Preparation method of high-tap-density iron phosphate material

A technology of tap density and iron phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of unfavorable lithium iron phosphate, large particle voids, etc., reduce the nucleation rate, and achieve uniform secondary particle size. , the effect of increasing the chance of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

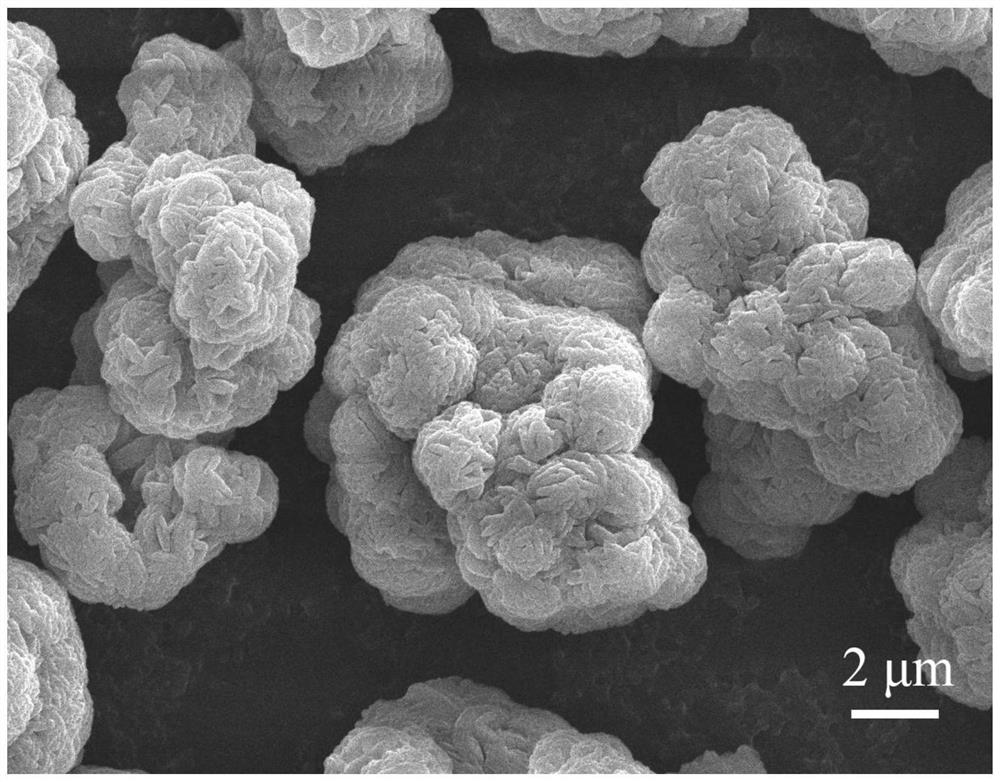

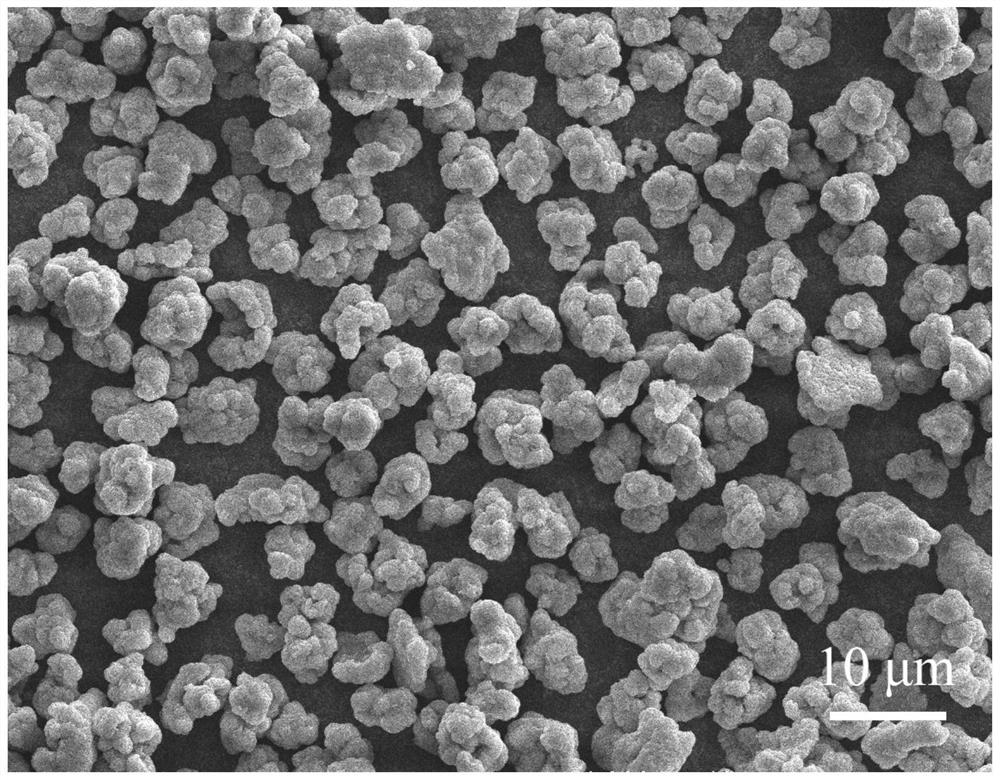

Embodiment 1

[0036] Embodiment 1 of the present invention is: a kind of preparation method of iron phosphate material of high tap density, comprises the following steps:

