Patents

Literature

34results about How to "Enhanced interface energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

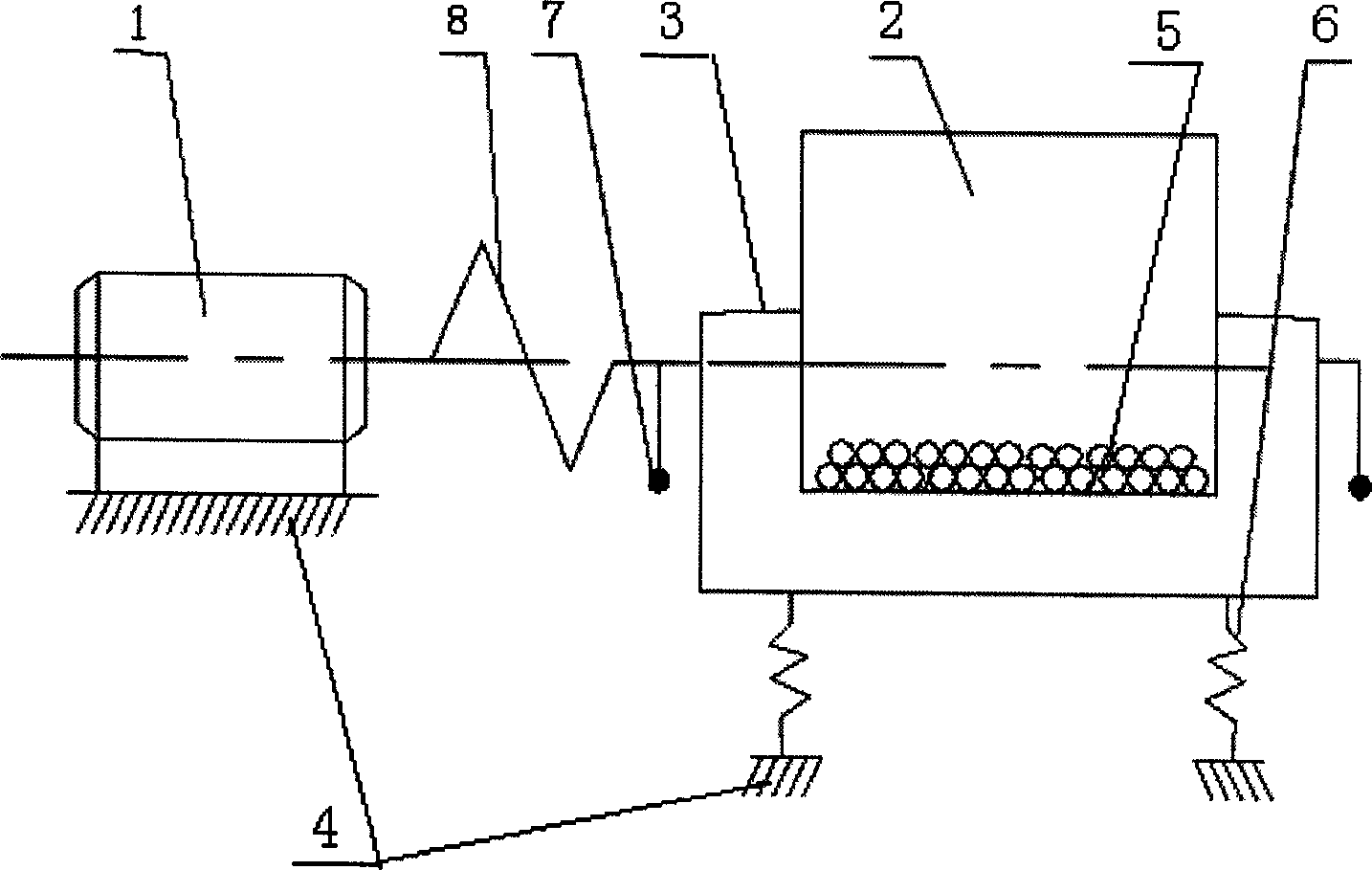

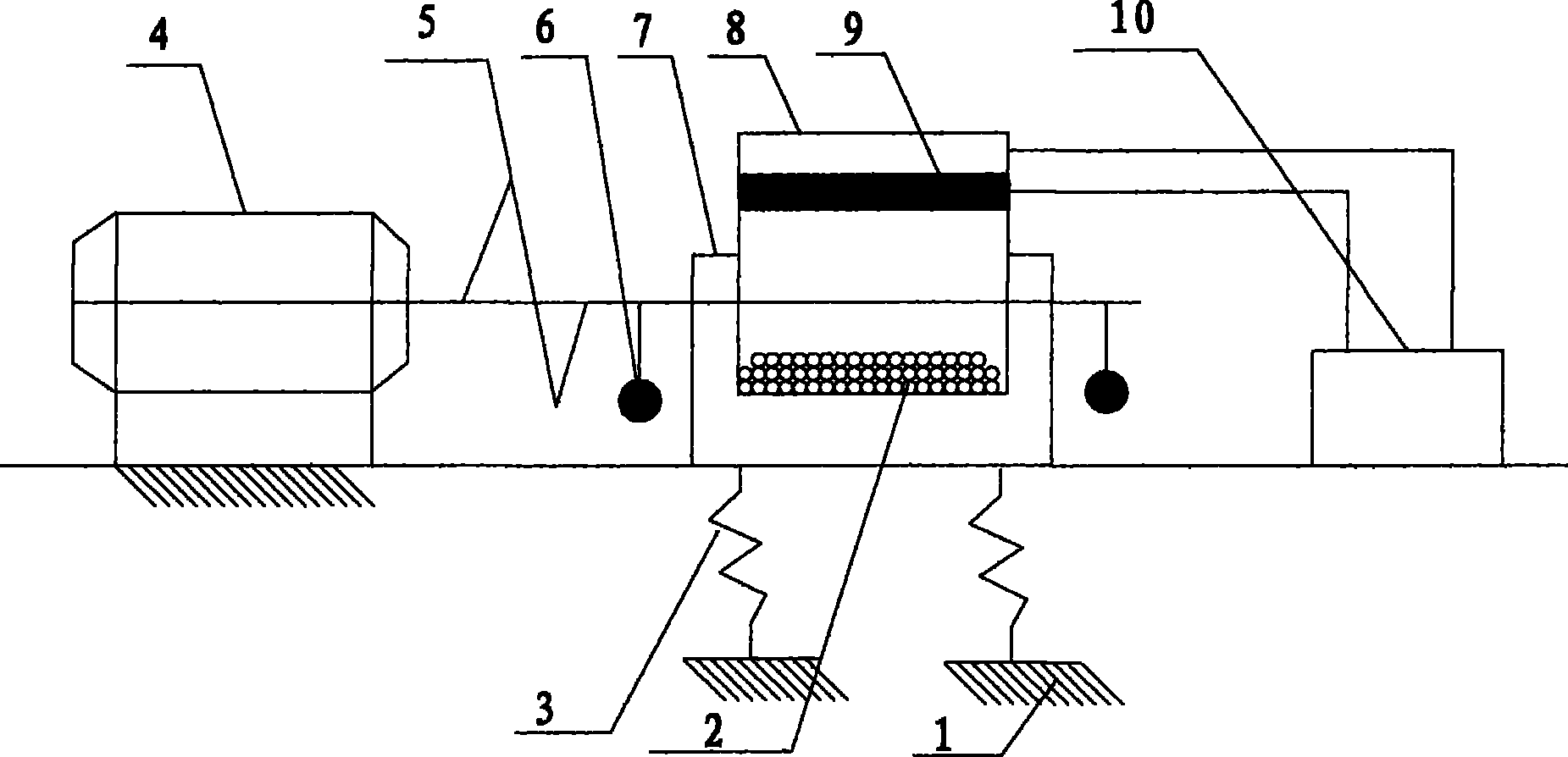

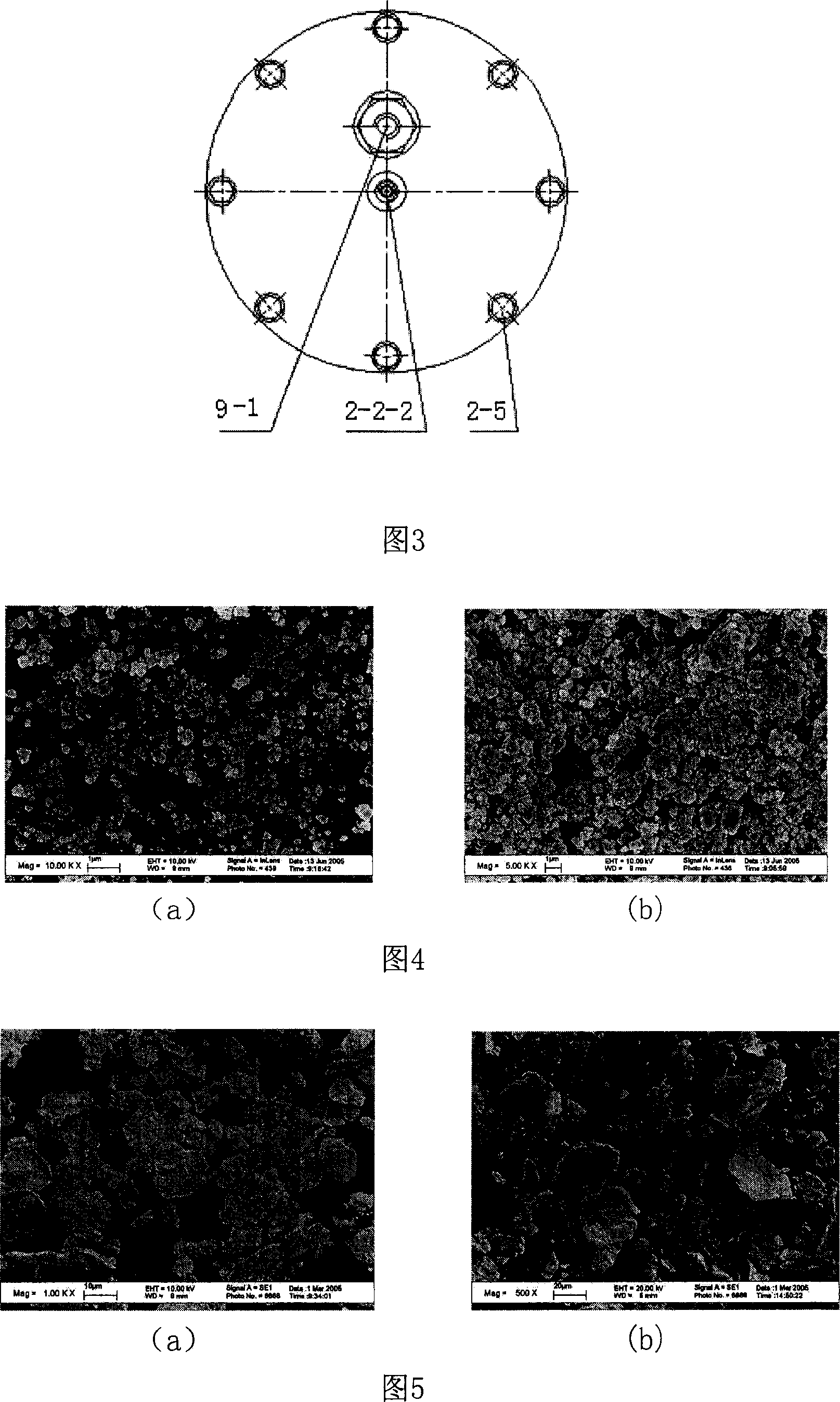

High energy ball mill method with plasma aid

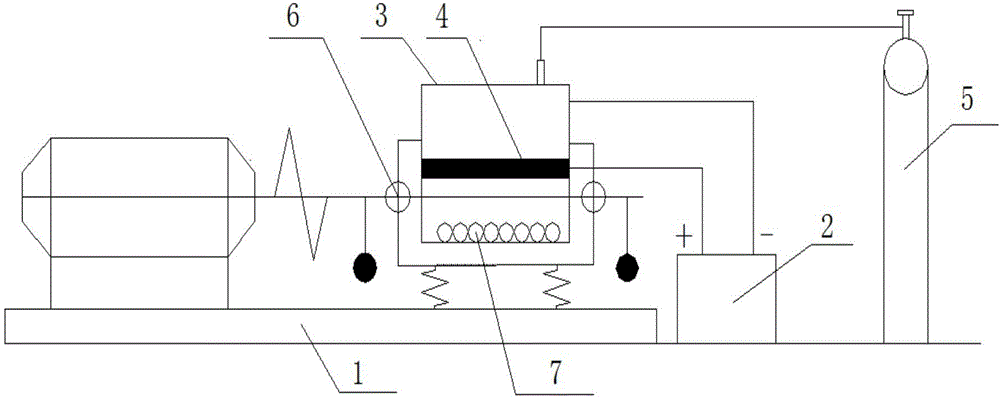

A plasma aided high-energy ball grinding method includes such steps as installing the front cover plate and rod electrode of ball grinder, respectively connecting the ball grinder and rod electrode to the poles of plasma power supply, loading the powder to be ground in the ball grinder, pumping negative pressure, filling discharging gas medium, turning on the plasma power supply, regulating discharge parameters for corona discharge or glow discharge, and turning on the motor to drive the vibration exciting block for ball grinding.

Owner:SOUTH CHINA UNIV OF TECH

Method for achieving high-melting-point material 3D printing through nanometer ink together with laser melting

InactiveCN103407296AWide range of choicesLarge specific surface areaOther printing apparatusDevice formInk printer

The invention discloses a method for preparing the nanometer ink through ceramics, metal, semiconductors, glass and other high-melting-point materials, carrying out 3D printing and utilizing the laser heating sintering in the process of printing to obtain 3D devices formed by combining the ceramics, the metal, the semiconductors and other composite. The method comprises the first step of processing raw materials needed to prepare the device into nanometer particles of 1-500nm, the second step of preparing the particles into ink jet printing ink, the third step of carrying out 3D printing by utilizing an improved ordinary ink printer and adopting the laser heating sintering in the process of printing, and the fourth step of achieving the melting and sintering molding of the nanometer particles. According to the method, micron-level precision devices with any complex shape can be directly prepared, the high surface energy of the nanometer particles is utilized, the sintering temperature is lowered, high density is achieved, and a superior property is obtained. The method can be used for manufacturing automobile metal ceramic composite pistons, aviation engine tail pipes, and ceramic bearings and ceramal composite precise components of watches and other precision instruments and for directly printing a circuit board.

