Preparation method of high-aluminum-doped small-particle-size cobalt carbonate particles

A technology of cobalt carbonate particles and small particle size, applied in the direction of cobalt carbonate, etc., can solve the problems of porous particle size, uneven distribution of aluminum, increase the amount of aluminum doping, etc., to eliminate large particles of agglomerates and avoid excessive nucleation. Fast, consistent crystallinity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

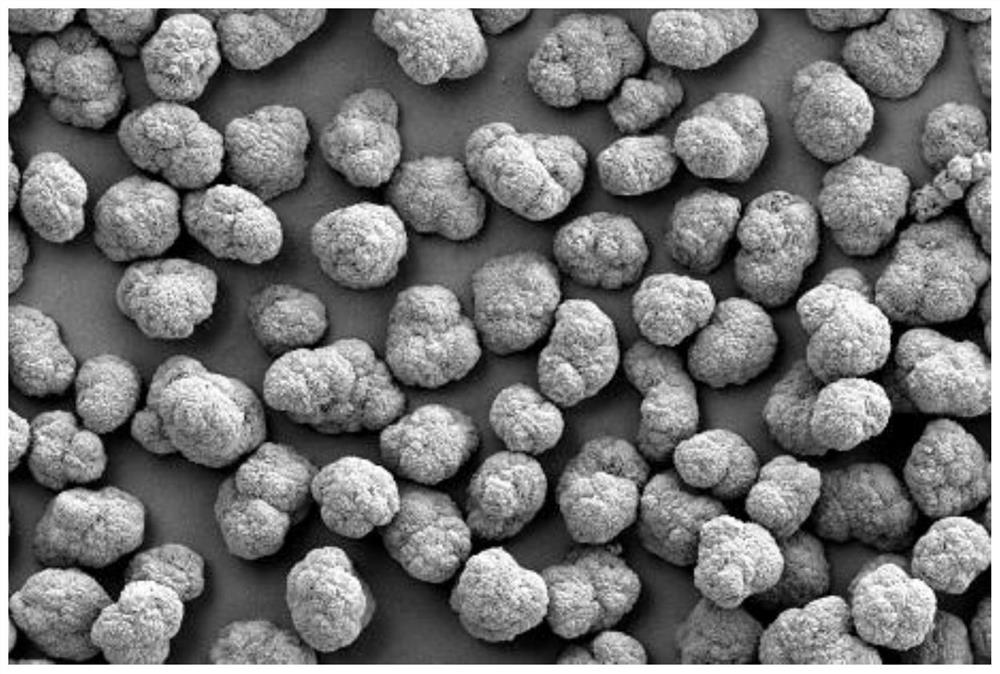

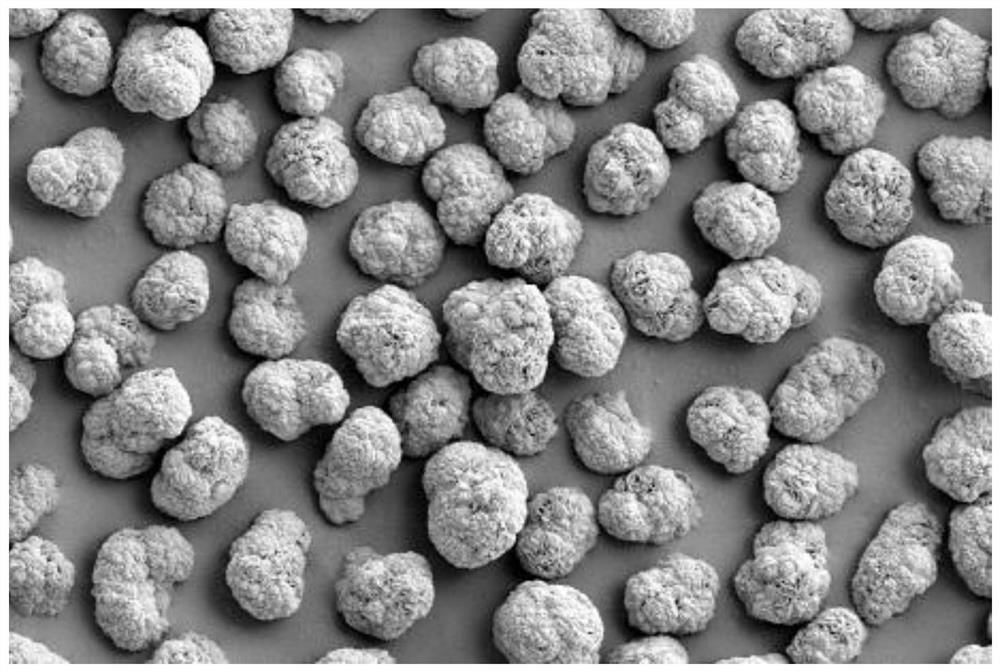

[0033] Based on above-mentioned findings, propose the preparation method of highly aluminum-doped small particle diameter cobalt carbonate particle of the present invention, this preparation method comprises the following steps:

[0034] (1) Prepare solution: prepare a mixed salt solution of soluble cobalt salt and aluminum salt, wherein the mass ratio of aluminum element to cobalt element is 0.011~0.014, and prepare ammonium bicarbonate solution;

[0035] (2) Preparation of seed crystals: add water and ammonium bicarbonate solution as the bottom liquid in the reactor, add mixed salt solution and ammonium bicarbonate solution in a parallel feeding mode, so that the feeding rate of cobalt ions relative to the volume of the reactor is 0.048 ±0.012mol / L / hour, control the reaction temperature at 35±5°C and keep it substantially constant, and react until cobalt carbonate seeds with a particle size D50 of 1.3-1.5 μm are obtained; and

[0036] (3) Synthetic growth: continue to add mi...

