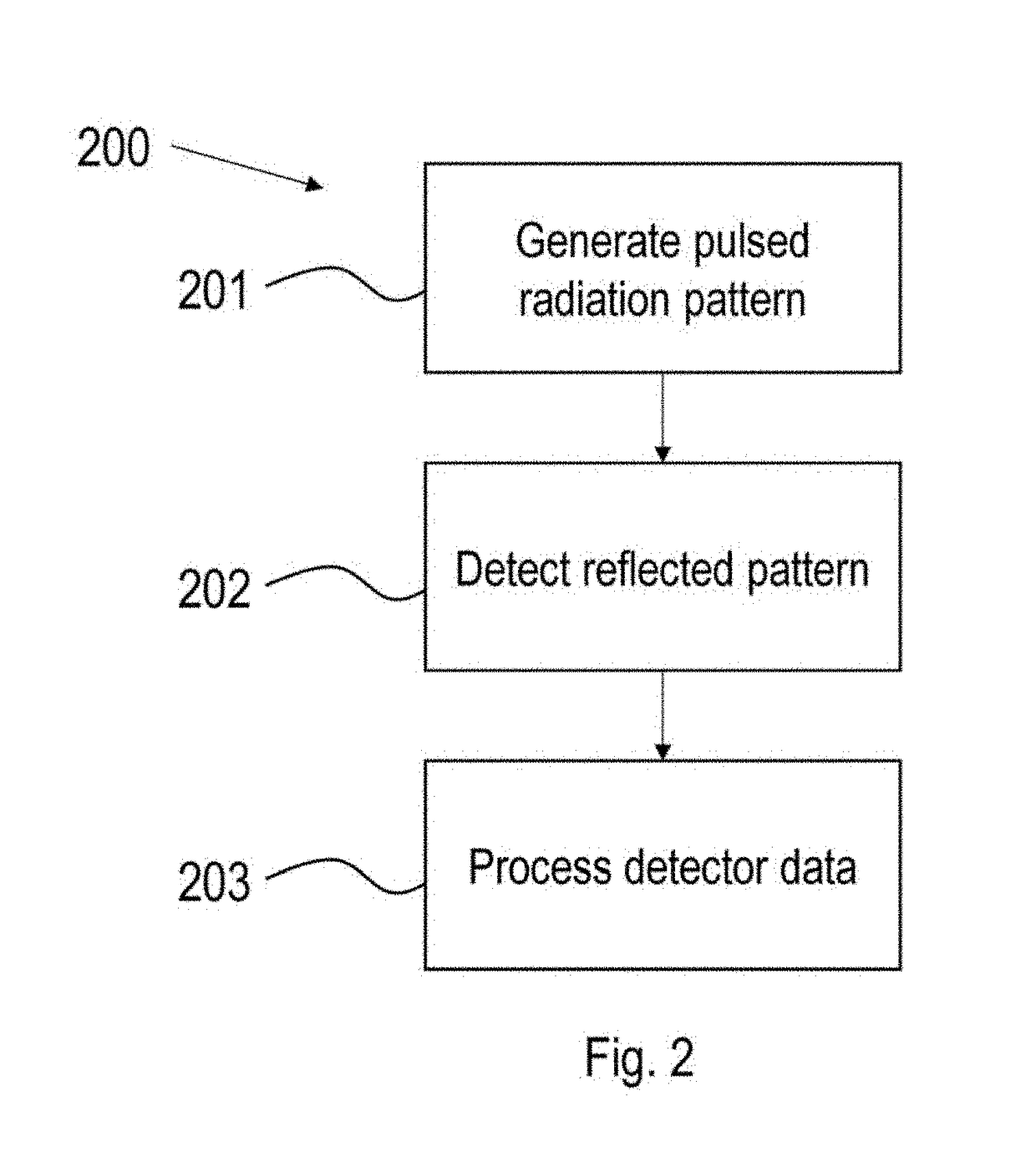

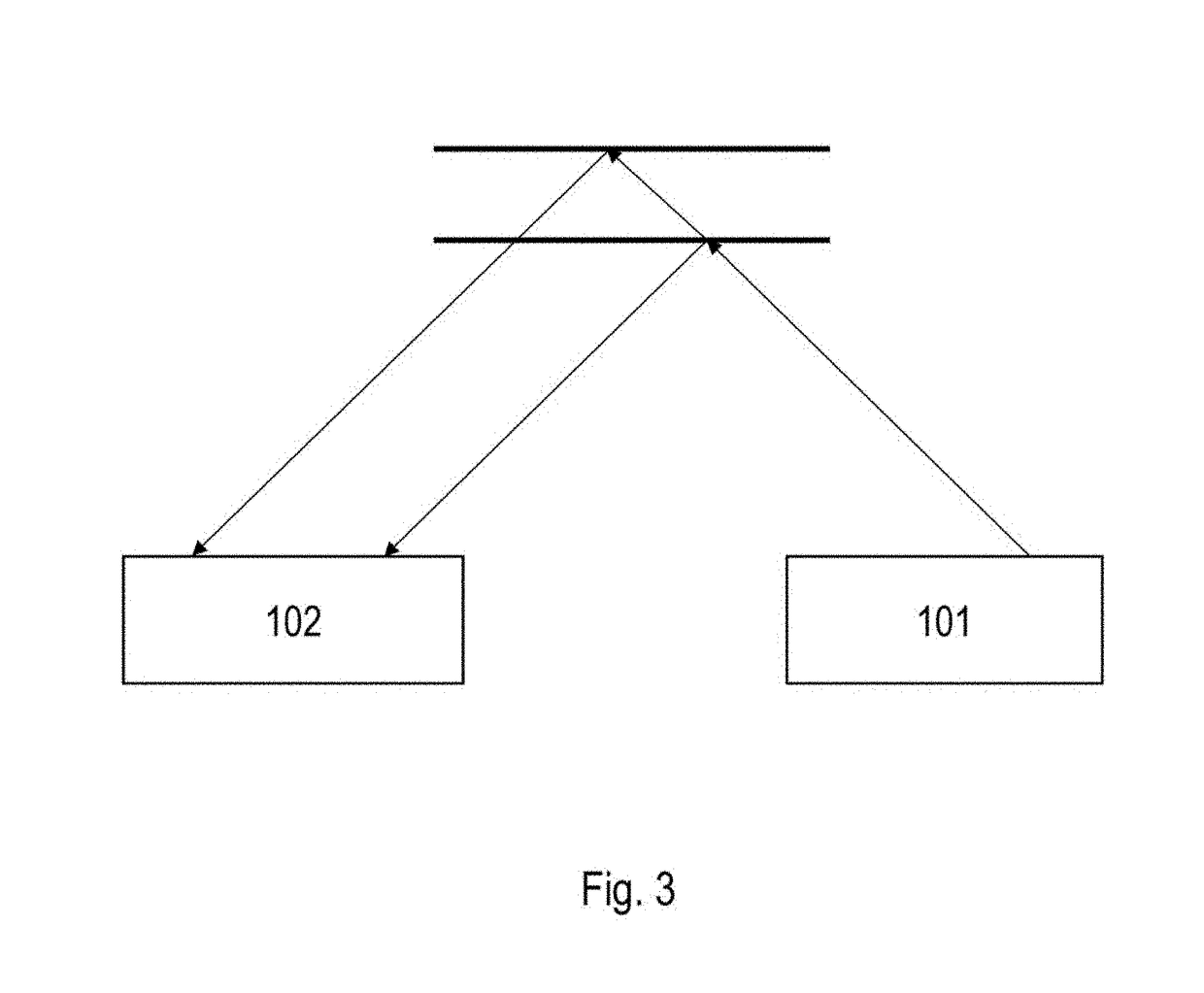

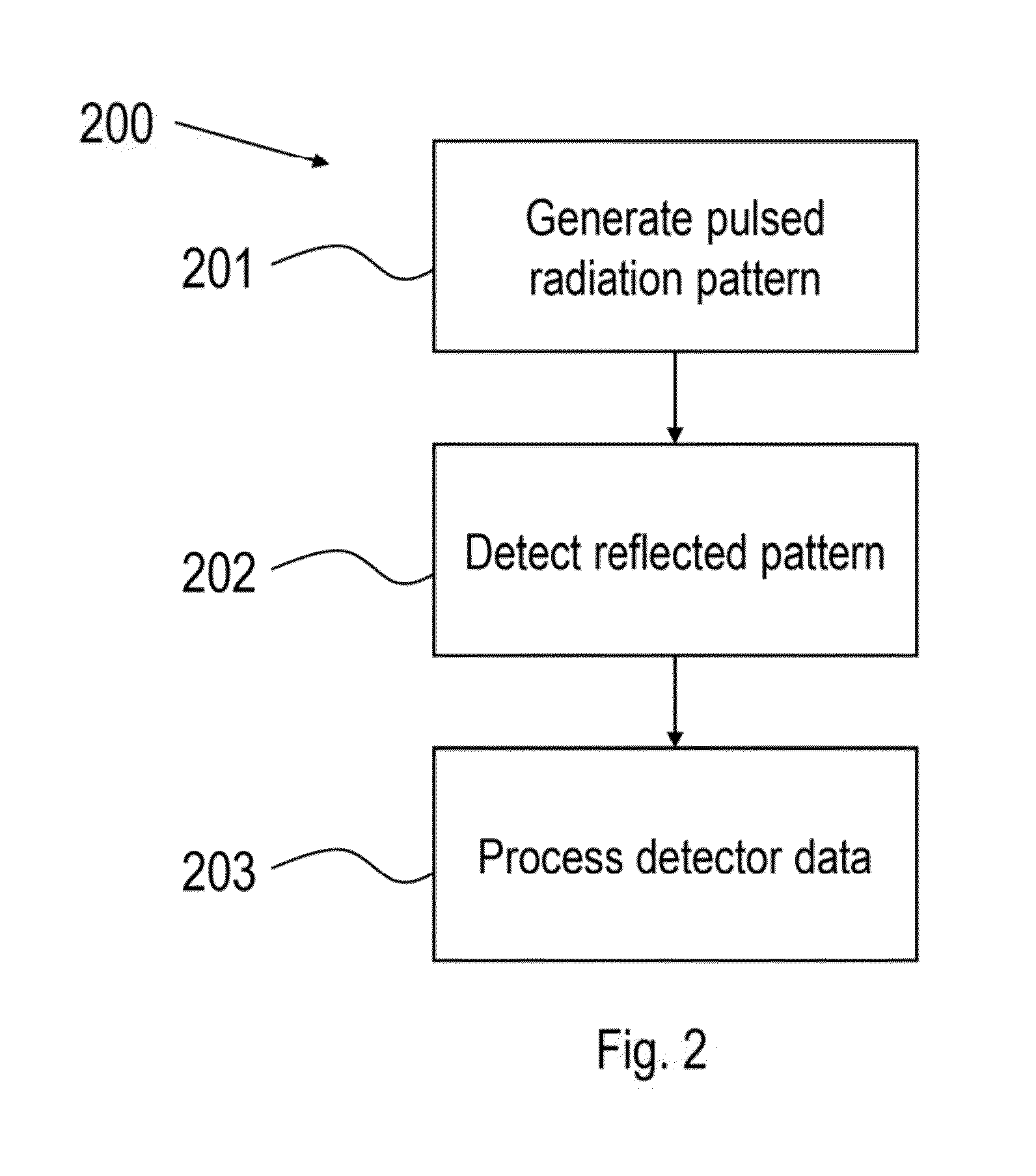

The invention pertains to a system comprising: a source to generate a pulsed radiation pattern; a detector; a processor to process data from the detector when radiation is reflected by an object; a synchronization means interfacing between the detector and the source; wherein: the detector is synchronized with the source so that radiation to be processed is detected only during the pulses, the processor determines a characteristic of the object by determining displacement of detected spots with reference to predetermined positions, the source emits monochromatic light and the detector is equipped with a bandpass filter and optics arranged so as to modify an angle of incidence onto said filter to confine light to a predetermined range around a normal of said filter, said optics comprising an image-space telecentric lens.

Owner:XENOMATIX NV

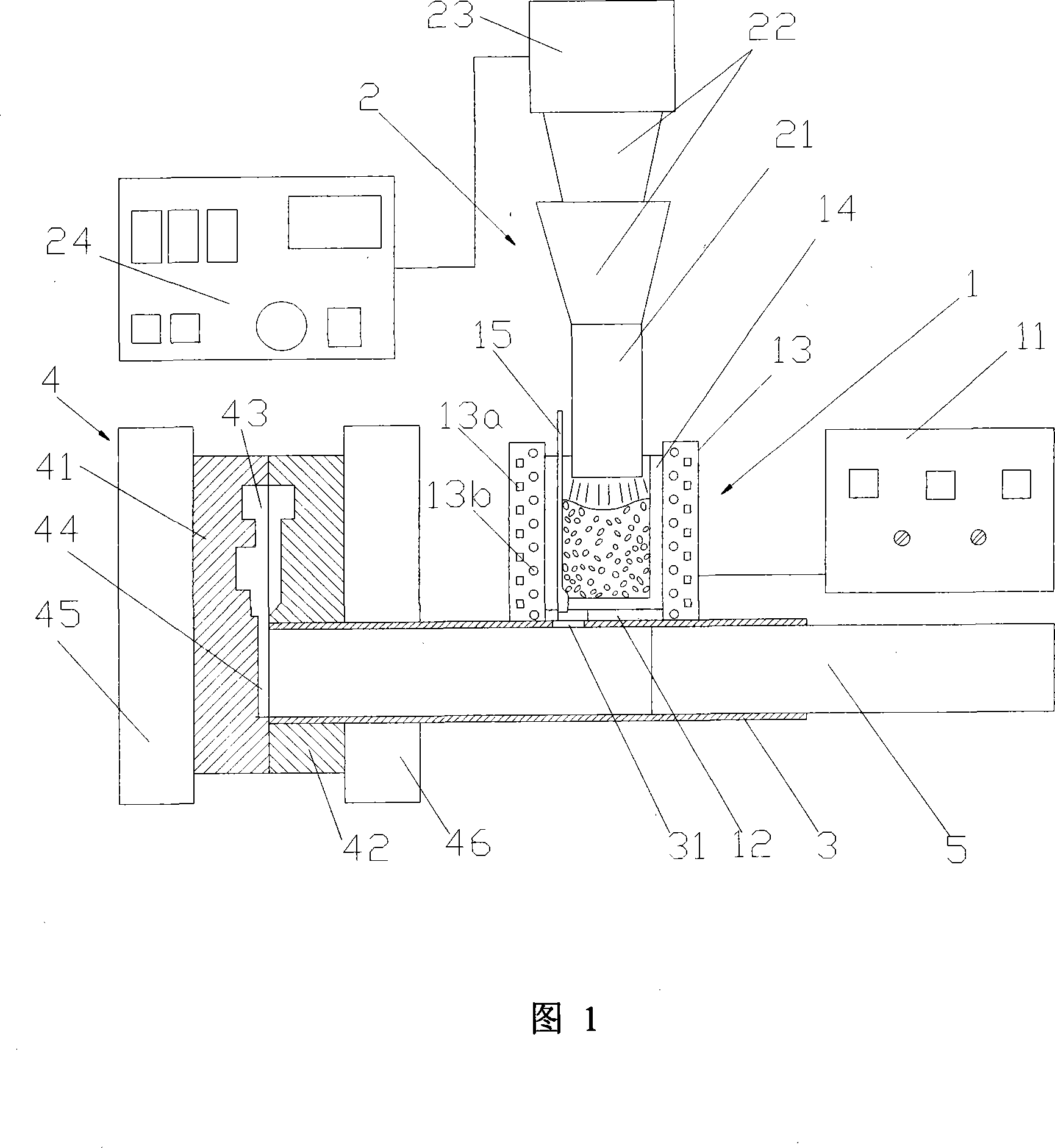

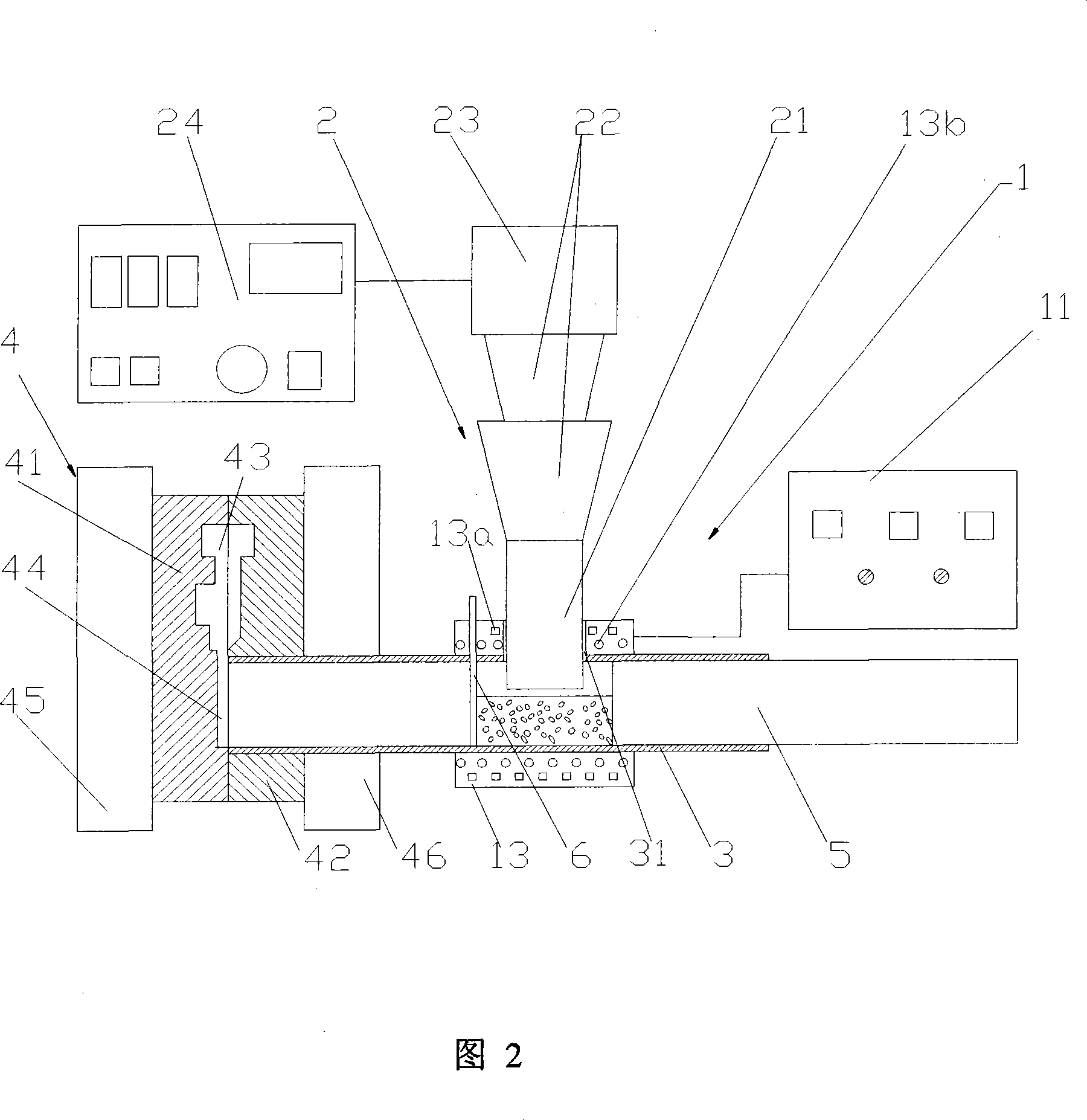

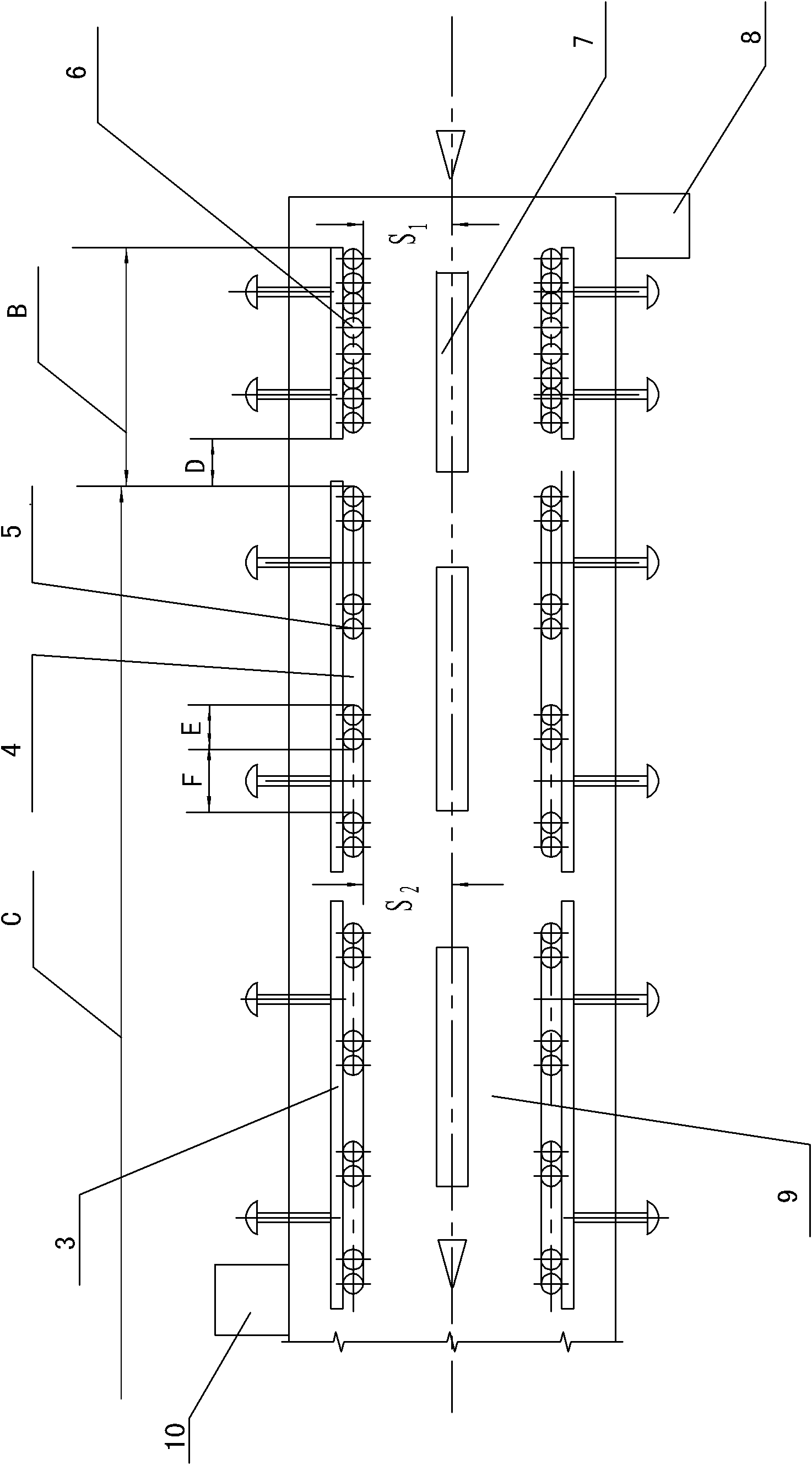

Semi solid rheoforming method for metal parts and device therefor

The invention relates to a semi-solid fluidized molding method and a device for metal parts. Liquid metal with the temperature from 0 to 40 DEG C above liquid phase is guided into a pulp container, and then an ultrasonic radiation is lowered down to 1 to 30mm above the liquid surface, ultrasonic radiation is started, and the slurry is cooled at the speed ranging from 0.1 DEG C per second to 3 DEG C per second. The ultrasonic radiation can be pulse radiation or non-radiation pulse with ultrasonic frequency ranging from 12kHz to 80kHz, radiation volume power 5W / cm<3> to 100W / cm<3>, and radiation time from 15s to 1000s; the slurry is poured into molding equipment to be molded into parts after the radiation. The molded part has dense organization, fine and equally distributed grains. The device of the invention comprises a pulp container, a thermostat, an ultrasonic generation and a control unit, a sleeve, and a mold and an injection rod and a molding device. The fluidized molding method and device can be used for fluidized molding of various alloy parts made from aluminum, magnesium, tin, copper and iron etc. The method has the advantages of non-contaminated pulp, long service life of ultrasonic equipment and high part production efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