Owner:南京鼎科纳米技术研究所有限公司

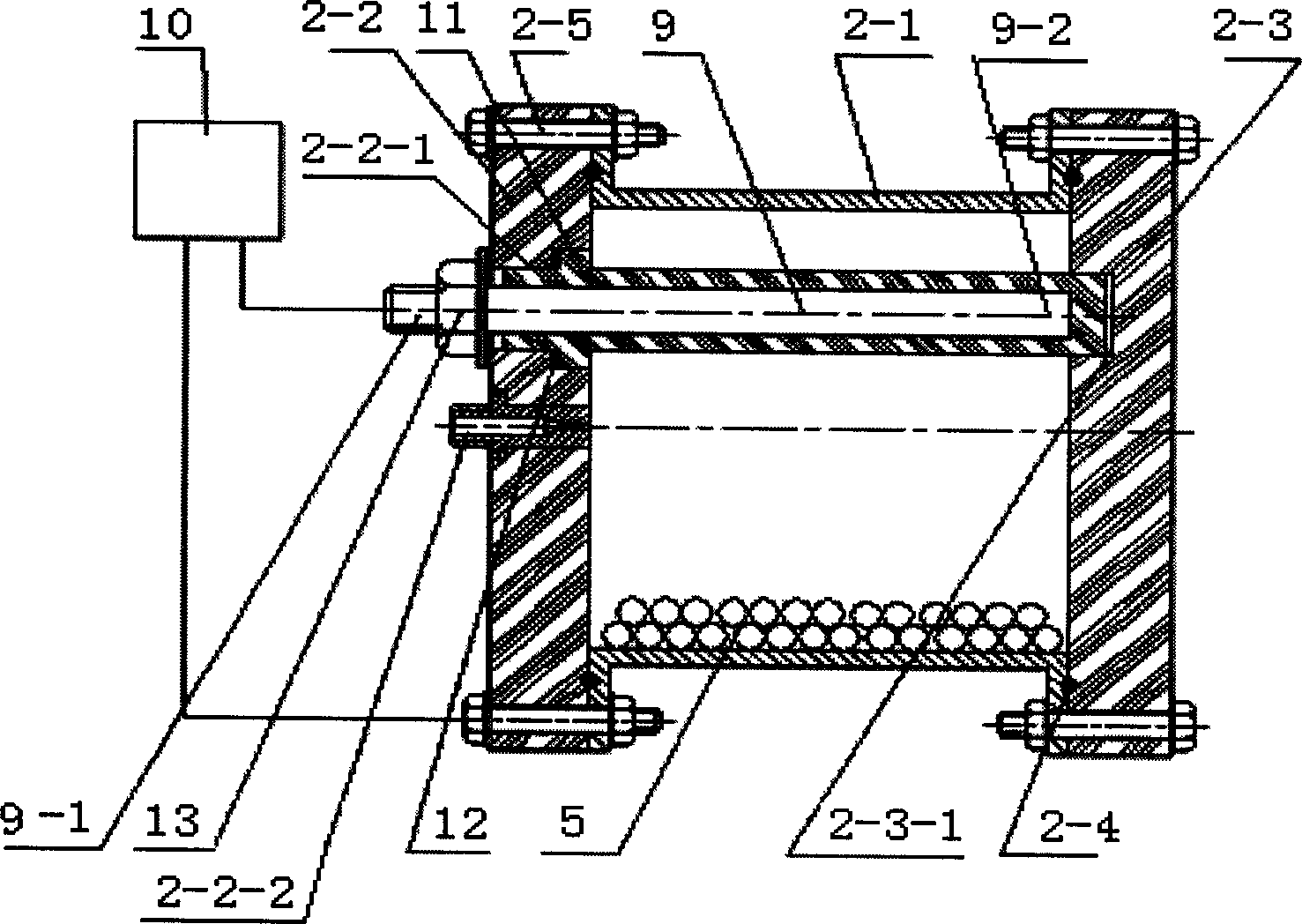

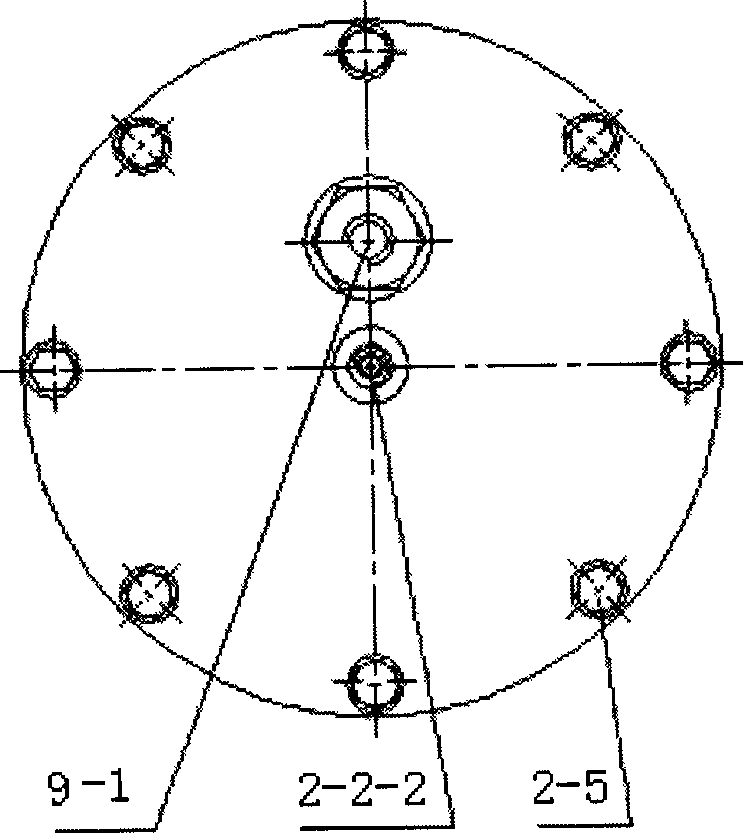

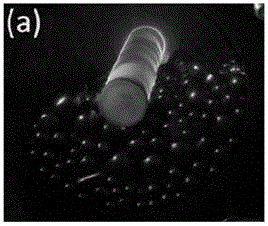

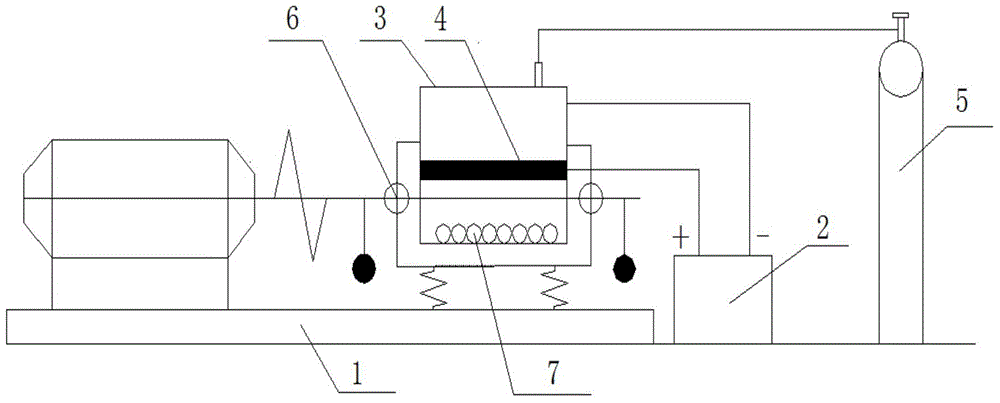

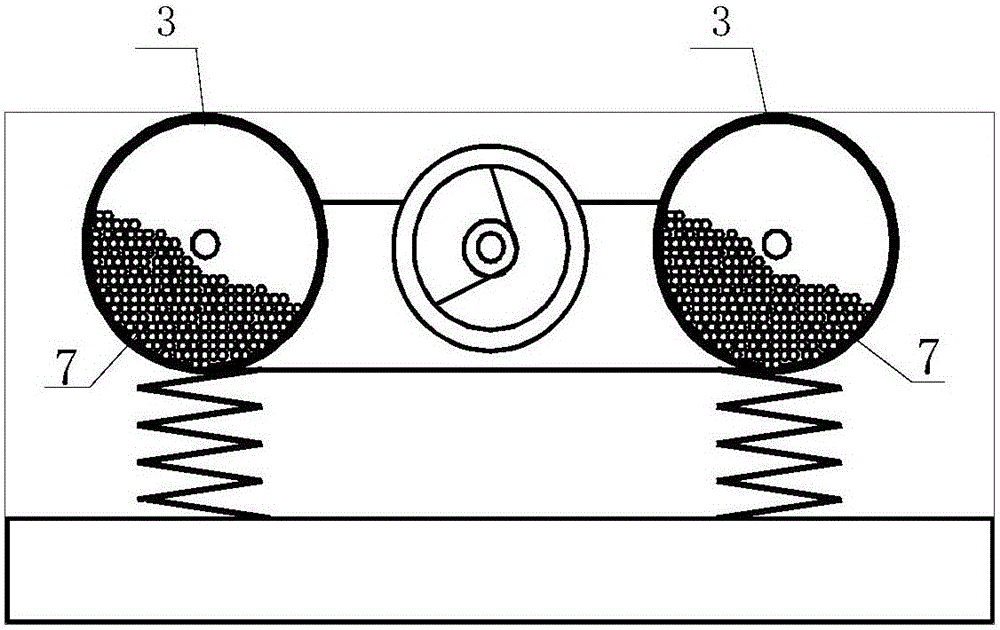

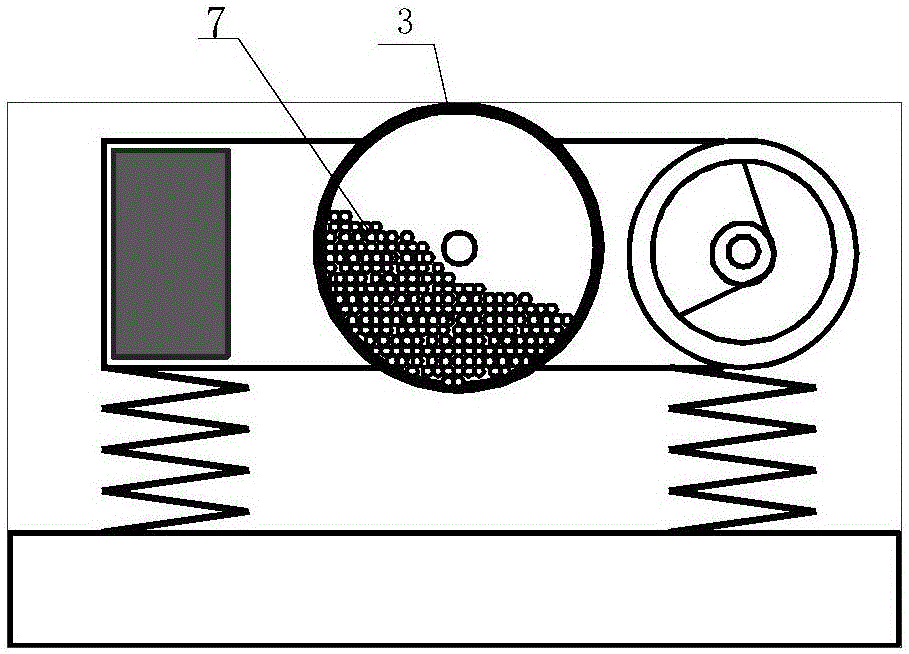

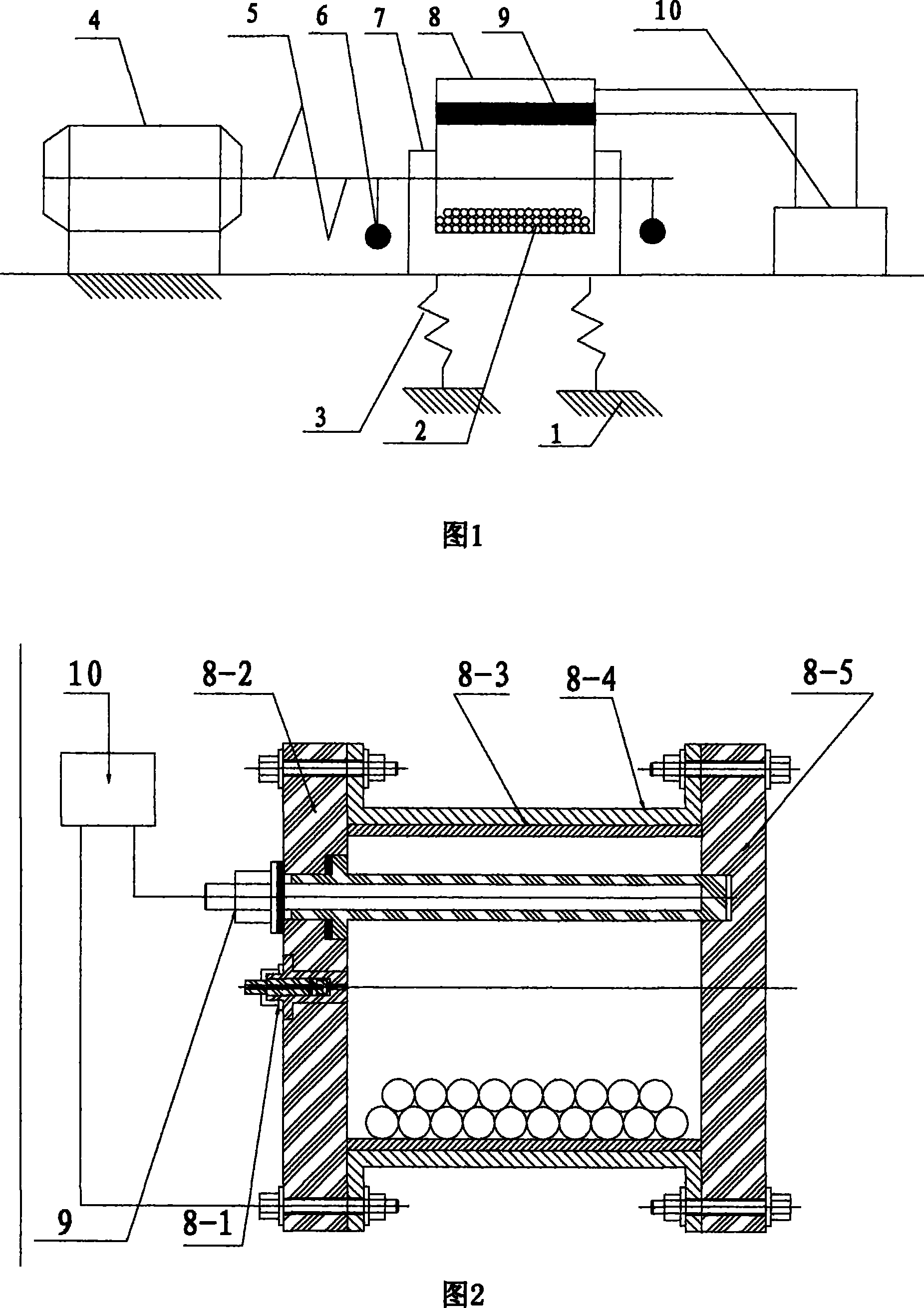

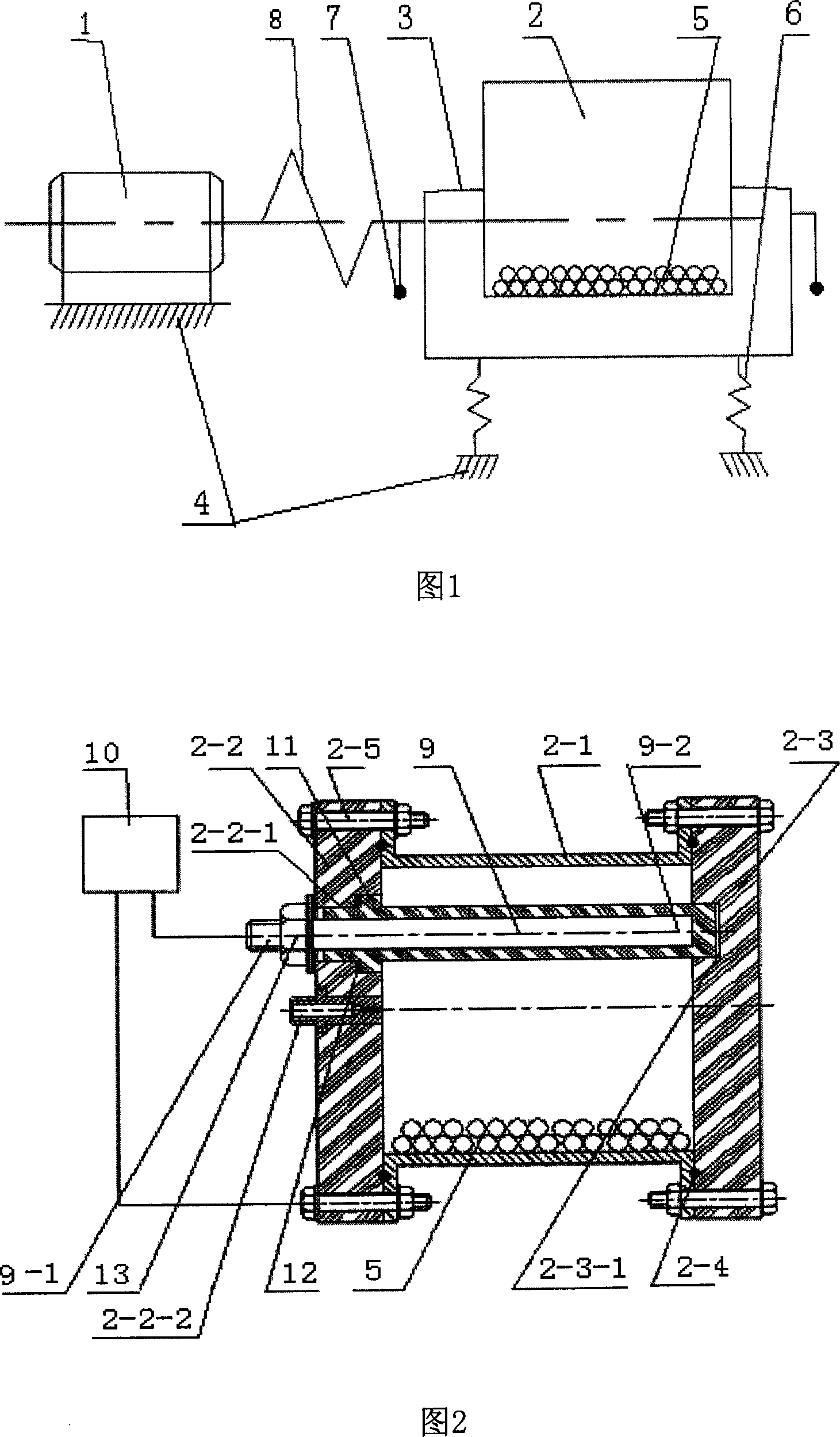

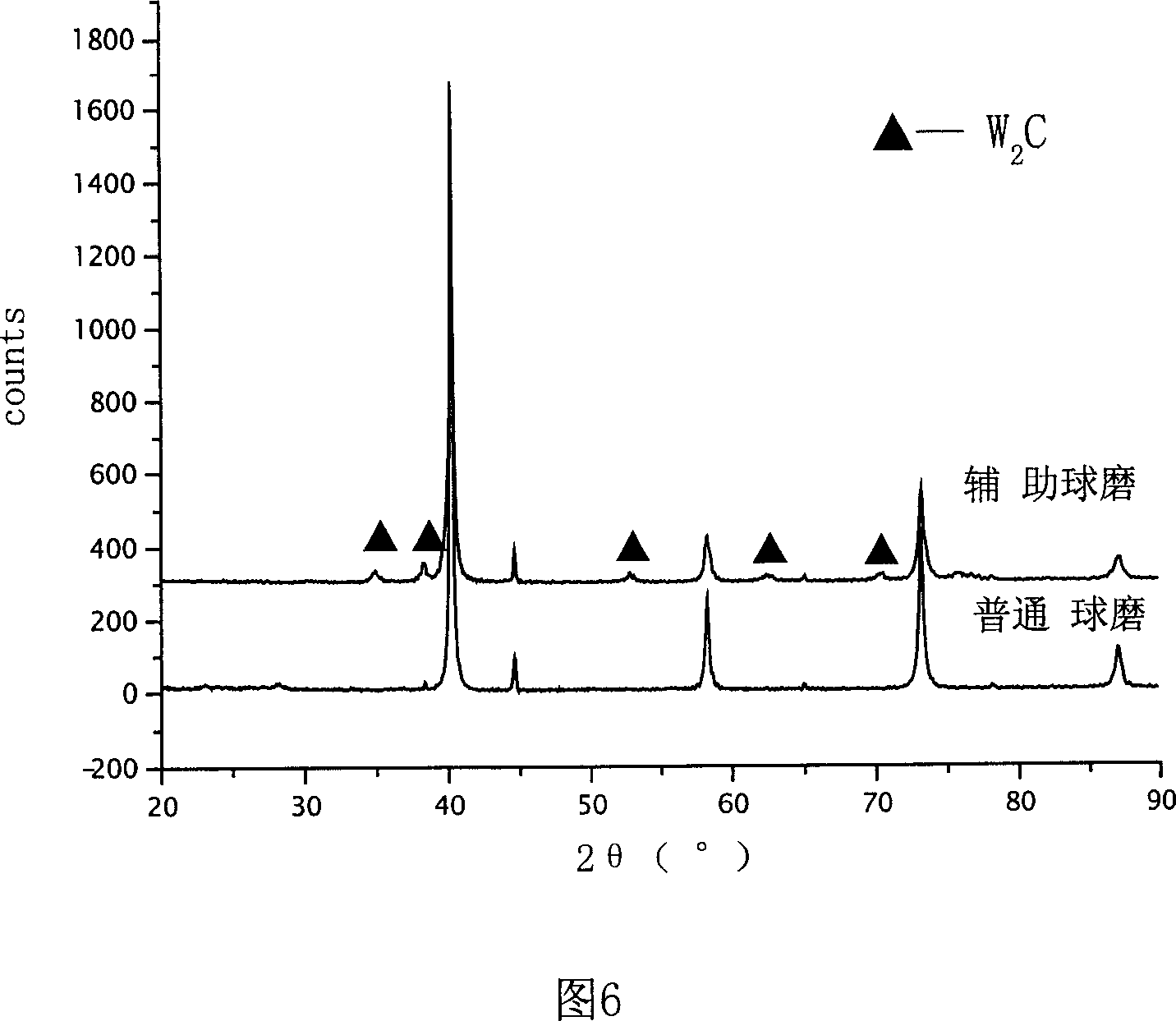

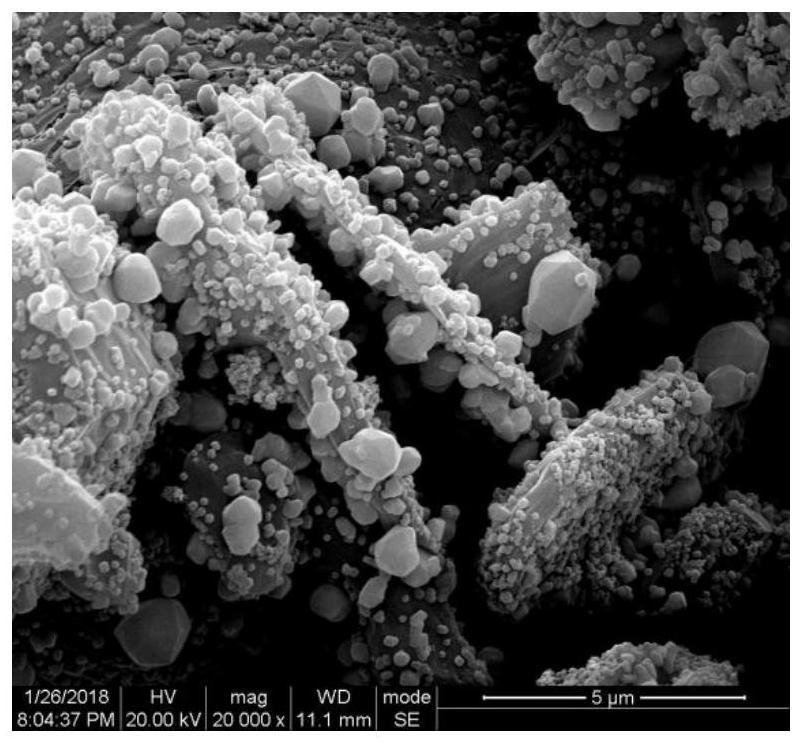

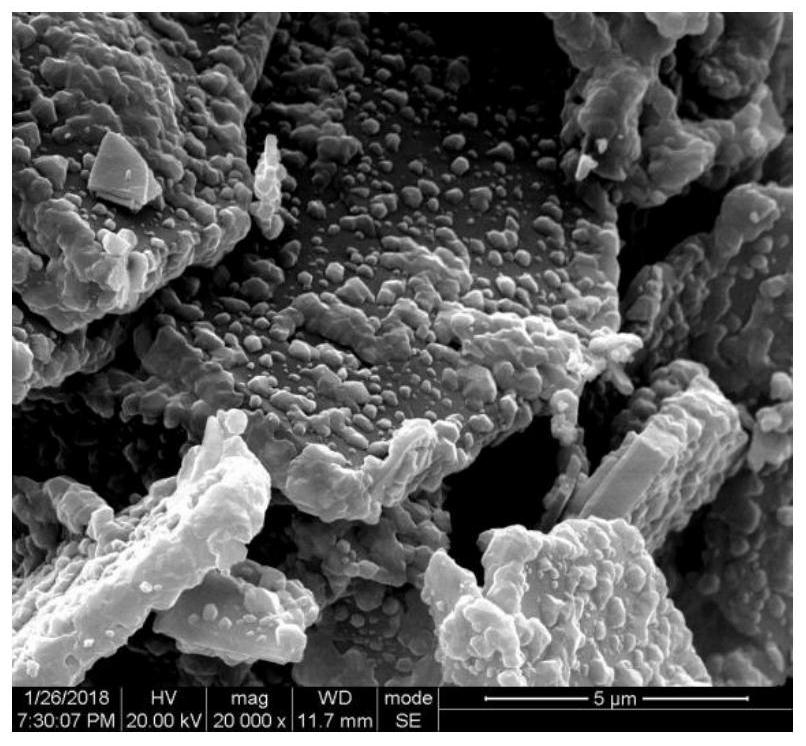

Application method of cold field plasma discharge assisted high energy ball milled powder and plasma assisted high energy ball milling device

The invention provides an application method of cold field plasma discharge assisted high energy ball milled powder and a plasma assisted high energy ball milling device using the cold field plasma discharge assisted high energy ball milling method. The method comprises the following steps: utilizing dielectric barrier discharge to generate plasmas, introducing a dielectric barrier discharge electrode bar into a high-speed vibrating ball-milling tank, on one hand, requiring a solid insulating medium on the outer layer of the electrode bar to simultaneously bear high-voltage discharge and mechanical shock failure of the grinding ball, and on the other hand, requiring the high-speed vibrating ball milling device to uniformly process the powder. The method is based on the ordinary ball milling technology; the processing efficiency and the effect of the ball mill can be greatly improved by the following steps: under a non-heat-balance discharge condition of the pressure that the discharge space pressure is set to be about 102-106 Pa, introducing the discharge plasmas to input another effective energy to the processed powder, promoting the powder to be processed to be subjected to combined action of the mechanical stress effect and the heat effect of the external electric field, and further accelerating refining of the powder and promoting the alloying progress.

