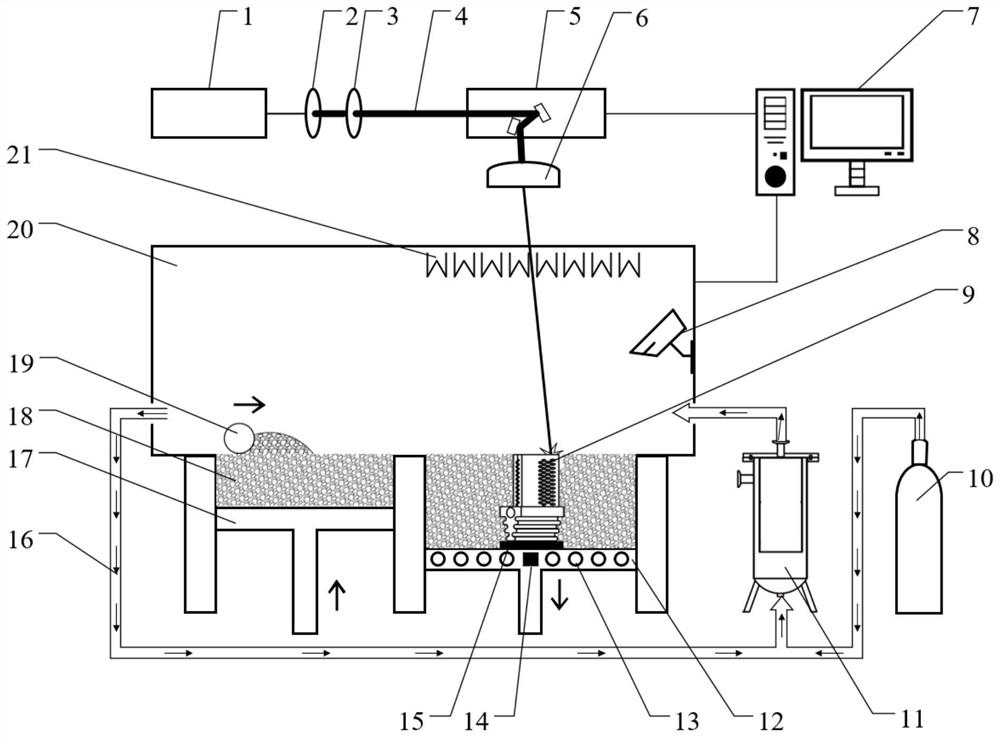

3D printing device and method for oriented crystal or single crystal high-temperature alloy and product

A technology of 3D printing and high-temperature alloys, which is applied in the field of additive manufacturing, and can solve problems such as the manufacture of complex hollow turbine blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

