Quenching machine accelerated cooling method for improving strength of normalized steel plate with thickness specification of being greater than or equal to 50 mm

A technology of accelerated cooling and quenching machine, used in heat treatment equipment, furnaces, heat treatment process control and other directions, can solve the problem of low strength of steel plates, and achieve the effect of large strength improvement, increased strength, and increased nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

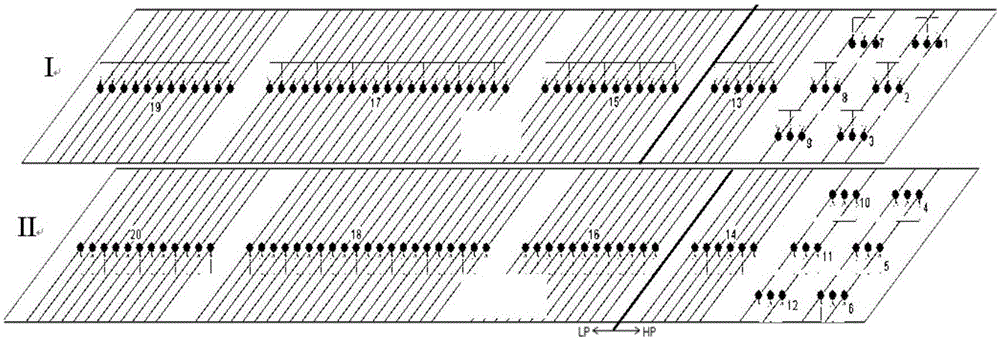

[0024] Aiming at the problem of insufficient strength margin of the normalized steel plate of the 50mm specification SM570N forklift beam, four low-pressure sections are turned on for water cooling. The opening of the 20-zone flow regulating valve is 53% / 78%, and the ratio of the upper and lower openings (water ratio) is 0.80-0.81; the roller speed is 23m / min; the average cooling speed is 8.9°C / S; The temperature is 612°C.

[0025] Under the condition of keeping the same composition, rolling and normalizing process, the average value of yield strength after conventional normalizing is 451MPa, and the average value of tensile strength is 592MPa, while the average value of yield strength after adopting normalizing and controlled cooling of the present invention is 533MPa, and the average value of tensile strength is 533MPa, and the average value of tensile strength is 688MPa, the overall strength is increased by 80-100MPa, and the performance margin of other indicators is reason...

Embodiment 2

[0027] In view of the insufficient strength margin of the 60mm specification S355NLZ35 marine engineering normalized steel plate, four low-pressure sections are turned on for water cooling. The opening of the flow regulating valve in the 20 zones is 56% / 79%, and the ratio of the upper and lower openings (water ratio) is 1.191; the roller speed is 20m / min; the average cooling speed is 9.3°C / S; the average temperature of the final cooling "returning red" is 608 ℃.

[0028] Under the condition of keeping the same composition, rolling and normalizing process, the average value of yield strength after conventional normalizing is 345MPa, and the average value of tensile strength is 502MPa, while the average value of yield strength after normalizing and controlled cooling of the present invention is 429MPa, the average value of tensile strength is 429MPa, and the average value of tensile strength is 595MPa, the overall strength is increased by 80-100MPa, and the performance margin of...

Embodiment 3

[0030] For the 80mm specification S460MZ25 structural steel plate shape incompatibility, six low-pressure sections are opened for water cooling, and the water cooling adjustment is as follows: the opening of the flow regulating valve in the 15th / 17th / 19th area of the low-pressure section is 32% / 42% / 62%, respectively, and the 16th area The opening degree of the flow regulating valve in zone 18 / zone 20 is 37% / 49% / 72%, and the ratio of the upper and lower openings (water ratio) is 1.167; the roller speed is 18m / min; the average cooling rate is 9.5℃ / S; the final cooling The average temperature of "returning red" is 602°C.

[0031] Under the condition of keeping the same composition and rolling process, the average value of yield strength in TMCP state is 478MPa, and the average value of tensile strength is 615MPa, while the average value of yield strength after adopting normalizing and controlled cooling of the present invention is 482MPa, the average value of tensile strength is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com