Owner:SOUTH CHINA UNIV OF TECH

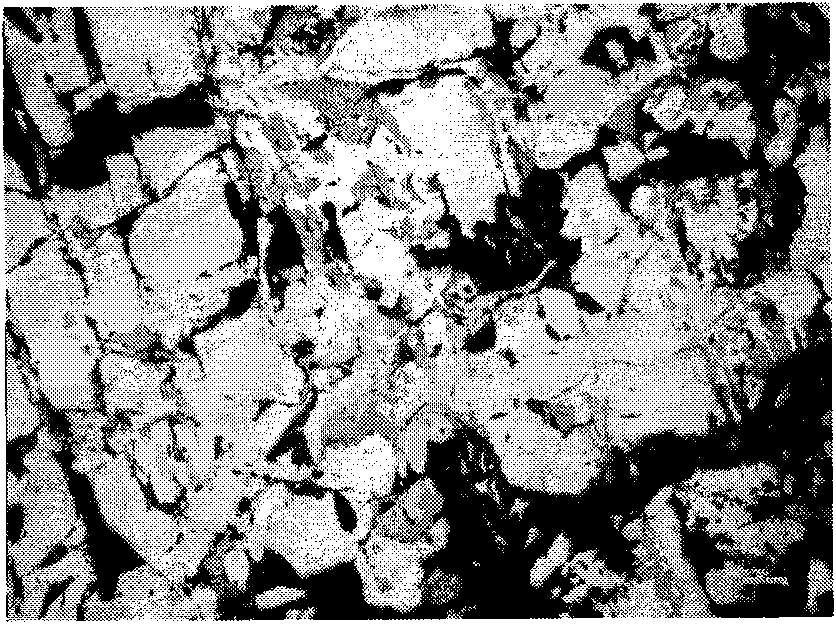

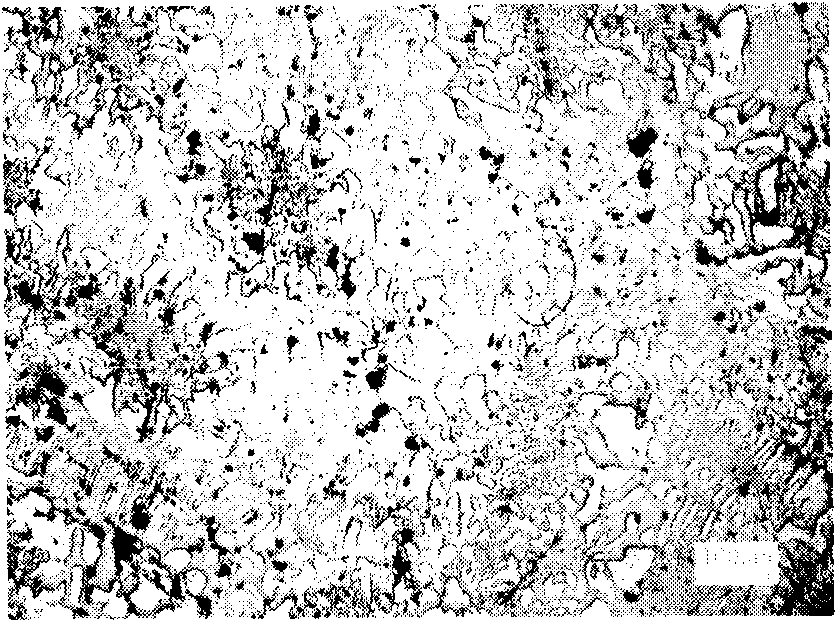

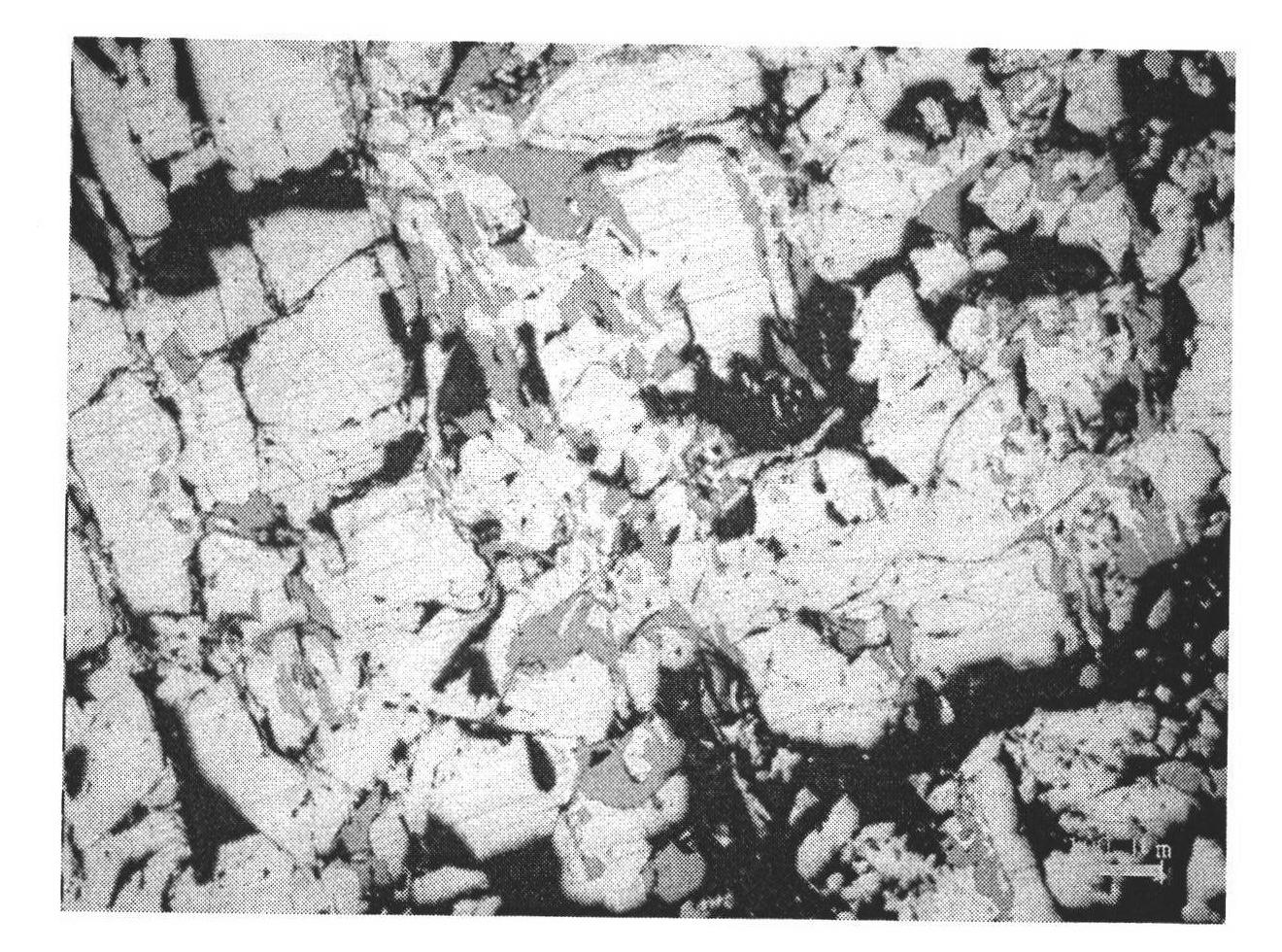

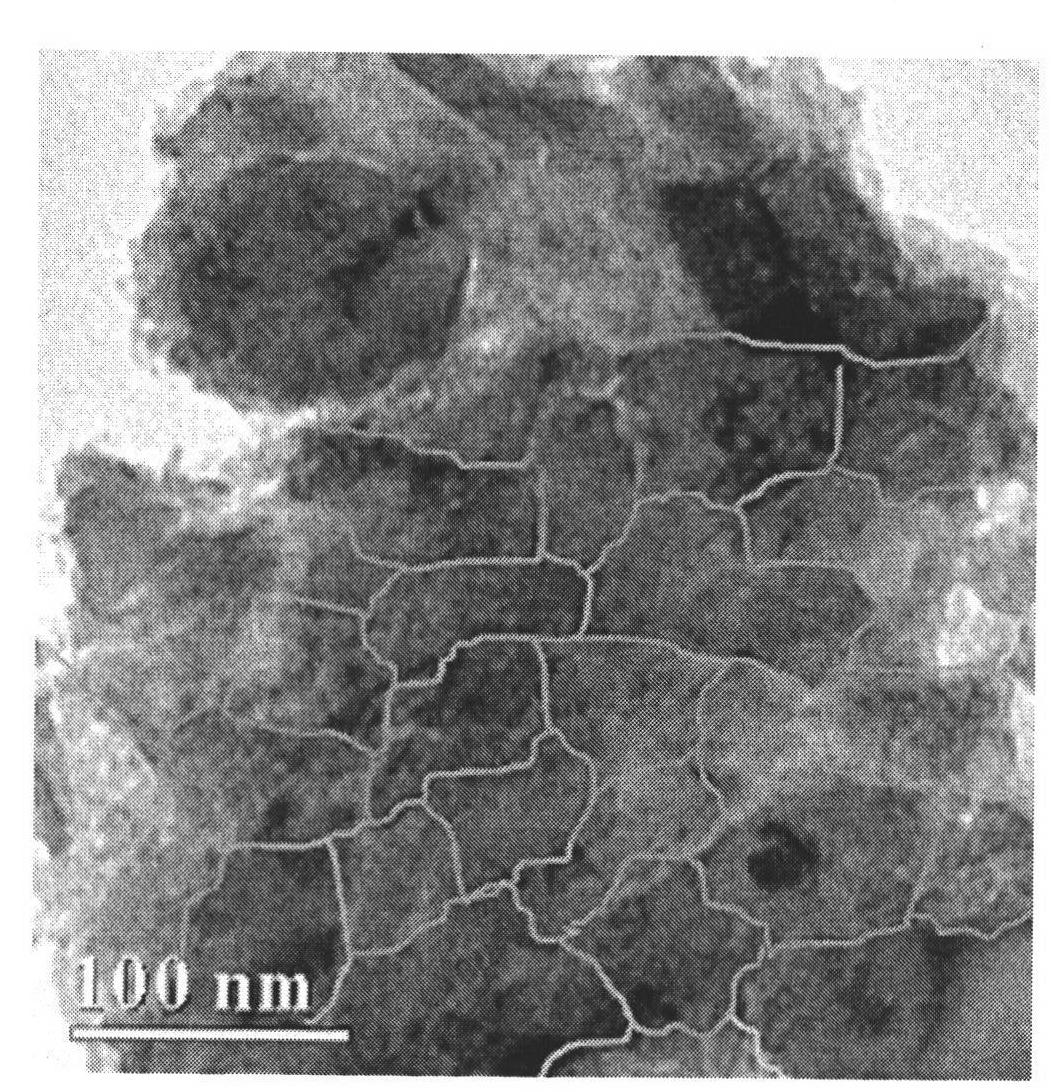

High-chromium cast iron composite inoculant, preparation method and application thereof

The invention relates to a high-chromium cast iron composite inoculant, a preparation method and an application thereof, in particular to cast iron alloy containing chromium. The high-chromium cast iron composite inoculant is a nanocrystalline high-chromium cast iron composite inoculant containing rare-earth ferrosilicon and ferroboron. The high-chromium cast iron composite inoculant comprises Fe-Ce-Si-Ca intermediate alloy and Fe-B intermediate alloy, wherein the weight ratio between the Fe-Ce-Si-Ca intermediate alloy and the Fe-B intermediate alloy is 1:0.07-0.13. The nanocrystalline crystal grains of the inoculant are less than 100nm, the inoculant is a flaky inoculant obtained by carrying out melt fast-quenching processing on raw materials which comprise commercially purchased rare-earth ferrosilicon and commercially purchased ferroboron, the inoculant is used for carrying out crystal grain and tissue refining processing on the tissue of the high-chromium cast iron alloy of high-chromium cast iron wear parts used for engineering machinery, the processing method is a metal melt casting method, the casting defect of the existing casting technology of the high-chromium cast iron alloy is overcame, and matrix crystal grains and cementite phases are obviously refined, so that the overall mechanical properties of the high-chromium cast iron alloy are obviously improved.

Owner:TIANJIN LIXINSHENG ADVANCED CASTING

2Cr13 heat treatment process

InactiveCN101608252AHigh surface hardnessImprove surface wear resistanceFurnace typesQuenching agentsLong axisMechanical equipment

The invention belongs to the field of a heat treatment process for reciprocating-compressor 2Cr13 piston-rods, and is applicable to all reciprocating compressors adopting a 2Cr13 piston-rod heat treatment process and mechanical equipment which requires high toughness and needs post-order surface heat treatment. The process can solve the problem that the prior heat treatment adopted for 2Cr13 piston rods is low in impact toughness, large in high-frequency quenching deformation of long-axis parts, large in hardening cracks and workpiece residual stress, and the like. The process comprises the forging molding of 2Cr13 piston rods, annealing, quenching-tempering, stabilizing, medium-frequency or high-frequency quenching and low-temperature tempering. The 2Cr13 heat treatment process can completely overcome the disadvantages of the prior heat treatment process such as incapability of eliminating residual stress and serious high-frequency quenching workpiece distortion, and is an ideal heat treatment process for long-axis workpieces.

Owner:SHENYANG BLOWER WORKS GROUP CORP

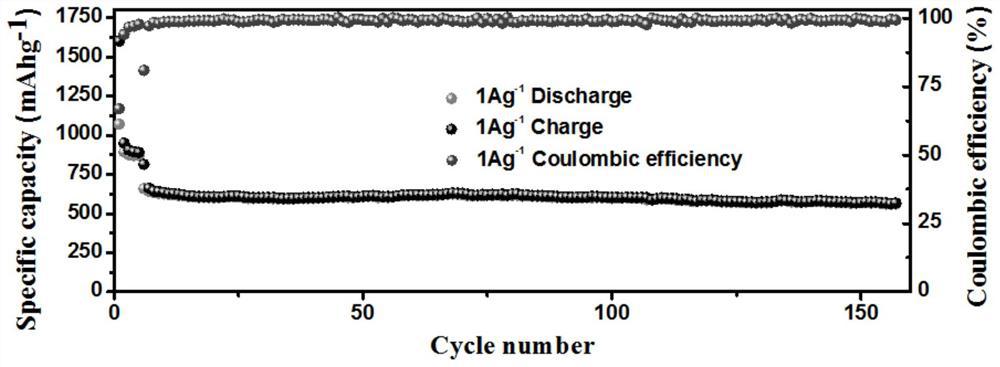

Gel polymer electrolyte, polymer battery, and preparation method thereof

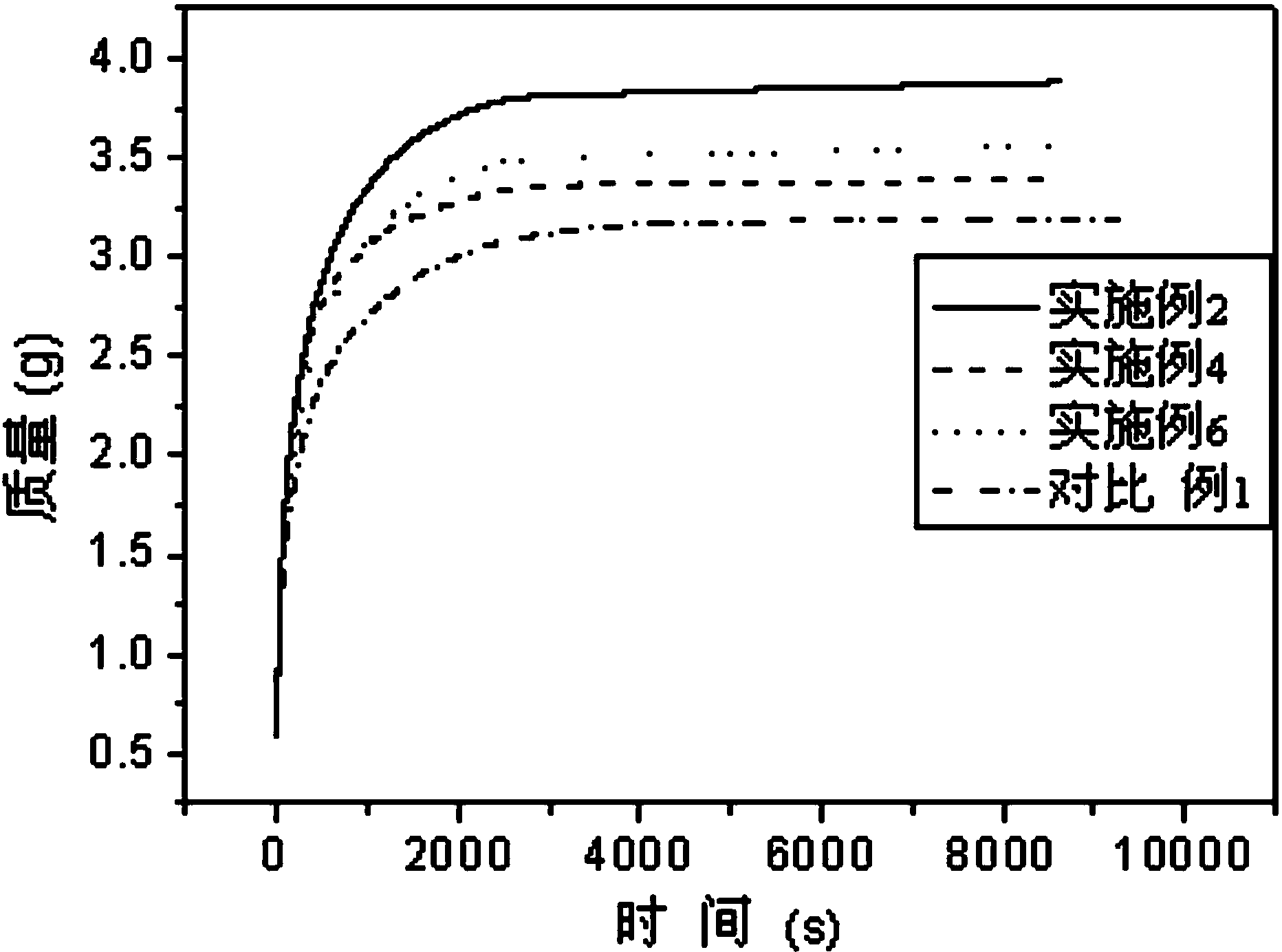

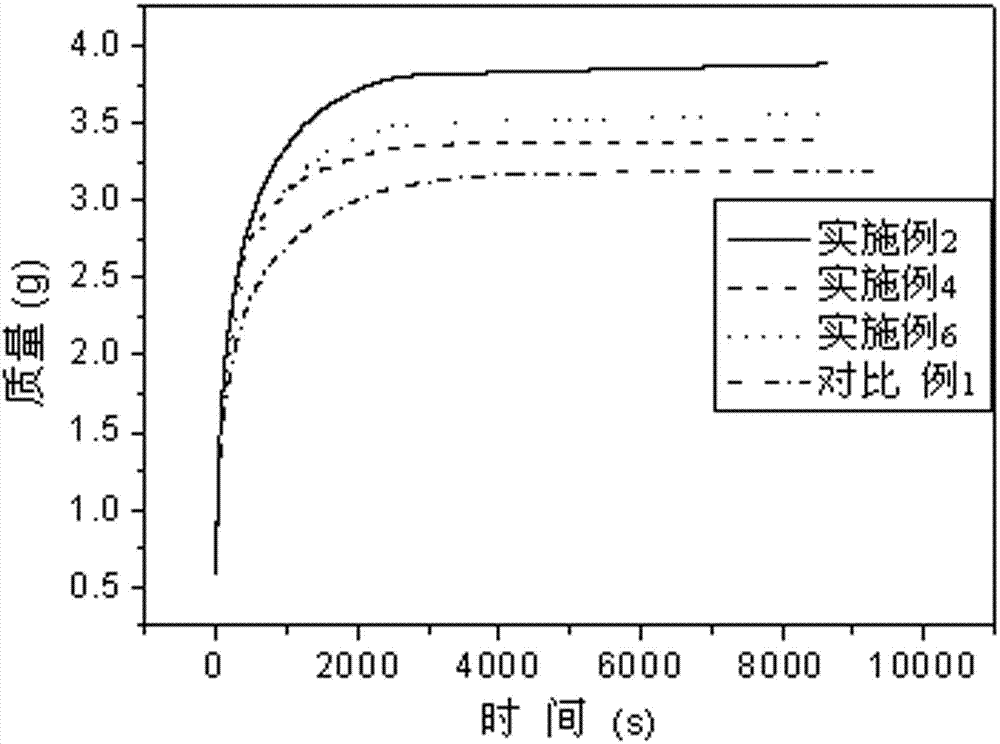

ActiveCN103427113AEnhanced interface energyIncrease liquid absorptionFinal product manufactureElectrolyte accumulators manufacturePolymer electrolytesPorosity

The invention provides a gel polymer electrolyte, a polymer battery containing the same, and a preparation method of the polymer batter. The gel polymer electrolyte comprises polymer, electrolyte, organic solvent, and inorganic stuffing, the electrolyte, organic solvent, and inorganic stuffing disperse in the polymer, wherein the inorganic stuffing is a metal and ceramic compound material. The gel polymer electrolyte has the advantages of higher conductivity, mechanic properties, electrochemical stability and thermostability, and high porosity, and is capable of improving the solution absorption performance of polymer.

Owner:BYD CO LTD

Method for preparing large grain anhydrous sodium sulfate

InactiveCN101007640AExtended induction periodEnhanced interface energyAlkali metal sulfite/sulfate dehydrationPhosphatePolyethylene glycol

The invention discloses a making method of large-particle anhydrous sodium sulfate, which comprises the following steps: adding 0.01%-10% surface activator with one or more of dodecyl phosphate ester, dodecyl sodium benzosulfonate, dodecyl dimethyl amine oxide, phenylethene or carbowax; adding water under 60-260 deg.c; keeping the constant density of solution to react 1.5-3.0h; stopping heating; filtering; drying; obtaining 80% product over 40 order.

