Semi solid rheoforming method for metal parts and device therefor

A semi-solid rheological and metal parts technology, applied in the field of semi-solid metal forming, can solve the problems of high performance requirements of screw materials, difficulty in installing heat preservation devices, and insufficient shear rate, so as to reduce slurry preparation costs, increase service life, The effect of reducing restrictions on the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

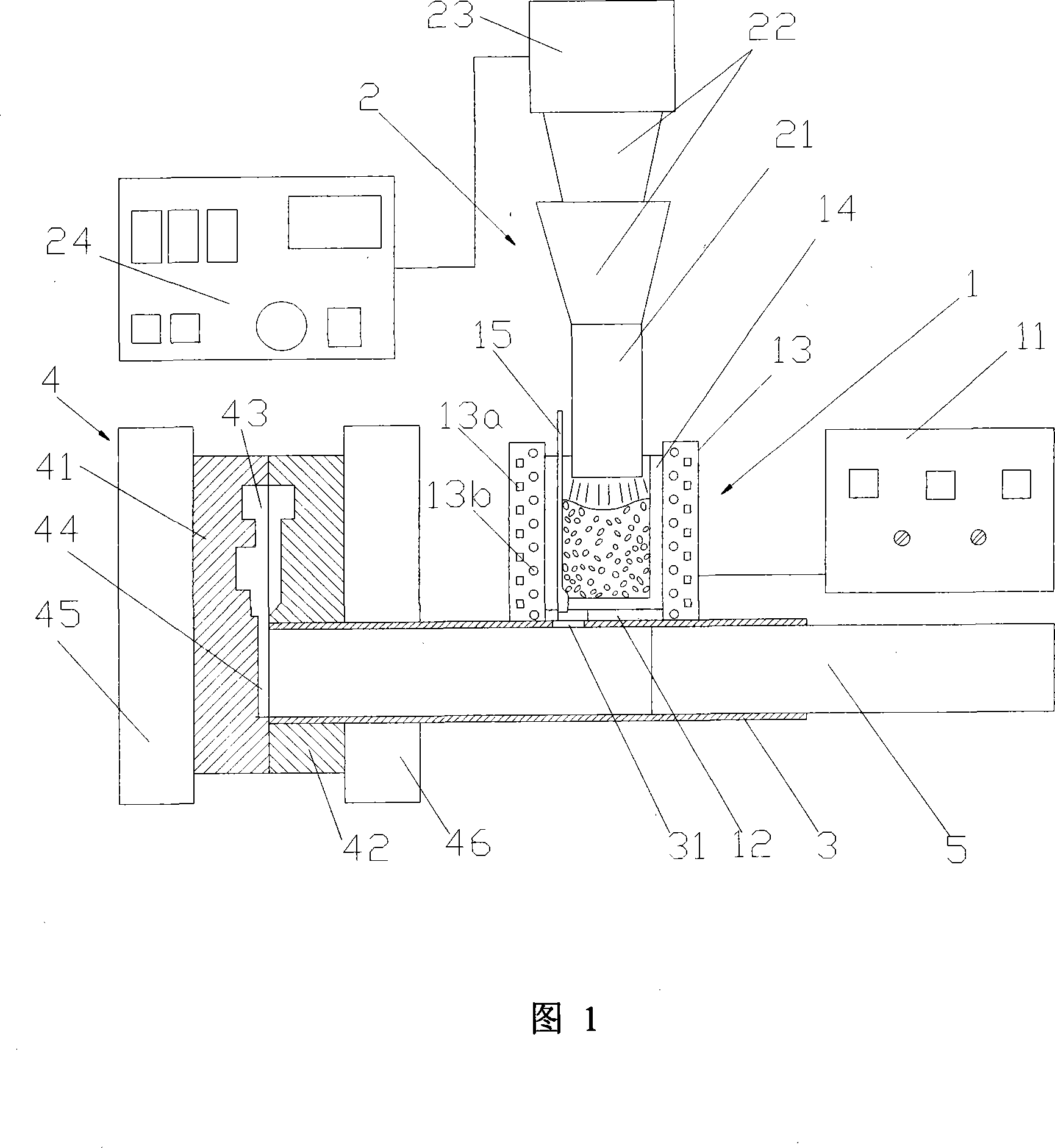

[0058] Ultrasonic vibration of ZL101 aluminum alloy was used to prepare semi-solid parts. The liquidus temperature of ZL101 aluminum alloy is 616°C and the solidus temperature is 567°C. The alloy is melted in a resistance furnace and heated to 740°C, refined and degassed for later use. The temperature of the alloy liquid is maintained at about 660°C by means of a temperature control device. Take an appropriate amount of molten aluminum, pour it into a slurry container, use the temperature control system (temperature adjustment device 13 and temperature controller 11) to control the temperature of the melt at 610°C, and the cooling rate of the melt is 0.1-3°C / s.

[0059] Move the ultrasonic radiation head 21 to 10 mm above the molten aluminum in the slurry container (FIG. 1), and perform ultrasonic pulse radiation on the melt. The radiation frequency is 20kHz, and the radiation volume power is 30W / cm 3 . The radiation time is 150s. After the ultrasonic treatment is stopped...

example 2

[0062] A390 aluminum alloy was used to prepare semi-solid state by ultrasonic vibration. The liquidus temperature of A390 aluminum alloy is 650°C and the solidus temperature is 505°C. The alloy is melted in a resistance furnace and heated to 770°C, refined and degassed for later use. The temperature of the alloy liquid is kept at about 680°C by means of a temperature control device. Take an appropriate amount of molten aluminum and pour it into a slurry crucible (Figure 1). Use a temperature control device to control the temperature of the alloy liquid at 650°C, and the cooling rate of the melt is 0.1-3°C / s.

