Fully-biodegradable high-barrier sheet for coffee capsule cup body, and preparation method thereof

A coffee capsule and high-barrier technology, which is applied in the field of packaging materials, can solve the problems of high water vapor and oxygen transmission rate, easy deformation of the coffee capsule cup, and poor aroma retention, so as to improve interface energy, good aroma retention, and improve Fragrance retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

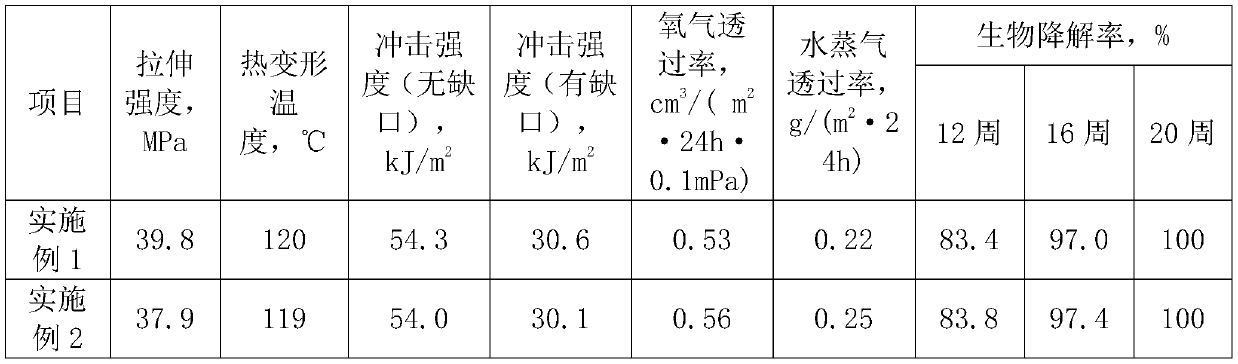

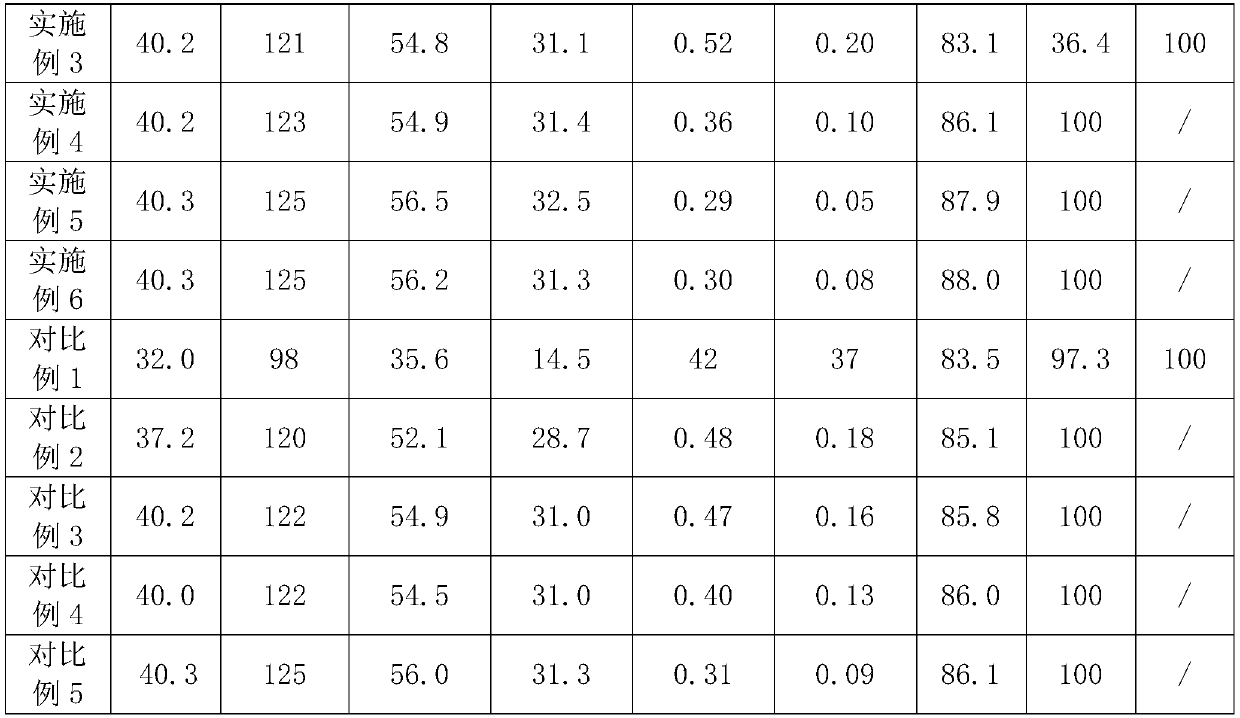

Examples

preparation example 1

[0040] Preparation Example 1: ① Primary treatment: Grind coffee grounds and pass through a 100-mesh sieve to obtain fine grounds, wash the fine grounds with deionized water, filter, and dry at 80°C for 3 hours to obtain first-grade coffee slag;

[0041] ②Secondary treatment: put the first-grade coffee grounds in 10wt% sodium hydroxide solution, the weight of the sodium hydroxide solution is 3 times that of the first-grade coffee grounds, soak the first-grade coffee grounds for 20 minutes, take it out, and wash with water After washing to neutrality, dry at 80°C for 3 hours to obtain secondary coffee grounds;

[0042] ③Roasting treatment: place the second-grade coffee grounds at a temperature of 300°C and roast for 3 hours to obtain third-grade coffee grounds;

[0043] ④ Preparation of modified solution: Take 10kg of hydroxyapatite, 10kg of hydroxypropyl-β-cyclodextrin, 6kg of sodium lauroyl sarcosinate, 2kg of sodium alginate, γ-methacryloxypropyl trimethoxy Silane 0.08kg an...

preparation example 2

[0045] Preparation example 2: ① Primary treatment: Grind coffee grounds and pass through a 100-mesh sieve to obtain fine grounds, wash the fine grounds with deionized water, filter, and dry at 80°C for 3 hours to obtain first-grade coffee slag;

