Preparation method of composite lithium metal negative electrode with three-dimensional structure and product thereof

A three-dimensional structure, metal negative electrode technology, applied in structural parts, battery electrodes, electrode carriers/collectors, etc., can solve Coulombic efficiency and battery capacity decay, hinder the practical application of lithium metal batteries, and unstable solid electrolyte membranes. Achieve the effects of inhibiting dendrite growth, reducing nucleation overpotential, and improving lithium-friendly performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

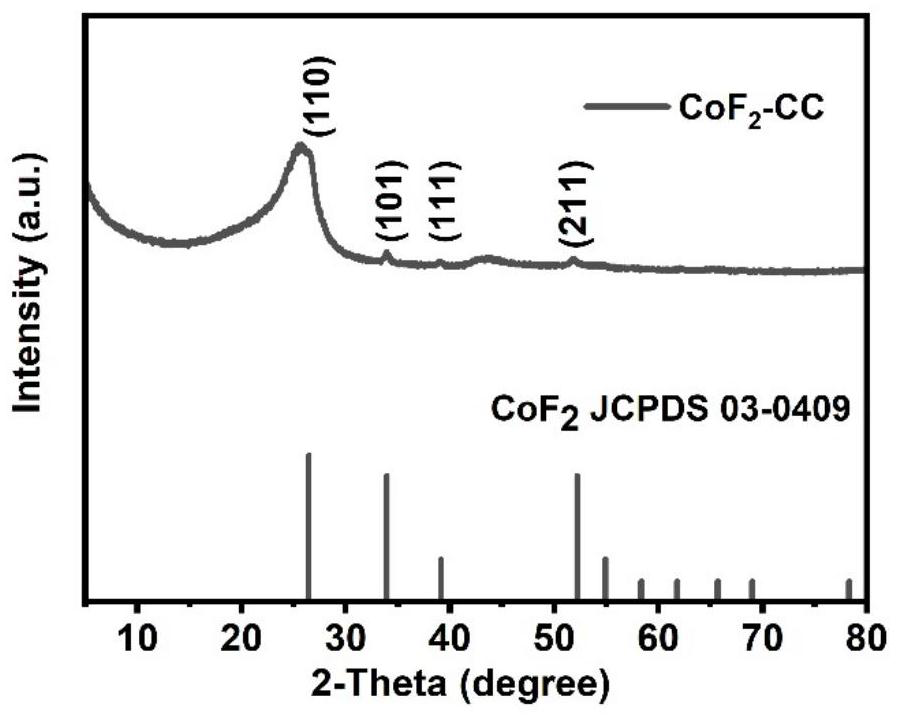

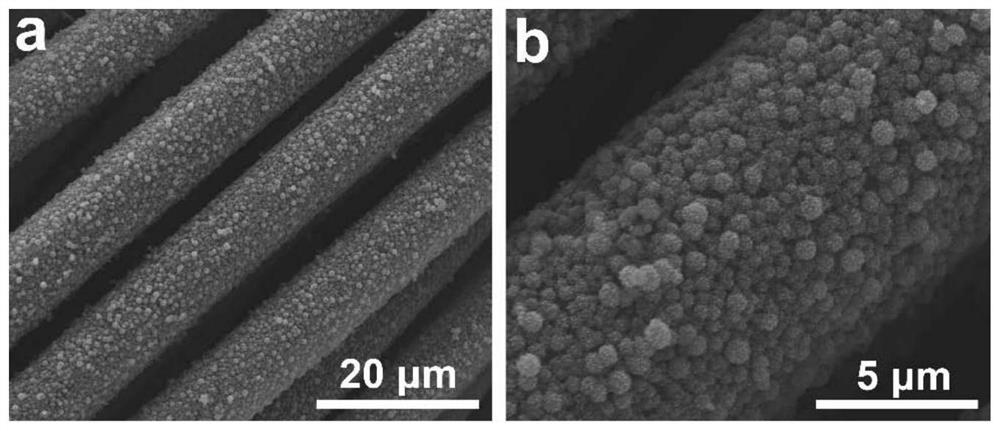

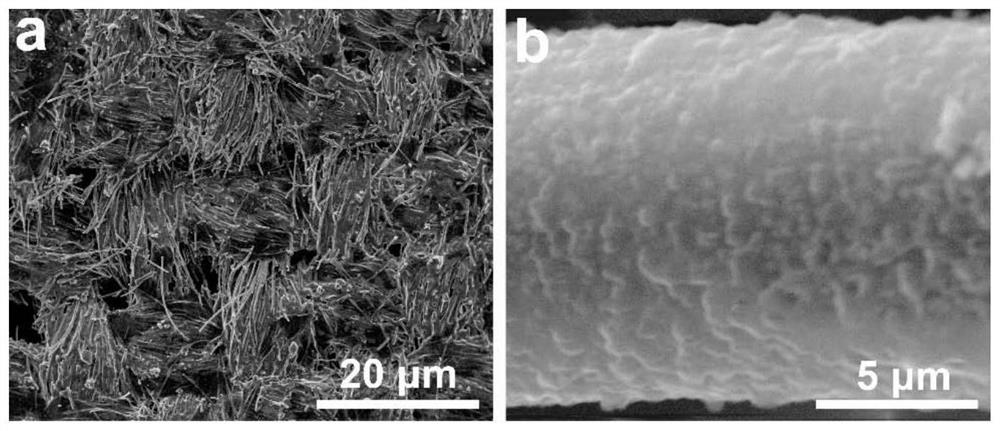

[0027] The carbon fiber cloth was soaked in concentrated nitric acid (mass fraction is about 68%) and heated in a gradient. The gradient temperature was 80°C, 90°C, 100°C and 120°C; the modification treatment time was 2h, 20min, 30min and 30min. Then it was washed with deionized water and ethanol to obtain a modified carbon fiber cloth. Get 0.3g of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 2.5ml of 1-butyl-3-methylimidazolium tetrafluoroborate ([BMIM]BF 4 ) in 25ml of ethanol solution, electromagnetically stirred until the solution is uniform, then transferred to a 50ml hydrothermal reaction kettle after ultrasonic treatment for 30 minutes, placed the modified carbon fiber in the hydrothermal reaction kettle into the reaction solution, and sealed the reaction Put it into an oven for solvothermal reaction, keep it at 150°C for 6h, take it out, wash it with water and ethanol several times, put it in an oven at 60°C, and dry it for 12h to obtain a carbon fiber cloth...

Embodiment 2

[0035] Embodiment 2 performance test

[0036] 1) Performance test of the prepared symmetrical battery

