Infrared pulse radiation heating method for curing board surface powder and equipment for implementing method

A heating method and infrared irradiation technology, which is applied in the field of infrared technology application, can solve the problems of large heating area space, reducing energy saving effect, etc., and achieve the effects of reducing heat absorption, avoiding heat damage, and shortening curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

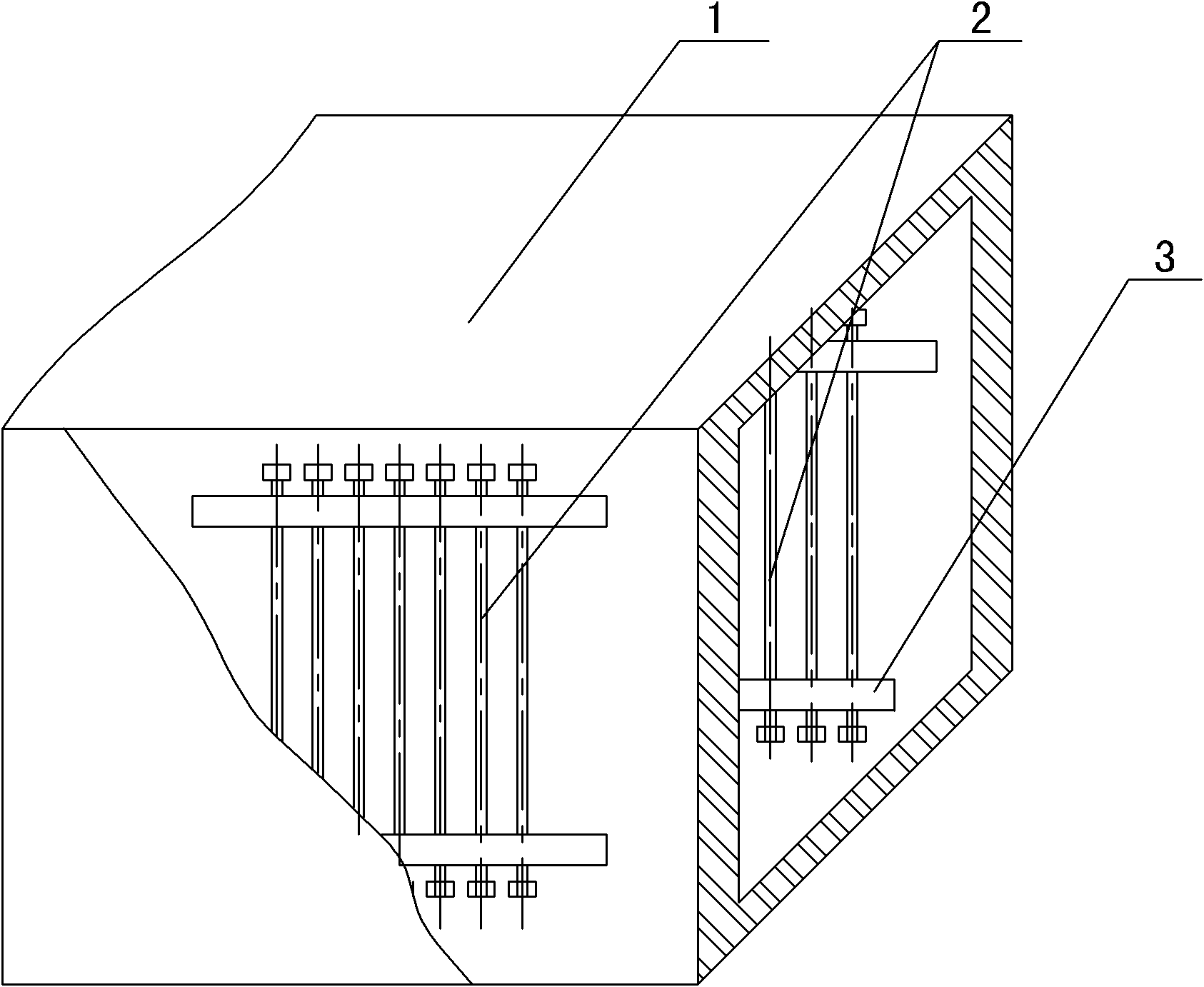

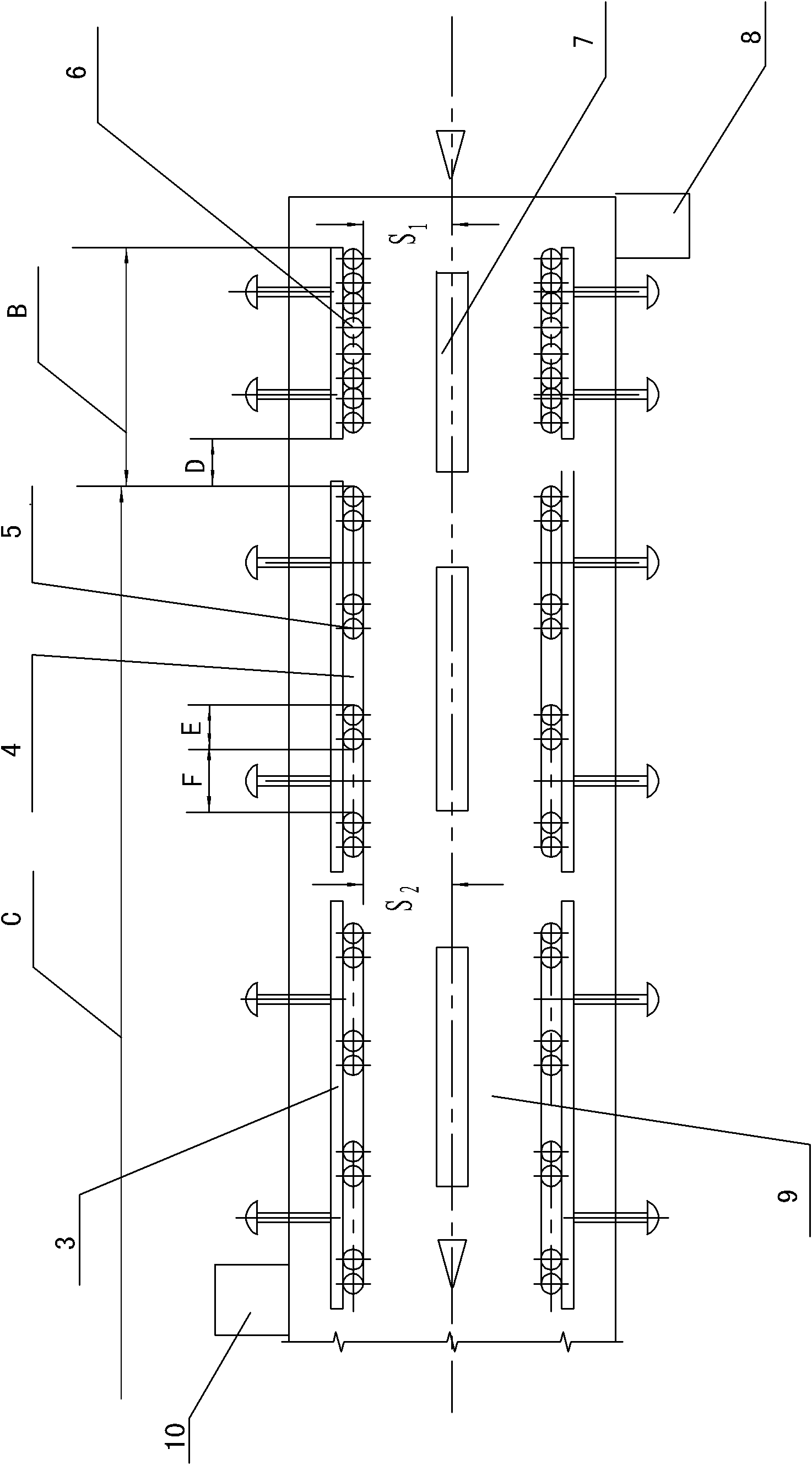

[0054] Such as Figure 1~5 Shown, in the embodiment, take MDF plank as example:

[0055] 1, the infrared pulse radiation heating method of plank surface powder solidification of the present invention, comprises the melting leveling that carries out successively and curing, curing is that the MDF plank 7 that is coated with powder coating is heated through the medium-wave infrared pulse irradiation area, heating It is high-temperature and low-temperature alternating heating, and the medium-wave infrared pulse irradiation area is composed of a continuous single medium-wave pulse irradiation heating unit, and the medium-wave infrared heating tubes 2 in the medium-wave infrared pulse irradiation area are vertically arranged The way.