Embodiment 1

[0051] Preparation of solution: preparation of cobalt sulfate solution with a cobalt content of 115g / L, doping with aluminum salt to obtain a mixed salt solution, so that the mass ratio of aluminum element to cobalt element in the mixed salt solution is 0.0113. Prepare ammonium bicarbonate solution.

[0052] Preparation of seed crystals: prepare 10 L of diluted ammonium bicarbonate solution with a concentration of 15 g / L in a reaction kettle with a volume of 50 L as the bottom liquid, and adjust the pH value of the bottom liquid to ≥ 8 by heating, stirring and drafting. Under the condition of constant temperature water bath at 30°C, the mixed salt solution and the ammonium bicarbonate solution were pumped into the reaction kettle concurrently, so that the pumping flow rate of the mixed salt solution was 16mL / min (approximately the feeding rate of cobalt ions relative to the volume of the reaction kettle) is 0.036mol / L / hour). During the co-current feeding process, the mass rat...

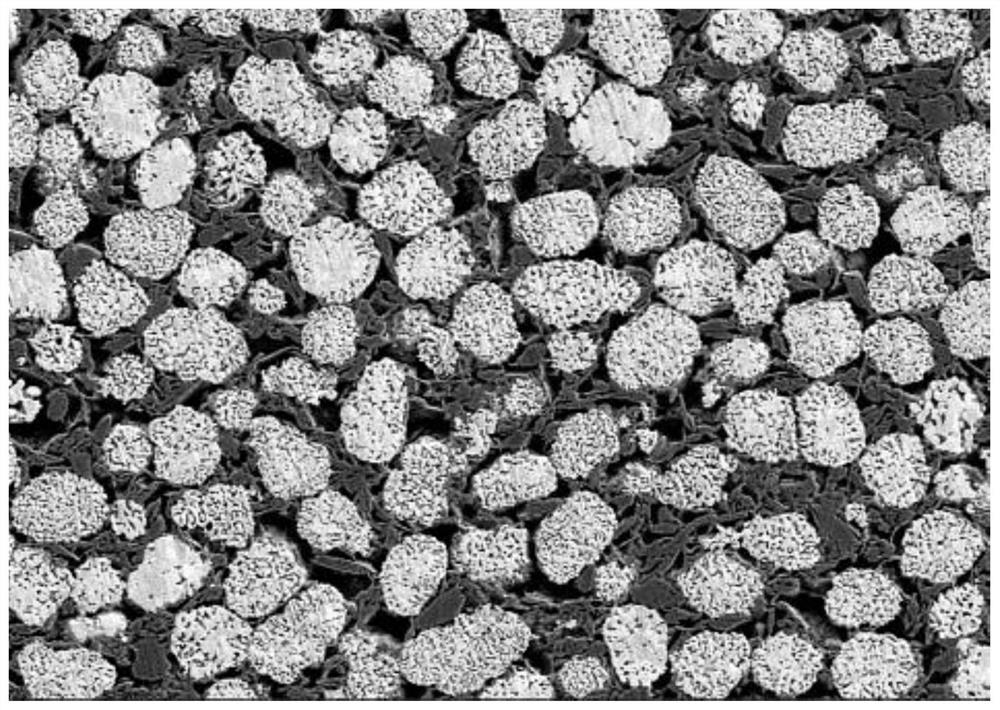

Embodiment 2

[0056] Prepare the solution: prepare a cobalt sulfate solution with a cobalt content of 120g / L, and dope it with an aluminum salt to obtain a mixed salt solution, so that the mass ratio of the aluminum element to the cobalt element in the mixed salt solution is 0.0126. Prepare ammonium bicarbonate solution.

[0057] Preparation of seed crystals: prepare 10 L of diluted ammonium bicarbonate solution with a concentration of 20 g / L in a reaction kettle with a volume of 50 L as the bottom liquid, and adjust the pH value of the bottom liquid to ≥ 8 by heating, stirring and drafting. Under the condition of constant temperature water bath at 35°C, the mixed salt solution and the ammonium bicarbonate solution were pumped into the reaction kettle in parallel, so that the pumping flow rate of the mixed salt solution was 20mL / min (approximately the feeding rate of cobalt ions relative to the volume of the reaction kettle) is 0.048mol / L / hour). During the co-current feeding process, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com