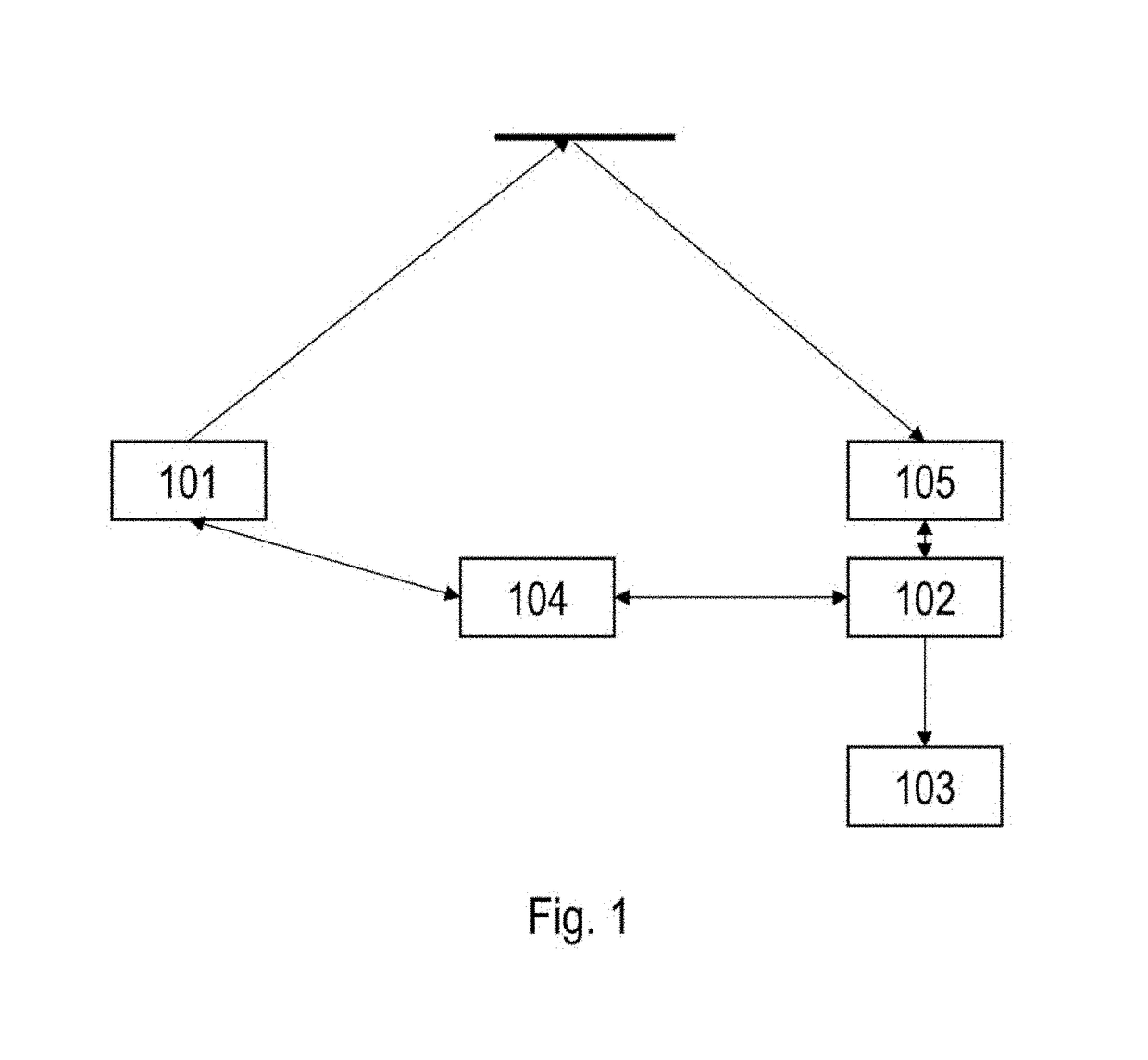

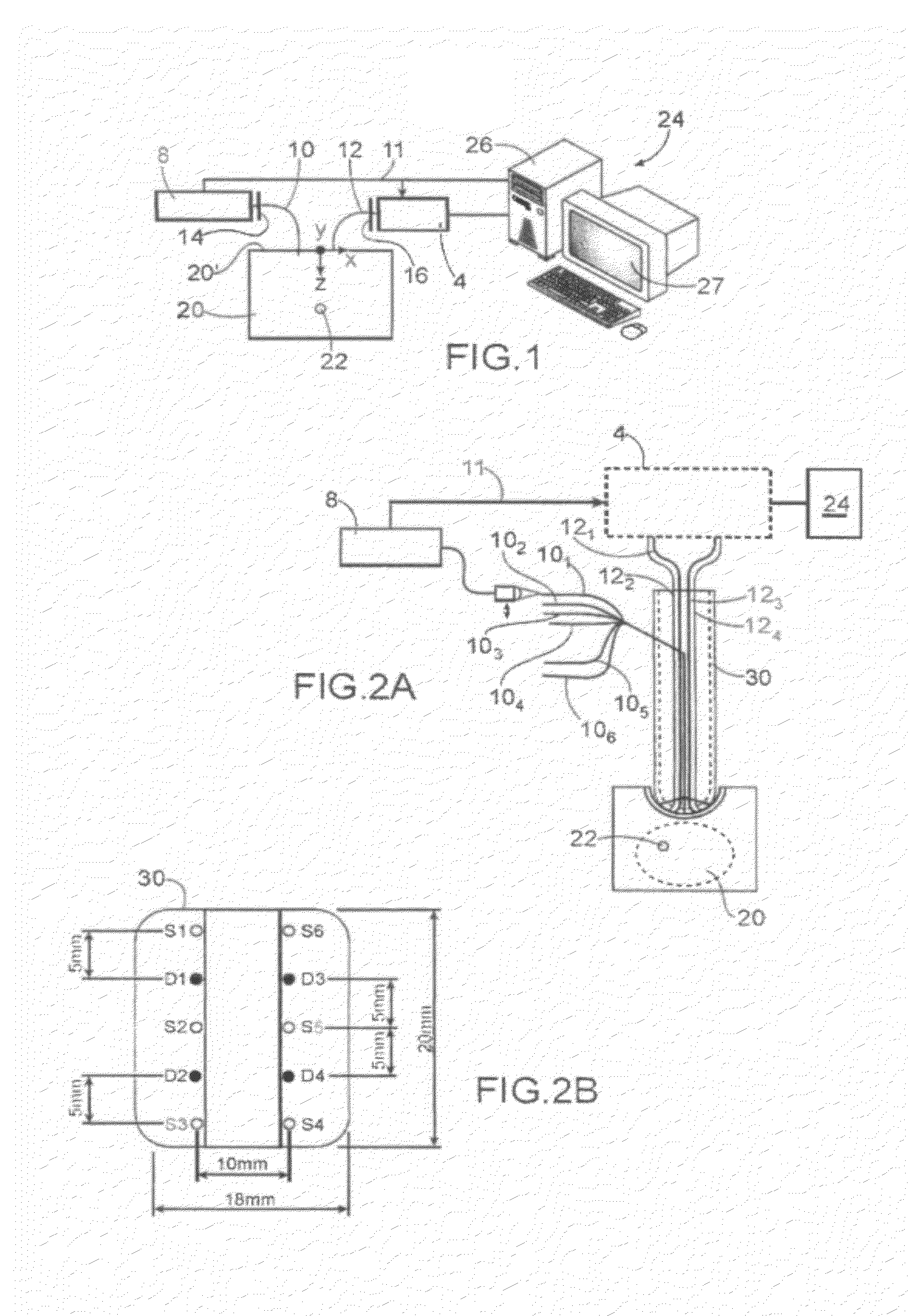

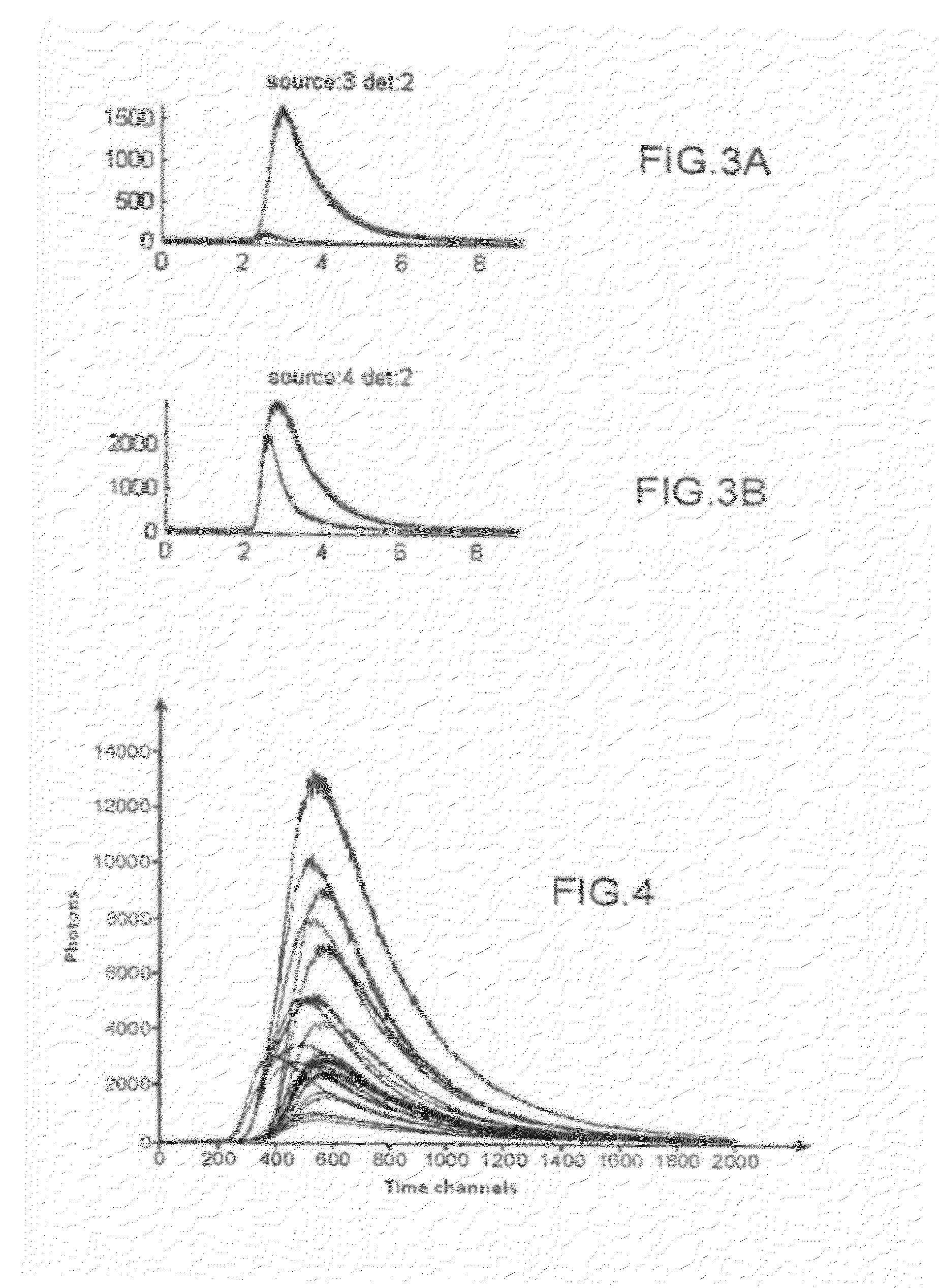

System for reconstructing optical properties in a diffusing medium, comprising a pulsed radiation source and at least two detectors of two different types, and associated reconstruction method

ActiveUS9407796B2Television system detailsScattering properties measurementsInformation processingOptical property

A system for reconstructing optical properties of a diffusing medium including at least one pulsed radiation source capable of illuminating the diffusing medium, at least one first detector of a first type, capable of receiving a signal emitted by the medium, the first detector being a time-resolved detector, and an information processing unit for processing at least one source—first detector pair, a time distribution of the signal received by the corresponding first detector. The reconstruction system also includes at least one second detector of a second type, each second detector being made up of a set of pixel(s) from an image sensor capable of acquiring an image of the medium, and the second detector being capable of measuring an intensity of the signal emitted by the medium, the intensity corresponding to an equivalent moment of order 0 for the corresponding source—second detector pair.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

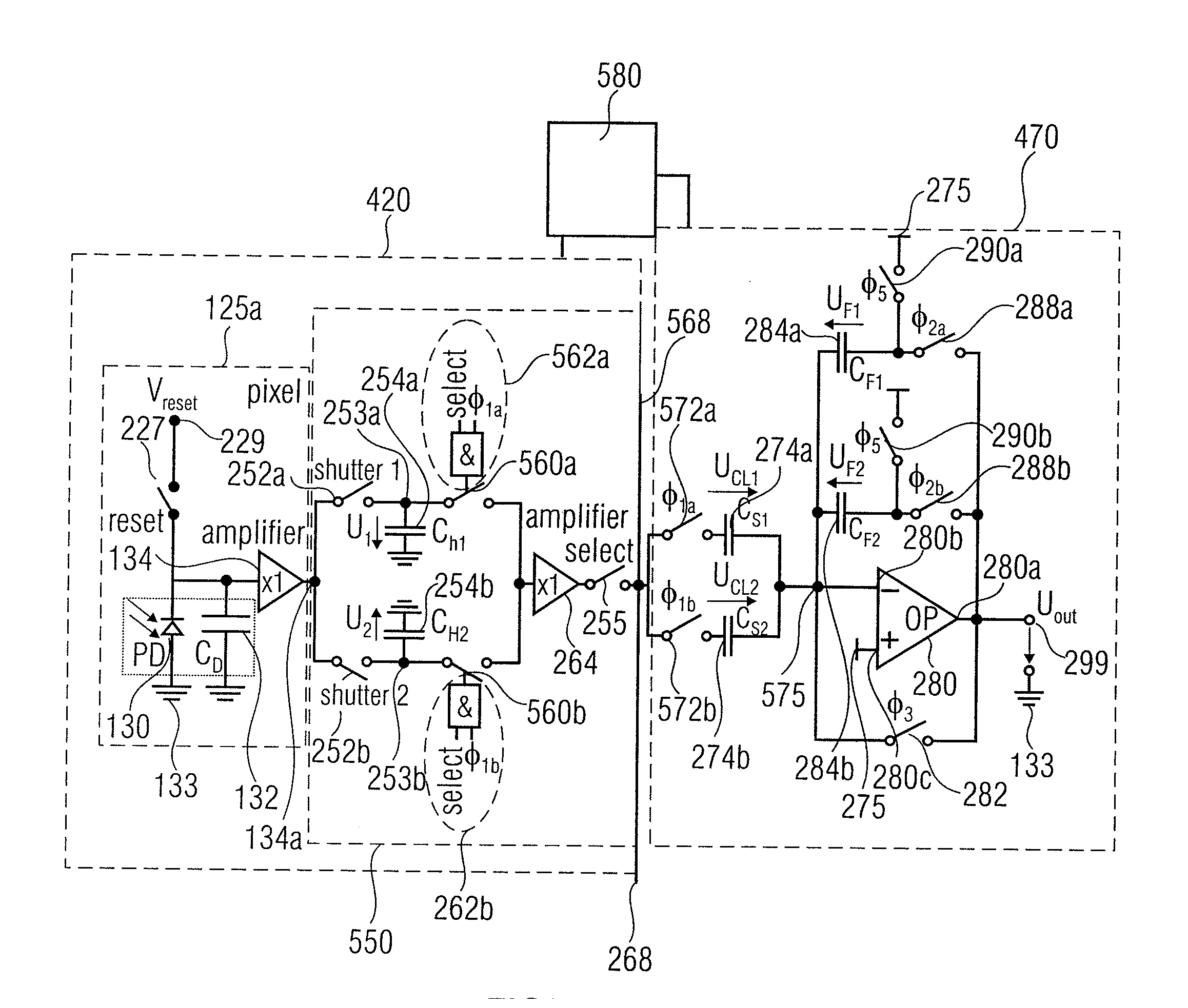

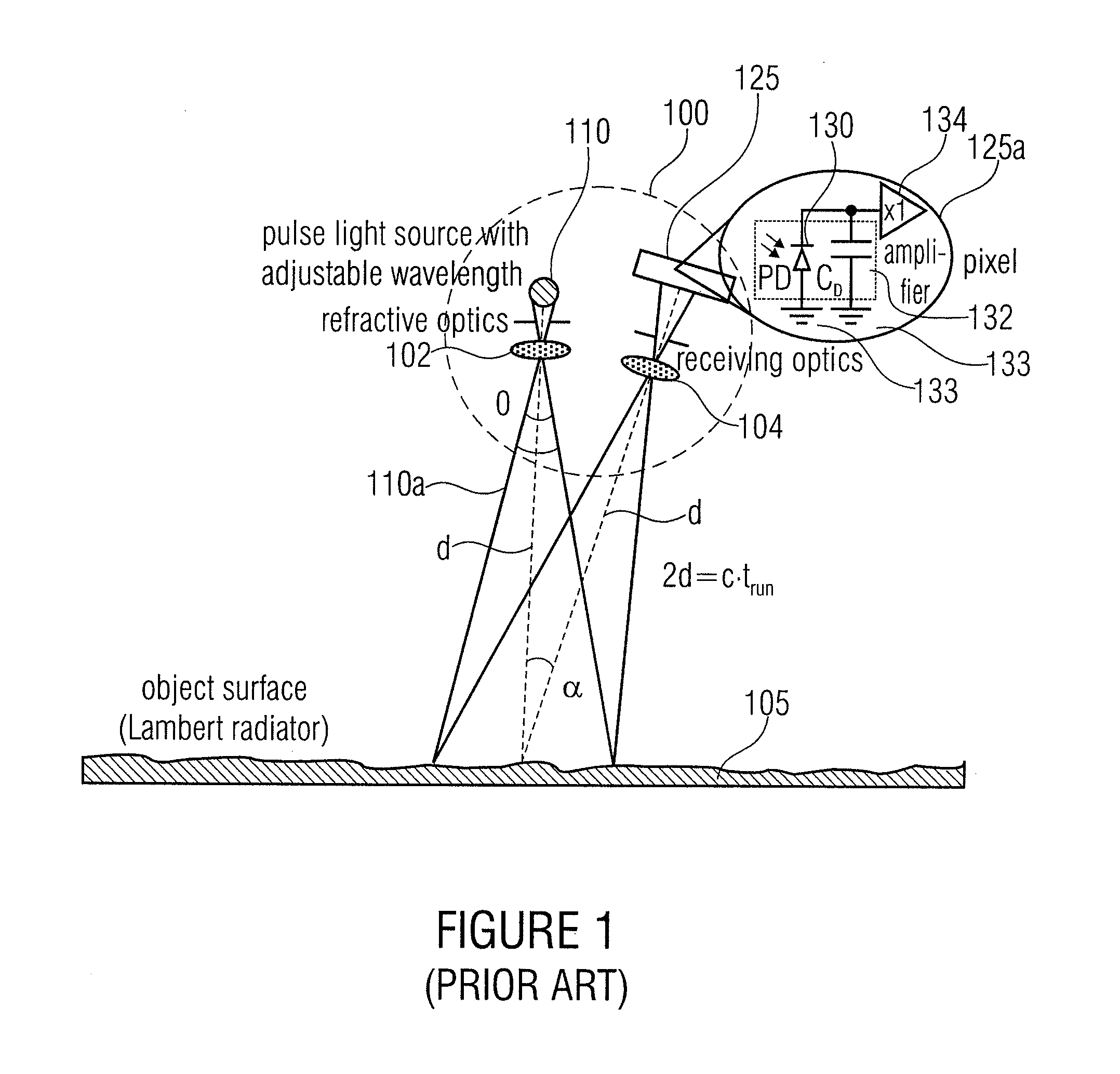

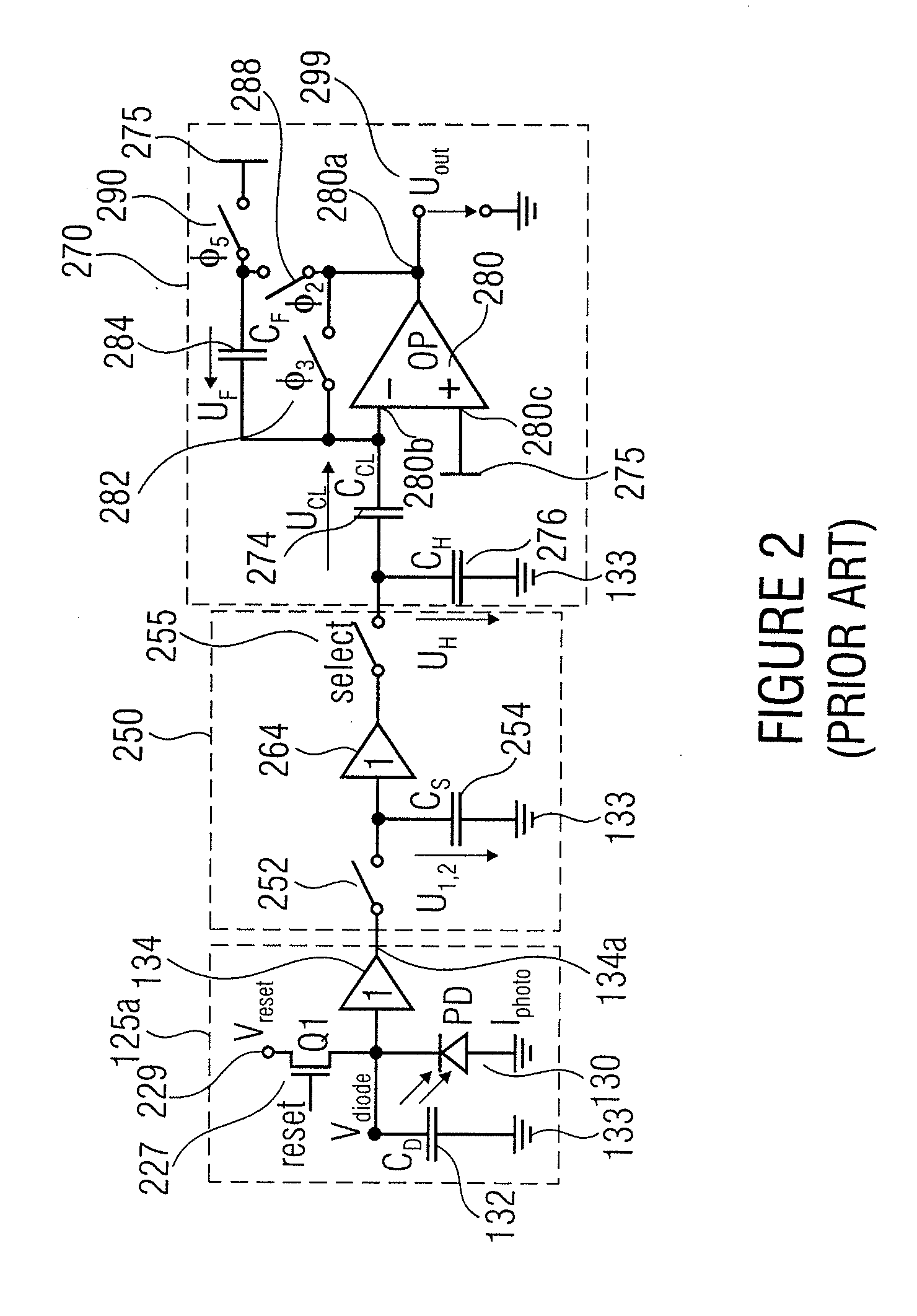

Optical Distance Measuring Device and Method for Optical Distance Measurement

ActiveUS20120268727A1Fast measurement speedReduce radiant energyOptical rangefindersMaterial analysis by optical meansObject basedRadiation pulse

The present invention describes an optical distance measuring device having a pulsed radiation source that is implemented to transmit, in a temporally contiguous radiation pulse period, a radiation pulse having a pulse duration tp that is shorter than the radiation pulse period, and to transmit no radiation pulse in a temporally contiguous dark period. Further, the optical distance measuring device includes a detector for detecting different amounts of radiation in two overlapping detection periods during the radiation pulse period to capture reflections of the radiation pulse at an object surface and a background radiation and / or in two overlapping detection periods during the dark period to capture background radiation. The optical distance measuring device further includes an evaluator determining a signal depending on a distance of the optical distance measuring device to an object based on the detected amount of radiation. Further, the present invention provides a method for optical distance measurement and for multiple sampling.