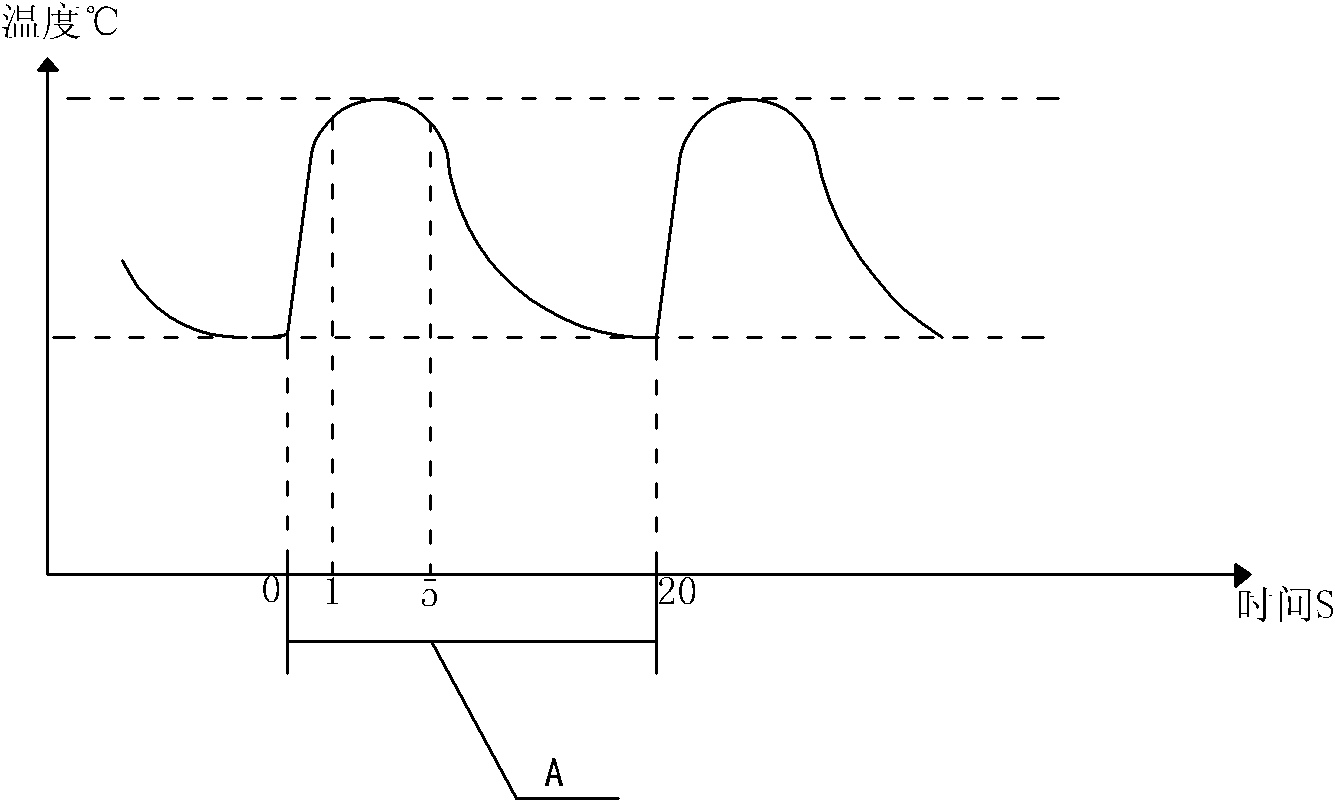

[0056] The working curve of the single medium-wave infrared pulse irradiation heating unit is: heating→high temperature→cooling, the surface of the coating film is heated up to 160°C, and after curing at this temperature, it is then cooled to 120-14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com