Flaky metal oxide and its controllable synthesis method and application

A flake metal and synthesis method technology, applied in the direction of manganese oxide/manganese hydroxide, cobalt oxide/cobalt hydroxide, nickel oxide/nickel hydroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

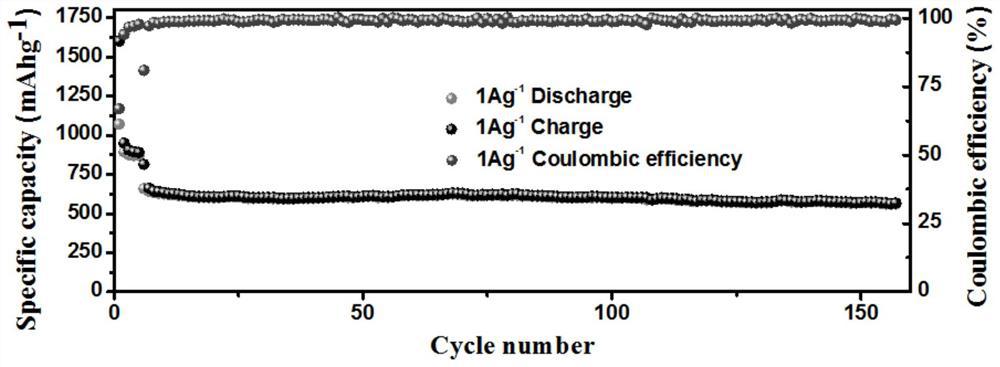

Examples

Embodiment 1

[0033] A controllable synthesis method of sheet metal oxides, comprising the steps of:

[0034] (1) Add 0.5g of template agent into 60ml of deionized water, and keep stirring for 5 minutes until the drug is completely dissolved; the template agent is 2-methylimidazole;

[0035] (2) Add the metal salt to the above solution and continue to stir for 10 minutes. The molar ratio of the metal salt to the template is 1:3. The metal salt is an inorganic metal salt containing one of cobalt, nickel, manganese, zinc, and iron, such as nitric acid salt, chloride salt;

[0036] (3) Transfer the solution prepared above into an oil bath, and react at a temperature of 60° C., and the time range is 8 hours;