Owner:VOLKSWAGEN AG

Detecting photons in the presence of a pulsed radiation beam

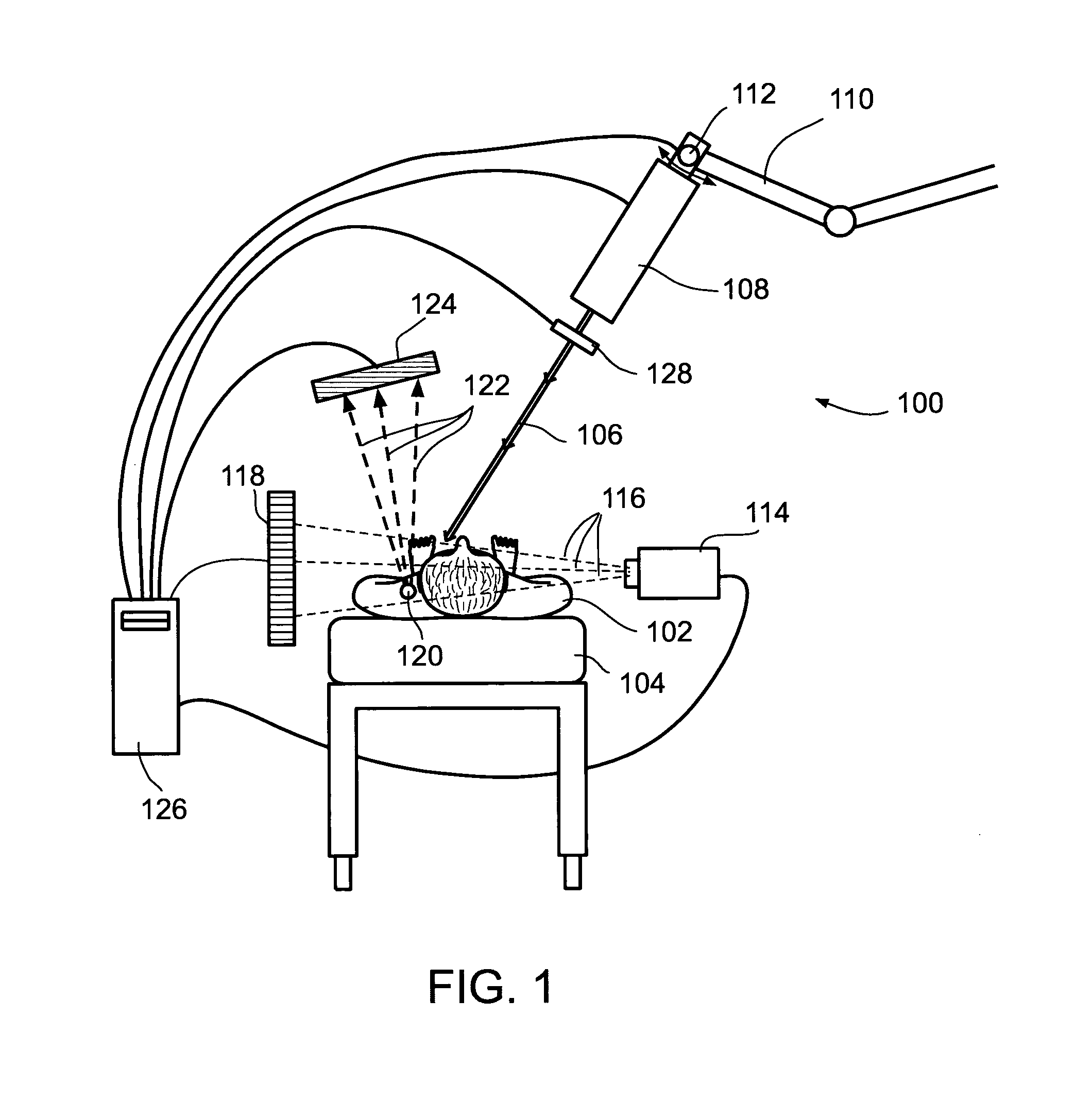

InactiveUS20110006212A1Reduces and avoids interferenceReduce sensitivityMaterial analysis using wave/particle radiationSurgeryPulse beamBeam source

A detector system adapted for monitoring a radiation treatment system comprising a pulsed beam radiation source for treating a body with a given beam intensity and beam configuration, with pulse times and intervals between pulses less than 100 milliseconds, using at least one monitoring radiation source located inside or outside the body, the detector system comprising; a) a detector designed to detect radiation from the monitoring source, and subject to interference radiation from the beam source; and b) control circuitry that creates a data record of radiation received by the detector, to provide information about the body; wherein, when the detector detects radiation in real time during operation of the beam, the data record selectively excludes data for radiation received by the detector during the pulses, as opposed to data for radiation received by the detector between pulses.

Owner:NAVOTEK MEDICAL

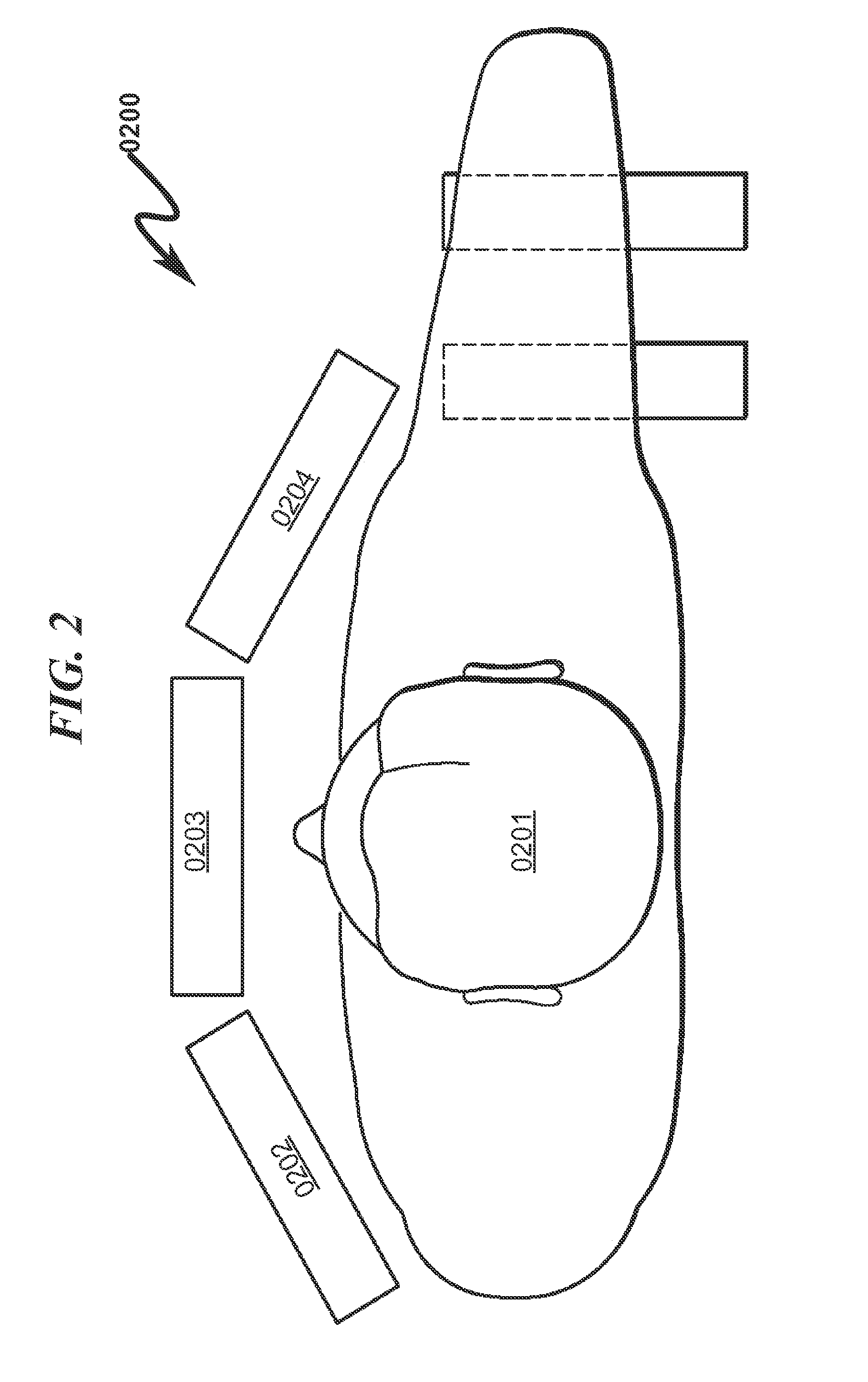

Surround sensing system with telecentric optics

ActiveUS20160200161A1Decrease the filling factorReduce lossesDigital data processing detailsAnimal undercarriagesBandpass filteringAngle of incidence

The invention pertains to a system comprising: a source to generate a pulsed radiation pattern; a detector; a processor to process data from the detector when radiation is reflected by an object; a synchronization means interfacing between the detector and the source; wherein: the detector is synchronized with the source so that radiation to be processed is detected only during the pulses, the processor determines a characteristic of the object by determining displacement of detected spots with reference to predetermined positions, the source emits monochromatic light and the detector is equipped with a bandpass filter and optics arranged so as to modify an angle of incidence onto said filter to confine light to a predetermined range around a normal of said filter, said optics comprising an image-space telecentric lens.

Owner:XENOMATIX NV

Laser desorption-electrospray ion (ESI) source for mass spectrometers

InactiveUS7525105B2Particle separator tubesMaterial analysis by optical meansDesorptionElectrospray ionization