[0037] S1. Under the condition that the stirring rate is 400rpm, according to the molar ratio of iron element and phosphorus element is 1:1.3, quickly add ammonium hydrogen phosphate solution (1.2mol / L) to the first iron source ferric sulfate solution After ferric sulfate solution (0.6mol / L), control the temperature of the reaction system to 92°C, the reaction time is 3h, and gradually convert into white slurry to obtain ferric phosphate seeds;

[0038] S2. Under the condition that the stirring speed is 200rpm and the system temperature is 92°C, ferric sulfate solution (0.25mol / L) and ammonium monohydrogen phosphate solution (0.5mol / L) are fed at a feed rate of 1.5L / h, and Add the liquid to the ferric phosphate seed crystal. When the material reaches the upper limit of the reaction vessel volume, stop feeding, and keep t...

Embodiment 2

[0042] Embodiment 2 of the present invention is: a kind of preparation method of iron phosphate material of high tap density, comprises the following steps:

[0043] S1. Under the condition that the stirring rate is 500rpm, according to the molar ratio of iron element and phosphorus element is 1:1.2, quickly add ammonium dihydrogen phosphate solution (1.45mol / L) to ferric chloride solution (1.45mol / L) Finally, control the temperature of the reaction system to 88°C, and the reaction time is 3 hours, gradually transforming into a white slurry to obtain ferric phosphate seeds;

[0044] S2. Under the condition that the stirring speed is 220rpm and the system temperature is 88°C, ferric chloride solution (0.4mol / L) and ammonium dihydrogen phosphate solution (0.4mol / L) are fed at a feed rate of 1L / h, and Add to the ferric phosphate seed crystal, when the material reaches the upper limit of the volume of the reaction vessel, stop feeding, and keep the existing stirring speed and temper...

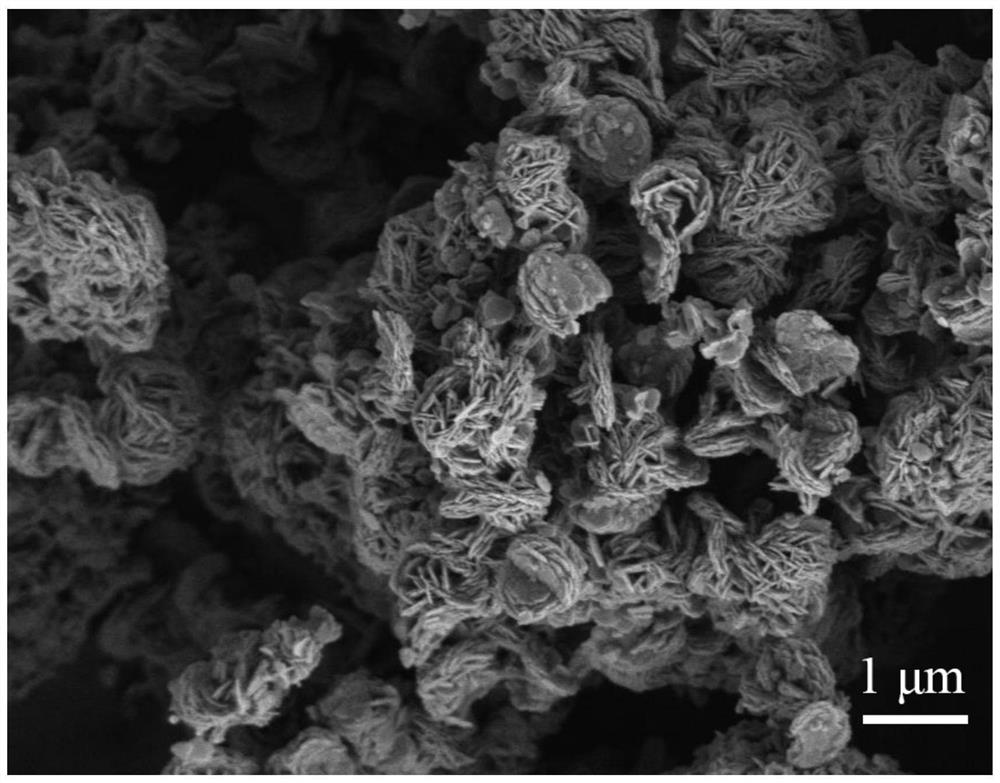

Embodiment 3

[0047] Embodiment 3 of the present invention is: a kind of preparation method of high tap density quasi-spherical ferric phosphate material, comprises the following steps:

[0048] S1. Under the condition of stirring rate of 480rpm, according to the molar ratio of iron element and phosphorus element of 1:1.15, quickly add ammonium hydrogen phosphate solution (1.3mol / L) to ferric nitrate solution (1.3mol / L) , control the temperature of the reaction system at 90°C, and the reaction time is 3h, gradually transforming into a white slurry to obtain iron phosphate seeds;

[0049] S2. Under the condition that the stirring rate is 200rpm and the system temperature is 90°C, feed ferric nitrate solution (1mol / L) and ammonium monohydrogen phosphate solution (1mol / L) at a feed rate of 1.5L / h, and flow Add the feed to the ferric phosphate seed crystal. When the material reaches the upper limit of the volume of the reaction vessel, stop feeding, and keep the current stirring rate and temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com