Composite inoculant used for grey cast iron and preparation method and application method of composite inoculant

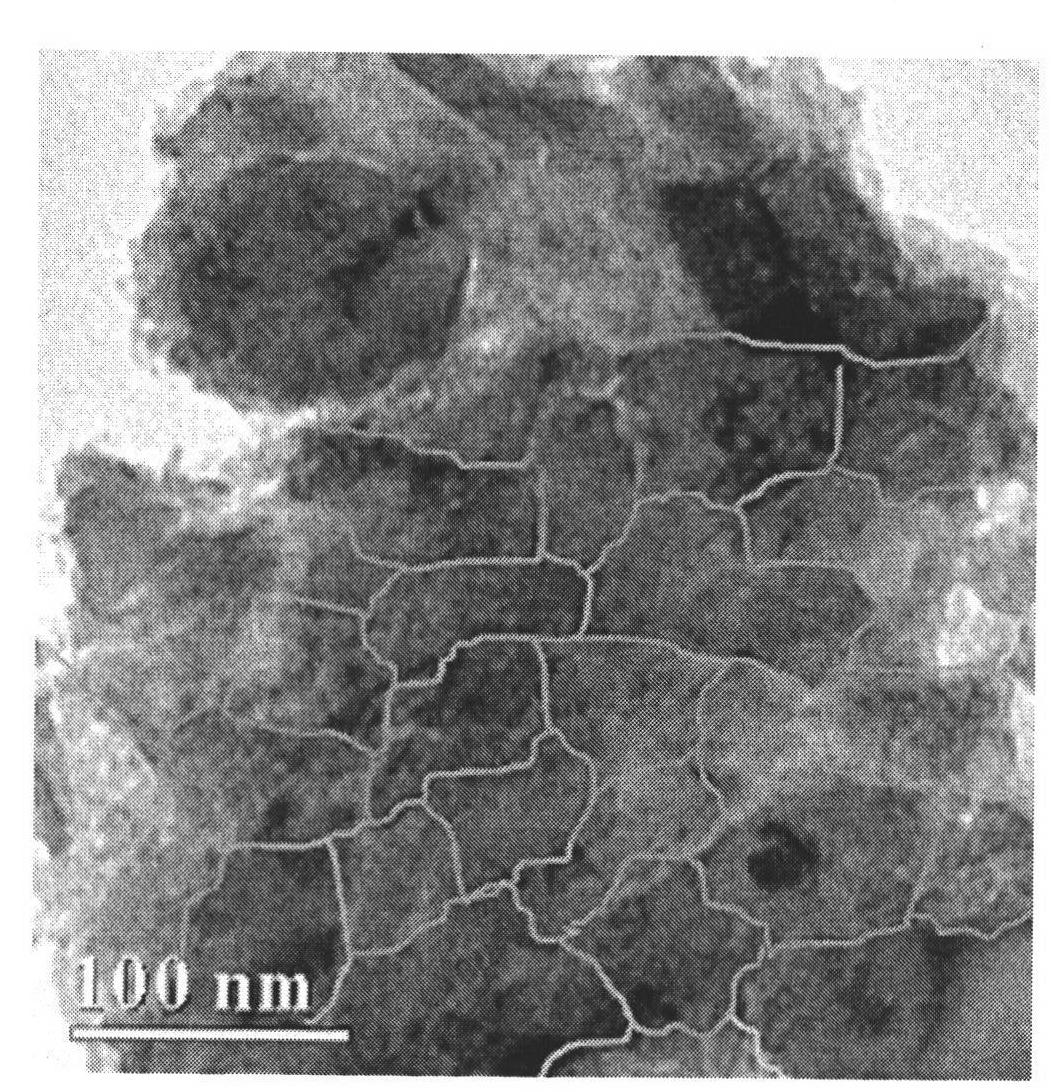

A composite inoculant and gray cast iron technology, which is applied in the field of cast iron alloys, can solve the problem that the inoculation refiner is not nano-scale, and achieve the effects of increasing interface energy, increasing wear resistance, and reducing casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