Owner:THERMO FINNIGAN

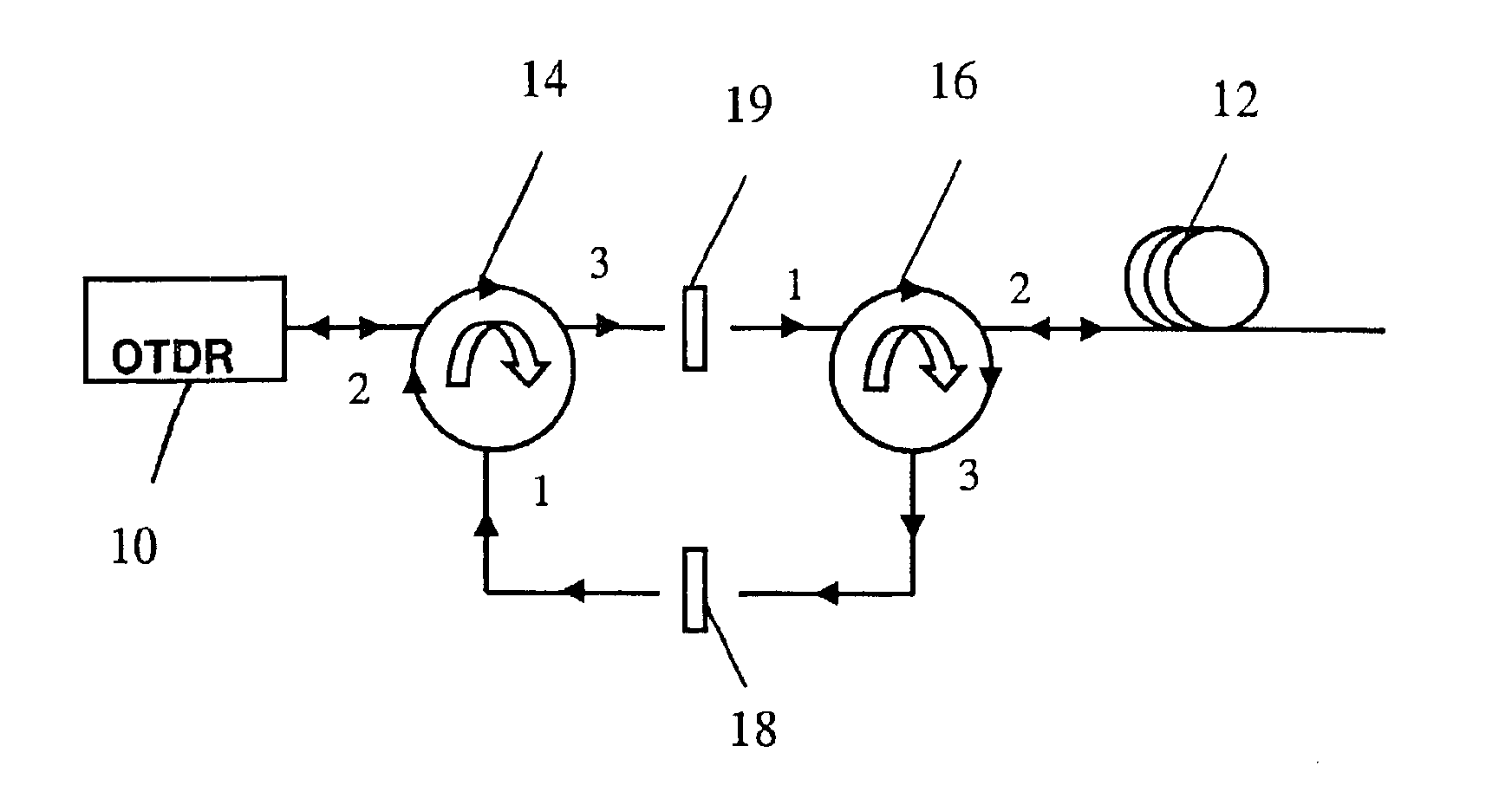

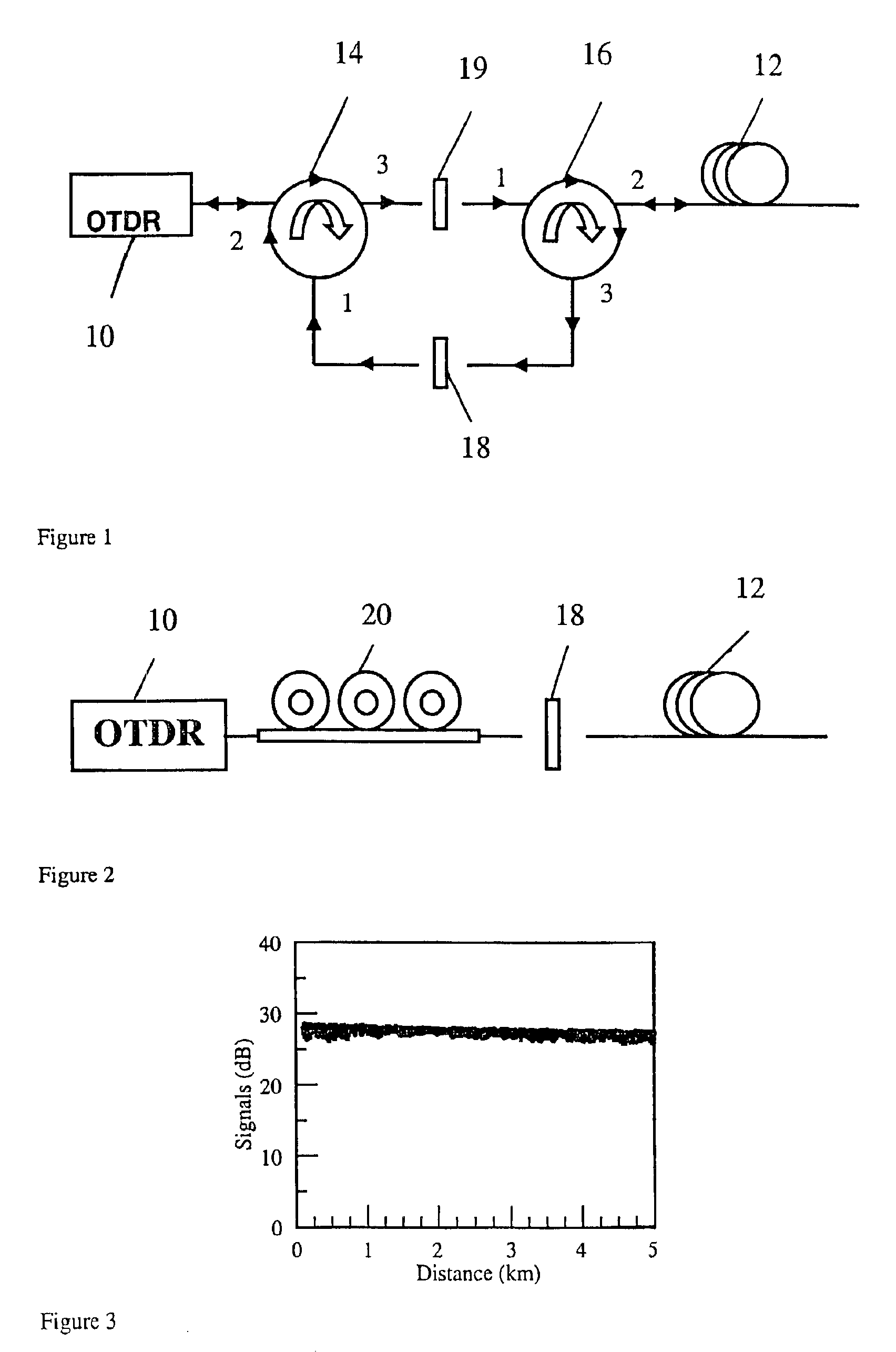

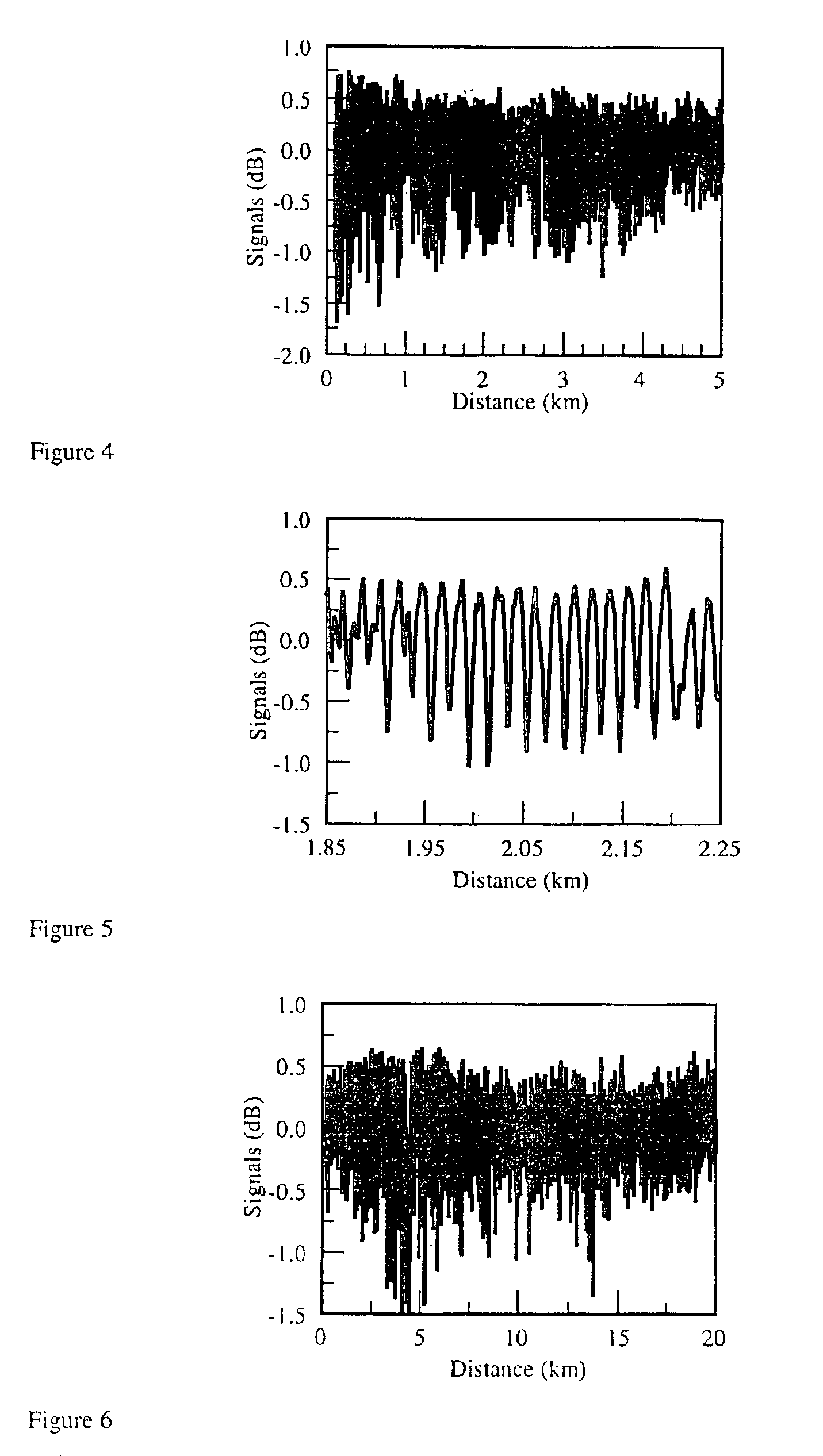

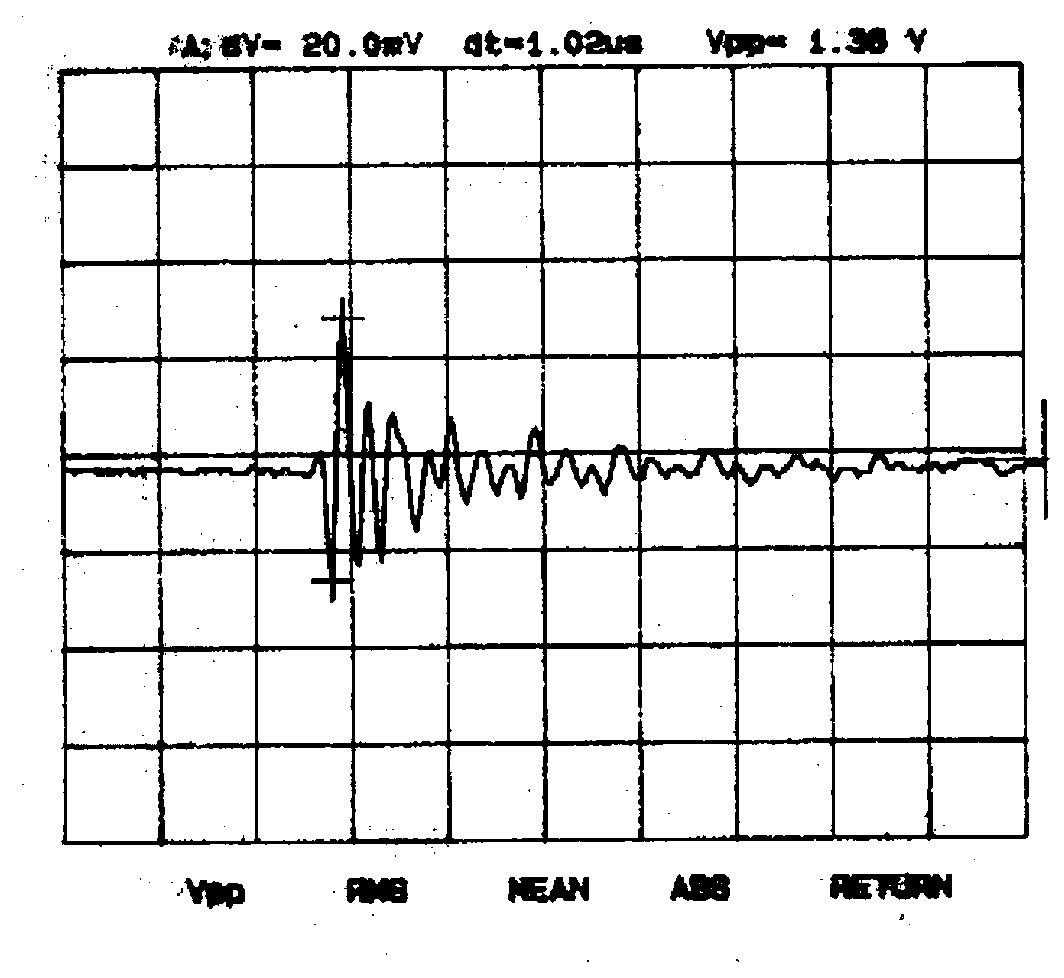

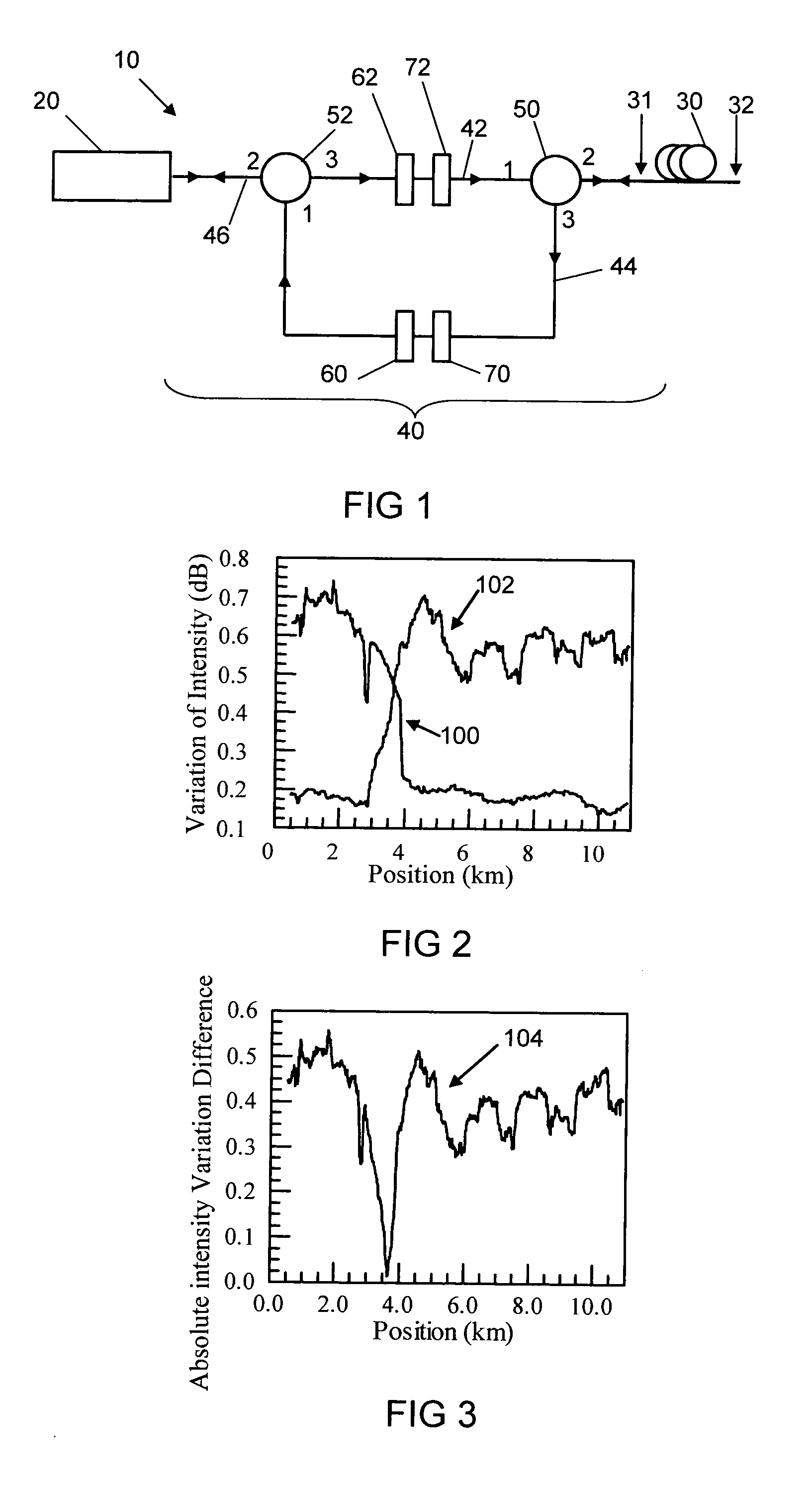

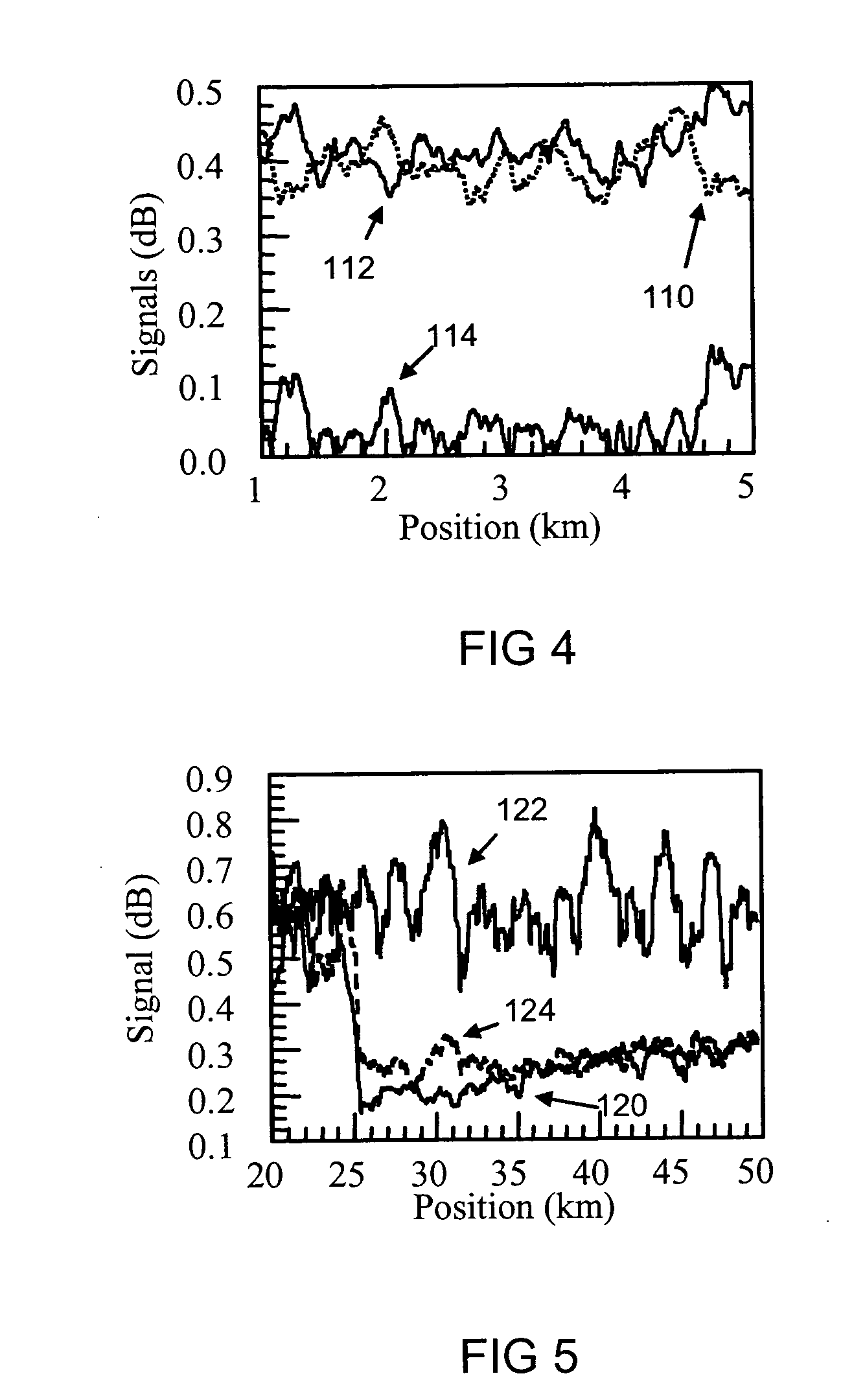

Method of evaluating fiber PMD using polarization optical time domain reflectometry

InactiveUS6946646B2Easy to identifyReflectometers dealing with polarizationRadiation pyrometryTime domainFiber

A method for screening fiber polarization mode dispersion using a polarization optical time domain reflectometer. A pulse radiation is emitted into the fiber under test, and the backscattered radiation is measured by the POTDR and used to obtain a POTDR trace. The POTDR trace is then analyzed to compare the variation of signals along the length of the fiber, the variation in signals relating to the level of PMD along the length of the fiber. Because high levels of PMD correspond to localized levels of low variability, by setting the variability of signal threshold sufficiently low, fibers having unacceptably high localized PMD can be identified and removed.

Owner:CORNING INC

Laser etching method and apparatus therefor

InactiveUS7169709B2Avoid depositionSemiconductor/solid-state device manufacturingPrintingLaser etchingOptoelectronics

The invention provides a laser etching method for optical ablation working by irradiating a work article formed of an inorganic material with a laser light from a laser oscillator capable of emitting in succession light pulses of a large energy density in space and time with a pulse radiation time not exceeding 1 picosecond, wherein, in laser etching of the work article formed of the inorganic material by irradiation thereof with the laser light from the laser oscillator with a predetermined pattern and with a predetermined energy density, there is utilized means for preventing deposition of a work by-product around the etching position.

Owner:CANON KK

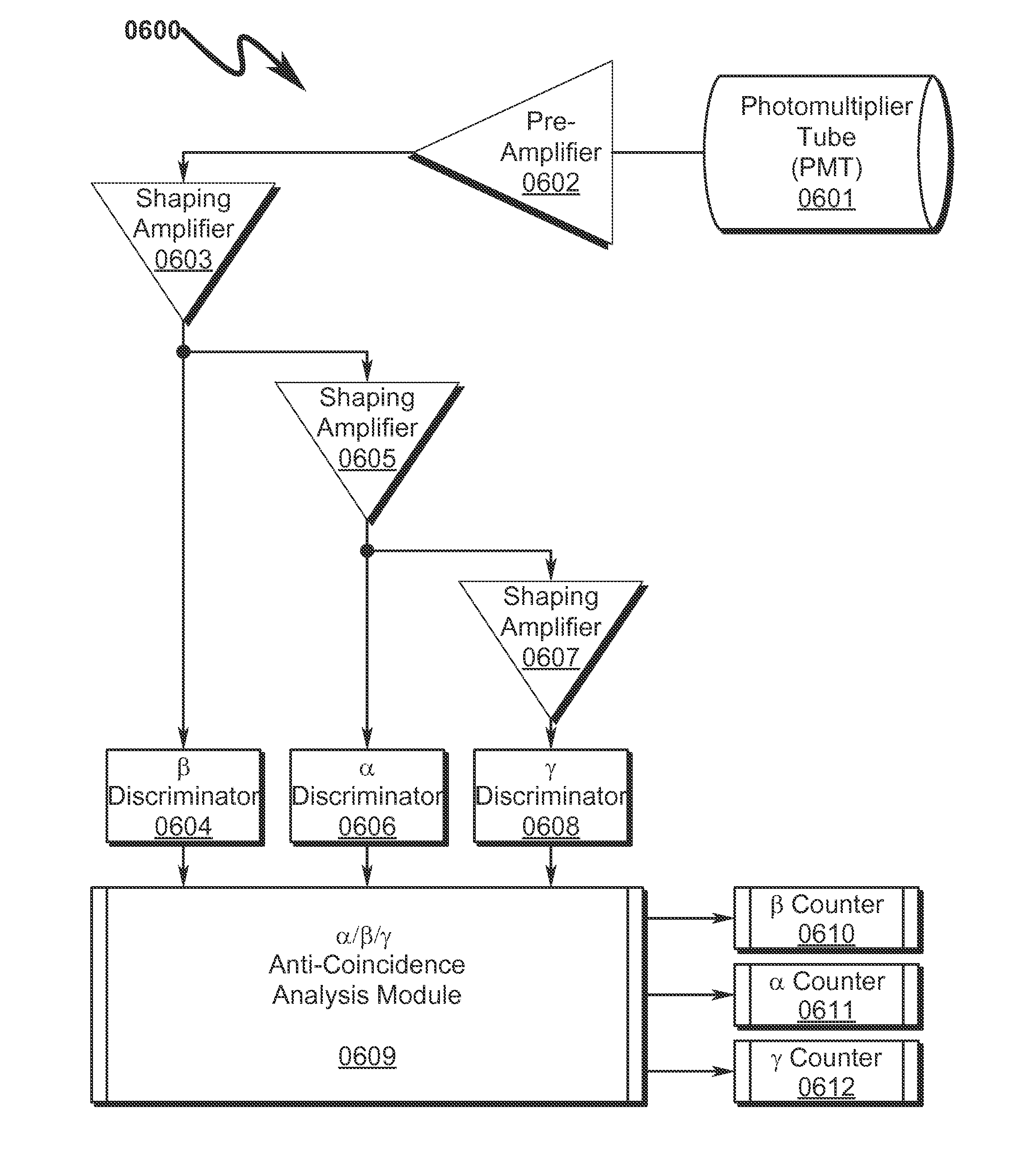

Radiation Detector System and Method

ActiveUS20130277565A1Increase beta sensitivityReduce gamma backgroundMaterial analysis by optical meansShieldingDiscriminatorWhole body

A radiation detector system / method that simultaneously detects alpha / beta, beta / gamma, or alpha / beta / gamma radiation, within an integrated detector is disclosed. The system incorporates a photomultiplier tube with radiation scintillation materials to detect alpha / beta / gamma radiation. The photomultiplier tube output is then shape amplified and fed through discriminators to detect the individual radiation types. The discriminator outputs are fed to anti-coincidence and pulse width and timing analysis module that determines whether individual alpha / beta / gamma pulses are valid and should be counted by corresponding alpha / beta / gamma pulse radiation counters. The system may include a radiation detection method to affect alpha / beta / gamma radiation detection in a variety of contexts. The system / method may be implemented in a variety of applications, including but not limited to whole body radiation contamination detectors, laundry radiation scanners, tool / article radiation detectors, and the like.

Owner:CANBERRA IND INC

Contraband detection system

A compact contraband detection system having a radiography device which pre-screens an article subject to inspection to locate regions of interest which may then be further interrogated with a pulsed radiation generator, such as a pulsed fast neutron generator. The pulsed radiation generator includes an integrated particle generator-accelerator having a charged particle generator connected to a compact linear accelerator which produces, injects, and accelerates a charged particle beam. A beam target is provided in the path of the accelerated beam to generate a pulse of interrogating radiation which is directed to the article for interrogation.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

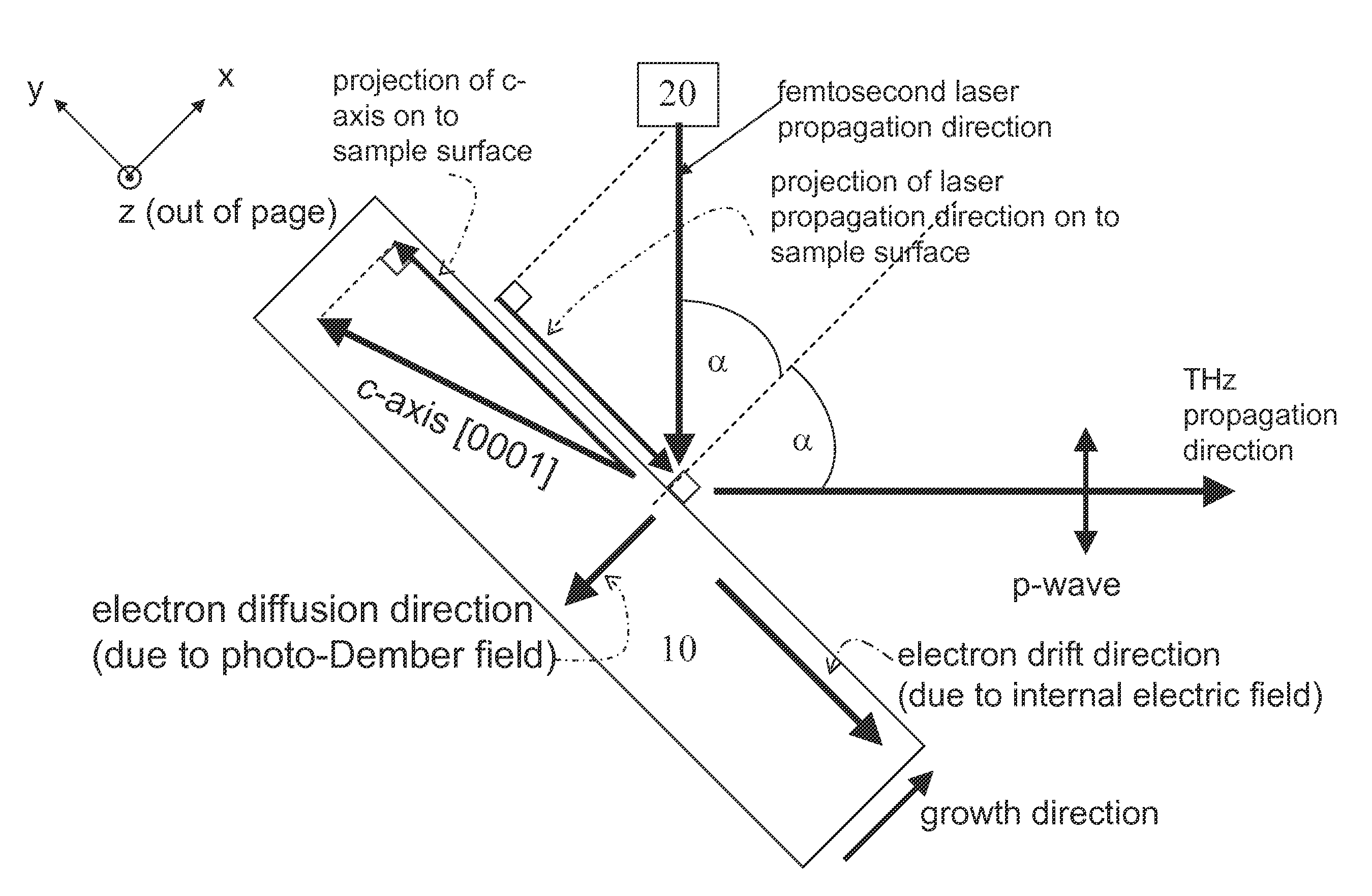

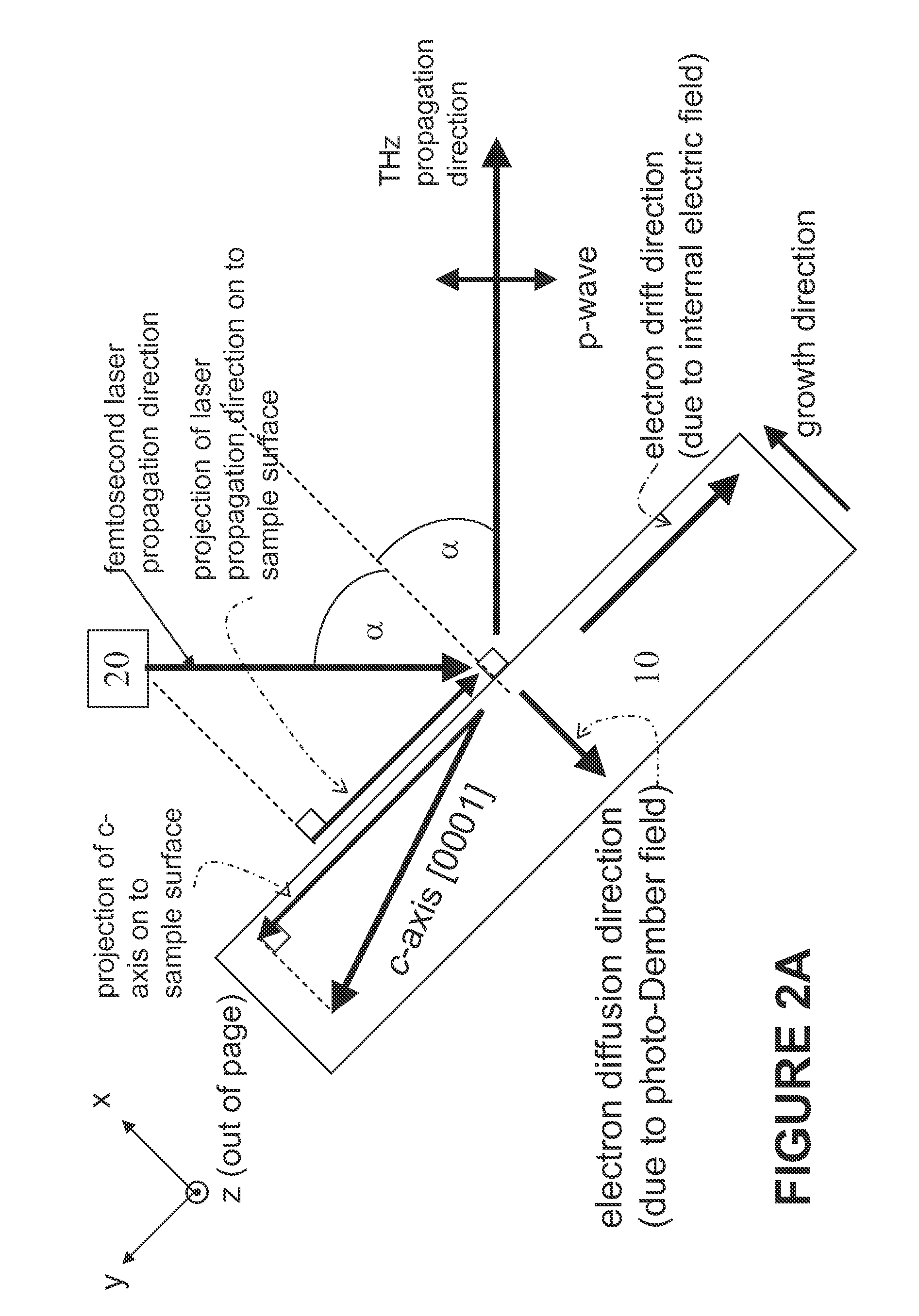

Method and Apparatus for Enhanced Terahertz Radiation from High Stacking Fault Density

ActiveUS20100006780A1Enhanced levelImprove efficiencyRadiation pyrometrySolid masersStacking faultTerahertz radiation

A method and device for generating terahertz radiation comprising a polar crystal material layer operative to emit terahertz radiation; the polar crystal material layer comprising a plurality of stacking faults; the stacking faults lying substantially perpendicular to the polar axis and forming boundaries at which the internal electric polarization terminates leading to charges accumulating at the boundaries, and creation of internal electric fields oriented along the polar axis; a pulsed radiation source for creating photogenerated carriers in the polar crystal material; whereby the photogenerated carriers accelerate in the internal electric fields associated with the termination of the internal electric polarization by the stacking faults to thereby generate terahertz radiation.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

