Lithium nickel manganese oxide positive electrode material and preparation method thereof

A cathode material, lithium nickel manganate technology, applied in the field of lithium nickel manganate cathode material and its preparation, can solve problems such as uneven composition of raw materials, achieve controllable morphology and particle size, improve performance, and simple process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

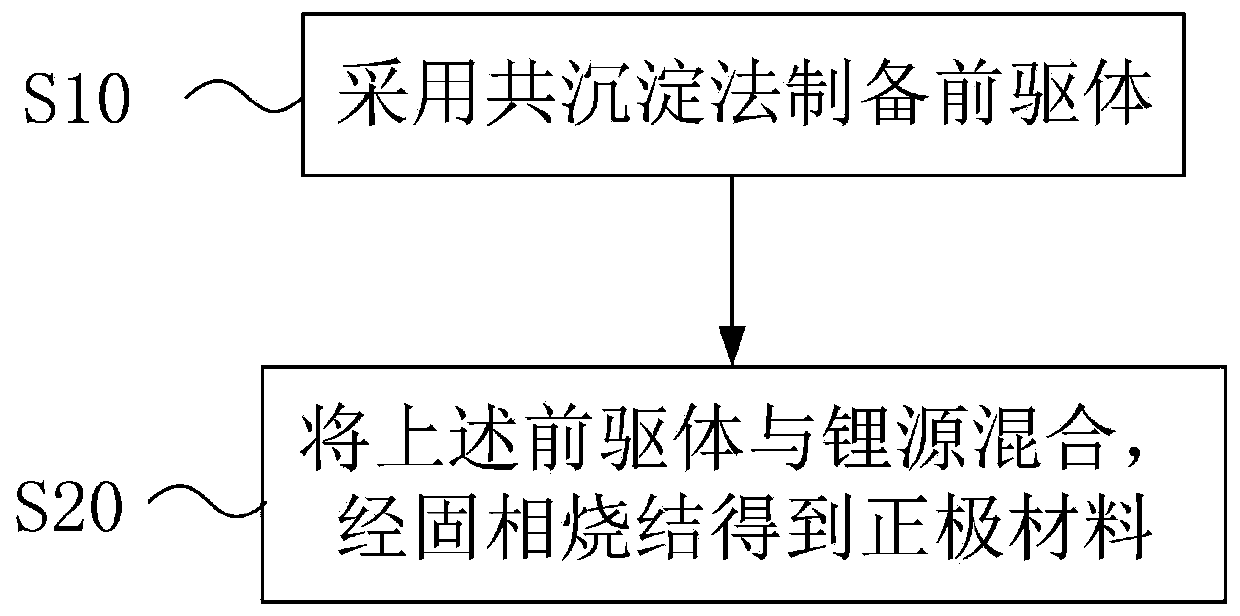

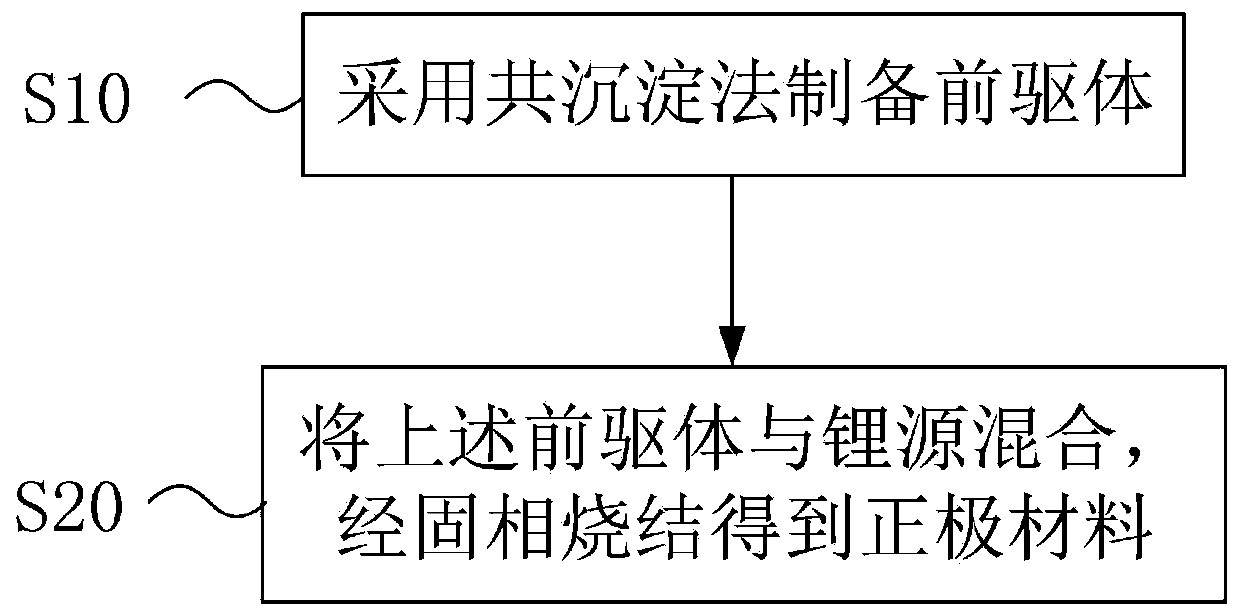

[0053] The invention provides a preparation method of lithium nickel manganese oxide positive electrode material, such as figure 1 shown, including:

[0054] S10: Prepare the precursor by co-precipitation method, specifically Ni x mn y (OH) 2 Precursor;

[0055] S20: Mix the above precursor with the lithium source, and obtain lithium nickel manganese oxide positive electrode material through solid phase sintering, the lithium nickel manganese oxide positive electrode material is LiNi x mn y o 4 , wherein, x+y=2, x>0, y>0.

[0056] The preparation method of above-mentioned Lithium Nickel Manganese Oxide cathode material, first by chelating agent complexation Ni 2+ , Mn 2+ to reduce its nucleation rate, and simultaneously with Ni 2+ , Mn 2+ Uniform co-precipitation and crystallization to prepare Ni with uniform composition and particle size distribution x mn y(OH) 2 Precursor, and then solid-state sintering of lithium source and precursor to prepare high-voltage lit...

