High energy ball mill method with plasma aid

A plasma and high-energy ball milling technology, applied in grain processing, etc., can solve the problems of low input mechanical energy of powder, long time required for processing, serious powder agglomeration, etc., and achieve shortened time required, large deformation and fine grain short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

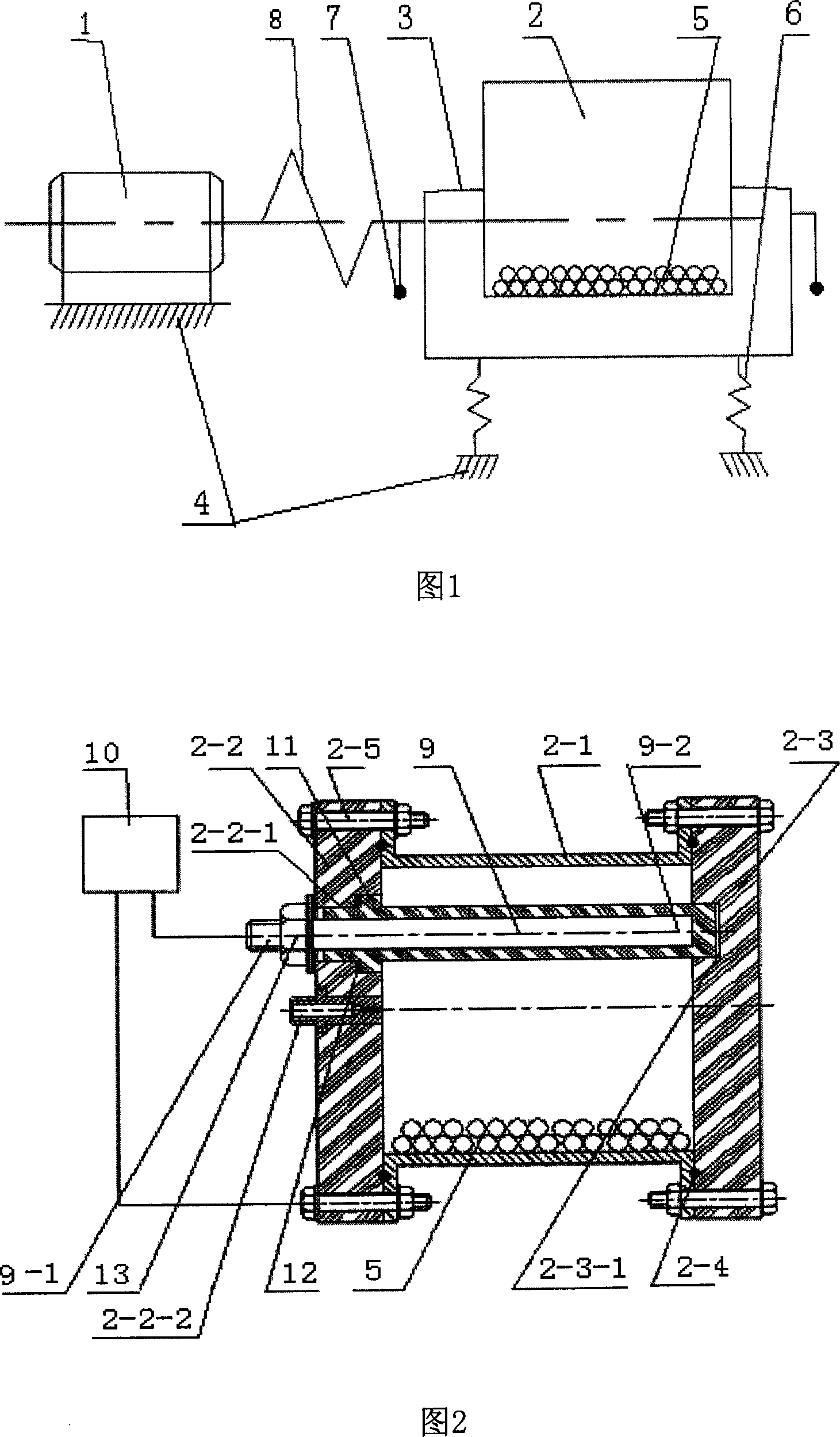

[0029] As shown in Figure 1, realize the plasma-assisted high-energy ball milling device of the present invention, comprise driving motor 1, ball mill jar 2, frame 3, base 4, ball mill jar 2 is installed on the frame 3, and grinding ball 5 is placed inside it , The frame 3 is installed on the base 4 through the spring 6, and an excitation block 7 is arranged on the outside thereof. The drive motor 1 is installed on the base 4, and is connected with the frame 3 and the excitation block 7 through an elastic coupling 8, respectively.