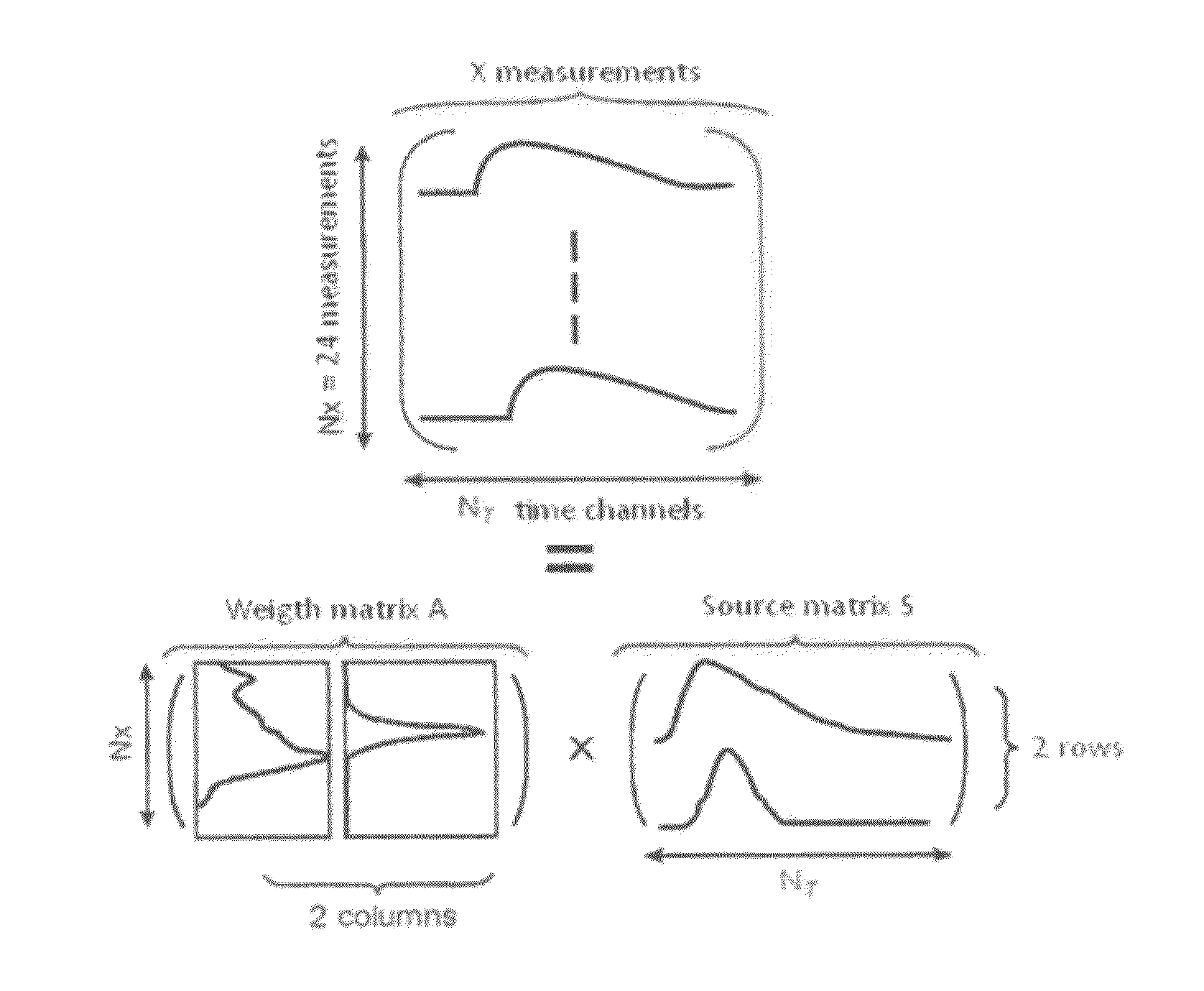

Method for locating an optical marker in a diffusing medium

A method for locating at least one optical marker in a diffusing medium, the marker having at least one optical property different from the diffusing medium, wherein: a) a pulsed radiation interacts with the medium and the at least one optical marker, producing an optical signal, and at least one acquisition of data of the optical signal is performed, each acquisition including one or more time components of interest, due to the at least one marker, and a spurious component, due to the medium other than the at least one marker, b) a multidimensional array X is formed from the optical signal data of the at least one of the acquisitions, c) the array X is processed by factorization into a product of only two non-negative multidimensional arrays A and S, and d) at least one of the time components is extracted from the arrays A and S.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

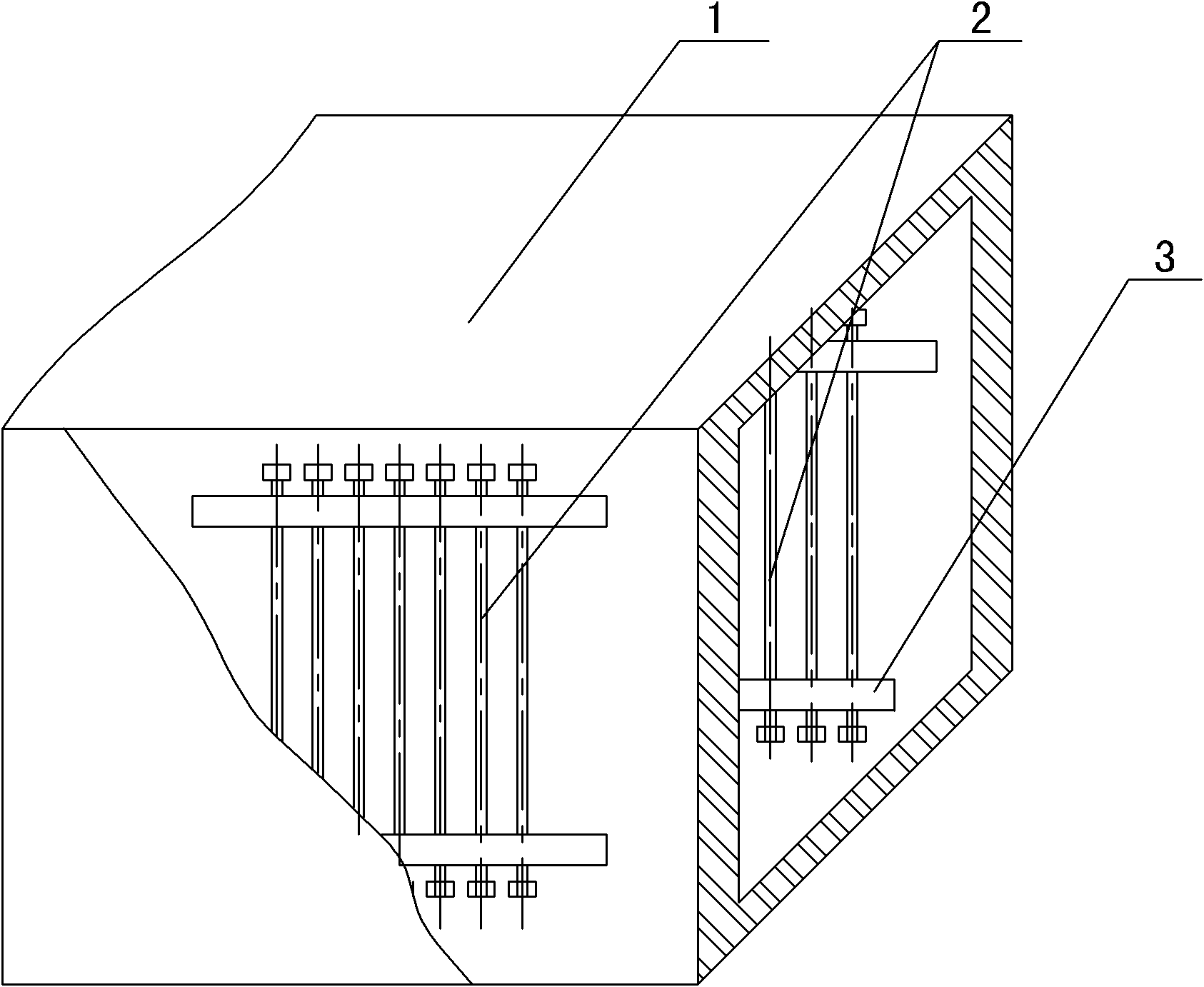

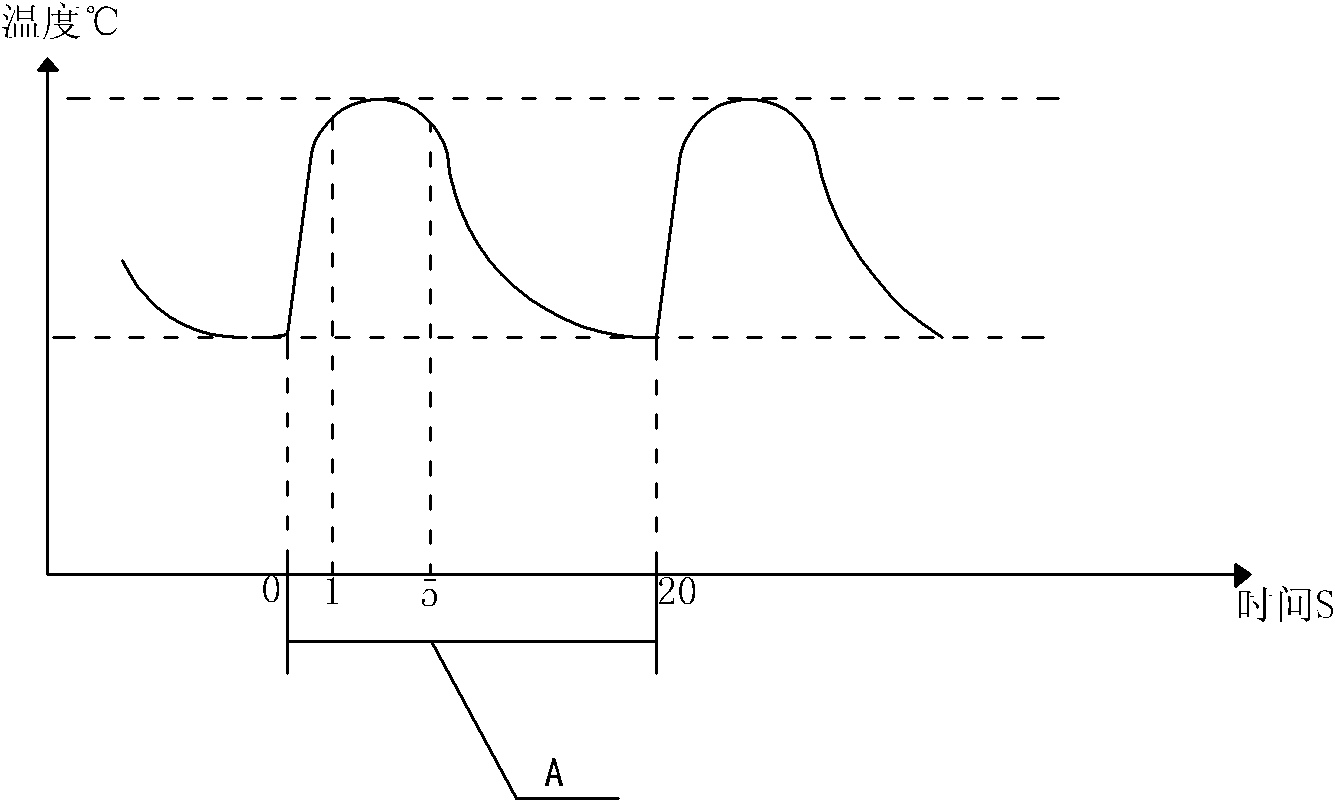

Infrared pulse radiation heating method for curing board surface powder and equipment for implementing method

InactiveCN102580902AAvoid heat damageShort curing timeDrying solid materials with heatPretreated surfacesPhysical chemistryMedium density fiberboard

The invention relates to an infrared pulse radiation heating method for curing board surface powder and equipment for implementing the method, which belong to the field of infrared technology application. The heating method uses the new concept of a medium-wave infrared pulse radiation heating unit, and pulsed high-temperature curing is performed for artificial MDF (medium density fiberboard) surface powder coatings by the aid of short-time pulsed high temperature, so that heat damage of a board surface is avoided. By the aid of a pulsed high-temperature curing accumulation effect, coated film curing time is greatly shortened, the heat absorption capacity of a board matrix is greatly decreased, and an MDF is ensured to be at the temperature lower than 100 DEG C during discharge. By the aid of the equipment for implementing the method, effective heating space and the length of a drying tunnel can be reduced, MDF surfaces in an automatic coating production line are ensured to be in the same heated state, coated films are uniformly cured, and an energy-saving effect is extremely remarkable.

Owner:SHANDONG LANGFARBE POWDER COATING TECH

Detecting photons in the presence of a pulsed radiation beam

InactiveUS8193508B2Reduces and avoids interferenceReduce sensitivityMaterial analysis using wave/particle radiationSurgeryPulse beamBeam source

A detector system adapted for monitoring a radiation treatment system comprising a pulsed beam radiation source for treating a body with a given beam intensity and beam configuration, with pulse times and intervals between pulses less than 100 milliseconds, using at least one monitoring radiation source located inside or outside the body, the detector system comprising; a) a detector designed to detect radiation from the monitoring source, and subject to interference radiation from the beam source; and b) control circuitry that creates a data record of radiation received by the detector, to provide information about the body; wherein, when the detector detects radiation in real time during operation of the beam, the data record selectively excludes data for radiation received by the detector during the pulses, as opposed to data for radiation received by the detector between pulses.