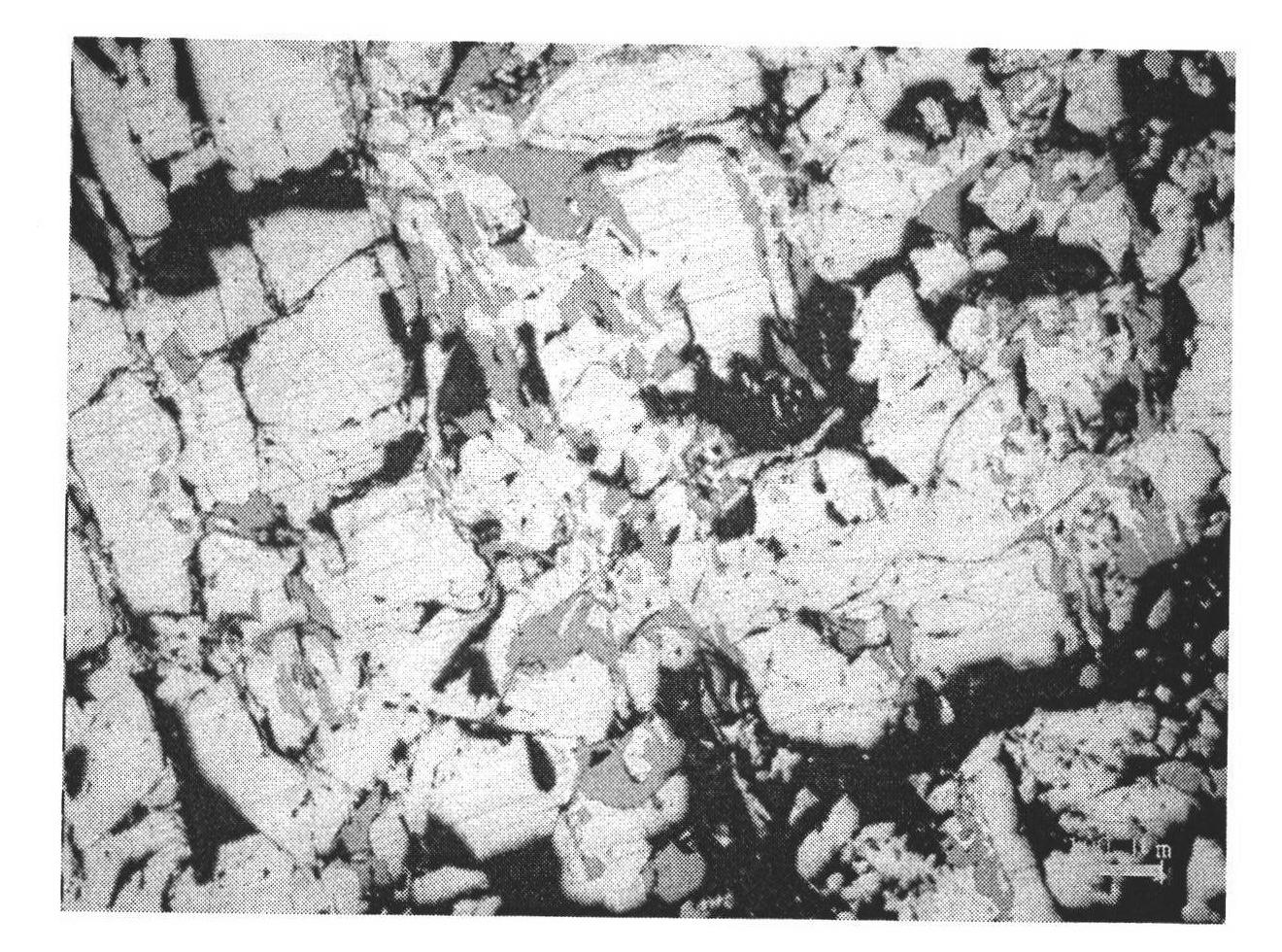

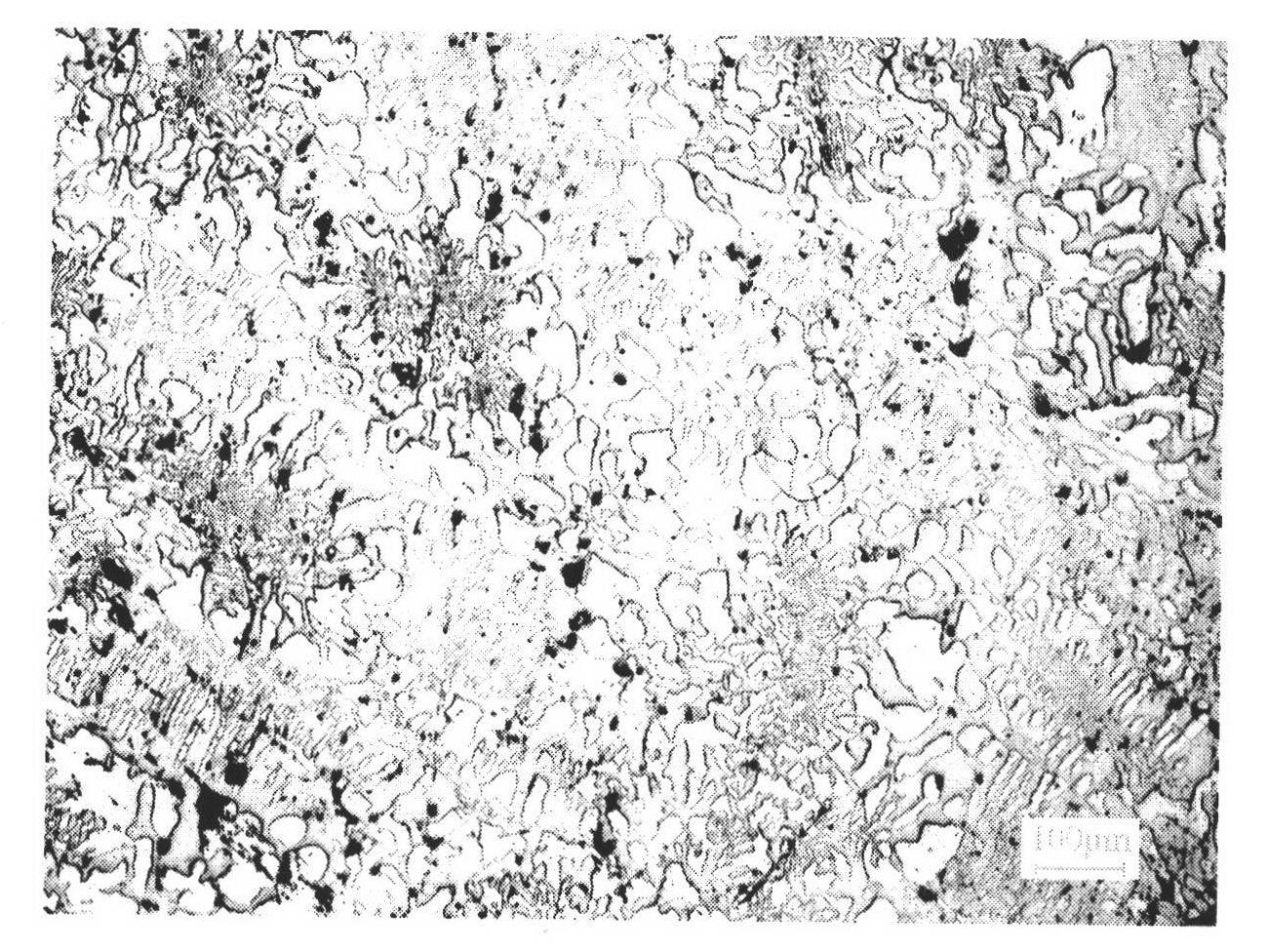

Image

Examples

Embodiment 1

[0041] Preparation of Fe-B-V master alloy:

Embodiment 1-1

[0043] The percentage by weight of the elemental composition is Fe: B: V=63.5: 33: 3.5 to take the required Fe, pure B and pure V, and prepare by smelting in an intermediate frequency induction heating furnace. This refining process is known, and thus Fe-B-V master alloy (I) is obtained.

Embodiment 1-2

[0045] The percentage by weight of the elemental composition is Fe: B: V=74.5: 23: 2.5 to take the required Fe, pure B and pure V, and prepare by smelting in an intermediate frequency induction heating furnace. This refining process is known, and thus Get Fe-B-V master alloy (II).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com