Method for preparing prussian blue material through composite reduction of graphene oxide, and application

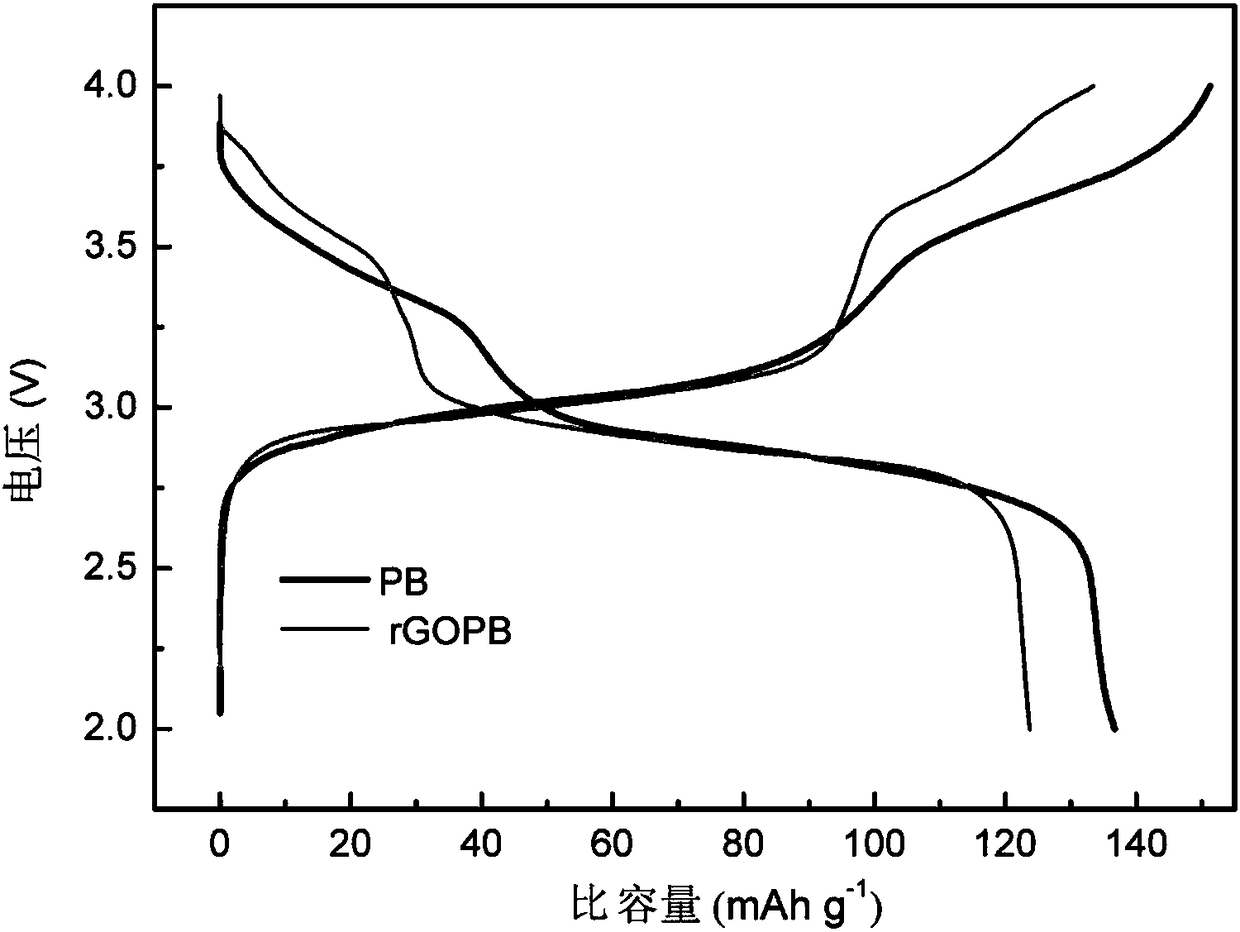

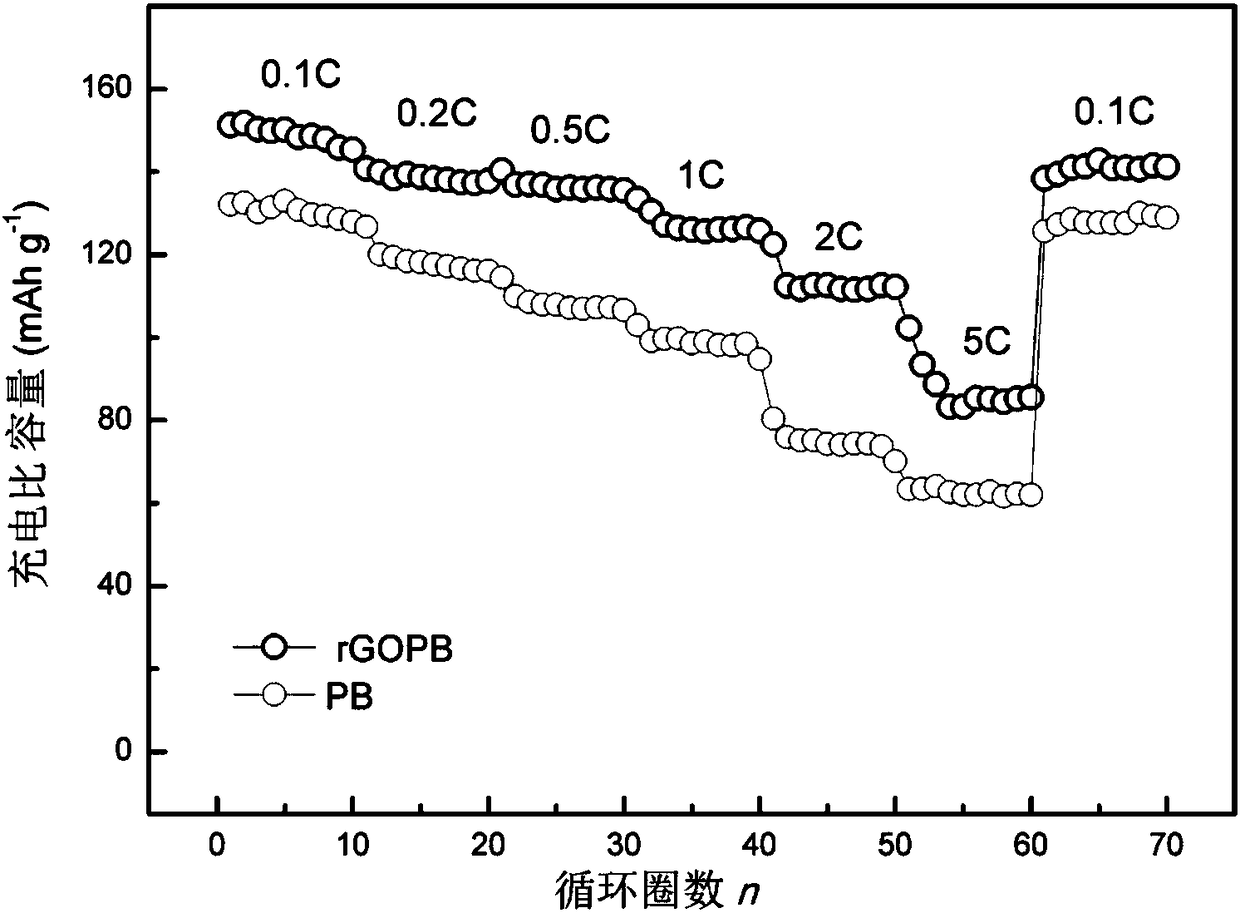

A Prussian blue and graphene technology, applied in the field of preparation of Prussian blue materials, can solve the problems of high method cost, poor rate performance, complicated operation, etc., and achieve the effects of low preparation cost, improved specific capacity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