Owner:NAVOTEK MEDICAL

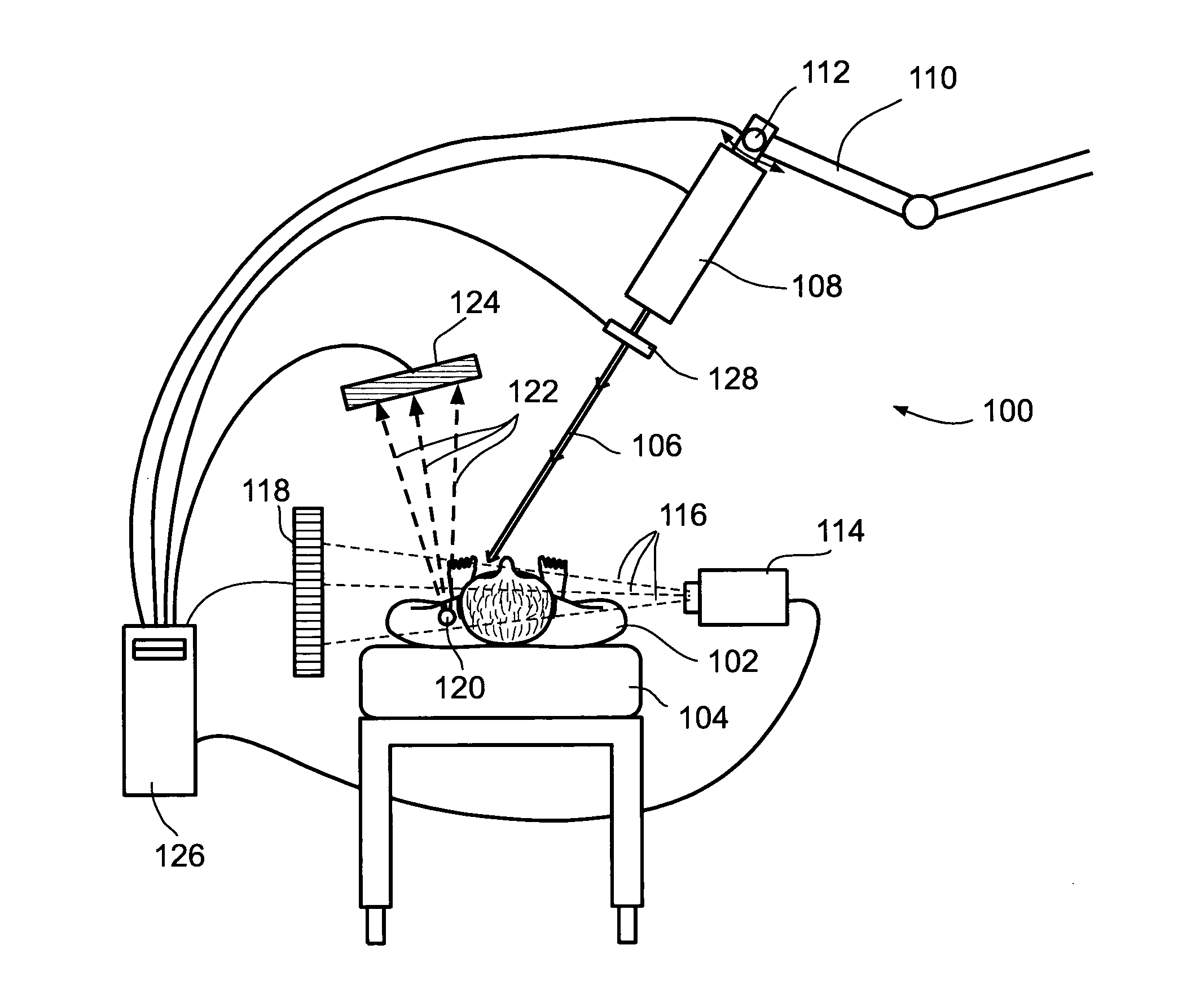

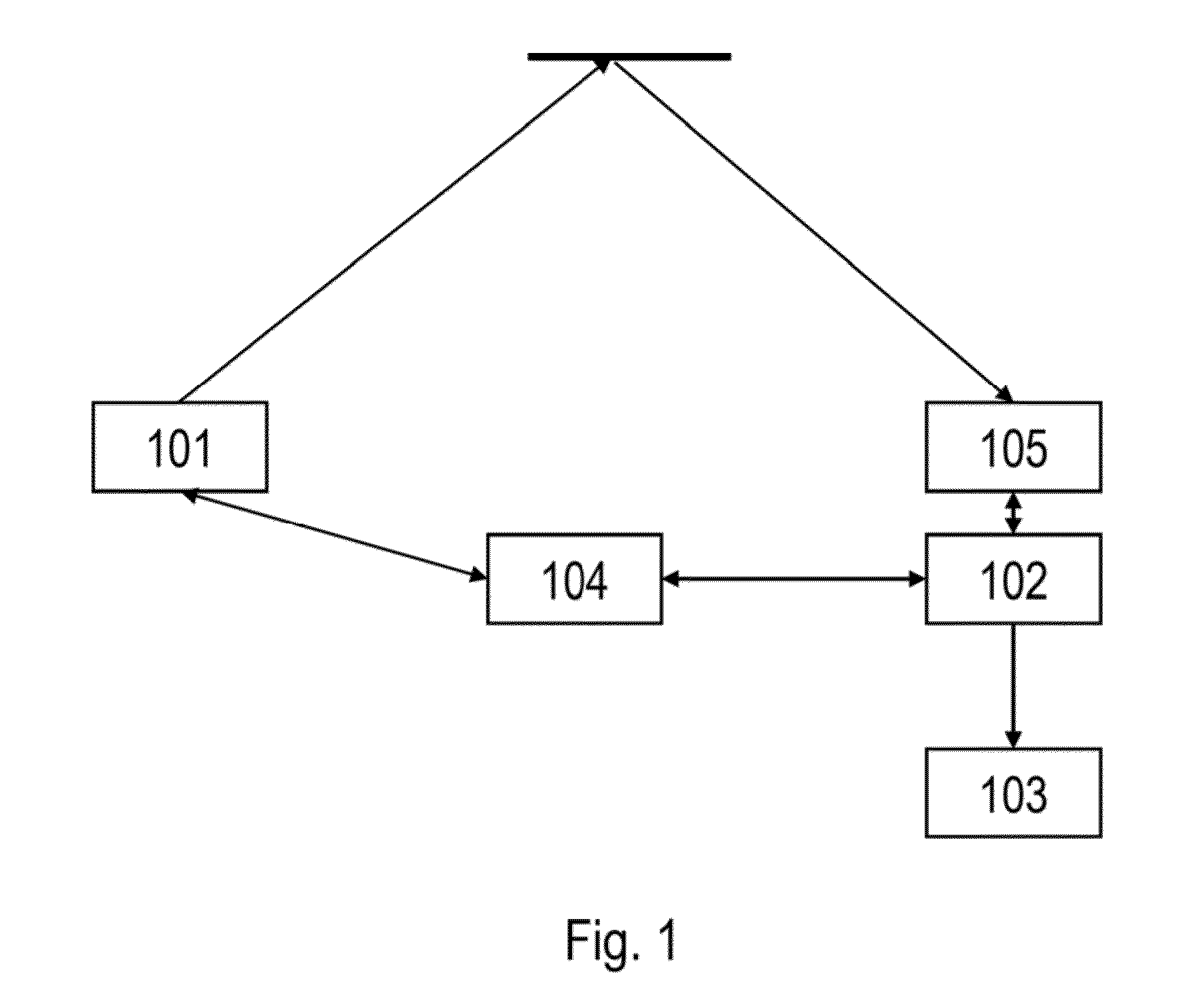

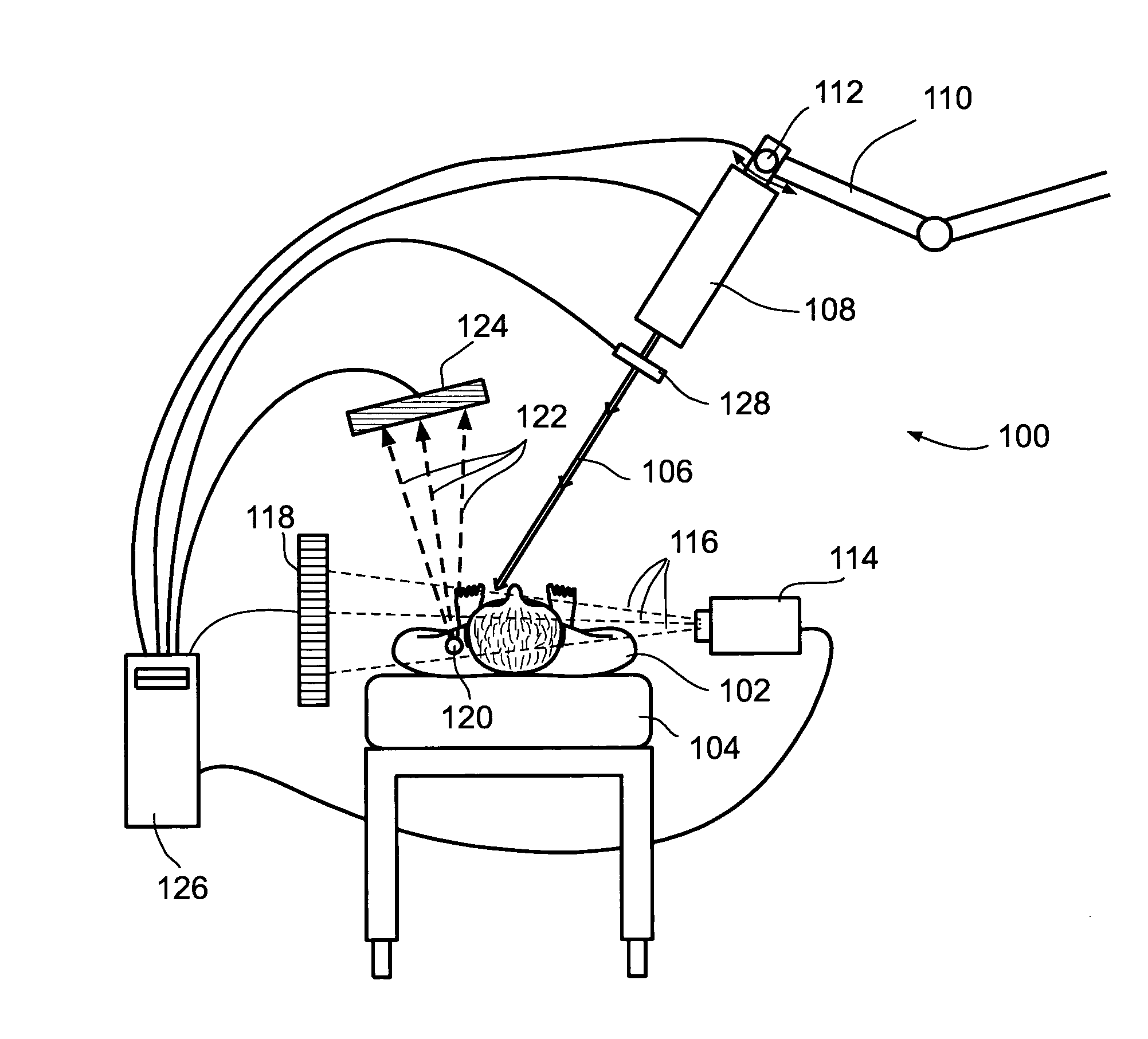

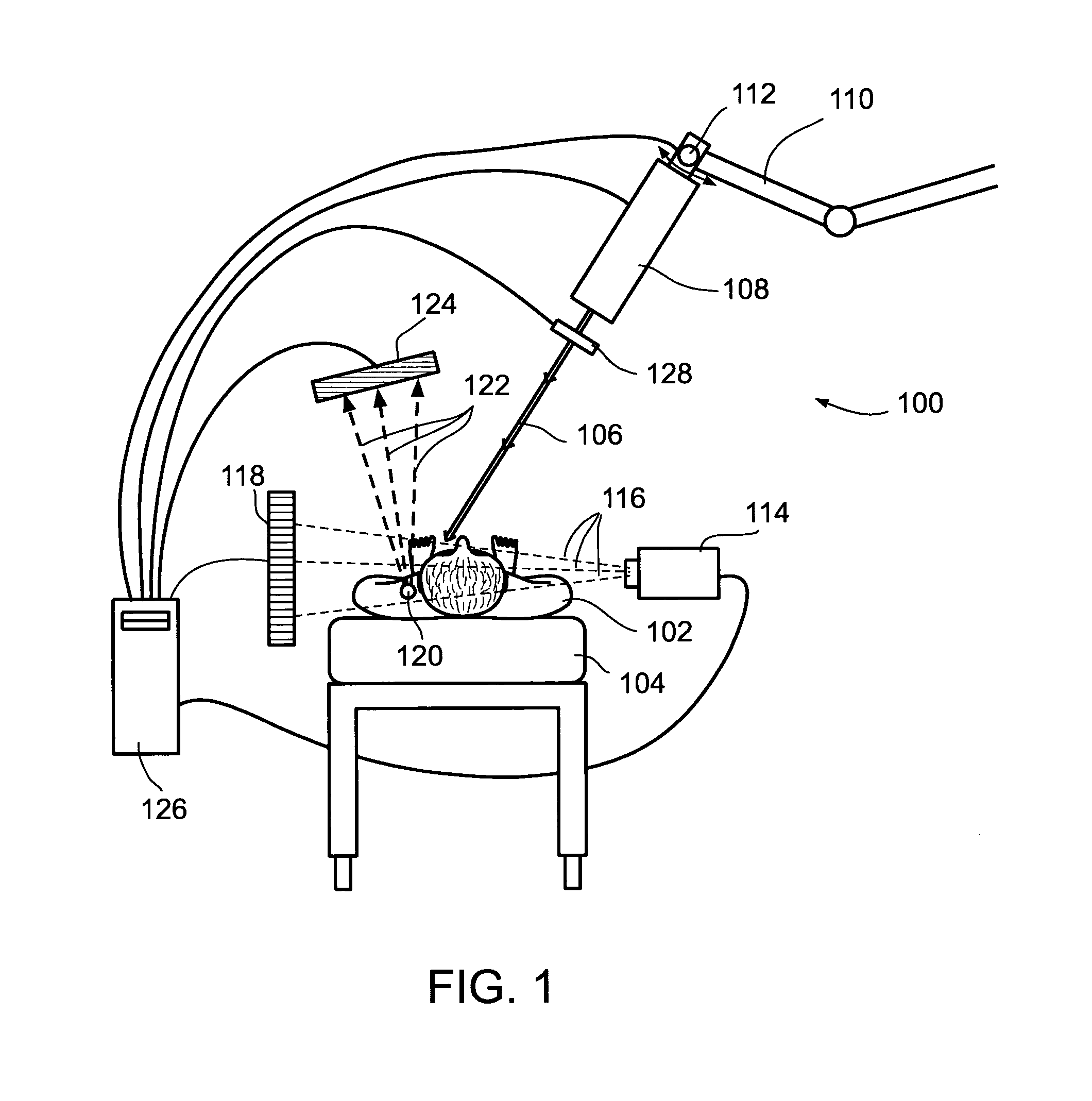

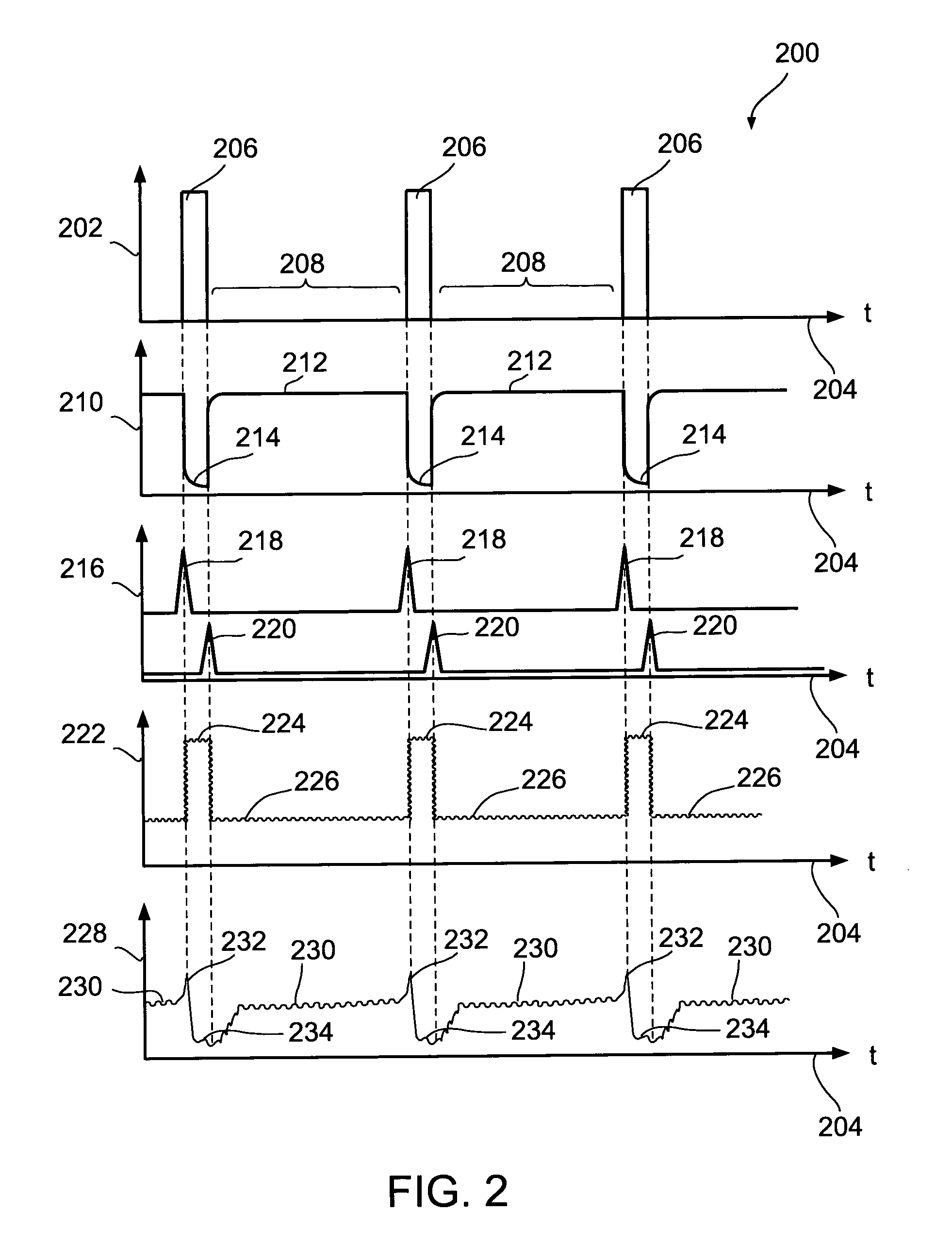

Device and method for high dose per pulse radiotherapy with real time imaging

ActiveUS10603514B2Effective treatmentOptimize treatment planLight therapyX/gamma/cosmic radiation measurmentRadiation pulseHigh doses

A radiotherapy system comprising at least one pulsed radiation source, at least one imaging system, a control system, and a synchronization system is disclosed. The pulsed radiation source deposits high dose radiation pulses to a target region inside the patient; simultaneously the imaging system is used to monitor the target region, synchronized by the synchronization system. The dose per radiation pulse is high enough to deposit, within few pulses, 1 Gy at a depth of at least 1 cm in water. At each irradiation time step, the pulsed radiation source delivers short pulses of radiation (<1 ms) and the imaging system performs a snapshot of the position, and eventually the shape, of the target region during the irradiation time, with a time resolution better than 200 ms. Being both the pulsed radiation source and imaging system synchronized by the synchronization system with less than 200 ms jitter, this system allows for very precise reconstruction of the map of the dose deposited into the target region.

Owner:FYZIKALNI USTAV AV CR V V I

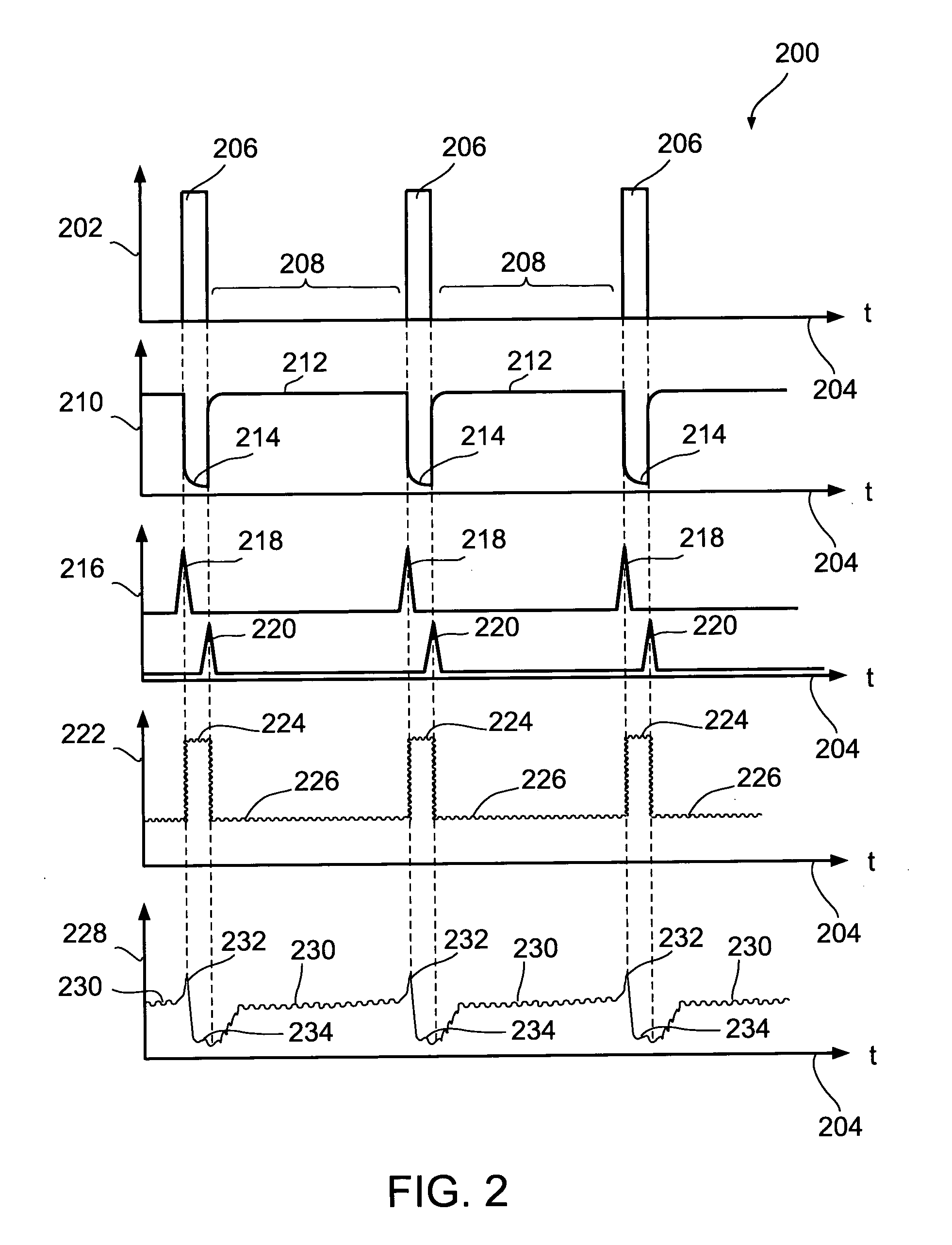

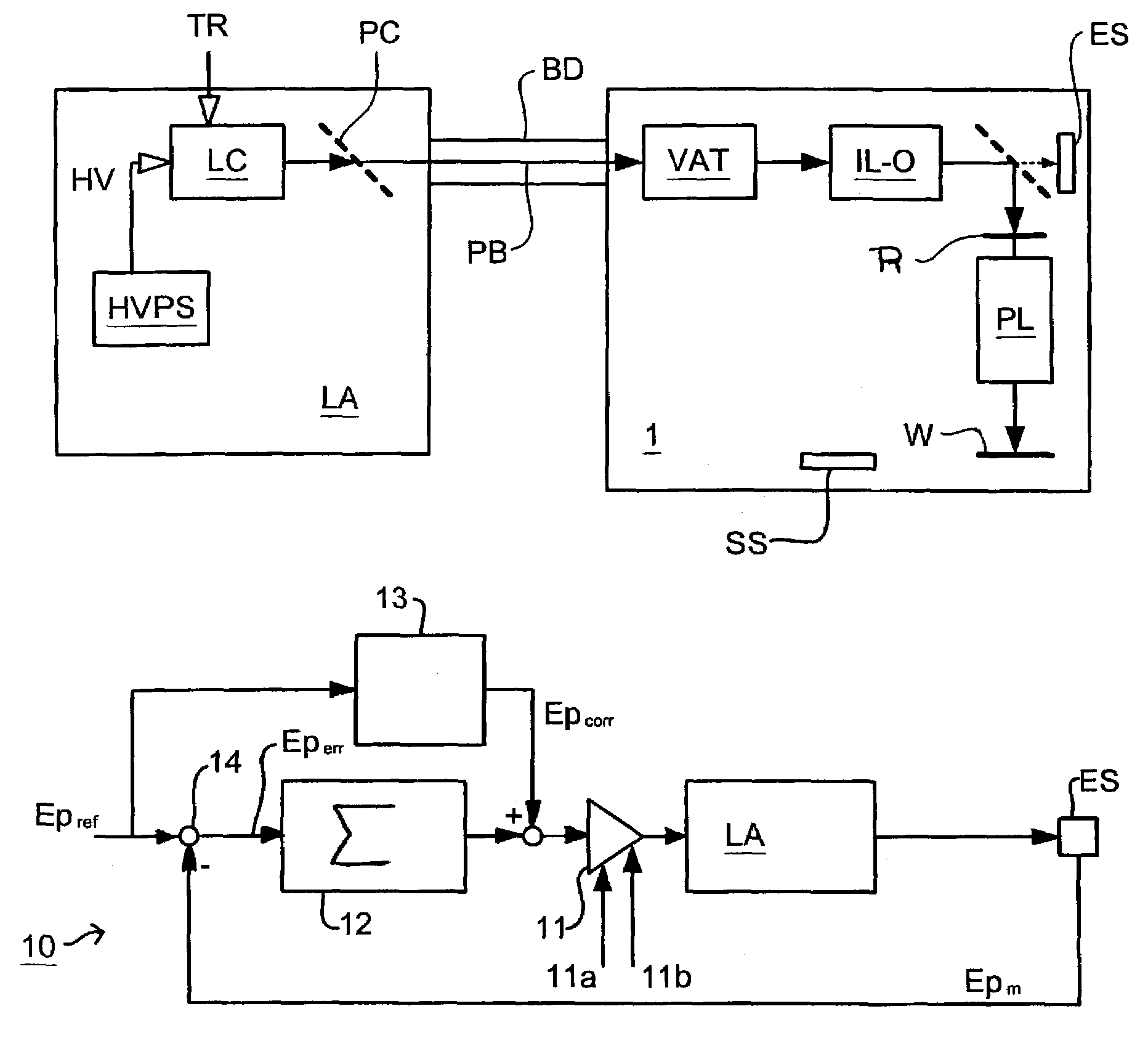

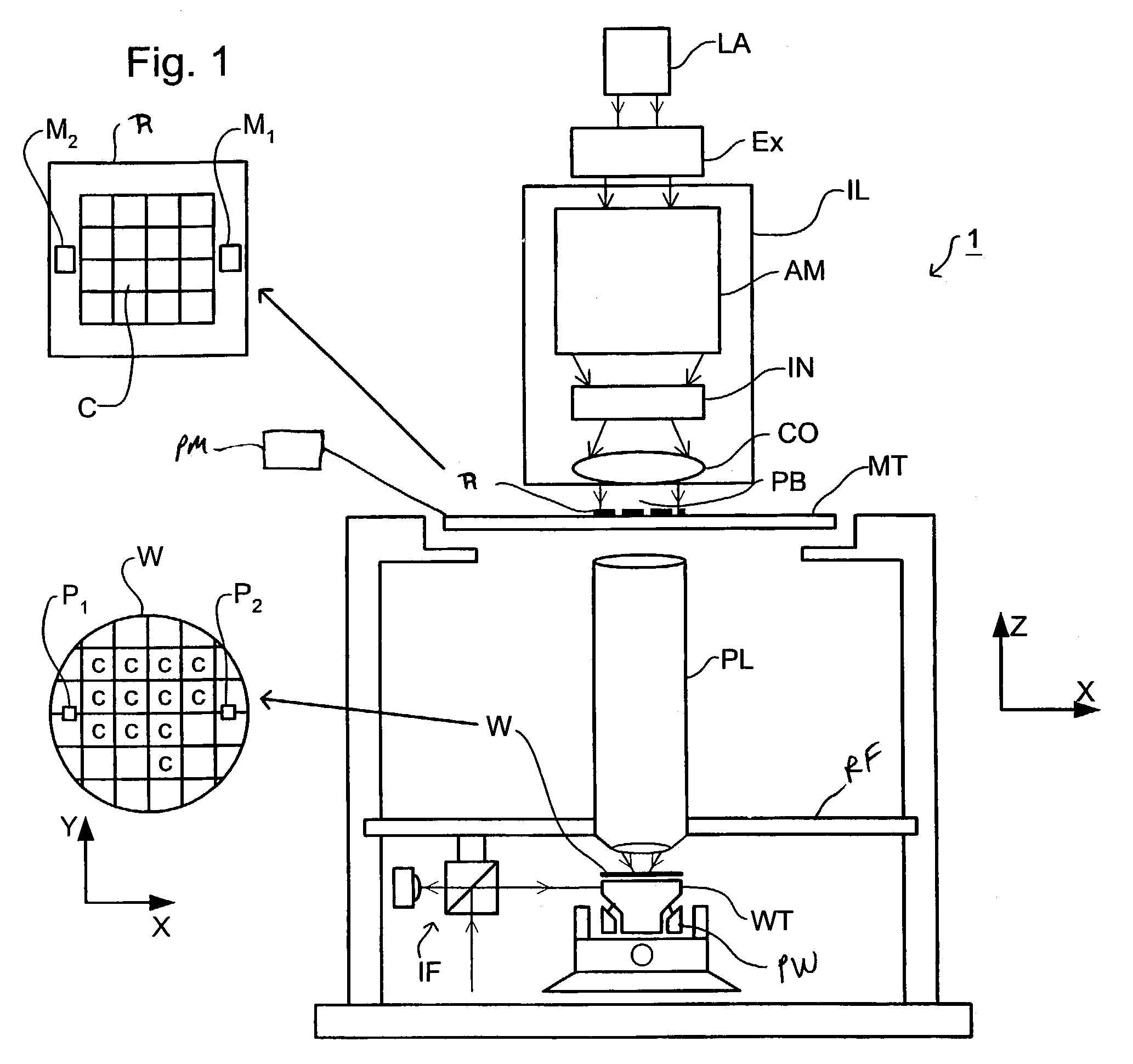

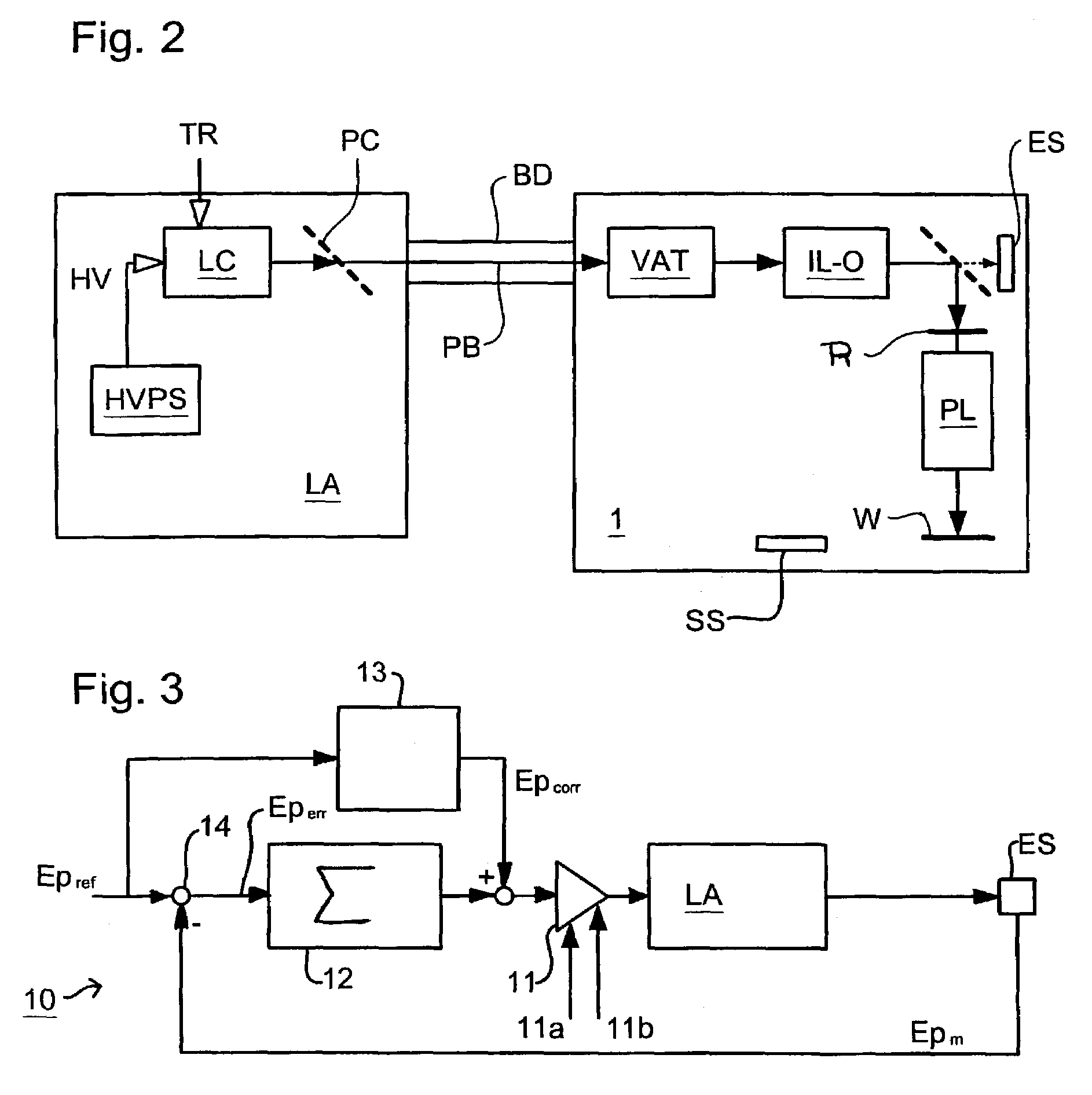

Lithographic apparatus, device manufacturing method, performance measuring method, calibration method and computer program

ActiveUS7057705B2Precise dose controlLaser detailsSemiconductor/solid-state device manufacturingMoving averageClosed loop

A controller for a pulsed radiation source is a closed-loop controller of minimum order, preferably first, to effect dead beat control. Performance indicators for a pulsed radiation source in a lithographic apparatus are based on moving averages (MA) and moving standard deviations (MSD) of the error between target and actual pulse energies. The normalized indicators are given by:MAE,n(xk)=1∑i=k-(Nslit-e-1)kEpref(i)·∑i=k-(Nslit-e-1)kEperr(i)(k=Nslit-e…Nscan),wherein Epref(i) and Eperr(i) indicate reference energy per pulse and energy error per pulse for point i andMSDE,n(xk)=1Nslit-e-1∑i=k-(Nslit-e-1)k[Eperr(i)Epref(i)-MAE,n(xk)]2(k=Nslit-e…Nscan).

