Preparation method for ceramic medium printing sizing agent

A technology for ceramic media and ceramic waste, applied in the field of printing paste, can solve the problems of poor wettability of powder and air bubbles, and achieve the effect of low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

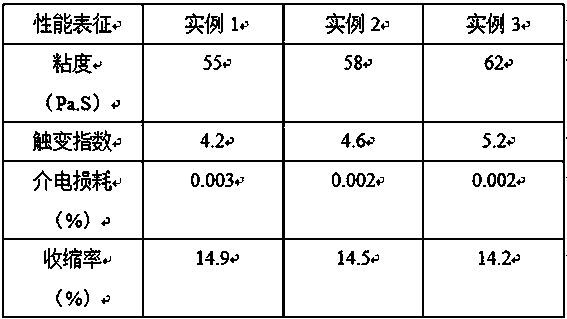

Examples

example 1

[0032] Take 20g of feldspar, 50g of quartz, 40g of clay and 10g of ceramic waste, crush and mix to obtain the material, preheat the muffle furnace to 300℃, put the material in the muffle furnace, heat up and burn, the heating rate is 20℃ / Min, heat up to 900℃, then keep this temperature and continue to burn for 2h to obtain the pre-burned material; continue to heat up the muffle furnace at a heating rate of 10℃ / min, heat up to 1250℃, heat preservation and burn for 1h to obtain the burnt material ; Close the muffle furnace to make the temperature of the muffle furnace drop. When the temperature of the muffle furnace drops to 800℃, turn on the muffle furnace again, control the cooling rate to 5℃ / min, and reduce the temperature to 400℃, close the muffle furnace, and at the same time Open the door of the muffle furnace and cool to room temperature naturally to obtain modified ceramics; take 100g of modified ceramics and 10g of glass powder to crush and grind to obtain ceramic powder...

example 2

[0034] Take 30g of feldspar, 75g of quartz, 60g of clay and 15g of ceramic waste, crush and mix to obtain materials, preheat the muffle furnace to 300°C, put the materials in the muffle furnace, heat up and burn at a rate of 20°C / Min, heat up to 900℃, then keep this temperature and continue to burn for 2h to obtain the pre-burned material; continue to heat up the muffle furnace at a heating rate of 10℃ / min, heat up to 1250℃, heat preservation and burn for 1h to obtain the burnt material ; Close the muffle furnace to make the temperature of the muffle furnace drop. When the temperature of the muffle furnace drops to 800℃, turn on the muffle furnace again, control the cooling rate to 5℃ / min, and reduce the temperature to 400℃, close the muffle furnace, and at the same time Open the door of the muffle furnace and cool to room temperature naturally to obtain modified ceramics; take 150g of modified ceramics and 15g of glass powder to crush and grind to obtain ceramic powder; take 1...

example 3

[0036] Take 40g of feldspar, 100g of quartz, 80g of clay and 20g of ceramic waste, crush and mix to obtain materials, preheat the muffle furnace to 300°C, put the materials in the muffle furnace, heat up and burn at a rate of 20°C / Min, heat up to 900℃, then keep this temperature and continue to burn for 2h to obtain the pre-burned material; continue to heat up the muffle furnace at a heating rate of 10℃ / min, heat up to 1250℃, heat preservation and burn for 1h to obtain the burnt material ; Close the muffle furnace to make the temperature of the muffle furnace drop. When the temperature of the muffle furnace drops to 800℃, turn on the muffle furnace again, control the cooling rate to 5℃ / min, and reduce the temperature to 400℃, close the muffle furnace, and at the same time Open the door of the muffle furnace and cool to room temperature naturally to obtain modified ceramics; take 200g of modified ceramics and 20g of glass powder to crush and grind to obtain ceramic powder; take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com