Preparation method of high-performance all-solid-state lithium ion battery

A lithium-ion battery, all-solid-state technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low ionic conductivity of the diaphragm of all-solid-state lithium-ion batteries, and achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

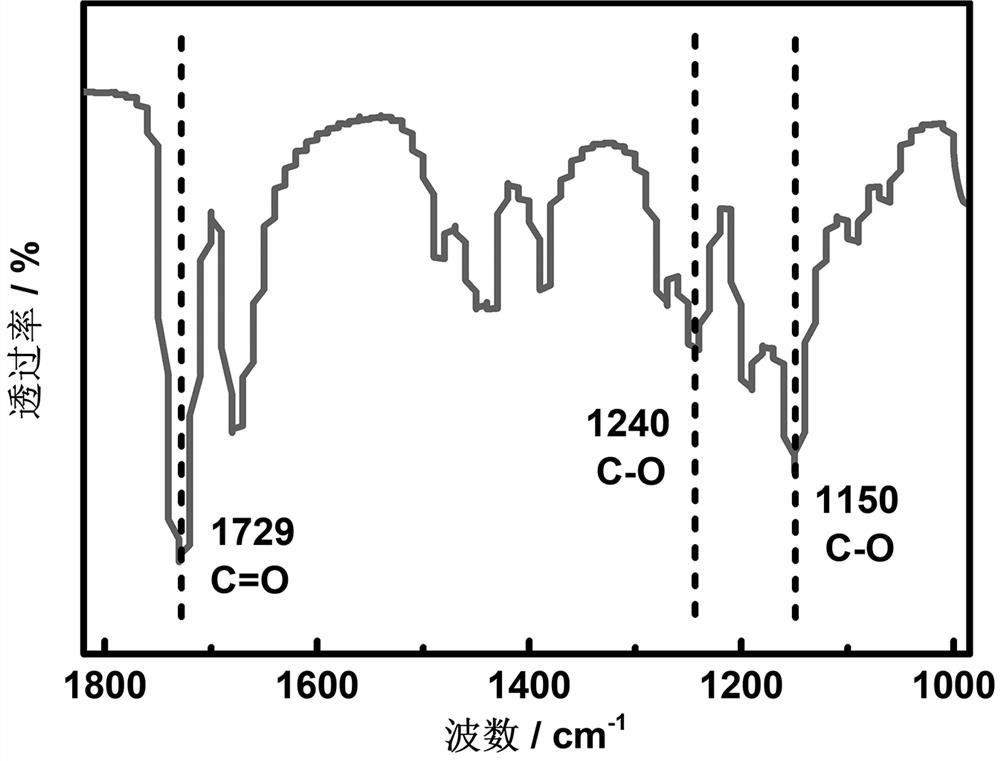

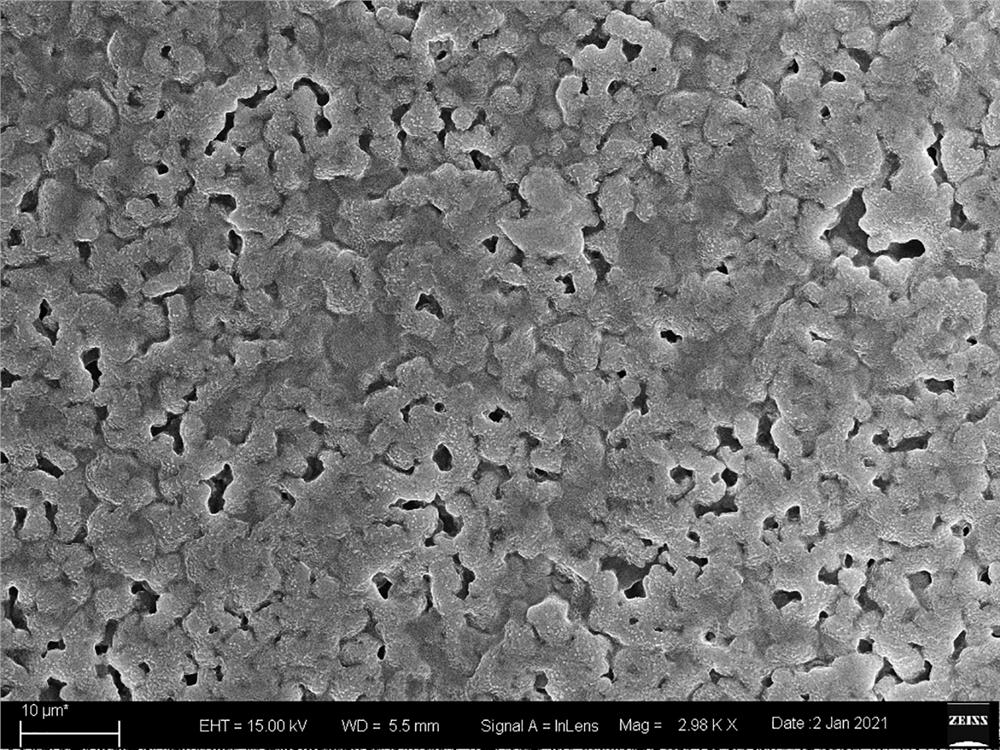

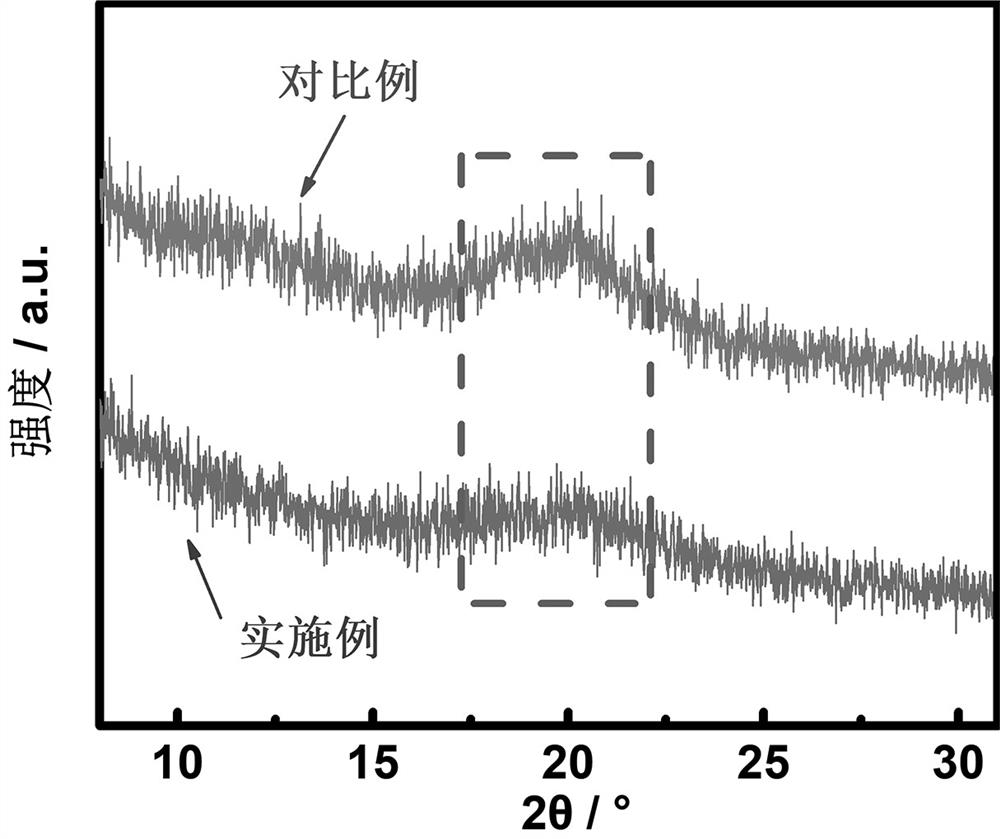

[0056] Embodiment 1: The preparation method of a kind of high-performance all-solid-state lithium-ion battery of this embodiment is to prepare according to the following steps:

[0057] 1. Pretreatment of polymer electrolyte precursor solution

[0058] Dissolve 0.4g of poly(vinylidene fluoride-hexafluoropropylene) copolymer, 0.1g of polyvinylidene fluoride and 0.1g of organic montmorillonite in organic solvent N,N-dimethylformamide, and stir evenly at room temperature , and mix the uniformly stirred solution;

[0059] 2. Preparation of polymer electrolyte precursor liquid monomer

[0060] Add 5.4 g of methyl methacrylate and 1 g of lithium salt to the homogeneous solution obtained in step 1, and stir at room temperature to obtain a uniform light yellow solution;

[0061] 3. Polymerization of polymer electrolyte precursor liquid monomer

[0062] Add an initiator to the light yellow solution in step 2, and pre-polymerize for 30 minutes under heating conditions to obtain a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com