Owner:ASML NETHERLANDS BV

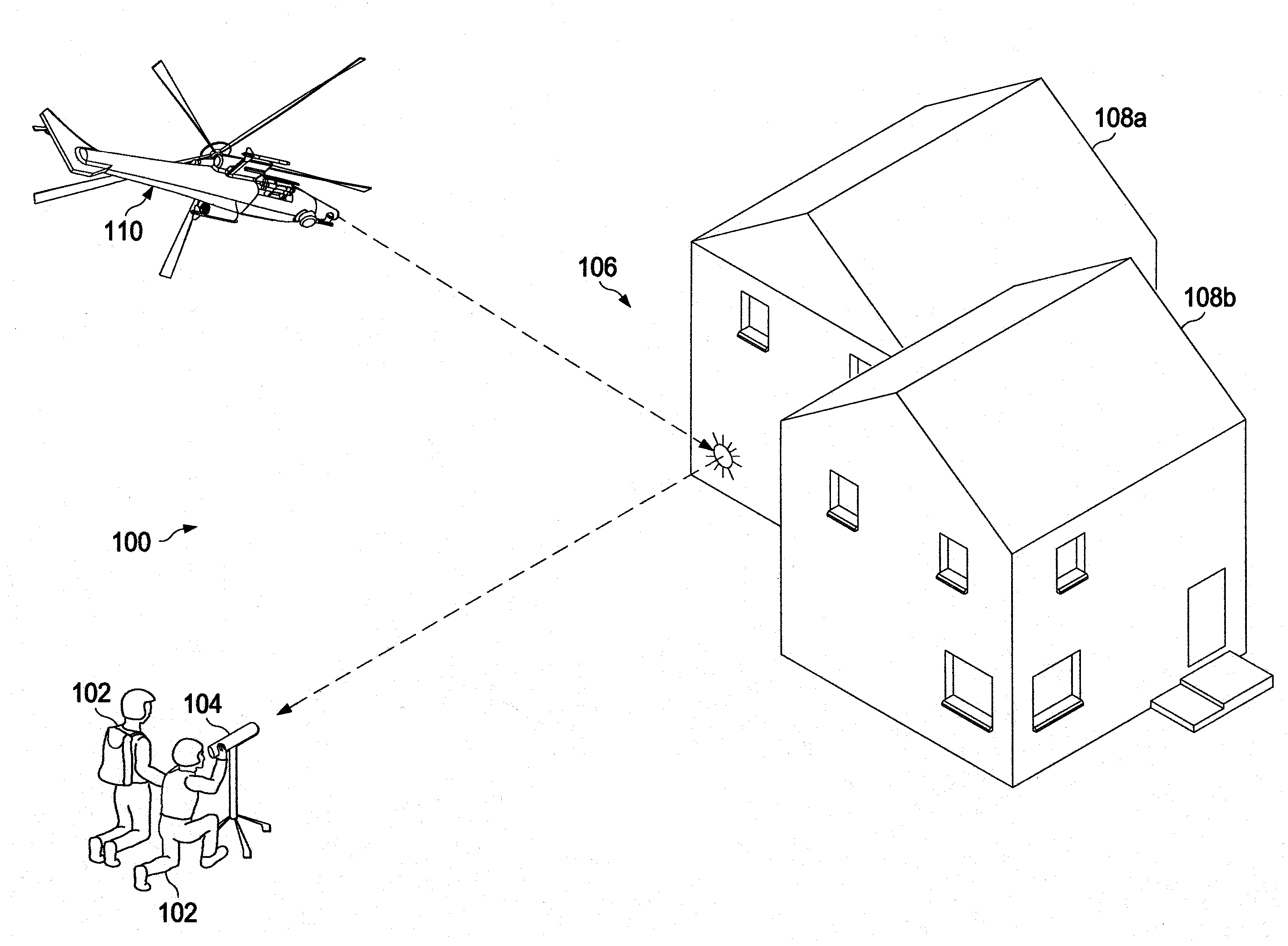

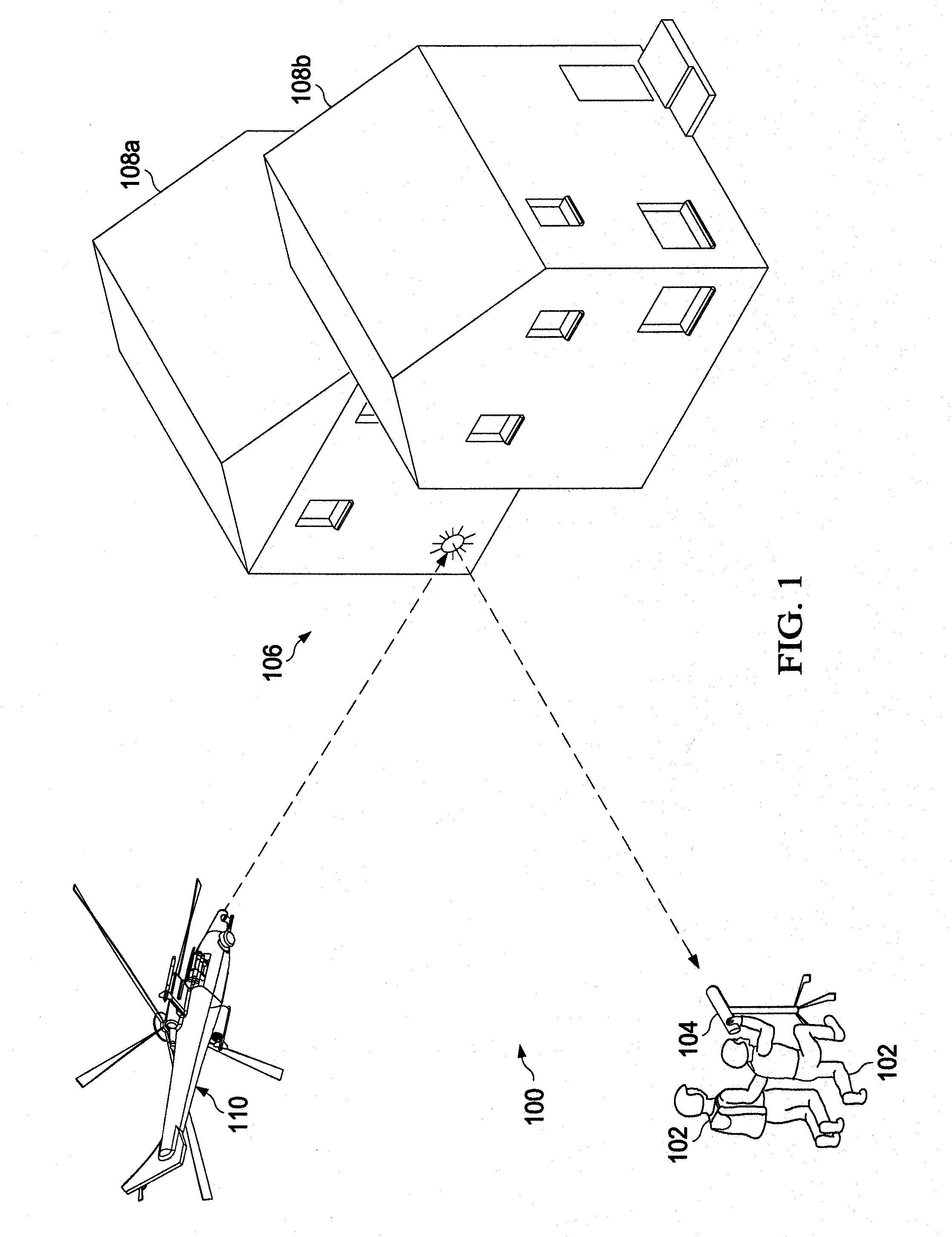

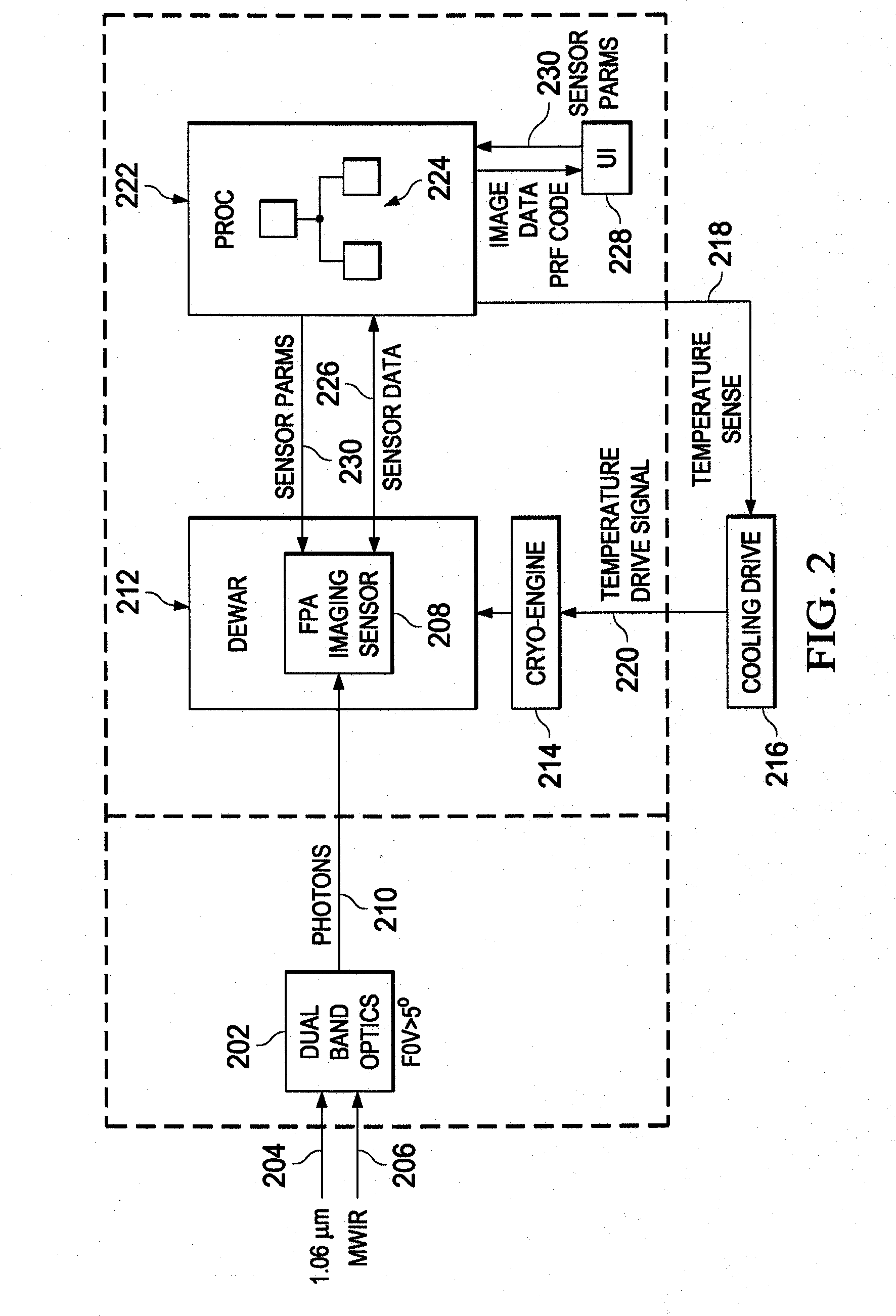

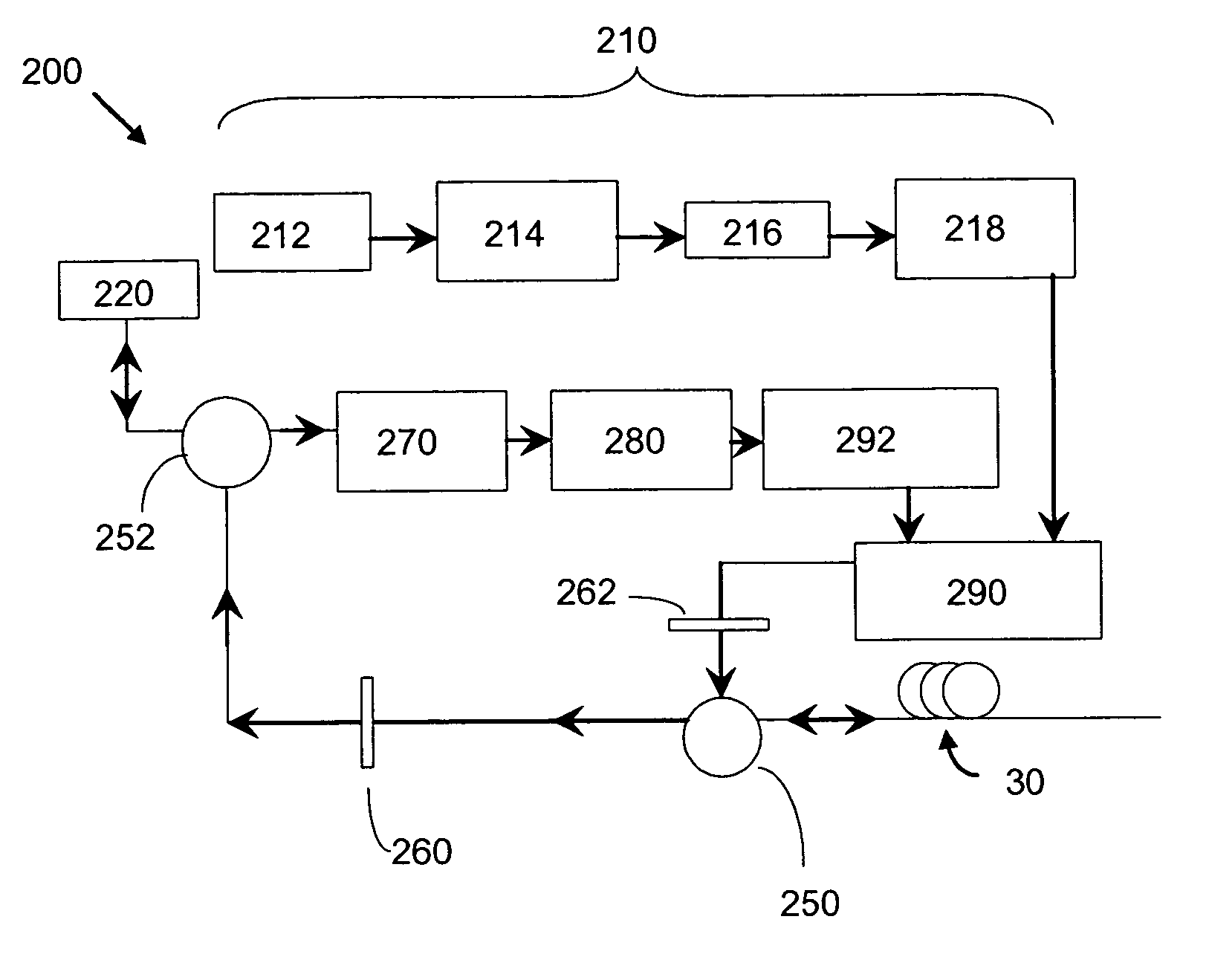

System and method for identifying non-cooperative pulsed radiation sources in a field-of-view of an imaging sensor

ActiveUS20120211665A1Expand field of viewConsumes less energyWave based measurement systemsDirection controllersField of viewImaging data

A system and method for identifying a pulsed radiation source may include an imaging sensor having a frame rate that is less than a pulse repetition frequency (PRF) of the pulsed radiation source. A processing unit may be in communication with the imaging sensor, and be configured to (i) process a sequence of image data of a scene captured by the imaging sensor to determine whether radiation of the pulsed radiation source is detected, (ii) determine a PRF code of the pulsed radiation source from possible multiple different PRF codes based on the processed sequence of image data, and (iii) notify a user of the PRF code or information associated with the PRF code.

Owner:DRS NETWORK & IMAGING SYST

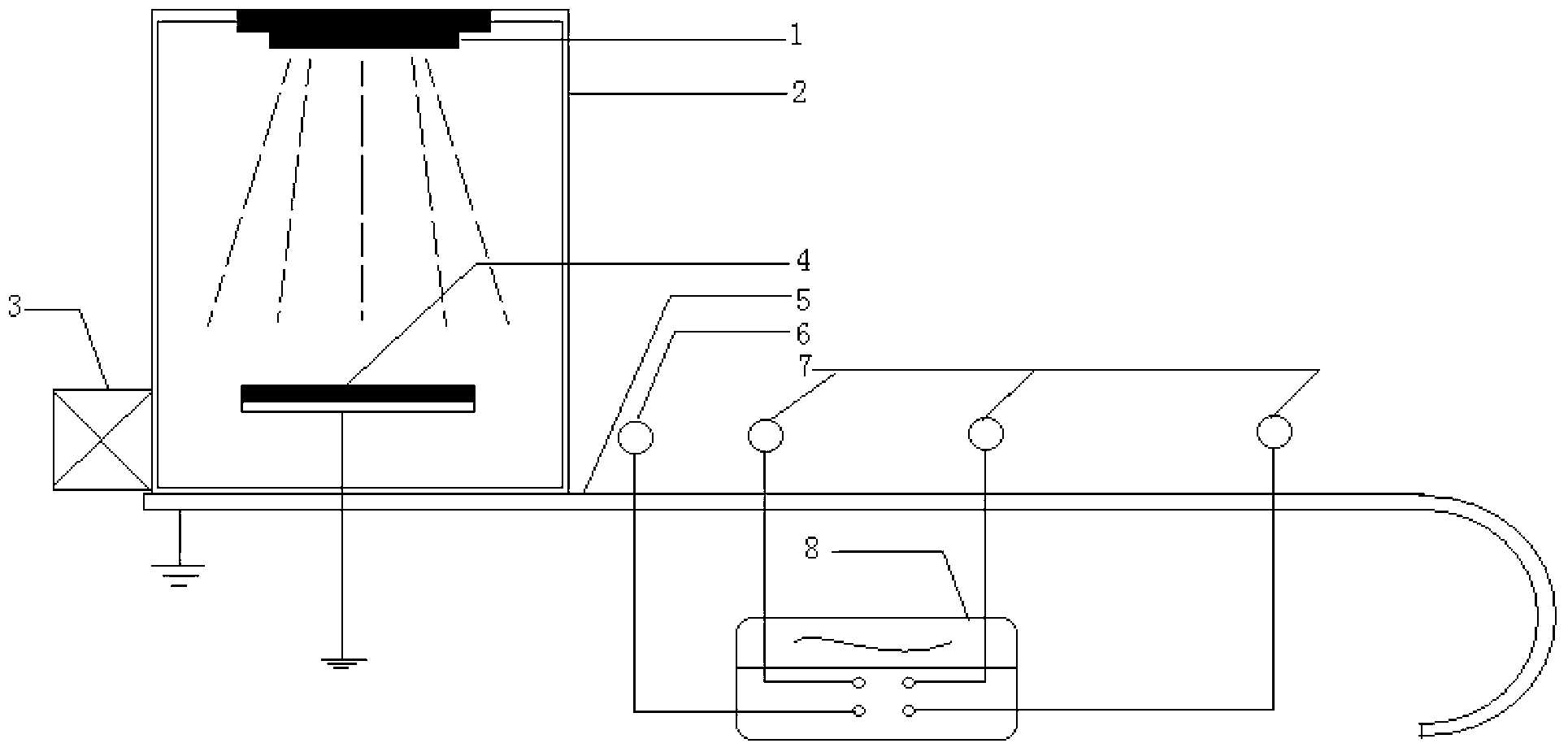

Device and method for measuring satellite material surface electrostatic discharge pulse characteristics

InactiveCN103267903AEliminate Boundary Reflection IssuesAvoid interferenceElectromagentic field characteristicsElectrostatic field measurementsMeasurement devicePulse characteristics

The invention relates to a device and a method for measuring satellite material surface electrostatic discharge pulse characteristics in the space plasma environment, and belongs to the field of measurement. The device comprises an electronic gun, a vacuum chamber, a vacuum pumping system, a grounded metal board, a reference pulse signal receiving antenna, arrayed pulse signal receiving antennas and a spectrometer. The method comprises the steps of placing satellite surface material samples into the vacuum chamber, start the vacuum pumping system, starting the electronic gun, regulating acceleration voltage and filament current of the electronic gun, conducting real-time monitoring on beams of the electronic gun by means of a Faraday cup, starting the spectrometer, respectively measuring frequency domains of discharge signals of the pulse signal receiving antennas of different positions, and conducting real-time monitoring on space distribution of discharge pulse radiation electromagnetic fields in an experiment process. An arc structure at the tail end of the grounded metal board resolves the problem of edge reflection of the radiation fields, and measurement of the space distribution of the radiation fields is conducted through the antennas.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Method and device for cutting wafers

ActiveUS20160315010A1Improve productivitySemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesPulse radiationRadiation beam

A method is described of radiatively cutting a wafer, the method comprising the steps of low power cutting of two trenches followed by high power cutting of a fissure. A single pulsed radiation beam is split into a first pulsed radiation beam for cutting at least one of the trenches and a second pulsed radiation beam for cutting the fissure. When cutting a fissure on the wafer in a cutting direction along a cutting street, the first and second radiation beams are directed simultaneously with the first radiation beam leading and the second radiation beam trailing. For cutting a fissure in the opposite cutting direction, a third pulsed radiation beam for trenching is split from said single pulsed radiation beam.