Owner:HEBEI UNIVERSITY

Composite inoculant used for grey cast iron and preparation method and application method of composite inoculant

The invention discloses a composite inoculant used for grey cast iron and a preparation method and an application method of the composite inoculant, relating to cast iron alloy. The inoculant is an inoculation refiner that consists of Fe-Ce-Is-Ca intermediate alloy and Fe-B-V intermediate alloy and takes the shape of a nanocrystal sheet. The nanocrystal particle is smaller than 100nm, and the average thickness, the average width and the average length of the sheet respectively range between 0.3-0.5mm, 0.3-0.75mm and 0.9-1.6mm. The preparation method is a fast quenching melt spinning method. The application method is a metal fusion casting process. When used for crystal particle and tissue refining treatment on the grey cast iron alloy tissue of grey cast iron wear resistant parts for engineering machinery, the inoculant overcomes casting defects, and obviously refines matrix crystal particle and cementite phase, thus notably improving the comprehensive mechanical property of grey cast iron alloy.

Owner:HEBEI UNIV OF TECH

High-chromium cast iron composite inoculant, preparation method and application thereof

Owner:TIANJIN LIXINSHENG ADVANCED CASTING

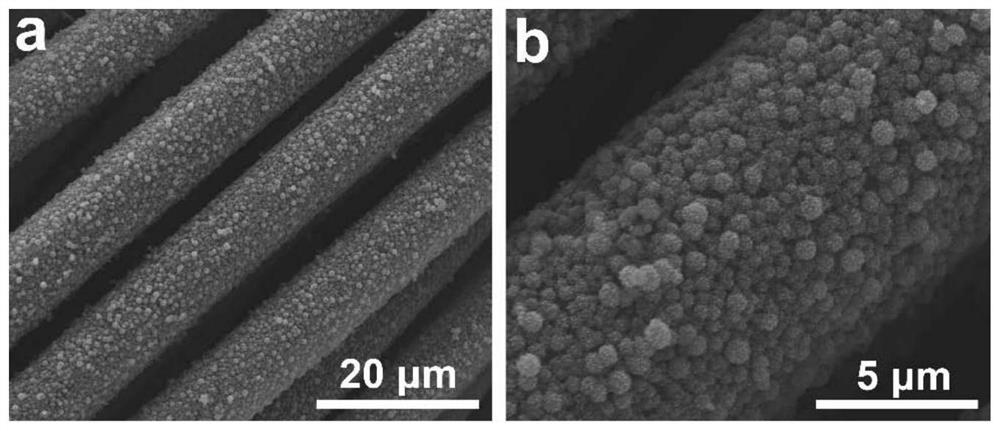

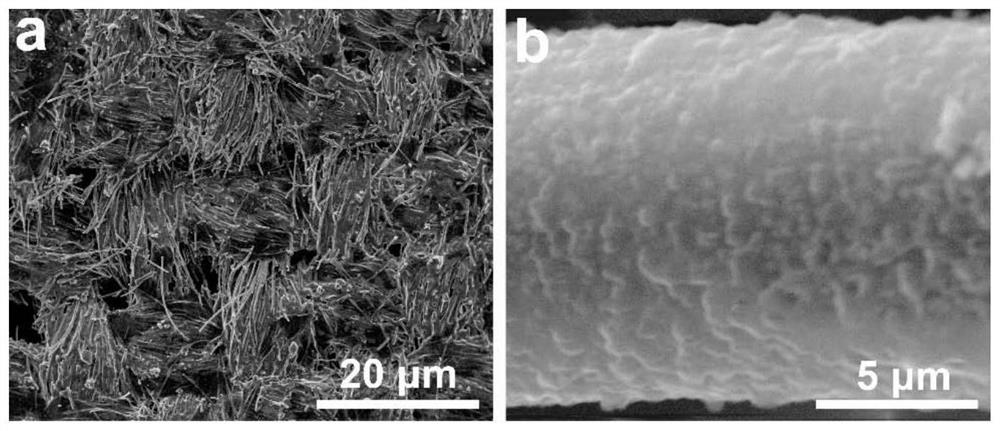

Preparation method of composite lithium metal negative electrode with three-dimensional structure and product thereof

PendingCN114284475AGood flexibilityImprove LithophilicityMaterial nanotechnologyElectrode carriers/collectorsMetallic lithiumFiber

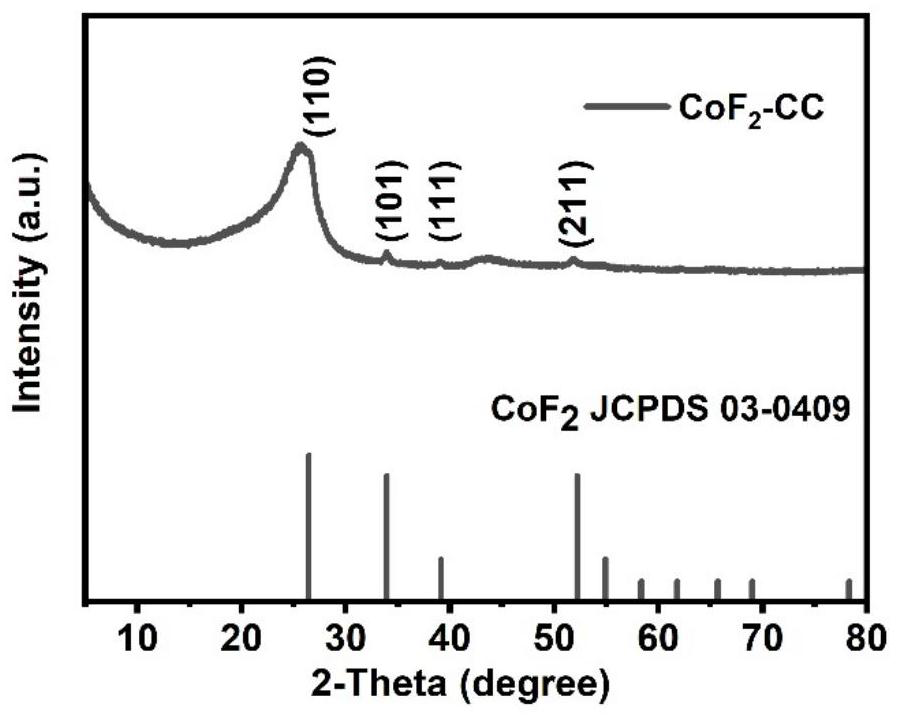

The invention discloses a preparation method of a composite lithium metal negative electrode with a three-dimensional structure and a product of the composite lithium metal negative electrode. An inherent pore structure of carbon fiber cloth taking thin-crystal graphite flakes as pore walls not only can relieve volume change in a lithium deposition / dissolution process, but also can introduce a lithium storage mechanism through a lithium insertion / extraction path; and meanwhile, the carbon cloth has light weight and good flexible mechanical properties, and can inhibit the growth of lithium dendrites. In the lithium electrochemical deposition process, the metal lithium and the cobalt fluoride are subjected to an irreversible reduction reaction to form cobalt nanoparticles and the lithium fluoride; the cobalt nanoparticles have smaller binding energy with the lithium metal, so that nucleation sites can be increased, the nucleation overpotential of the lithium metal is reduced, and uniform diffusion of lithium ions is promoted. The lithium fluoride formed in situ has good interface contact with the carbon fiber cloth, has high mechanical modulus, high chemical stability and high interface energy with lithium, and can uniformize lithium ion flux and effectively inhibit dendritic crystal growth of lithium.