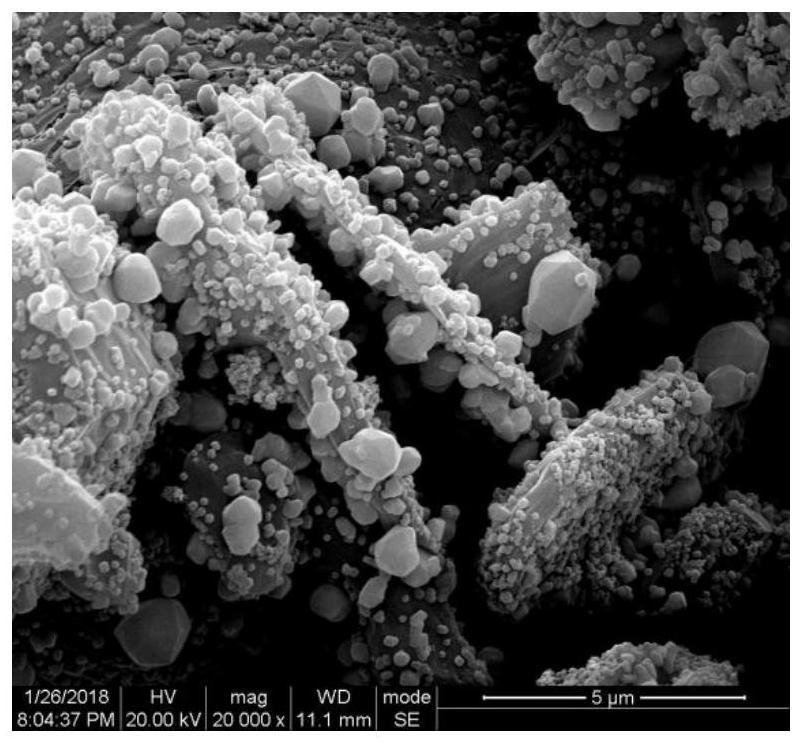

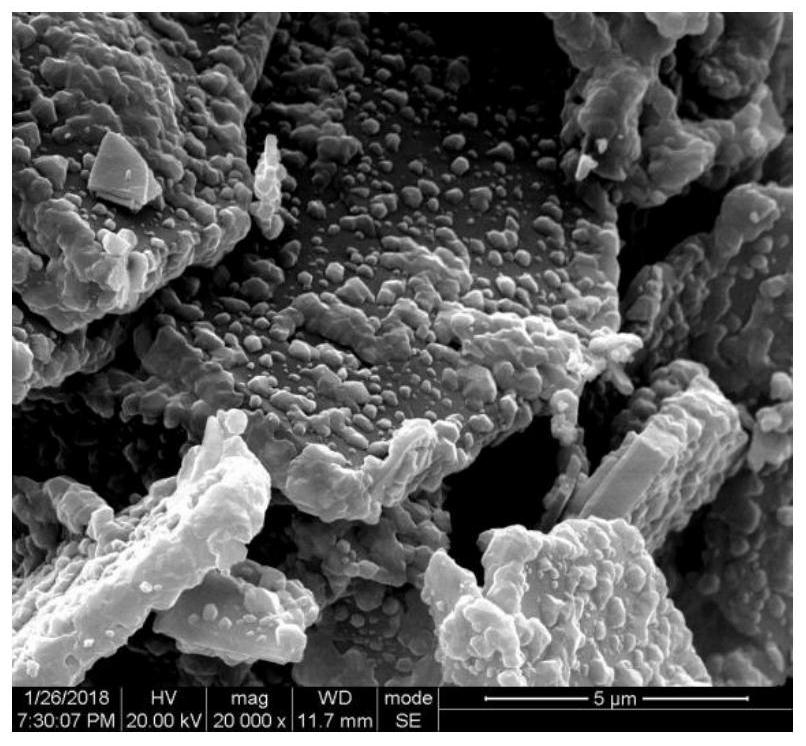

[0037] (4) Cool the above product to room temperature, wash it with deionized water and absolute ethanol, dry it at 60°C for 4 hours, put it into a tube furnace, calcinate it to 250°C, keep it for 4 hours, and finally get the shape of Flaky metal oxides. The calcination atmosphere is N...

Embodiment 2

[0040] A controllable synthesis method of sheet metal oxides, comprising the steps of:

[0041] (1) Add 3g of template agent into 120ml of deionized water, and continue to stir for 10 minutes until the drug is completely dissolved; the template agent is 1,2,3,4-butanetetracarboxylic acid;

[0042] (2) Add the metal salt to the above solution and continue to stir for 15 minutes, the molar ratio of the metal salt to the template is 3:1, and the metal salt is manganese acetylacetonate;

[0043] (3) transfer the solution prepared above into an oil bath, and react at a temperature of 100° C., and the time range is 16 hours;

[0044] (4) Cool the above product to room temperature, wash it with deionized water and absolute ethanol, dry it at 90°C for 6 hours, put it into a tube furnace, calcinate it to 700°C, keep it for 8 hours, and finally get the shape of Flaky metal oxides. The calcination atmosphere is N 2 , Ar, or air atmosphere, so that the sintered material only contains m...

Embodiment 3

[0047] A controllable synthesis method of sheet metal oxides, comprising the steps of:

[0048] (1) Add 1g of template agent into 80ml of deionized water, and keep stirring for 7 minutes until the drug is completely dissolved; the template agent is 1,2,3,4-butanetetracarboxylic acid;

[0049] (2) Add the above solution according to the metal salt and continue to stir for 12 minutes. The molar ratio of the metal salt to the template is 2:1. The metal salt is an inorganic metal salt containing one of cobalt, nickel, manganese, and zinc, such as CoCl 2 , NiCl 2 , MnCl 2 , Co(NO 3 ) 2 , Ni(NO 3 ) 2 , Mn(NO 3 ) 2 ;

[0050] (3) transfer the solution prepared above into an oil bath, and react at a temperature of 80° C., and the time range is 10 h;

[0051] (4) Cool the above product to room temperature, wash it with deionized water and absolute ethanol, dry it at 70°C for 5h, put it into a tube furnace, calcinate it to 350°C, keep it for 5h, and finally get the shape of Flak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com