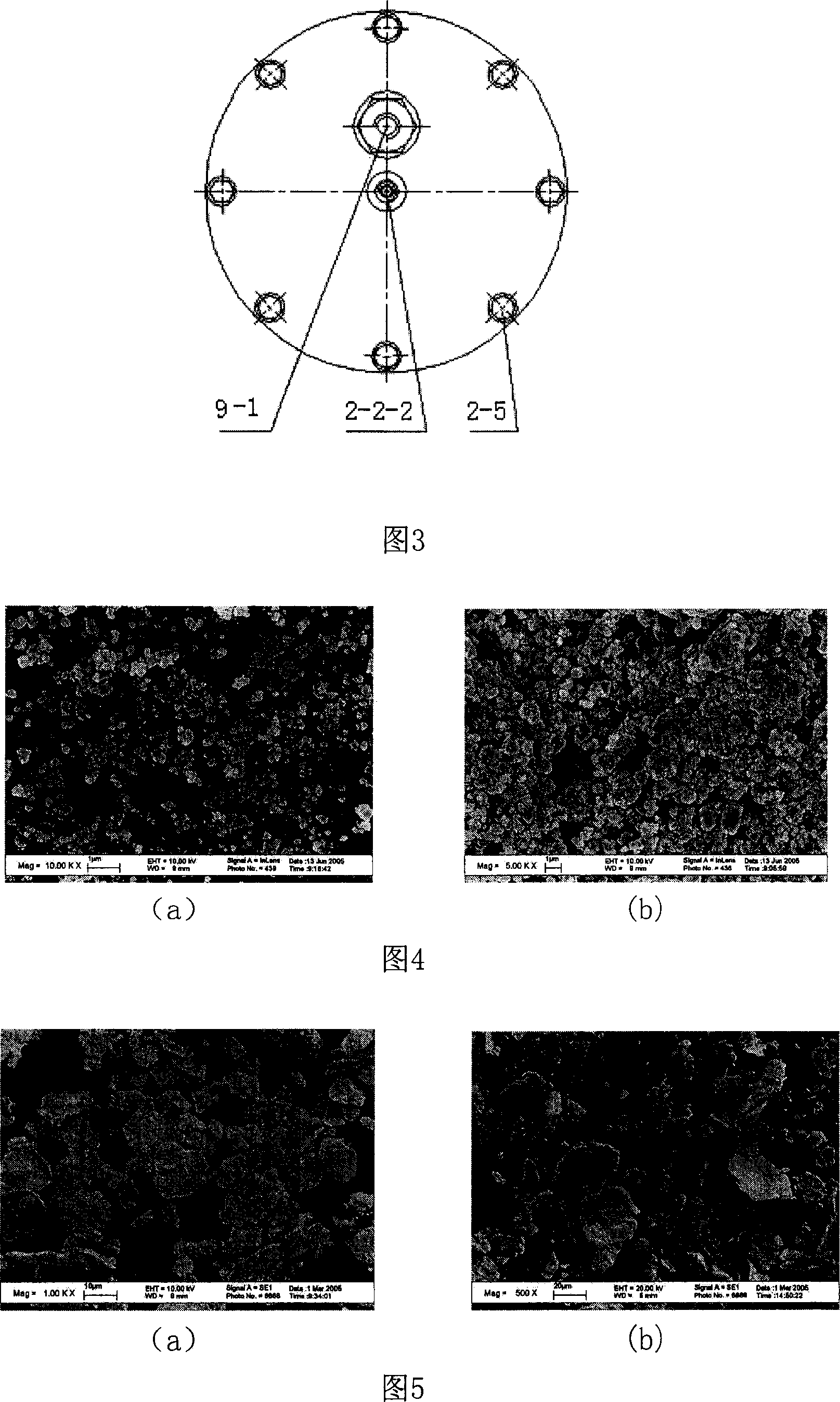

[0030] As shown in Figures 2 and 3, the grinding ball 5 is placed in the ball milling tank 2, and the ball milling tank 2 is also connected with an electrode rod 9 and a plasma power supply 10. The ball milling tank 2 includes a cylinder body 2-1, a front cover plate 2-2, The rear cover 2-3, the flanges at both ends of the cylinder body 2-1 are respectively sealed and connected with the front cover 2-2 and the rear cover 2-3 through the sealing ring...

Embodiment 2

[0040] Using the device of Example 1, the process conditions of this plasma-assisted high-energy ball milling method are basically the same as those of Implementation 1, except that the total volume of balls accounts for 75% of the volume of the ball milling tank, and balls with a diameter of 22 mm account for 75% of the total ball milling volume. 15%, grinding balls with a diameter of 18mm accounted for 75% of the total number of grinding balls, grinding balls with a diameter of 10mm accounted for 10% of the total number of grinding balls, and the loose volume of the powder to be processed accounted for 130% of the gap between the grinding balls; the negative pressure of the ball mill tank to 0.01Pa; the discharge voltage is 3kv, the frequency is 5kHz to realize corona discharge; the excitation block adopts 10mm double amplitude, and the motor speed is 930r / min.

Embodiment 3

[0042] Using the device of Example 1, the process conditions of this plasma-assisted high-energy ball milling method are basically the same as those of Implementation 1, except that the total volume of balls accounts for 72% of the volume of the ball milling tank, and balls with a diameter of 20 mm account for 72% of the total ball milling volume. 12%, grinding balls with a diameter of 18mm accounted for 78% of the total number of grinding balls, grinding balls with a diameter of 10mm accounted for 10% of the total number of grinding balls, and the loose volume of the powder to be processed accounted for 80% of the gap between the grinding balls; the negative pressure of the ball mill tank to 0.05Pa; the discharge voltage is 10kv, the frequency is 20kHz, and corona discharge is realized; the excitation block adopts 8mm double amplitude, and the motor speed is 930r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com