Owner:CENT SOUTH UNIV

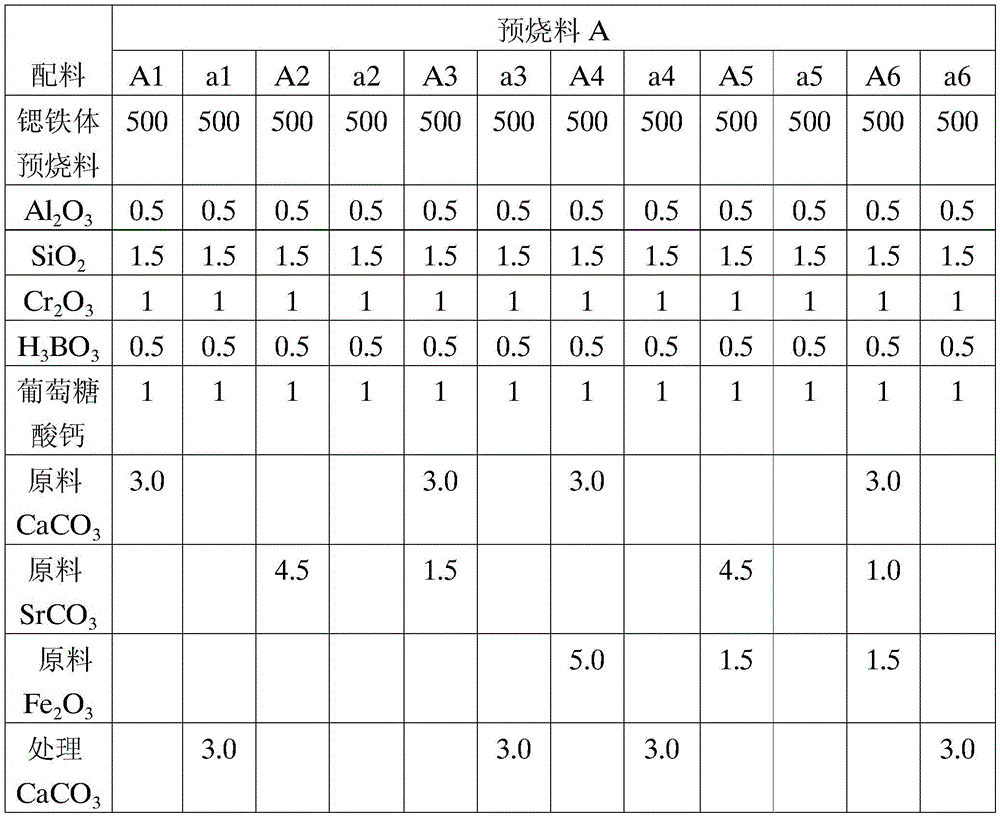

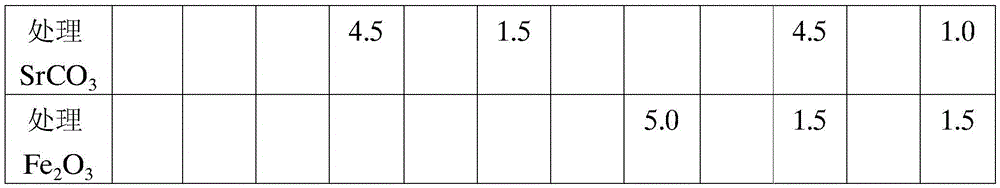

High-coercivity permanent magnetic ferrite and preparation method thereof

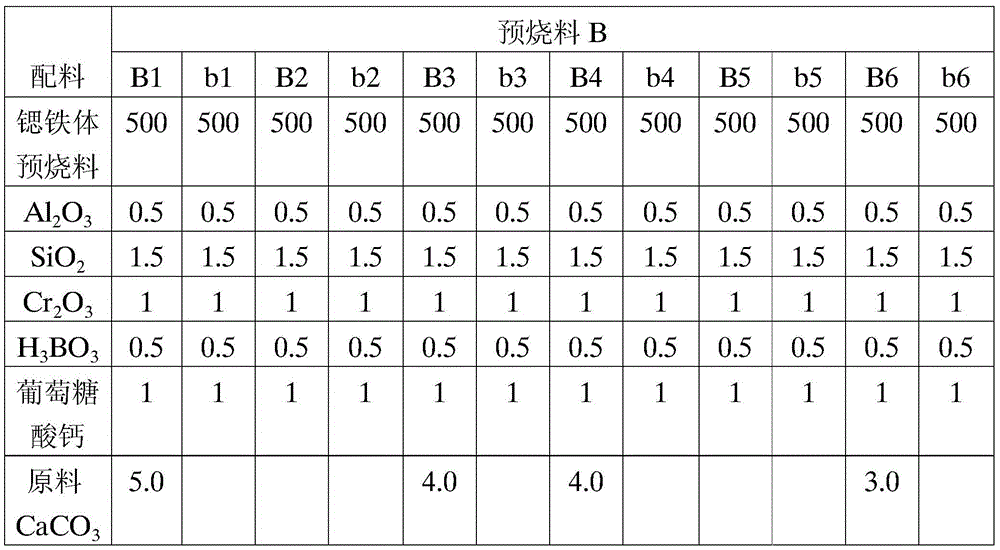

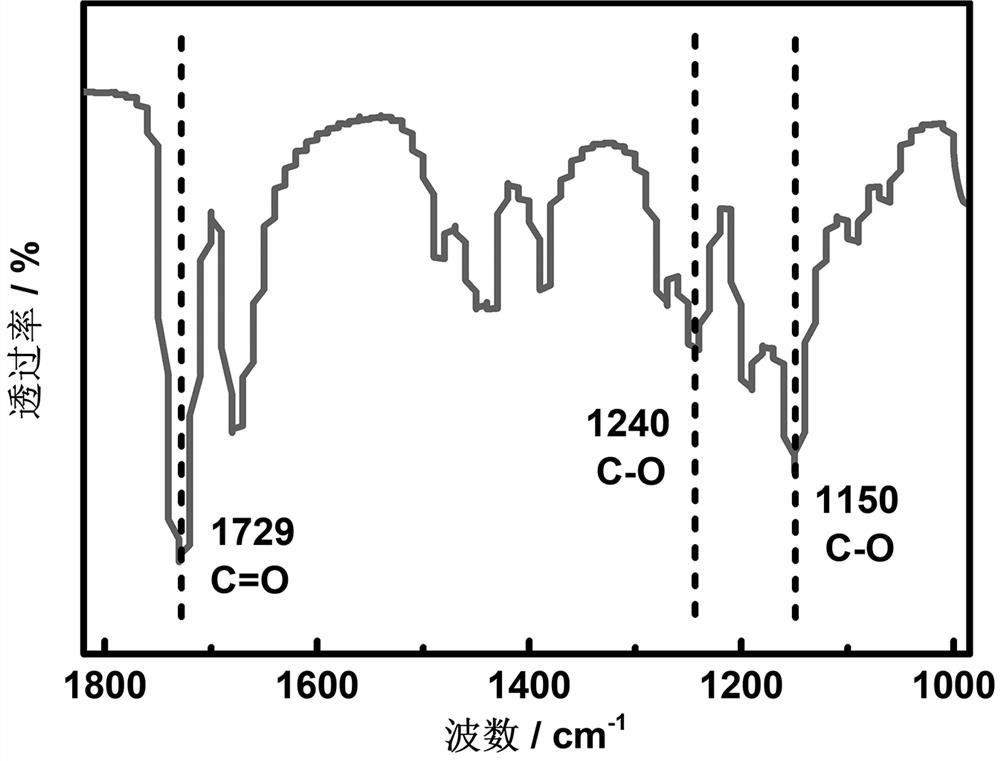

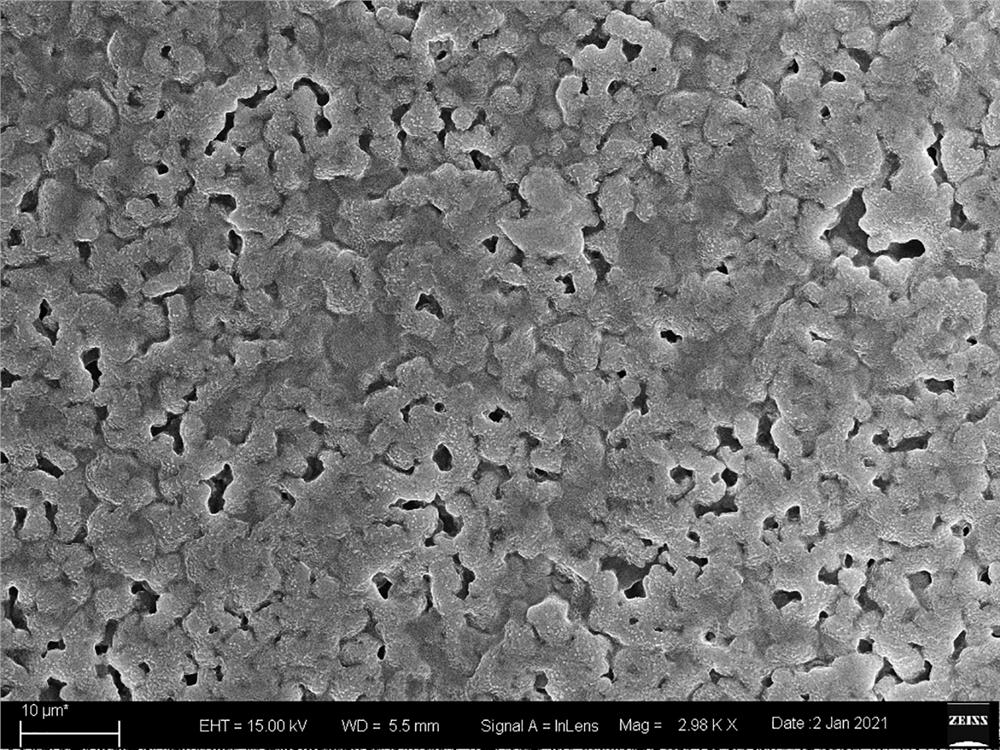

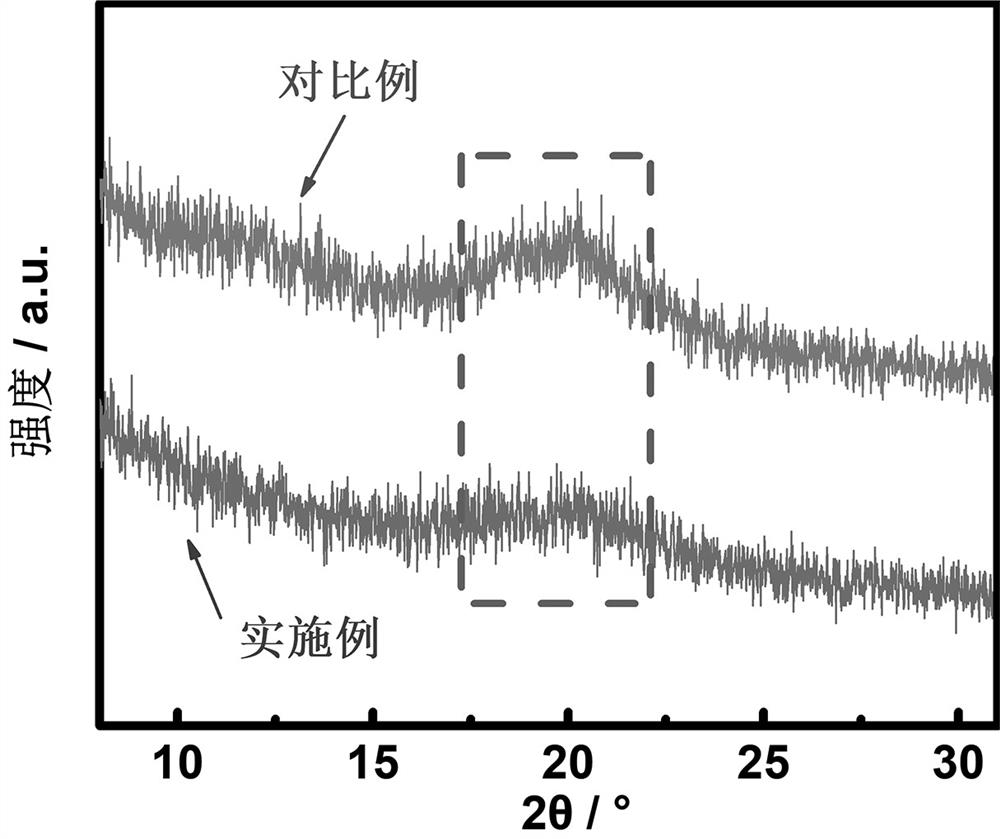

The invention discloses a high-coercivity permanent magnetic ferrite and a preparation method thereof. According to the method, one or a mixture of two or more selected from the group consisting of treated raw materials, i.e., CaCO3, SrCO3 and Fe2O3 are added on the basis of the mass of strontium ferrite pre-sintered material in the procedure of batching, and CaCO3 or SrCO3 is definitely used. The method employs raw materials used in conventional processes and treats the raw materials including CaCO3, SrCO3 and Fe2O3; since one powder selected from or mixed powder of the treated CaCO3, SrCO3 and Fe2O3 is added in the procedure of batching and the powder has substantially increased surface areas and good dispersibility, a contact area is increased and great interfacial energy is produced among pre-sintered ferrite particles after the powder is mixed with the pre-sintered ferrite particles, so growth of ferrite crystal grains is inhibited, the single domain structure of a magnet is maintained, and distribution of crystal grains in the magnet is uniform; and thus, the coercive force of the magnet is improved.

Owner:SINOSTEEL TIANYUAN MAANSHAN TONGLI MAGNETIC MATERIAL

Preparation method of high-performance all-solid-state lithium ion battery

PendingCN113839099AImprove performanceImprove securityFinal product manufactureElectrolyte accumulators manufactureLithium-ion batteryElectronic conductivity

The invention relates to a preparation method of a high-performance all-solid-state lithium ion battery. The invention aims to solve the problem of low conductivity of a diaphragm of the all-solid-state lithium ion battery prepared by the existing method. The method comprises the following steps of 1, preparing a polymer electrolyte precursor solution; 2, preparing a polymer electrolyte precursor solution monomer; 3, preparing the polymer electrolyte precursor solution monomer polymerization; 4, preparing the polymer electrolyte of the all-solid-state lithium ion battery; and 5, assembling the battery. The ionic conductivity sigma of the diaphragm of the all-solid-state lithium ion battery prepared by the method reaches 1.1*10 <-3> S.cm <-1>, the safety performance of the lithium ion battery is greatly improved, and the all-solid-state lithium ion battery has the advantages of high charge / discharge specific capacity, stable cycle performance, safe operation, simplicity and convenience and the like, and is suitable for large-scale preparation and commercial application. The method is applied to the field of all-solid-state lithium ion batteries.

Owner:HARBIN UNIV OF SCI & TECH

High-strength antibacterial polyethylene film and preparation method thereof

ActiveCN113209840AHigh strengthImprove antibacterial propertiesSemi-permeable membranesMembranesPropionatePropanoic acid

The invention discloses a high-strength antibacterial polyethylene film and a preparation method thereof. The polyethylene film is a film formed by taking a polyethylene microporous film as a substrate and an ethylene-vinyl alcohol copolymer film as a surface layer and chemically bonding the polyethylene microporous film and the ethylene-vinyl alcohol copolymer film through polyvinyl alcohol. The high-strength antibacterial polyethylene film has the beneficial effects that a pomegranate extracting solution is added, so that the bonding strength and the antibacterial property are improved; an ethylene-vinyl alcohol copolymer film is prepared as a surface layer by using a water-induced reversed-phase method, and the precipitation of PVP is accelerated and the formation of pores is accelerated by using the synergistic effect between polyhexamethylene guanidine propionate and PVP, so that the time cost is reduced; acid groups in the polyhexamethylene guanidine propionate are utilized, so that the polyhexamethylene guanidine propionate / metal nanoparticles spontaneously move towards the surface of the film to form a hydration layer, and the film is antibacterial and antifouling; and the chelating property of the polyhexamethylene guanidine propionate on the metal nanoparticles is utilized, the polyhexamethylene guanidine propionate is attached to the surfaces of the metal nanoparticles, agglomeration of the metal nanoparticles is inhibited, and the uniform dispersity is improved.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

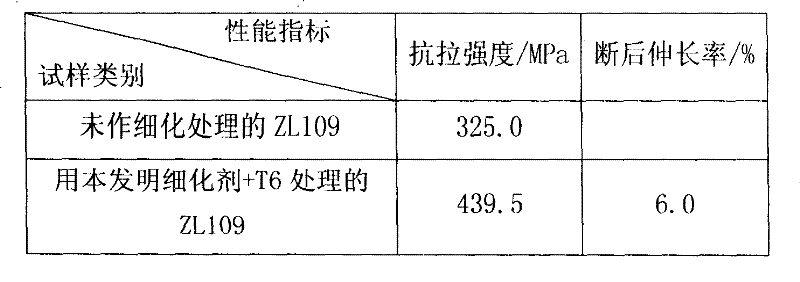

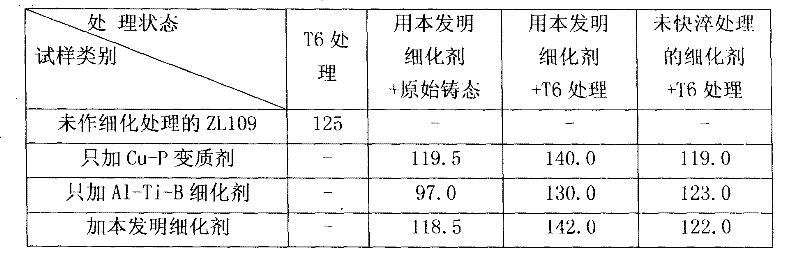

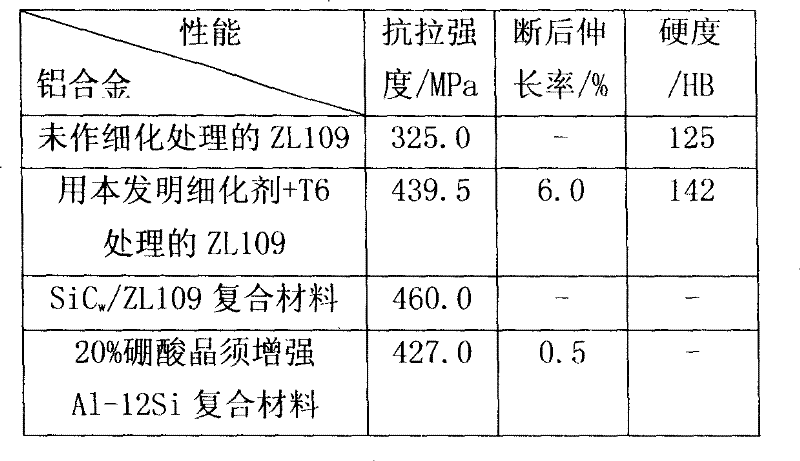

Preparation process and application of grain fining agent for casting aluminium alloy

This invention relates to the crystal grain refining agent which is used to produce aluminium alloy and the method of preparation and application thereof. It is composed of intermediate alloy Cu-P and Al-Ti-B and the crystal grain refine reagent has nanometer crystal band, the weight ratio of the alloy Cu-P to alloy Al-Ti-B is 0.35-0.45:0.65-0.55, the average thickness of bank is 0.3-0.6mm, and the average width is 0.4-1.2mm. The bank is made by quickly quenching flailing. It can be applied to the plunger of the combustion engine by melting metal casting. During the production of aluminium alloy by melting metal, the primary crystal silicon and eutectic silicon can be refined by adding into the crystal grain refine reagent, this increases the energy of interface, so it can decrease the flaw of casting, the over-all properties of the aluminium alloy can be increased. At last, the mechanical property of plunger which is made of aluminium alloy, the abrasion of it and the lifetime of it can improve distinctly.

Owner:HEBEI UNIV OF TECH

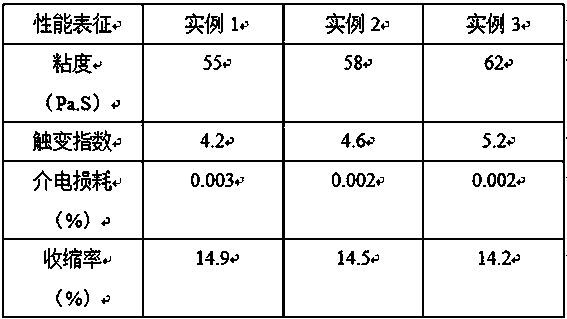

Preparation method for ceramic medium printing sizing agent

InactiveCN108947484AIncrease pressureAchieve defoaming effectCeramic materials productionClaywaresEvaporationSolid surface

The invention relates to a preparation method for a ceramic medium printing sizing agent and belongs to the technical field of printing sizing agents. According to the invention, air bubbles with larger diameters are eliminated through slow mechanical stirring and then a de-foaming agent is used for replacing the bubble walls of the air bubbles, so that the air bubbles with small diameters in thesizing agent are merged into the air bubbles with larger diameters; the pressure in the air bubbles is increased in the manner of vacuumizing and then the air bubbles are separated from the sizing agent and are broken, so that the de-foaming effect can be achieved; when the liquid evaporation pressure is ignored, the interfacial energy of solid-liquid interface is equivalent to the interfacial energy of solid surface according to young's equation, and the wetting property between water and powder can be promoted in the manner of increasing the interfacial energy of ceramic powder surface, so that the purpose of reducing air bubbles can be achieved; in the cooling stage of the preparation process of modified ceramics, the interfacial energy of ceramics can be increased by increasing the cooling speed of the ceramics, so that the air bubbles can be reduced. The ceramic medium printing sizing agent prepared according to the invention has the characteristics of excellent wetting property and few air bubbles, the production equipment is common and the raw material cost is low.