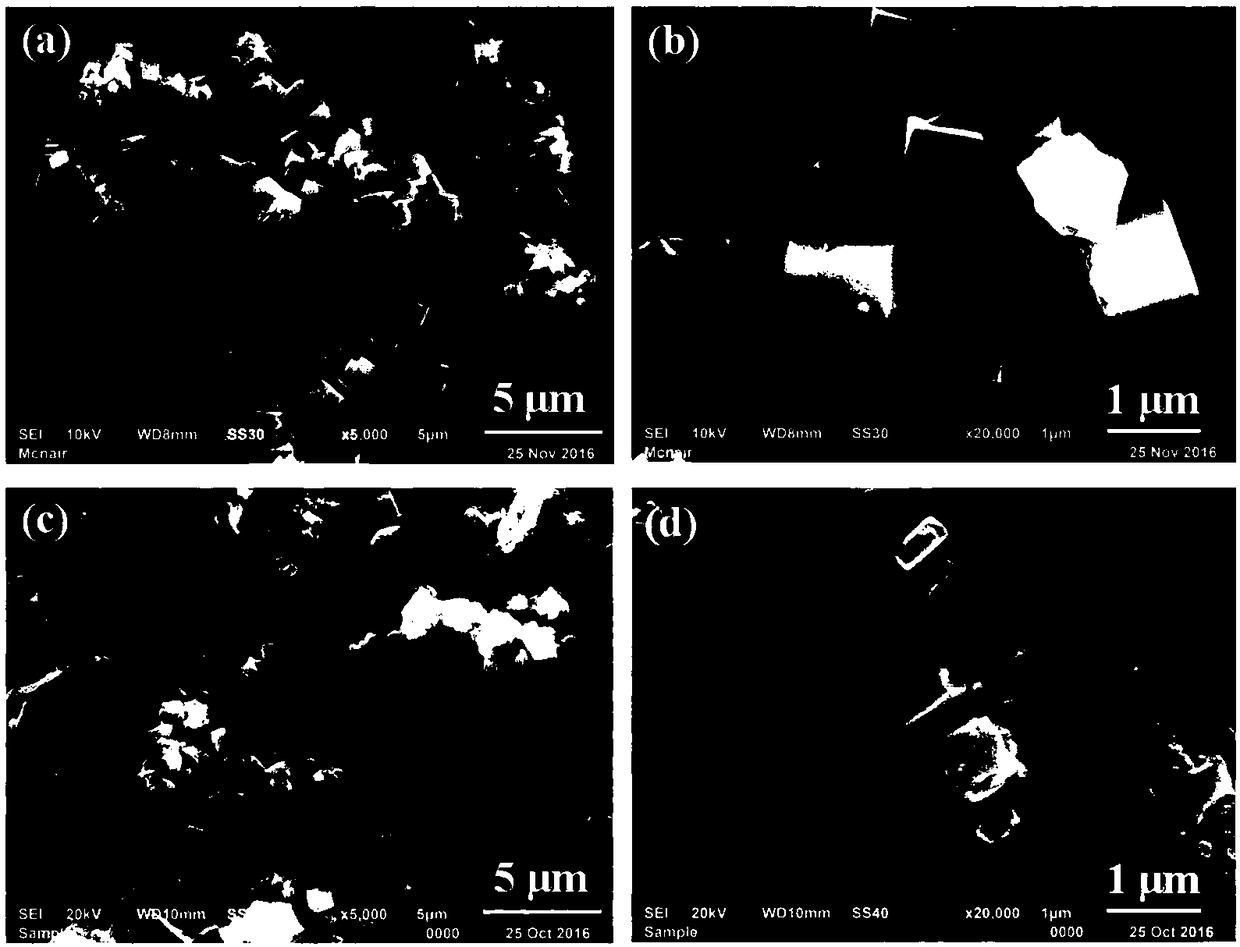

[0048] The preparation method of the Prussian blue material of composite reduced graphene oxide adopts the following steps:

[0049] 1) Prepare 200ml of Na with a concentration of 10mM 4 Fe(CN) 6 Solution A, transfer it to a beaker with a magnet, and stir with a magnetic stirrer at a low speed of 300rpm. 2) Using commercially available graphene oxide GO, according to relative Na 4 Fe(CN) 6 The mass ratio of 2% was weighed and added to solution A, ultrasonicated for 10 minutes to make it uniformly dispersed to obtain solution B.

[0050] 3) Add ascorbic acid and 1 mM sodium citrate to the solution B so that the final concentration is 1 mM, and stir for 5 min to obtain a mixed solution C.

[0051] 4) Use a pH tester to measure the pH value of solution C in real time, and add hydrochloric acid dropwise to pH = 1 to obtain solution D.

[0052] 5) Transfer the above solution D to a flask and fix it in a water bath, pass an inert gas such as nitrogen, and place it in the dark, ...

Embodiment 2

[0061] The preparation method of the Prussian blue material of composite reduced graphene oxide comprises the steps:

[0062] 1) Prepare 200ml of Na with a concentration of 20mM 4 Fe(CN) 6 Solution A, transfer it to a beaker with a magnet, and stir with a magnetic stirrer at a low speed.

[0063] 2) Pre-prepared graphene oxide GO by Hummers method, according to relative Na 4 Fe(CN) 6 The mass ratio of 5% was weighed and added to solution A, and it was ultrasonically dispersed for 15 minutes to obtain solution B evenly.

[0064] 3) Add ascorbic acid and sodium citrate to solution B to make the final concentration of each 2.5mM, stir for 8min to obtain mixed solution C.

[0065] 4) Use a pH tester to test the pH value of solution C in real time, add hydrochloric acid dropwise to pH = 1.2, and obtain solution D.

[0066] 5) Transfer the above solution D to a flask and fix it in a water bath, pass an inert gas such as nitrogen or hydrogen-argon mixed gas, keep it away from li...

Embodiment 3

[0072] The preparation method of the Prussian blue material of composite reduced graphene oxide comprises the steps:

[0073] 1) Prepare 200ml of Na with a concentration of 30mM 4 Fe(CN) 6 Solution A, transfer it to a beaker with a magnet, and stir with a magnetic stirrer at a low speed.

[0074] 2) Pre-prepared graphene oxide GO by Hummers method, according to relative Na 4 Fe(CN) 6 The mass ratio of 10% was weighed and added to solution A, ultrasonicated for 30 minutes to make it uniformly dispersed to obtain solution B.

[0075] 3) Add ascorbic acid and 5 mM sodium citrate to solution B with a final concentration of 5 mM, and stir for 10 min to obtain mixed solution C.

[0076] 4) Use a pH tester to test the pH value of solution C in real time, and add hydrochloric acid dropwise to pH=2 to obtain solution D.

[0077] 5) Transfer the above solution D to a flask and fix it in a water bath, pass through an inert gas such as nitrogen or hydrogen-argon gas mixture, keep it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com