Owner:ASMPT SINGAPORE PTE LTD

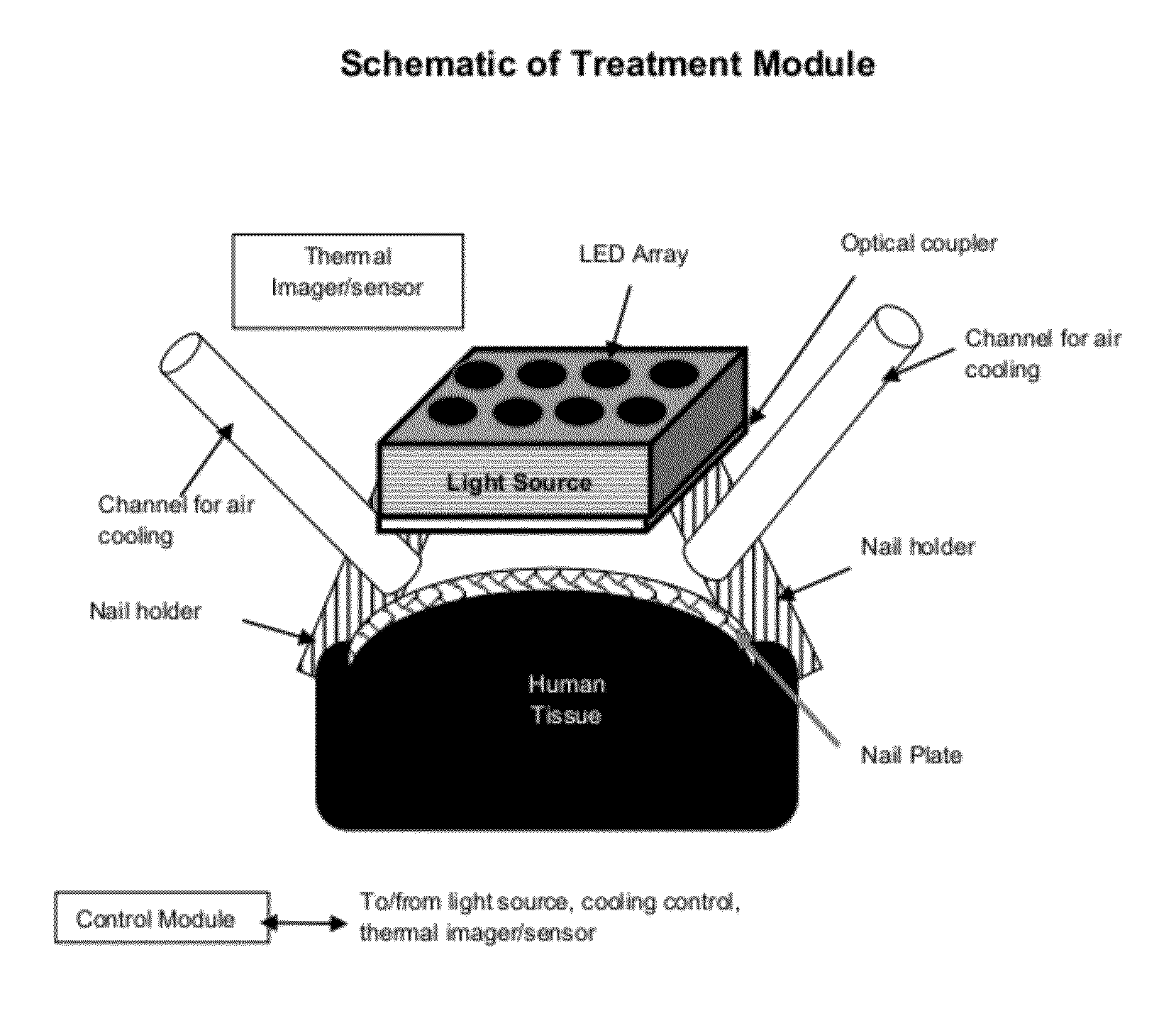

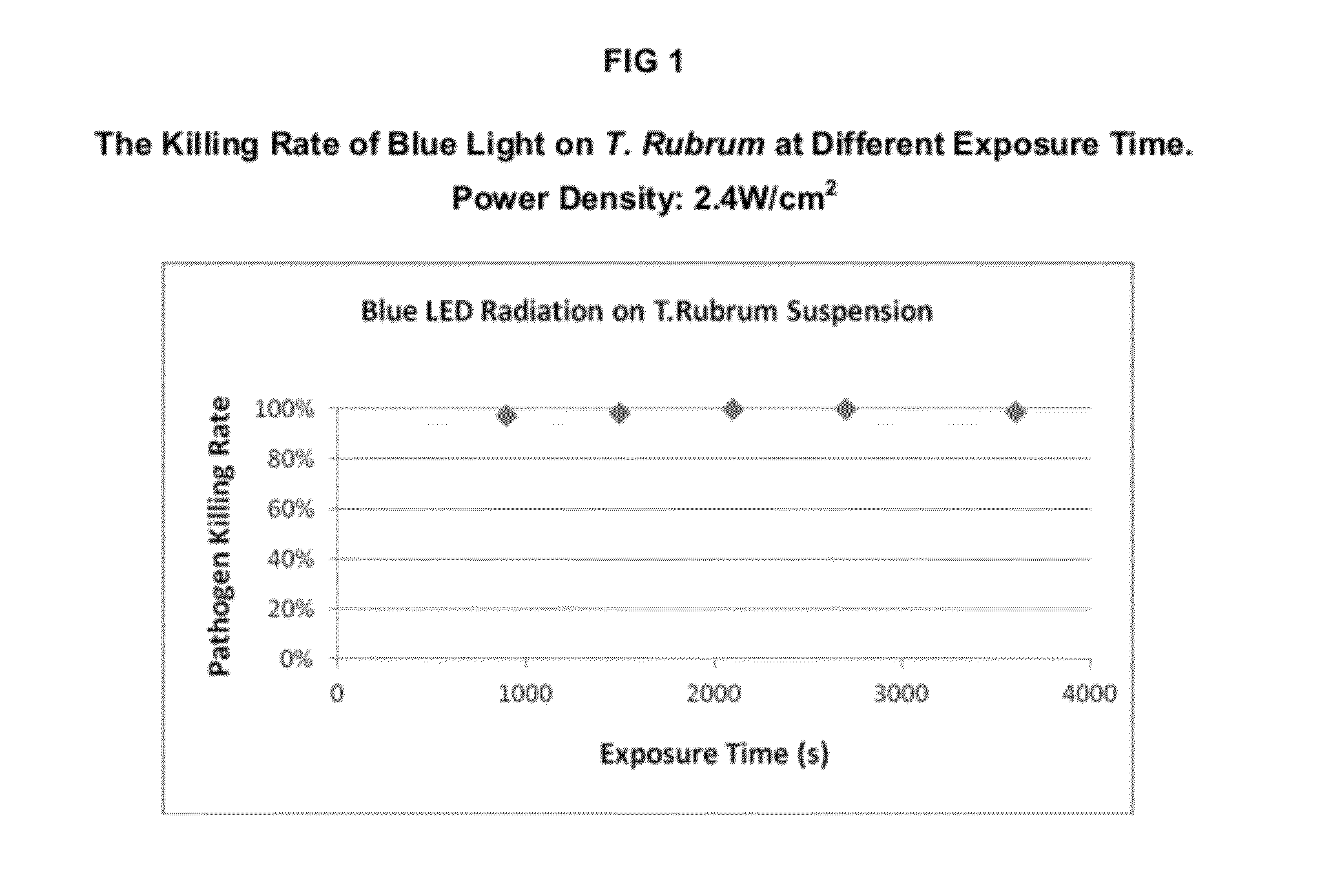

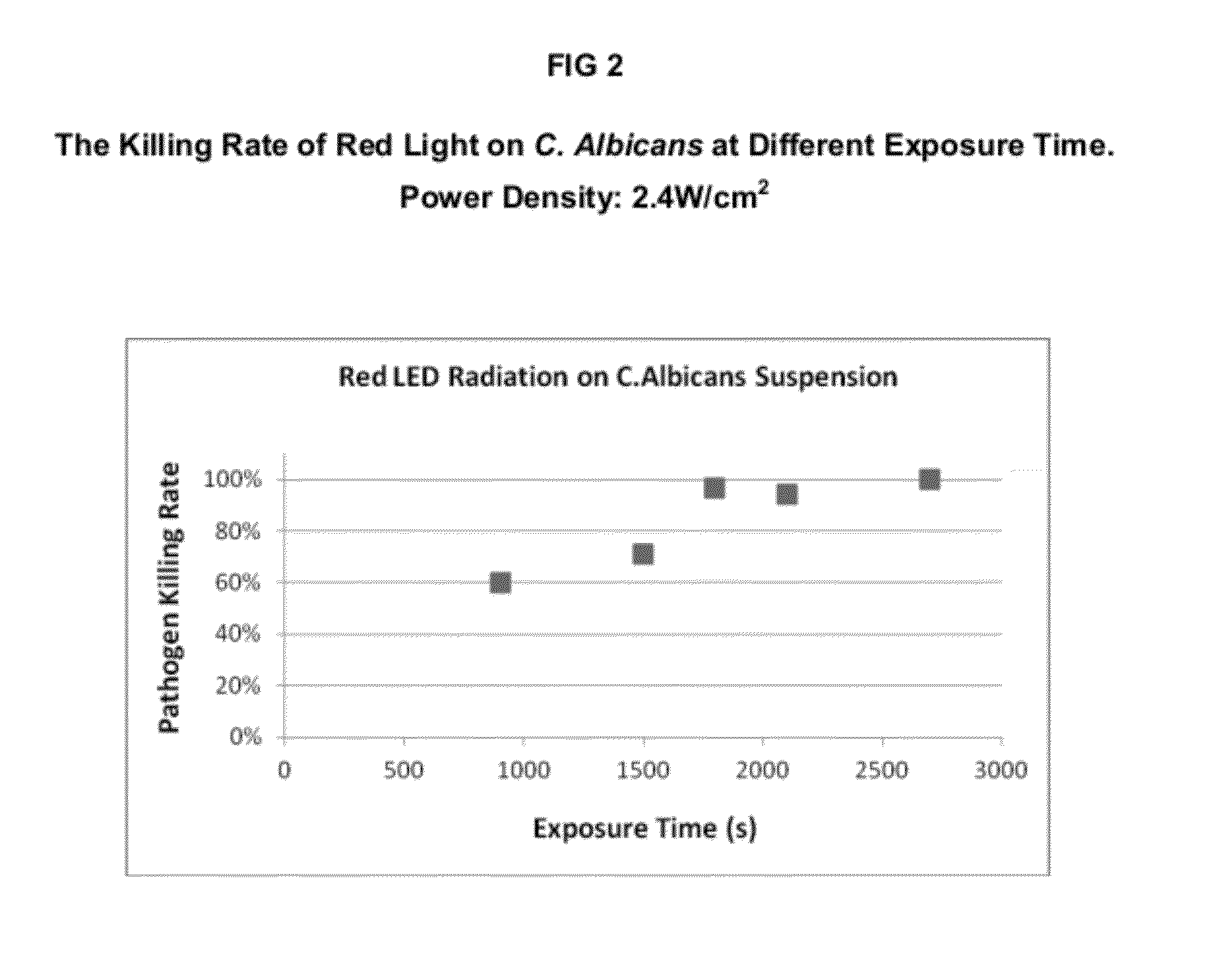

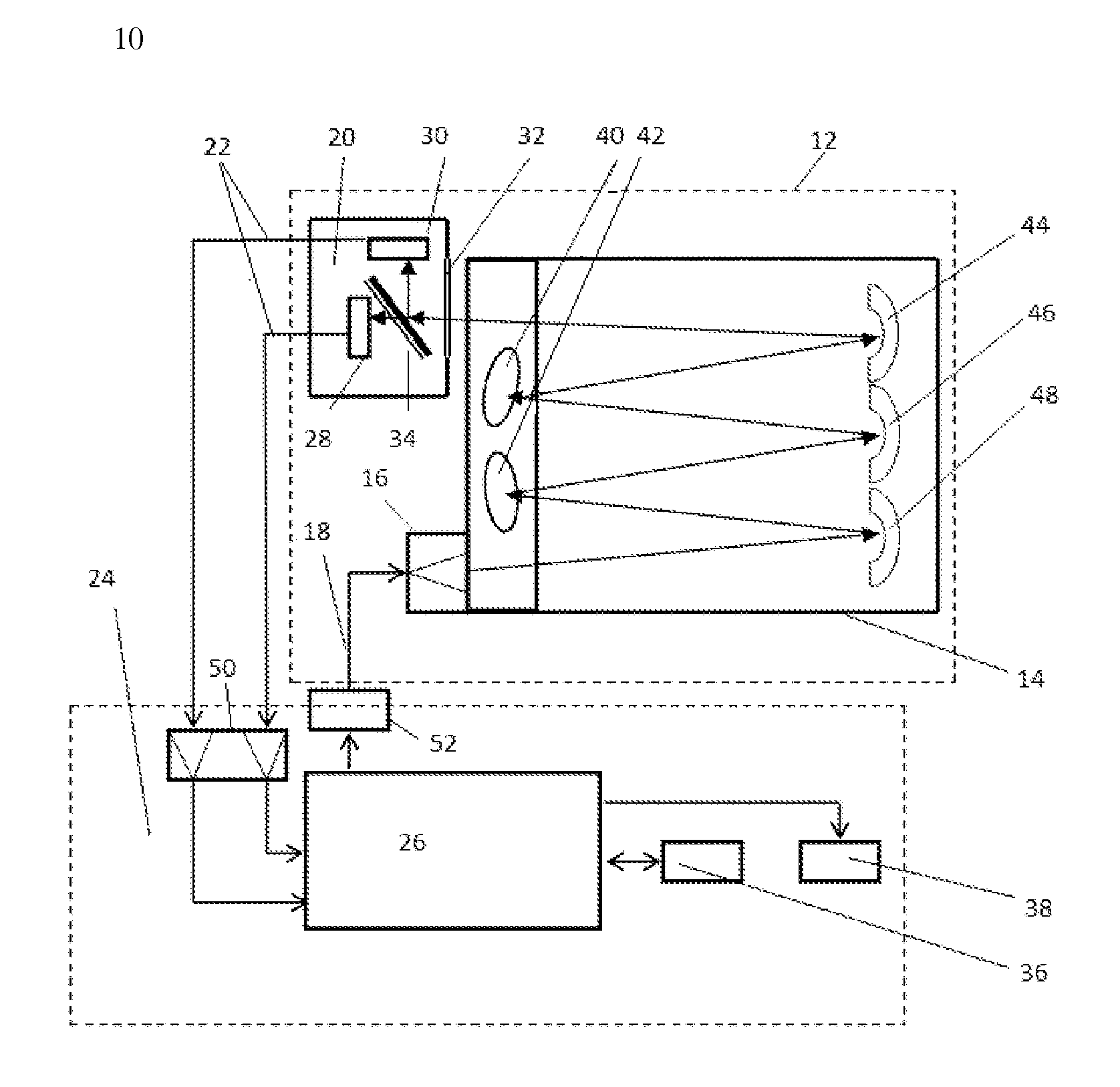

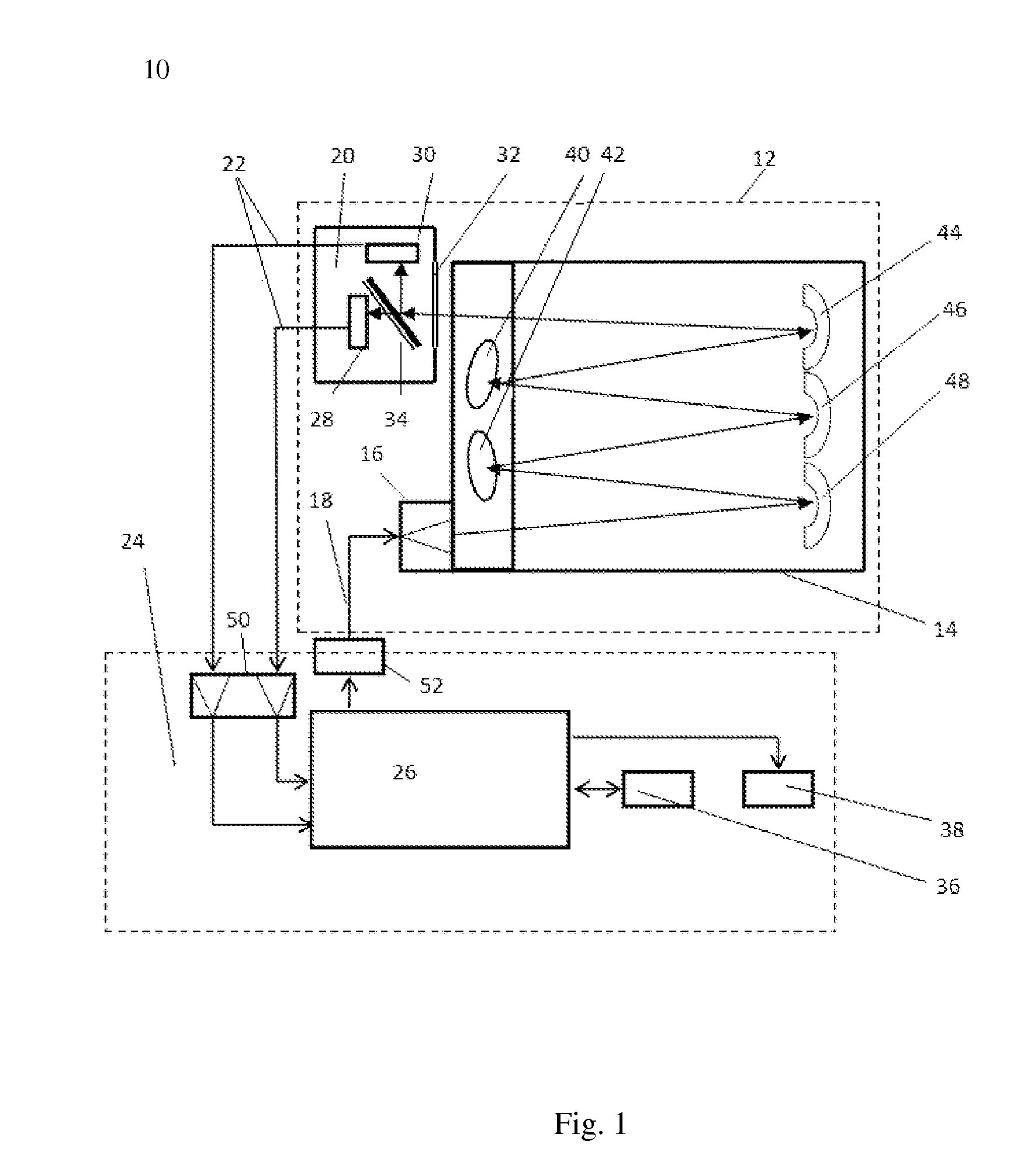

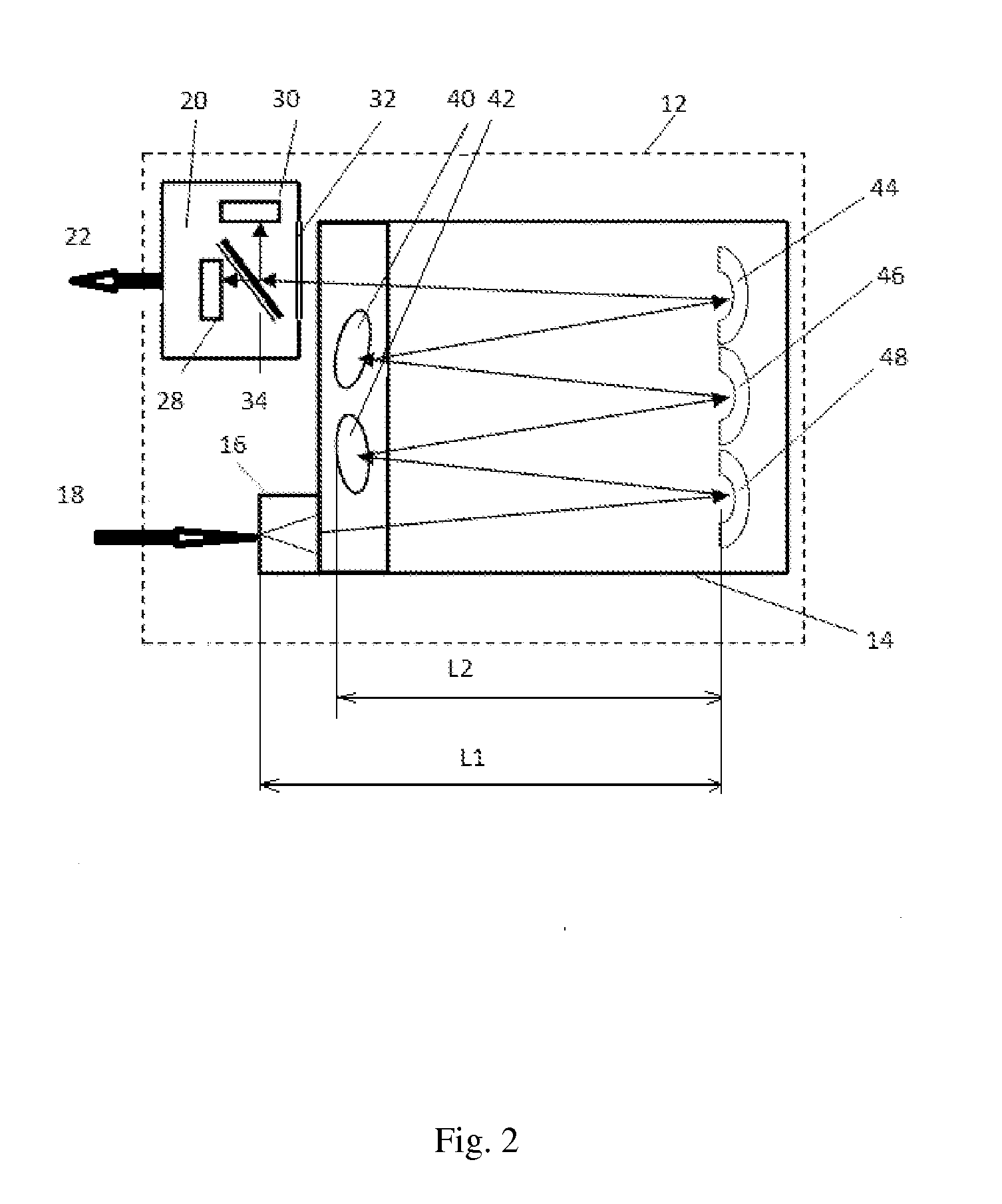

Treatment of fungal infection by light irradiation

Described herein are the systems and methods of treating diseases related to fungal infection with light therapy. In one embodiment, an apparatus that utilizes one or multiple light emitting diodes (LED) to treat the fungus is applied externally to the infection area. Light therapy may applied periodically at scheduled times with continuous or pulsed radiation.

Owner:ZHOU BO

Optical Gas Analyzer

ActiveUS20150241339A1Improve detectabilityRapid responseRadiation pyrometryColor/spectral properties measurementsSpectral transmissionOpto electronic

An optical gas analyzer, preferably for hydrocarbons, comprises an optical gas cell, an infrared LED pulse radiation source and a radiation detector at the inlet and outlet of the cell, respectively, and a control unit. The detector comprises measuring and reference photovoltaic detectors, a filter window at the detector inlet, and a filter mirror inside the same. Resulting spectral transmission and reflection characteristics of the filter window and filter mirror match the absorption spectrum for the gas and the radiation spectrum of the source. The filter window and filter mirror compensate external influence upon the radiation path trajectory within the cell on the gas concentration result.The cell comprises spherical or parabolic and flat mirrors arranged in a checker order to transmit the beam of the source via a zigzag-like trajectory between the mirrors.The analyzer offers a fast response and high sensitivity along with minimized power consumption and dimensions.

Owner:MAKSYUTENKO MICHAIL A +3

Method of evaluating fiber pmd using potdr trace

InactiveUS20070046928A1Reflectometers dealing with polarizationMaterial analysis by optical meansFiberTime-domain reflectometer

A method for screening fiber polarization mode dispersion using a polarization optical time domain reflectometer is disclosed. A pulse radiation is emitted into an end of the fiber under test, and the backscattered radiation is measured by the POTDR and used to obtain an OTDR trace. A pulse radiation is emitted into an opposite end of the fiber under test, and the backscattered radiation is measured by the POTDR and used to obtain another OTDR trace. Either one or both traces are analyzed to compare the variation of intensity of signals along the length of the fiber, the variation in signals relating to the PMD along the length of the fiber.

Owner:CORNING INC

Laser working method and method for producing ink jet recording head

InactiveUS6760973B1Simplify work stepsHigh precisionWriting implementsPhotographic printingHigh energyPicosecond

A laser working method, for conducting laser ablation working on a workpiece by irradiating the workpiece with a laser beam, includes the following steps. In working by projecting a mask pattern with the laser beam, a laser beam of plural pulses having a very high energy density in space and time, emitted from a laser oscillator that can oscillate with a pulse radiation time of 1 picosecond or less, is employed. Scanning illumination is conducted by relative movement of a source of the laser beam and the mask pattern. The relative movement between the source of the laser beam and the mask pattern may be conducted by a reciprocating movement in a direction perpendicular to an optical axis of the laser beam, asynchronously with laser oscillation, and a form of the mask pattern may be formed stepwise and in succession on the workpiece.

Owner:CANON KK

Intrusion Detecting System With Polarization Dependent Sensing Elements

A detection system includes a length of optical fiber and an OTDR coupled to the optical fiber. The OTDR includes a radiation source providing pulsed radiation to the fiber, a detector detecting radiation that is backscattered through the fiber, and a processor capable of analyzing the variation of the radiation that is backscattered through the fiber. At least two polarization dependent sensing elements are positioned along the length of optical fiber.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com