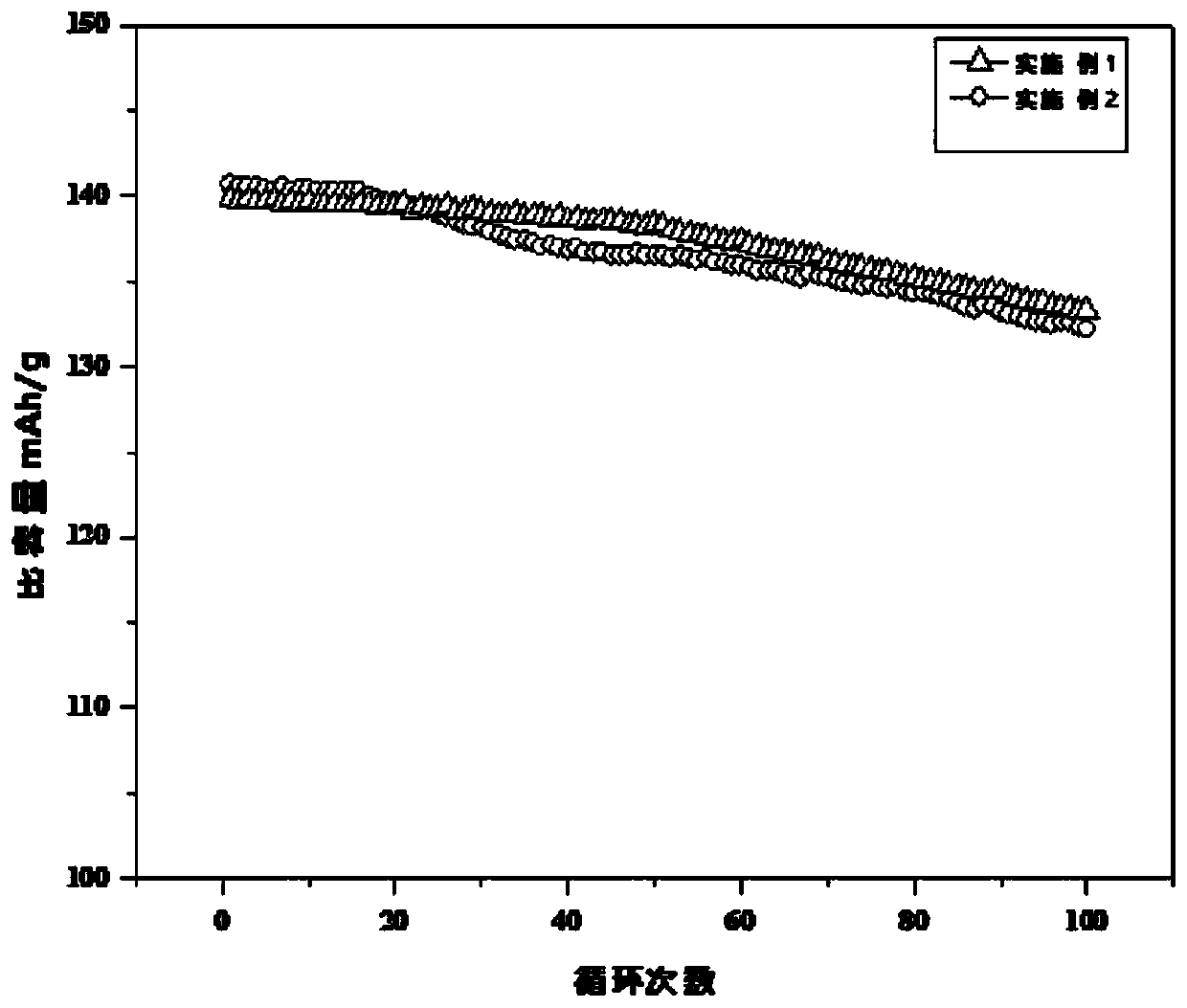

Embodiment 1

[0082] A preparation method of lithium nickel manganese oxide positive electrode material, comprising:

[0083] S110: Preparation of precursor: the total concentration of preparation is 5mol / L and Ni 2+ :Mn 2+ The molar ratio of the metal sulfate solution is 1:3, and the molar concentration is 10mol / L Na 2 CO 3 The solution, a 2-methyl-8-hydroxyquinoline solution with a molar concentration of 5 mol / L, is pumped into the reactor simultaneously in a co-current manner, the pH of the reaction system is controlled to be 9.0, and the temperature of the reaction system is 50°C. The precursor after the reaction was completed was washed in deionized water at 30° C. to neutrality, and dried at 50° C. for 50 hours to obtain a lithium nickel manganese oxide cathode material precursor.

[0084] S120: Preparation of high-voltage lithium nickel manganese oxide: Weigh the precursor and lithium source at a molar ratio of lithium hydroxide monohydrate: precursor of 2:1, mix well, and raise t...

Embodiment 2

[0087] A preparation method of lithium nickel manganese oxide positive electrode material, comprising:

[0088] S210: Preparation of precursor: the total concentration of preparation is 2mol / L and Ni 2+ :Mn 2+ The molar ratio of the metal sulfate solution is 1:3, and the molar concentration is 4mol / L Na 2 CO 3 The solution, a lactic acid solution with a molar concentration of 2 mol / L, is pumped into the reactor simultaneously in a co-current manner, the pH of the reaction system is controlled to be 10.0, and the temperature of the reaction system is 70°C. The precursor after the reaction was completed was washed in deionized water at 80° C. until neutral, and dried at 80° C. for 20 hours to obtain a lithium nickel manganese oxide cathode material precursor.

[0089] S220: Preparation of high-voltage lithium nickel manganese oxide: Weigh the precursor and lithium source according to the molar ratio of lithium carbonate: precursor of 1:1 and mix them evenly, raise the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com