[0037] The composite negative electrode (CoF) of three-dimensional structure in embodiment 1 2 -CC@Li) was placed on both sides of the separator to form a symmetrical battery; in Comparative Examples 1 and 2, Cu@Li and CC@Li were placed on both sides of the separator to form a symmetrical battery. The electrolyte is 1M LiTFSI+DOL:DME(1:1,v / v)+2wt%LiNO 3 .

[0038] The symmetrical battery that embodiment 1 and comparative example 1 and 2 are formed is in 2mA cm -2 and 1mAh cm -2 Under the condition of , its time-voltage curve is as follows Figure 5 , it can be seen that the symmetrical battery with the composite negative electrode of the three-dimensional structure can maintain a relatively small polarization voltage stable cycle of 3600h.

[0039] The symmetrical battery that embodiment 1 and comparative example 1 and 2 are formed is in 3mA cm -2 and 1mAh cm -2 Unde...

Embodiment 3

[0045] The carbon fiber cloth was soaked in hydrogen peroxide solution (30% by mass) and heated at 80° C. for 12 h, and then washed with deionized water and ethanol to obtain a modified carbon fiber cloth. Get 0.3g of cobalt chloride hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 0.5 g of ammonium fluoride (NH 4 F) Mix in 25ml of methanol solution, stir electromagnetically until the solution is uniform, transfer it to a 50ml hydrothermal reaction kettle after ultrasonic treatment for 30 minutes, place the modified carbon fiber in the hydrothermal reaction kettle into the reaction solution, and seal Reactor, put it in an oven for solvothermal reaction, keep it at 120°C for 8 hours, take it out, wash it with water and ethanol several times, then put it in an oven at 40°C and dry it for 24 hours to obtain a carbon fiber cloth uniformly coated with cobalt fluoride (CoF 2 -CC).

[0046] In a glove box filled with argon, commercial lithium metal foil (diameter 15.6 mm, thickness 1.5 mm)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com