Gel polymer electrolyte and polymer battery and preparation method thereof

A gel polymer and electrolyte technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc. The room temperature conductivity of the material electrolyte is low, and it cannot meet the ideal requirements, so as to achieve the effect of improving the interface energy, excellent electrochemical performance, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

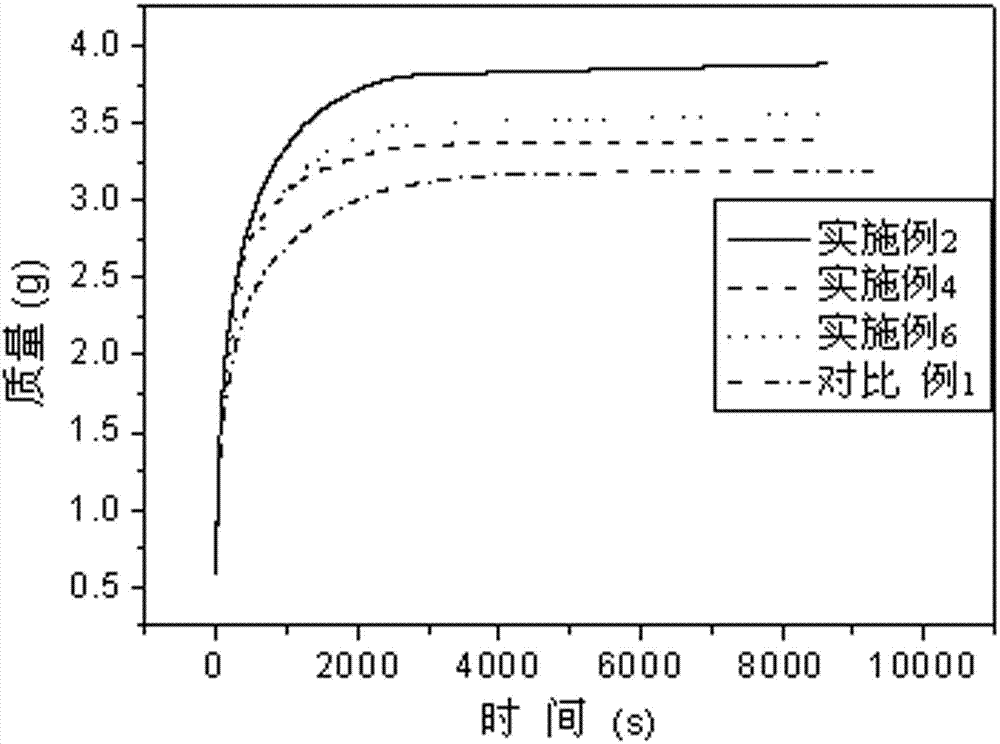

Examples

preparation example Construction

[0026] The present invention also provides a method for preparing the above-mentioned polymer battery, wherein the method includes adding a mixed solution containing electrolyte, inorganic filler, polymerizable monomer and organic solvent between the positive electrode and the negative electrode of the battery, and then under polymerization conditions The polymerizable monomer in the mixed liquid is subjected to a polymerization reaction to obtain a gel state substance, and the inorganic filler is a metal-ceramic composite material.

[0027] Among them, the polymerizable monomer is generally a polymer monomer, which can be vinylidene fluoride, methyl methacrylate, acrylonitrile, butyl acrylate, methyl acrylate, butyl methacrylate, benzyl methacrylate, One or more of acenaphthylene, vinylpyridine, acrylamide, methyl vinyl ether, vinyl acetate, hexafluoropropylene and vinylpyrroline. In the present invention, vinylidene fluoride and hexafluoropropylene are preferred, and polyvin...

Embodiment 1

[0035] This example is used to illustrate the gel polymer electrolyte, polymer battery and preparation method thereof provided by the present invention.

[0036] (1) 80 parts by weight of vinylidene fluoride, 18 parts by weight of hexafluoropropylene and 10 parts by weight of Ni-YSZ (obtained by sol-gel method, the median particle size of the particles is about 80nm, and the content of Ni element is 15wt%) was dissolved in acetone, stirred ultrasonically at 50°C for 1 hour to obtain a jelly, and 110 parts by weight of electrolyte (1.1 parts by weight of LiPF 6 , 108.9 parts by weight EC:DMC:EMC=1:2:2), and continued to stir for 30 minutes to obtain a mixed solution A1.

[0037] (2) The mixed solution A1 prepared in (1) is injected into the mixture containing 6.3 grams of LiCoO 2 The aluminum foil positive electrode and the copper foil negative electrode containing 3.0 grams of graphite are arranged in parallel and sealed, and then placed in an oven with a temperature of 90 ° ...

Embodiment 2

[0039] This example is used to illustrate the gel polymer electrolyte, polymer battery and preparation method thereof provided by the present invention.

[0040] (1) 80 parts by weight of vinylidene fluoride, 18 parts by weight of hexafluoropropylene and 10 parts by weight of Mg-YSZ (obtained by sol-gel method, the median particle size of the particles is about 100nm, and the content of Mg element is 18wt%) was dissolved in acetone, stirred ultrasonically at 50°C for 1 hour to obtain a jelly, and 110 parts by weight of electrolyte (1.2 parts by weight of LiPF 6 , 108.8 parts by weight EC:DMC:EMC=1:2:2), and continued to stir for 30 minutes to obtain a mixed solution A2.

[0041] (2) The mixed solution prepared in (1) is injected into the mixture containing 6.3 grams of LiCoO 2 The aluminum foil positive electrode and the copper foil negative electrode containing 3.0 grams of graphite are arranged in parallel and sealed, and then placed in an oven with a temperature of 90 ° C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com