[0063] The ultrasonic radiation head 21 was moved to 15 mm above the molten aluminum in the crucible 14 to perform ultrasonic pulse radiation on the melt. Radiation frequency is 25kHz, radiation volume power is 40W / cm 3 . The radiation time is 180s. After the ultrasonic treatment is stopped, the temperature of the semi-solid melt is lowered to 630° C. to 635° C. thr...

example 3

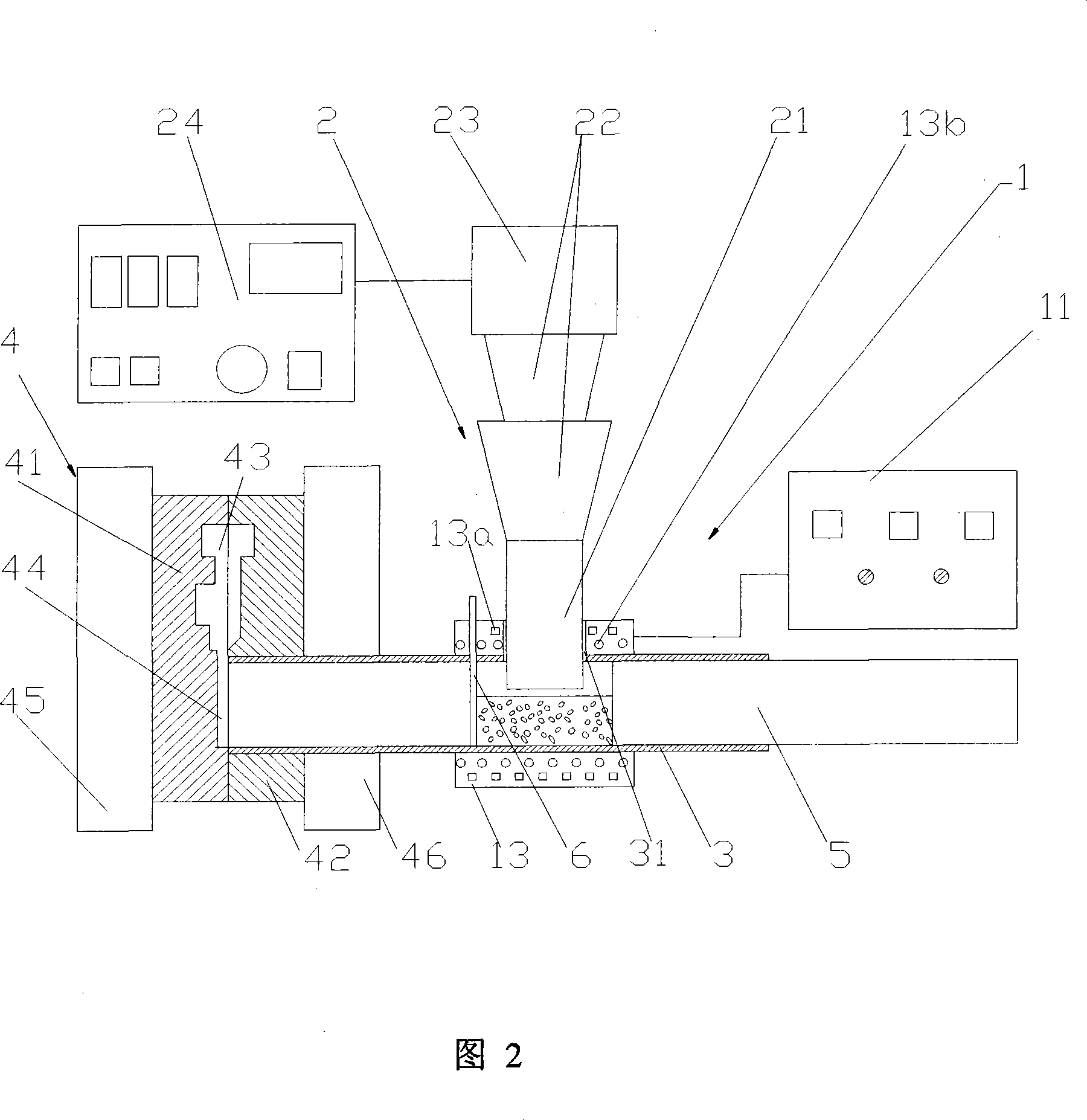

[0066] Ultrasonic vibration of AZ91 magnesium alloy was used to prepare semi-solid state. The liquidus temperature of AZ91 magnesium alloy is 595°C and the solidus temperature is 470°C. The alloy is melted in a resistance furnace and heated to 680°C, refined and degassed for later use. The temperature of the alloy liquid is maintained at about 640°C by means of a temperature control device. Take an appropriate amount of magnesium liquid and pour it into the sleeve 3 (Figure 2). Use the temperature control system to control the temperature of the sleeve and the melt at 590°C, and the cooling rate of the melt is 0.1-3°C / s.

[0067]The ultrasonic radiation head 21 was moved to 10 mm above the molten magnesium in the sleeve 3 to perform ultrasonic pulse radiation on the melt. The radiation frequency is 20kHz, and the radiation volume power is 20W / cm 3 . The radiation time is 100s. After the ultrasonic treatment is stopped, the temperature of the semi-solid melt is lowered to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com