High-coercivity permanent magnetic ferrite and preparation method thereof

A permanent magnet ferrite, high coercivity technology, applied in the field of magnetic material preparation, can solve the problems of increased input cost, complex preparation process and high price cost, and achieves increased contact area, uniform grain distribution, and improved coercivity. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

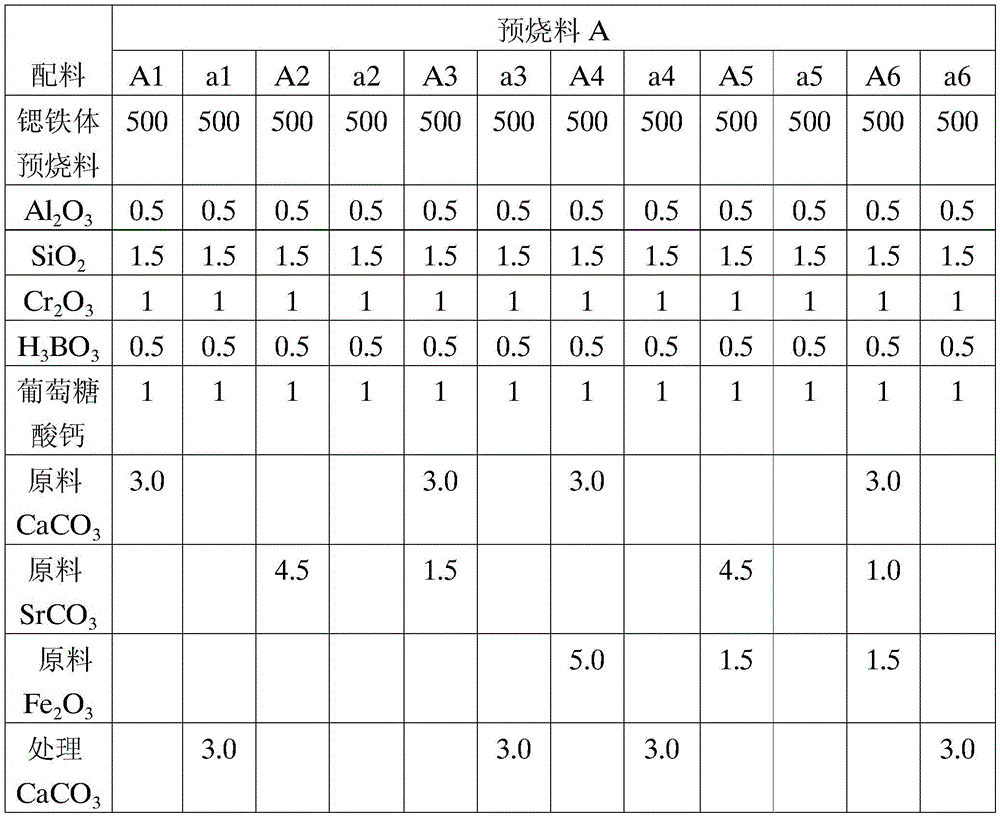

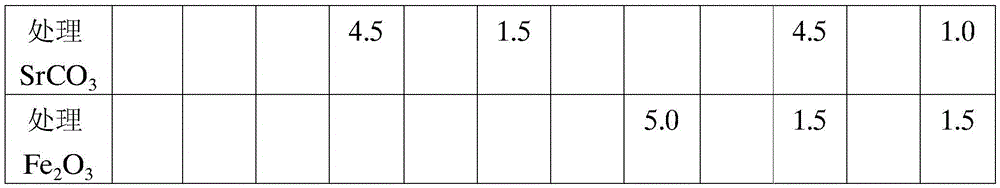

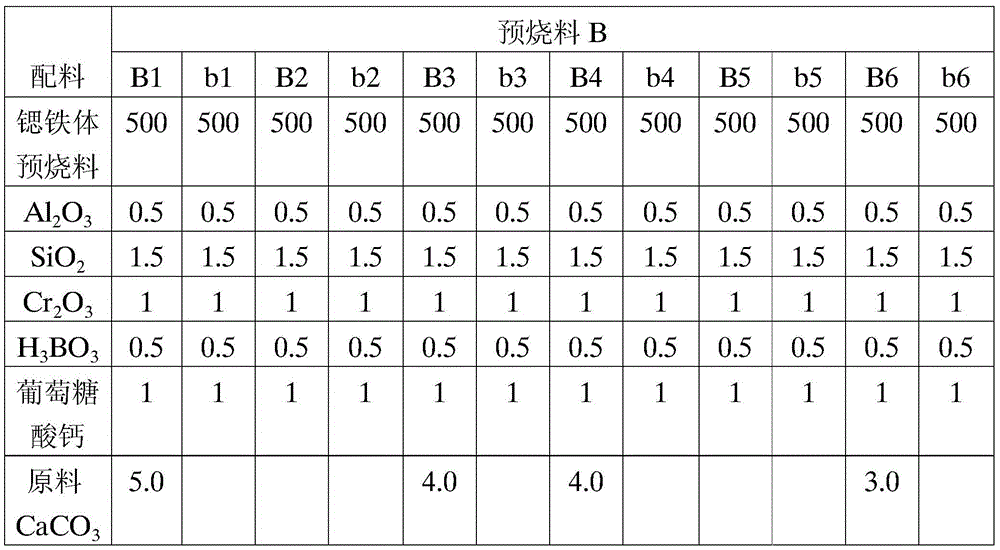

Examples

Embodiment a1

[0031] In this embodiment, at first the raw materials are processed, and the specific processing method is as follows:

[0032] 1) Ball milling: the raw material 500gCaCO 3 , 2.5g calcium gluconate and 3.0g sorbitol are put into sand mill, and water is medium, material: ball: water=1:20:1.5, rotating speed 400r / min, stir 8 hours;

[0033] 2) Sintering: Use a program-controlled box-type electric furnace to pre-sinter the material obtained in step 1), and the sintering temperature is raised from 100°C to 500°C. The specific sintering process is as follows: 100°C / 1.0h+180°C / 1.0h +380°C / 1.0h+450°C / 1.0h+500°C / 2h, the above time is holding time;

[0034] 3) Milling: Grinding the material obtained in step 2) to prepare powder for future use.

[0035] Using the same raw materials and the same process as Comparative Example A1, the only difference is that the CaCO obtained by the above-mentioned treatment is added 3 , relative to the calcined material, the weight percentage of the a...

Embodiment a2

[0039] Using the same raw materials and the same process as Comparative Example A2, the only difference is that the 4.5gSrCO obtained by adding the above treatment 3 , the magnetic performance test of the prepared product was carried out with a magnetic material automatic measuring device, and the specific performance parameters are shown in Table 2.

Embodiment a3

[0043] Using the same raw materials and the same process as Comparative Example A3, the only difference is that the 3.0g CaCO obtained by adding the above treatment 3 and 1.5gSrCO 3 , the magnetic performance test of the prepared product was carried out with a magnetic material automatic measuring device, and the specific performance parameters are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com