[0046] ②Secondary treatment: put the first-grade coffee grounds in 10wt% sodium hydroxide solution, the weight of the sodium hydroxide solution is 3 times that of the first-grade coffee grounds, soak the first-grade coffee grounds for 40 minutes, take it out, and wash with water After washing to neutrality, dry at 80°C for 3 hours to obtain secondary coffee grounds;

[0047] ③Roasting treatment: place the second-grade coffee grounds at a temperature of 350°C and roast for 4 hours to obtain third-grade coffee grounds;

[0048] ④ Preparation of modified solution: Take 15kg of hydroxyapatite, 15kg of hydroxypropyl-β-cyclodextrin, 8kg of sodium lauroyl sarcosinate, 2.5kg of sodium alginate, γ-methacryloxypropyl trimethoxy Base silane 0....

preparation example 3

[0050] Preparation Example 3: ① Primary treatment: Grind coffee grounds and pass through a 100-mesh sieve to obtain fine grounds, wash the fine grounds with deionized water, filter, and dry at 80°C for 3 hours to obtain first-grade coffee slag;

[0051] ②Secondary treatment: put the first-grade coffee grounds in 10wt% sodium hydroxide solution, the weight of the sodium hydroxide solution is three times that of the first-grade coffee grounds, soak the first-grade coffee grounds for 60 minutes, take them out, and rinse with water. After washing to neutrality, dry at 80°C for 3 hours to obtain secondary coffee grounds;

[0052] ③Roasting treatment: place the second-grade coffee grounds at a temperature of 400°C and roast for 5 hours to obtain third-grade coffee grounds;

[0053] ④ Preparation of modified solution: Take 20kg of hydroxyapatite, 20kg of hydroxypropyl-β-cyclodextrin, 10kg of sodium lauroyl sarcosinate, 3kg of sodium alginate, γ-methacryloxypropyl trimethoxy Silane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com