Owner:吴亚琴

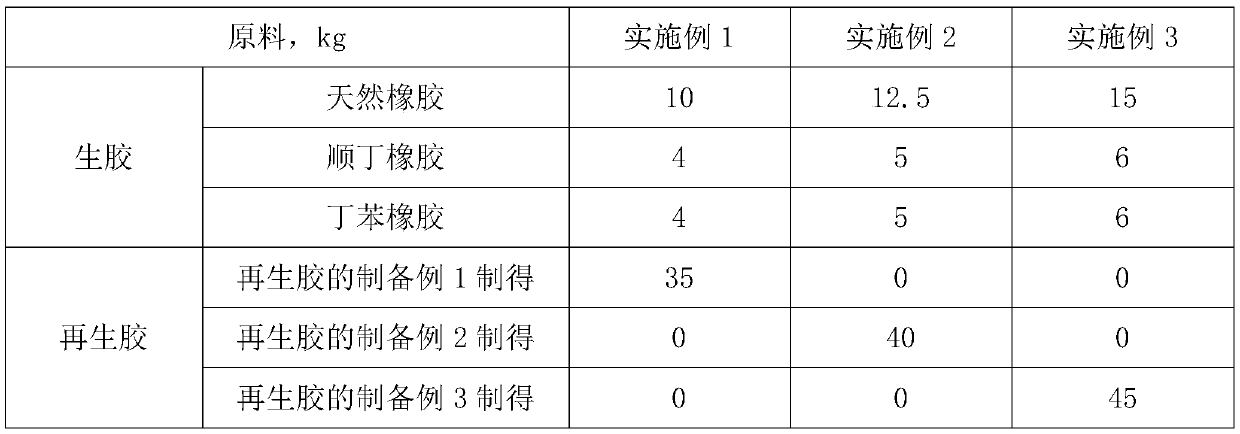

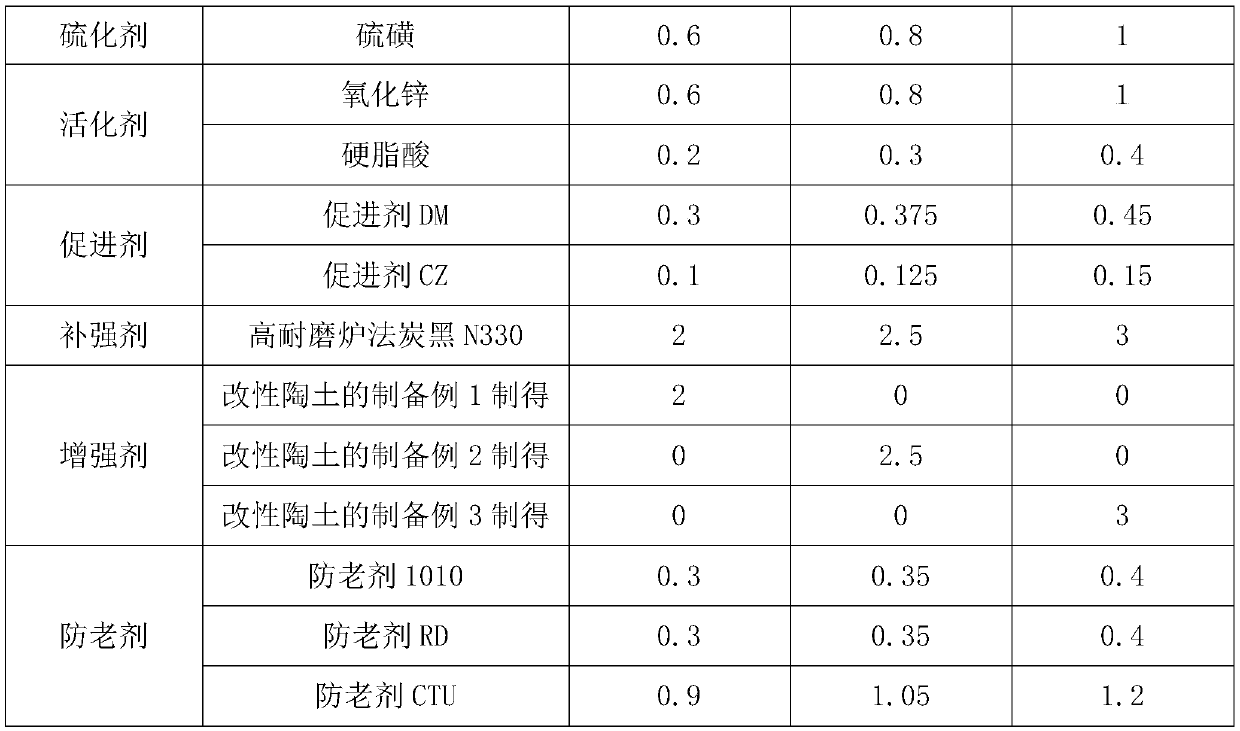

Tread rubber for tire of dune buggy

The invention discloses tread rubber for the tire of a dune buggy. The rubber comprises the following components in parts by weight: 10-15 parts of natural rubber, 8-12 parts of synthetic rubber, 35-45 parts of reclaimed rubber, 0.6-1 parts of sulfur, 0.6-1 parts of zinc oxide, 0.2-0.4 parts of stearic acid, 0.4-0.6 parts of an accelerant, 2-3 parts of carbon black, 2-3 parts of a reinforcing agent and 1.5-2 parts of an anti-aging agent. The reclaimed rubber is prepared by the following method: a, crushing waste tires to obtain waste rubber powder; b, adding a softener and a regenerant into the waste rubber powder, and performing banburying for 10-15 min at the temperature of 110-130 DEG C; and adding the reinforcing agent and the plasticizer to mix for 10-15 minutes at the temperature of50-60 DEG C, and performing cooling to obtain the reclaimed rubber. The tread rubber provided by the invention has the advantages of low cost, good wear resistance and good tear resistance.

Owner:宁波市骏凯橡胶工贸有限公司

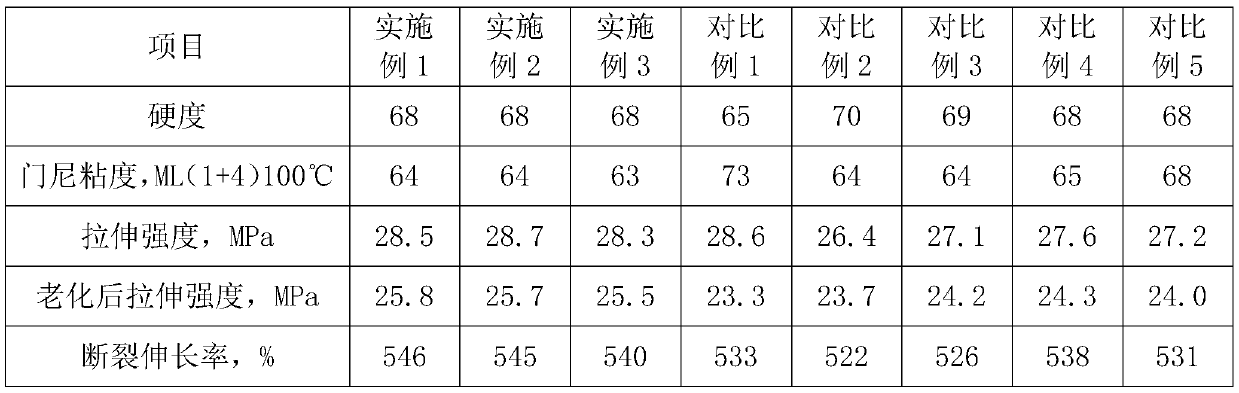

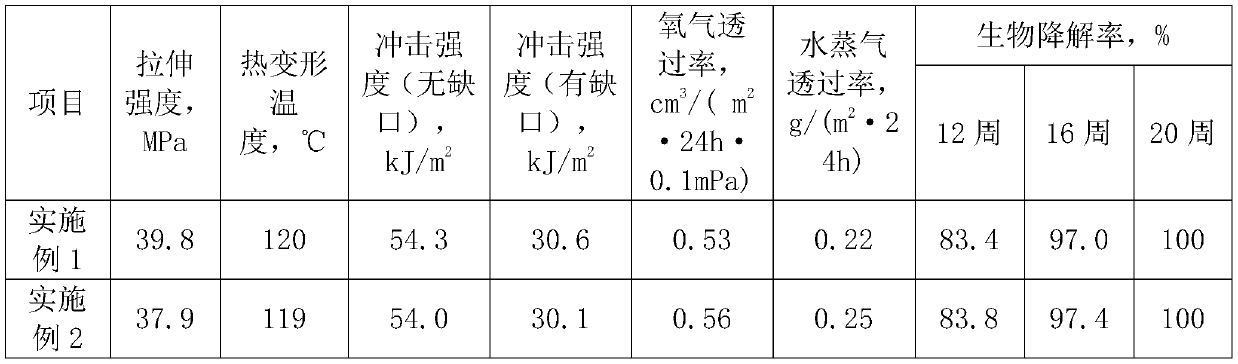

Fully-biodegradable high-barrier sheet for coffee capsule cup body, and preparation method thereof

InactiveCN111114078AGood barrier to water and oxygenImprove water and oxygen barrier performanceSynthetic resin layered productsDomestic containersPolymer scienceThermal deformation

The invention discloses a fully-biodegradable high-barrier sheet for a coffee capsule cup body, and a preparation method thereof, and relates to the technical field of packaging materials. The sheet is of a five-layer structure and comprises an inner film layer, bonding layers arranged on two sides of the inner film layer and base material layers arranged on ones side, away from the inner film layer, of the bonding layers; the raw materials of the inner film layer comprise high-barrier degradable resin; the raw material of the bonding layer is degradable bonding resin; the raw material of thebase material layer is fully-degradable plastic; the high-barrier degradable resin is BVE8049 provided by Japanese synthetic chemistry; and the degradable adhesive resin is BTR8002P provided by Japanese synthetic chemistry. The sheet provided by the invention has excellent degradability, water and oxygen barrier property and fragrance retention property, and good impact resistance and thermal deformation resistance.

Owner:周锐

Cold field plasma discharge assisted high energy ball milling powder device

The invention provides an application method of cold field plasma discharge assisted high energy ball milled powder and a plasma assisted high energy ball milling device using the cold field plasma discharge assisted high energy ball milling method. The method comprises the following steps: utilizing dielectric barrier discharge to generate plasmas, introducing a dielectric barrier discharge electrode bar into a high-speed vibrating ball-milling tank, on one hand, requiring a solid insulating medium on the outer layer of the electrode bar to simultaneously bear high-voltage discharge and mechanical shock failure of the grinding ball, and on the other hand, requiring the high-speed vibrating ball milling device to uniformly process the powder. The method is based on the ordinary ball milling technology; the processing efficiency and the effect of the ball mill can be greatly improved by the following steps: under a non-heat-balance discharge condition of the pressure that the discharge space pressure is set to be about 102-106 Pa, introducing the discharge plasmas to input another effective energy to the processed powder, promoting the powder to be processed to be subjected to combined action of the mechanical stress effect and the heat effect of the external electric field, and further accelerating refining of the powder and promoting the alloying progress.

Owner:SOUTH CHINA UNIV OF TECH

Construction of up-conversion material combined signal quenching sensing device

ActiveCN114674892ALow costExperiment operation is simplePhotovoltaic energy generationMaterial electrochemical variablesPhotocurrentElectron transfer

The invention discloses a construction method of an up-conversion material combined signal quenching sensing device, which is characterized in that NaYF4: Yb, Er (at) Bi2MoO6 (at) Bi which can be excited by near-infrared light and has good photoelectrochemical signals is synthesized, and NaYF4: Yb and Er are used as one of the up-conversion materials and have excellent light transmission, low light damage and high light stability; meanwhile, in NaYF4: Yb, Er (at) Bi2MoO6 (at) Bi, plasma Bi serves as an optical concentrator and an energy conveyor, and the absorption cross section and the interface energy of an up-conversion system can be effectively improved; the sensing system is excited by near-infrared light, and the near-infrared light has the advantages of low phototoxicity and corrosivity and minimum photobleaching; in addition, Au (at) CeO2 is modified on the second antibody to serve as a signal amplification carrier, electron transfer can be effectively hindered and light current can be reduced through the steric hindrance effect brought by introduction of a second antibody marker Au (at) CeO2, meanwhile, Au (at) CeO2 can also serve as simulated peroxidase to effectively catalyze 4-chloro-1-naphthol to generate corresponding precipitates, the light current is further reduced, and the sensitivity of the sensor is improved.

Owner:UNIV OF JINAN

Gel polymer electrolyte and polymer battery and preparation method thereof

ActiveCN103427113BImprove conductivityImprove electrochemical stabilityFinal product manufactureElectrolyte accumulators manufacturePorosityPolymer science

The invention provides a gel polymer electrolyte, a polymer battery comprising the gel polymer electrolyte, and a preparation method of the polymer battery. The gel polymer electrolyte contains polymer, electrolyte, organic solvent and inorganic filler, and the electrolyte, organic solvent and inorganic filler are dispersed in the polymer, wherein the inorganic filler is a metal-ceramic composite material. It has high electrical conductivity, high mechanical properties, electrochemical stability and thermal stability, and can improve the liquid absorption performance of polymers, and has high porosity.

Owner:BYD CO LTD

Method for preparing large grain anhydrous sodium sulfate

InactiveCN100450929CExtended induction periodEnhanced interface energyAlkali metal sulfite/sulfate dehydrationPhosphatePolyethylene glycol

The invention discloses a making method of large-particle anhydrous sodium sulfate, which comprises the following steps: adding 0.01%-10% surface activator with one or more of dodecyl phosphate ester, dodecyl sodium benzosulfonate, dodecyl dimethyl amine oxide, phenylethene or carbowax; adding water under 60-260 deg.c; keeping the constant density of solution to react 1.5-3.0h; stopping heating; filtering; drying; obtaining 80% product over 40 order.

Owner:HEBEI UNIVERSITY

Preparation method of yogurt adhesion-free cover

InactiveCN107955521AReduce adhesionReduce hydrophilicityMetallic material coating processesPorosityAluminium hydroxide

The invention relates to the field of packaging material preparation, in particular to a method for preparing non-stick yogurt lids. In the present invention, the self-made polyamic acid sol is mixed with tetraethyl orthosilicate and tert-butanol, and after aging, it is mixed and dispersed with silica sol to obtain a composite sol, and aluminum foil is immersed in the composite sol to form a nanometer-sized hybrid film , the silicon hydroxyl group of silica in the hybrid film is destroyed, and the hydrophilic property decreases, so that the yogurt cover has hydrophobic properties, thereby reducing the adhesion of yogurt on the cover, and the silica freeze-dried gel has a high specific surface area and high porosity , leading to low thermal conductivity, aluminum hydroxide powder and silica lyophilized gel are mixed to obtain mixed rubber powder, so that the whole yogurt non-stick cover forms a stable system, and the yogurt cover with high specific surface area has an inhibitory effect on the evaporation of water in yogurt , so that the solid content of the yogurt is not easy to deposit, and the density of the yogurt is uniform when it flows, so that the yogurt will not stick to the lid, and the application prospect is broad.

Owner:仇颖超

A kind of high-strength antibacterial polyethylene film and preparation method thereof

ActiveCN113209840BHigh strengthImprove antibacterial propertiesSemi-permeable membranesMembranesHydration reactionPropanoic acid

The invention discloses a high-strength antibacterial polyethylene film and a preparation method thereof. The polyethylene film is a film formed by chemically bonding the polyethylene microporous film and the ethylene-vinyl alcohol copolymerized film with the polyethylene microporous film as the base and the ethylene-vinyl alcohol copolymerized film as the surface layer. Beneficial effects: Add pomegranate extract to increase bond strength and antibacterial properties; use water-induced reverse phase method to prepare ethylene-vinyl alcohol copolymer film as the surface layer, and utilize the synergistic effect between polyhexamethylene guanidine propionate and PVP, Accelerate the precipitation of PVP, accelerate the formation of pores, and reduce time costs; use the acidic groups in polyhexamethyleneguanidine propionate to make polyhexamethyleneguanidine propionate / metal nanoparticles move spontaneously to the membrane surface to form a hydration layer , Antibacterial and antifouling; use polyhexamethylene guanidine propionate to chelate metal nanoparticles, attach to the surface of metal nanoparticles, inhibit the agglomeration of metal nanoparticles, and increase uniform dispersion.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

Preparation method of silicon carbide ceramic sealing material

The invention belongs to the technical field of preparation of sealing materials and particularly relates to a preparation method of a silicon carbide ceramic sealing material. The preparation methodtakes rice husk ash as a raw material and comprises the following steps: adding palm wax and peels to obtain fermentation filter dreg; mixing the fermentation filter dreg and diamond grains to obtainridged powder; putting the rigid powder into a muffle furnace and roasting to obtain self-lubricating silicon carbide micro-powder; mixing the self-lubricating silicon carbide micro-powder with additives including maganthophyllite powder, white corundum, walnut shell powder and the like to obtain a material to be sintered; finally, putting the material to be sintered into a graphite mold to obtainthe silicon carbide ceramic sealing material. Nitrogen-containing composite powder and a boron-containing ceramic binding agent are mixed and then are hotly pressed and sintered to form a hexagonal boron nitride crystal, so that the wear-resisting performance and self-lubricating performance of the sealing material are improved; the fermentation filter dreg containing the rice husk ash is reducedand carbonized on the surface of a diamond, and the densification of the sealing material is promoted; then a polytetrafluoroethylene film is sprayed to form an impermeable lubricating protection layer on the surface of the sealing material; the silicon carbide ceramic sealing material has a wide application prospect.

Owner:陈天姿

Method for preparing WC-Co series nano composite hard alloy powder

The invention provides a preparation method for a nanocomposite hard alloy powder of WC-Co series. The preparation method comprises the following steps: a front covering board and electrode rods provided with a ball mill pot are respectively connected with both poles of a plasma power; the ball mill pot is provided with a mill ball and W, C, Co material in a certain proportion, and a back cover board is covered when the electrode rods are contacted with W, C and Co materials; the airtight ball mill pot is exhausted to a negative pressure of 0.01 to 0.1Pa by a vacuum valve, or filled with a discharge gas dielectric by the vacuum valve after the ball mill pot is exhausted to negative pressure until the pressure is 0.01 to 0.1MPa; then the ball mill pot is electrified with the plasma power, and discharge parameters are regulated according to the discharge gas and the pressure of the discharge gas, thus being high-energy ball milled for different types of corona discharge plasmas; finally, the mixing powder of W, C and Co is taken out and placed into a thermal source environment for synthesis reaction, and the hard alloy is prepared. The invention can not only save energy, but also improve the synthesis efficiency.