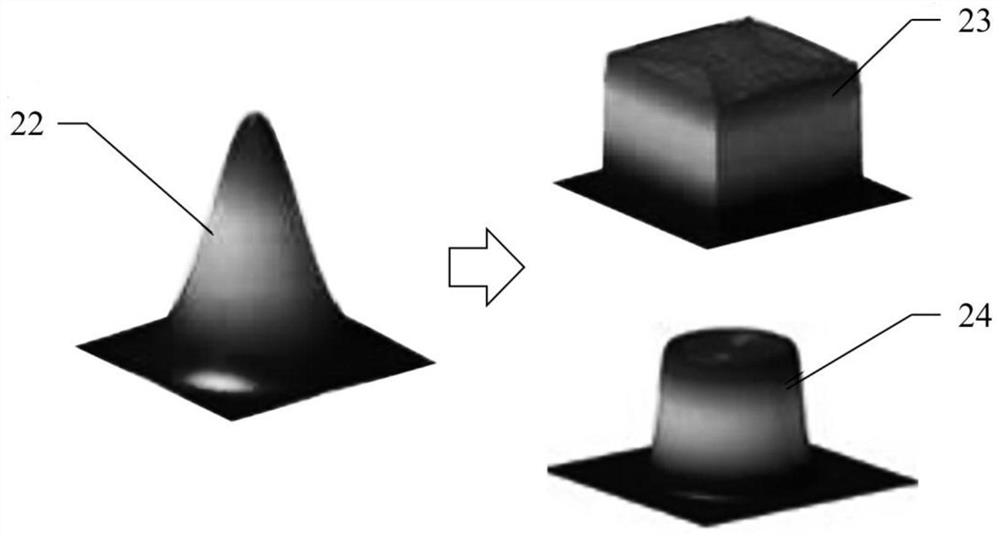

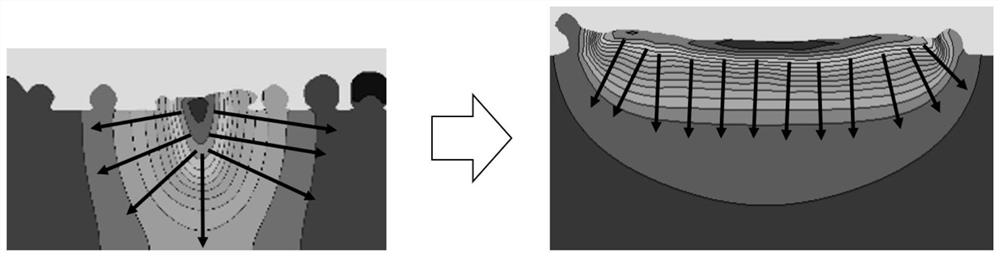

[0075] In order to test the reliability of the above-mentioned device for forming oriented crystals or single crystals, taking a rectangular laser spot as an example, the finite volume simulation method is used to simulate the characteristics of the molten pool during the laser forming process, and the shape of the molten pool, the internal temperature field and the flow field are predicted. distribution, it can be seen that:

[0076] For melt pool shapes, see image 3 with Figure 4 In the picture on the left, because the internal energy of the Gaussian laser is high in the middle and low on both sides, the molten pool formed is deep and narrow, in the shape of an awl, while the internal energy distribution of the rectangular laser on the right is uniform, so the formed molten pool is shallow and wide. It is flat. Theoretically, the direction of the temperature field inside the flat molten pool is more uniform, the flow field is more stable, the bottom of the molten pool is...

Embodiment 2

[0081] In order to test the reliability of the above-mentioned device for forming oriented crystals or single crystals, a single-pass test is carried out to check whether the crystals in the molten pool on the side of the single pass grow epitaxially along the single-crystal substrate. Specific steps are as follows:

[0082] (1) Use UG three-dimensional modeling software to draw a 10×10×10mm block, and export the STL file format for future use. In a single-pass experiment, set the scanning distance to more than 10mm to form a single cladding pass;

[0083] (2) Put the DD91 nickel-based single crystal superalloy powder into a vacuum oven, and dry it at 80°C for 8 hours to remove the moisture on the surface of the powder. alloy rod cut into The wafer is used as a forming substrate, and its internal crystals are required to grow along [001], and the orientation angle deviation is less than 5°. One of the circular sections is selected as the deposition surface, and it is polishe...

Embodiment 3

[0089] In order to test the reliability of forming oriented crystals or single crystals by the above-mentioned device, a multi-pass lap test is carried out to check whether the crystals at the multi-pass laps grow epitaxially along the single crystal substrate. The specific steps are substantially the same as in Example 2, and the laser forming process parameters are power 300W, scanning speed 500mm / s, layer thickness 50μm, and scanning distance 100μm.

[0090] Depend on Figure 7 In (a) and (b), it can be seen that when multiple layers are overlapped, the crystal in the molten pool can continue to grow in the [001] orientation of the single crystal substrate. That is to say, by correcting the laser spot shape and energy distribution, and cooperating with the forced temperature difference unit, it is possible to realize the strict [001] orientation growth of crystals in the molten pool during multi-channel overlapping, without generating miscellaneous crystals, freckles, small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com