Optical fiber secondary coating device

A secondary plastic sleeve, optical fiber technology, applied in optics, light guides, optical components, etc., can solve the problem of inability to meet the production requirements of high-speed production of hydrogel-filled loose tubes or fully dry environmental protection optical cable loose tubes, unable to loosen The shrinkage rate of the casing is controlled within a reasonable range, which affects the production quality and production efficiency of the loose casing, so as to improve the production quality and production speed, improve the reliability, and ensure the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

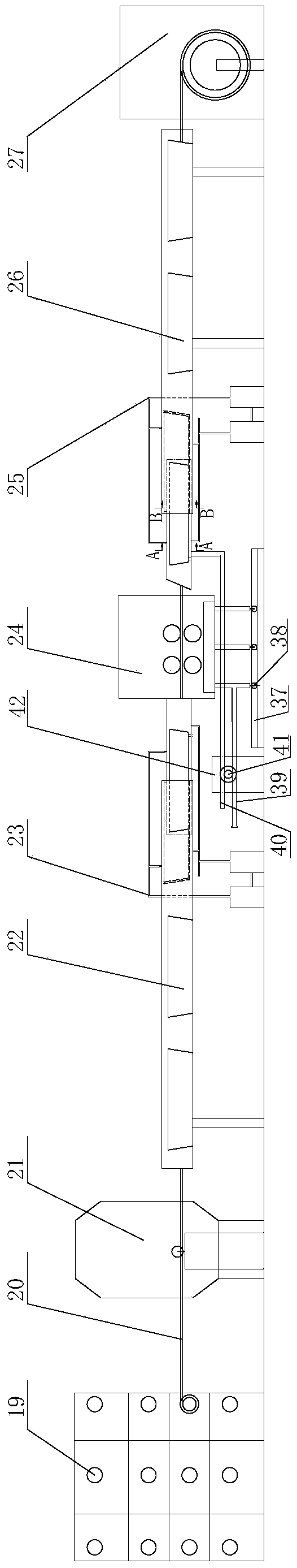

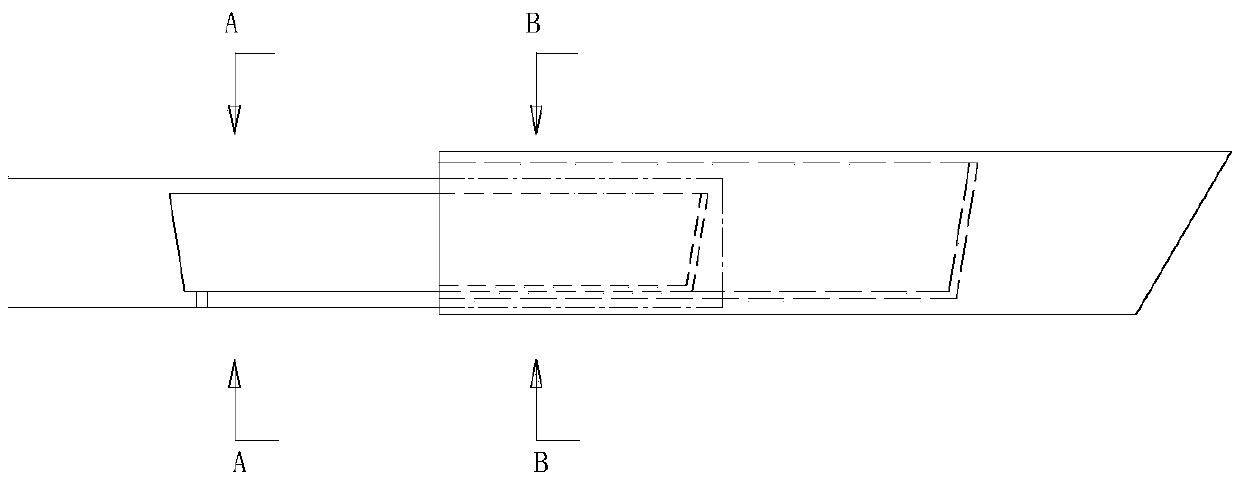

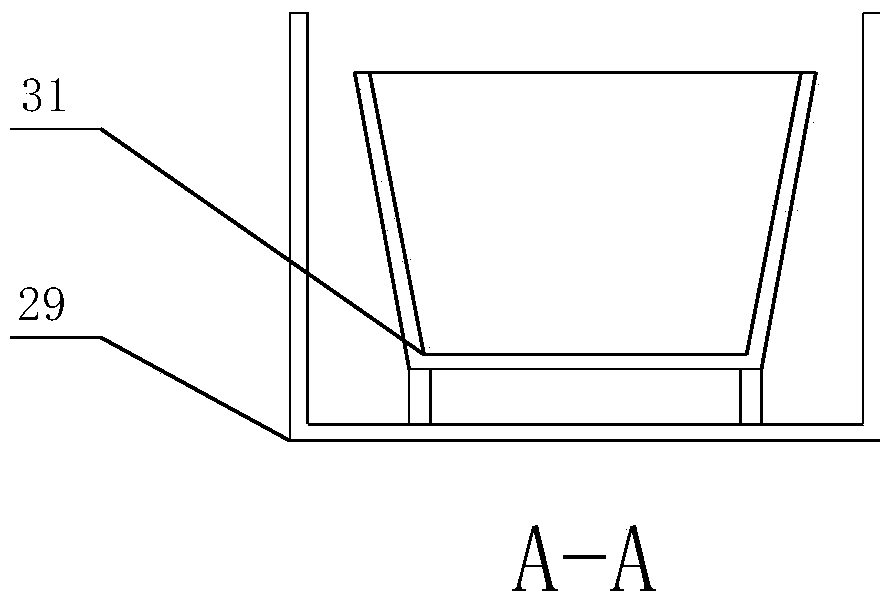

[0028] As shown in Figures 1-7, this embodiment provides a secondary plastic sheathing equipment for optical fibers, including an extruder head 19, a front cooling water tank device 22, a front cooling water supply device 23, and an optical cable loose tube shrinkage compensation device 24 , the rear cooling water tank device 26, the rear cooling water supply device 25, the optical fiber take-up device 27, the front cooling water tank device 22 and the rear cooling water tank device 26 are shrinkable water tank devices, and the front cooling water tank device 22 It shrinks or stretches synchronously with the cooling water tank device 26 at the rear stage.

[0029] In the present invention, the structure of the front cooling water tank device 22 and the rear cooling water tank device 26 is the same, therefore, there are many ways to realize the synchronous contraction or syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com