Owner:SOUTH CHINA UNIV OF TECH

High energy ball mill method with plasma aid

A plasma aided high-energy ball grinding method includes such steps as installing the front cover plate and rod electrode of ball grinder, respectively connecting the ball grinder and rod electrode to the poles of plasma power supply, loading the powder to be ground in the ball grinder, pumping negative pressure, filling discharging gas medium, turning on the plasma power supply, regulating discharge parameters for corona discharge or glow discharge, and turning on the motor to drive the vibration exciting block for ball grinding.

Owner:SOUTH CHINA UNIV OF TECH

Flaky metal oxide and its controllable synthesis method and application

ActiveCN108529691BSimple processShort processIron oxides/hydroxidesManganese oxides/hydroxidesManganeseCarboxylic acid

The invention provides a flake metal oxide and its controllable synthesis method and application, comprising the steps of: adding a template agent into deionized water, and continuously stirring until the medicine is completely dissolved; the template agent is 2-methylimidazole or terephthalic acid Or 1,2,3,4-butane tetracarboxylic acid; metal salt is added to the above solution and continuously stirred, and the metal salt is an inorganic metal salt or acetylacetonate containing one of cobalt, nickel, manganese, zinc, and iron; The above-mentioned prepared solution is transferred to an oil bath for reaction, the above-mentioned product is cooled to room temperature, washed, dried, then put into a tube furnace for calcination, and finally a sheet-like metal oxide is obtained; the present invention has prepared The lithium battery anode material with a sheet shape adopts the static precipitation method, which is simple, reliable, and controllable. This structure can expand the interaction between the electrode and the electrolyte, enhance the surface and interface energy, offset the capacity loss, and provide a negative electrode material with high lithium battery performance.

Owner:SINOCAT ENVIRONMENTAL TECH

Sm2Co17 type rare earth permanent magnet material and preparation method thereof

ActiveCN113539596AExpanding the Scope of Ingredient DesignIncrease Fe contentInductances/transformers/magnets manufactureMagnetic materialsMetallurgySamarium cobalt

The invention relates to a Sm2Co17 type rare earth permanent magnet material and a preparation method thereof. The Sm2Co17 type rare earth permanent magnet material consists of the following components in percentage by mass: Sm, heavy rare earth, Co, Fe, Cu and Zr. The preparation method comprises the following steps: preparing a samarium cobalt-based rare earth permanent magnet material sintered blank, heating the sintered blank to 1150-1200 DEG C by adopting microwaves at a heating speed of 15-90 DEG C / min in a protective atmosphere, carrying out solid solution and heat preservation, rapidly cooling by circulating gas to obtain a microwave solid solution blank, heating the solid solution blank to 820-880 DEG C by adopting microwaves at a heating speed of 15-90 DEG C / min, carrying out aging and heat preservation for 20-170min, and cooling. The method is reasonable in process design and convenient to operate, the preparation period of the Sm2Co17 type rare earth permanent magnet material can be greatly shortened, the prepared Sm2Co17 type rare earth permanent magnet material is better in magnetic performance, and remarkable industrial application value and economic benefits are achieved.

Owner:CENT SOUTH UNIV

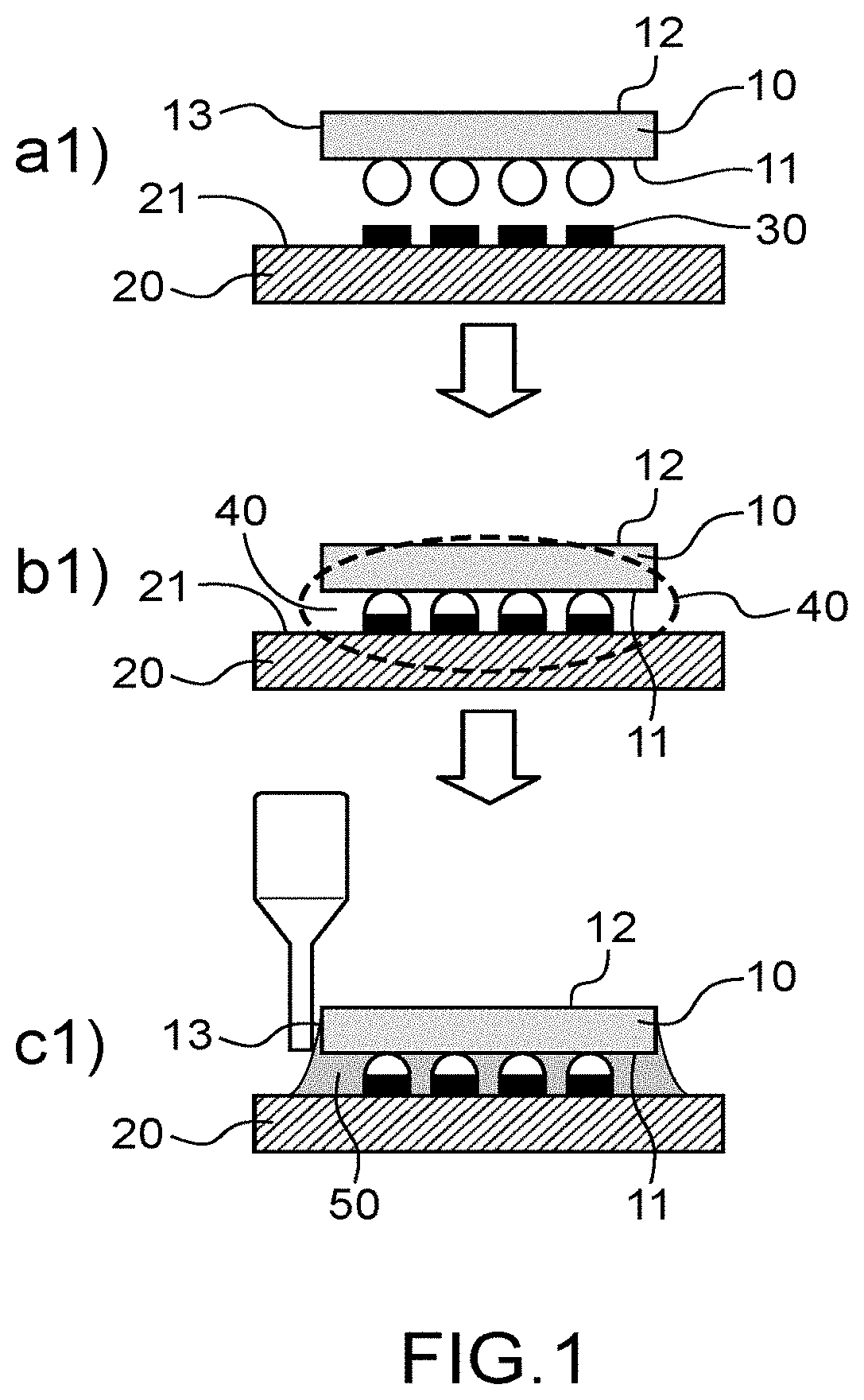

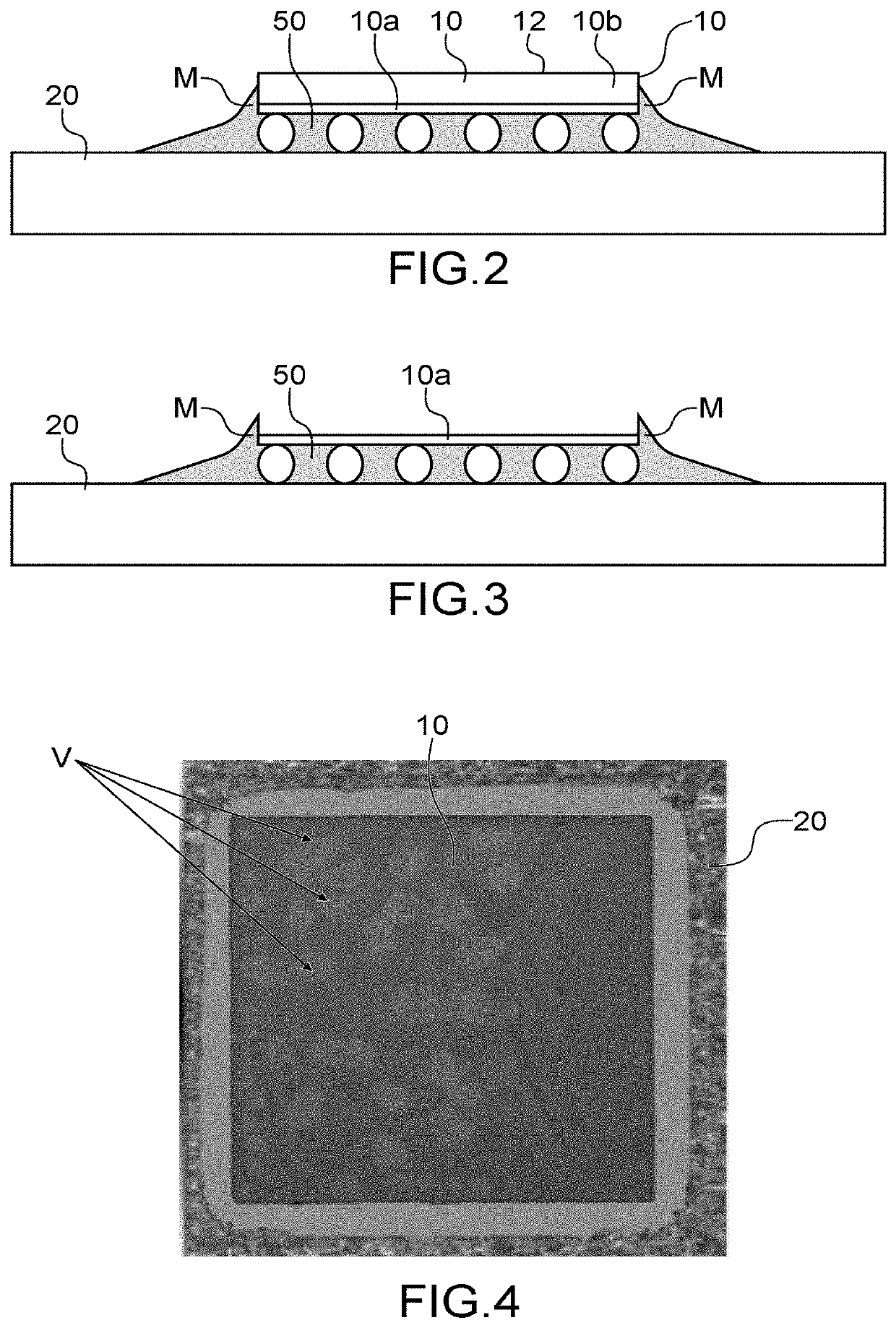

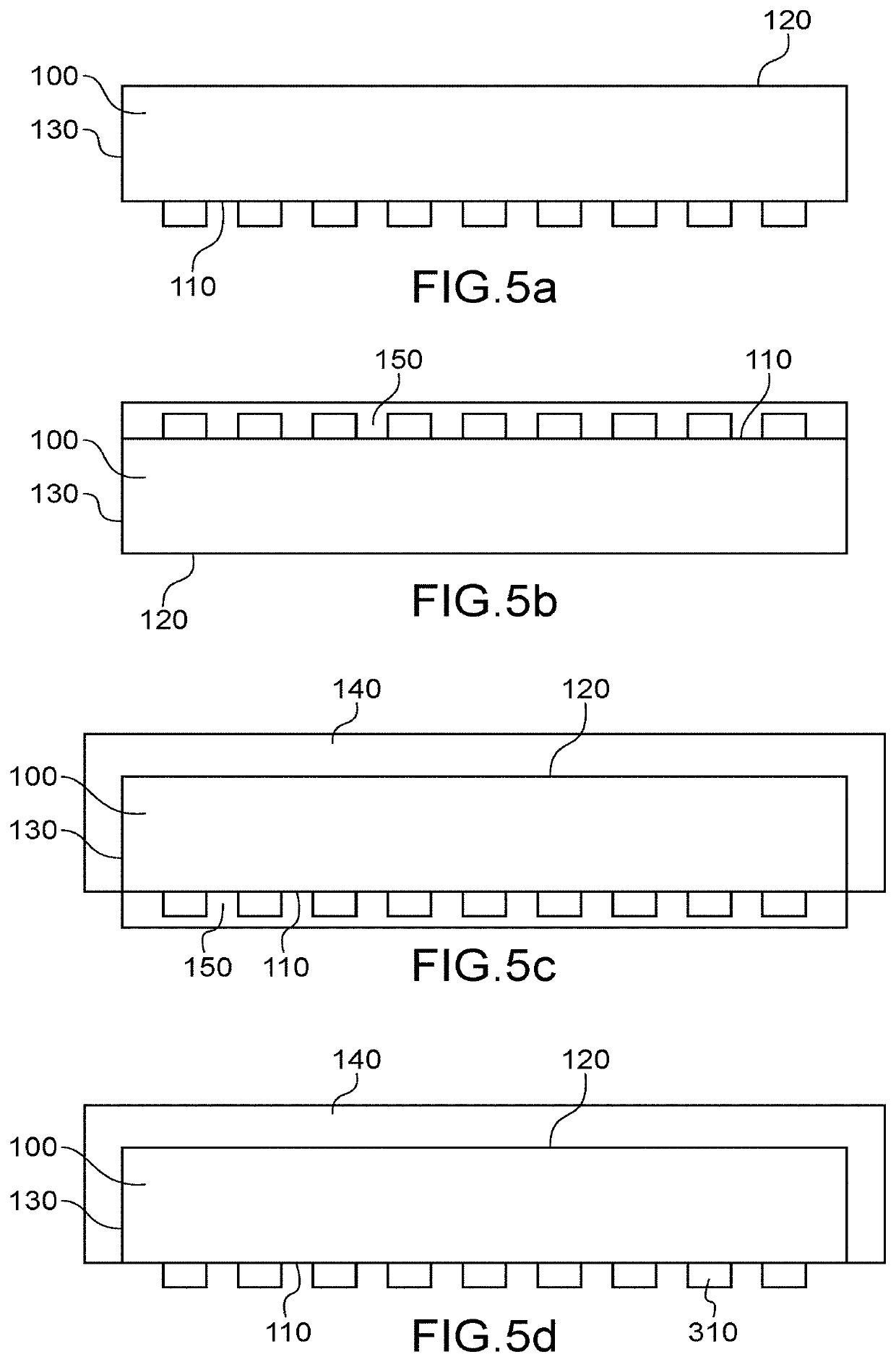

Method for manufacturing a structure

PendingUS20220189910A1Improve wettabilityLimit wettingSemiconductor/solid-state device detailsSolid-state devicesAdhesive glueEngineering

A method for manufacturing a structure includes: supplying an active element provided with a front and rear face connected by a contour; assembling the front face and a main face of a support; filling a space of interconnections between the front face and the main face with glue. The method also includes, before the assembling, forming, by a method other than a plasma method, a first passivation layer covering the contour, and made from a first compound that makes it possible to limit the wetting of said contour by the glue regarding the front face and the main face.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Composite inoculant used for grey cast iron and preparation method and application method of composite inoculant

The invention discloses a composite inoculant used for grey cast iron and a preparation method and an application method of the composite inoculant, relating to cast iron alloy. The inoculant is an inoculation refiner that consists of Fe-Ce-Is-Ca intermediate alloy and Fe-B-V intermediate alloy and takes the shape of a nanocrystal sheet. The nanocrystal particle is smaller than 100nm, and the average thickness, the average width and the average length of the sheet respectively range between 0.3-0.5mm, 0.3-0.75mm and 0.9-1.6mm. The preparation method is a fast quenching melt spinning method. The application method is a metal fusion casting process. When used for crystal particle and tissue refining treatment on the grey cast iron alloy tissue of grey cast iron wear resistant parts for engineering machinery, the inoculant overcomes casting defects, and obviously refines matrix crystal particle and cementite phase, thus notably improving the comprehensive mechanical property of grey castiron alloy.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com