Environment-friendly dry mortar mixer

A dry-mixed mortar and mixer technology, which is applied in cement mixing devices, liquid ingredient supply devices, clay preparation devices, etc., can solve the problems of large dust and violations, and achieve the effects of reasonable structure, energy saving, and shortened mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

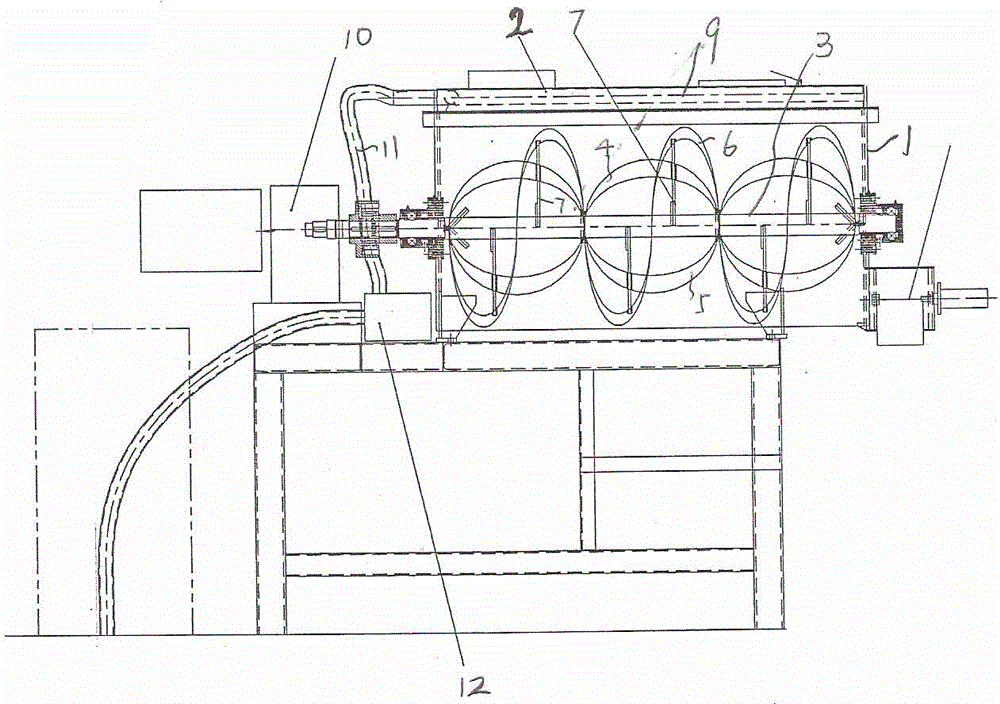

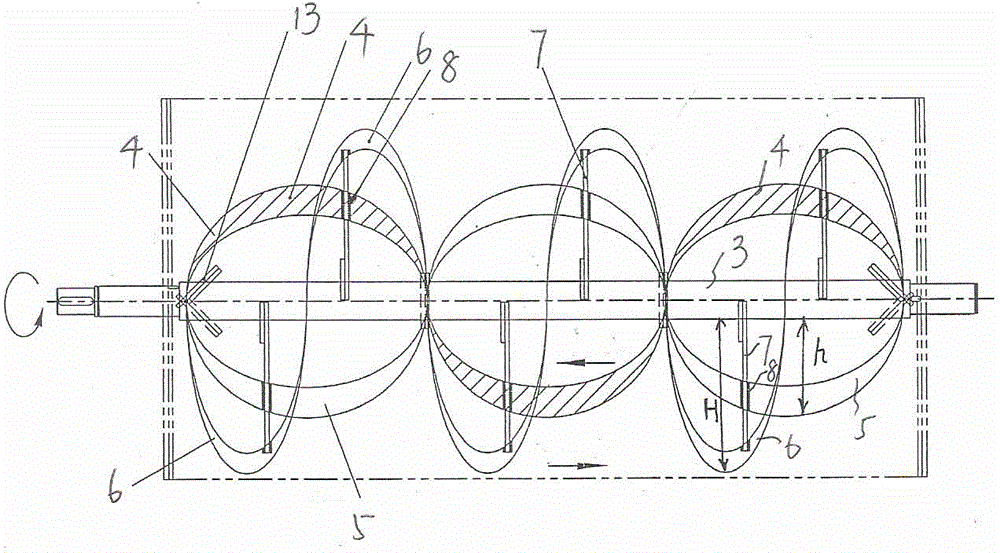

[0014] An environment-friendly dry-mixed mortar mixer, comprising a housing 1 installed on a frame, a cover 2 is mounted on the housing, a feeding port is provided on the cover, and a driving mechanism (including a motor, a reducer, a coupling, etc.) is arranged inside the housing. Agitator shaft 3 driven by shaft device) 10, two inner ribbons 4, 5 and one outer ribbon 6 are mounted on the mixer shaft, the height H of the outer ribbon is greater than the height h of the inner ribbon, and the lower end of the outer ribbon is at The bottom area of the shell; the inner spiral belt is a left-handed spiral belt, and the outer spiral belt is a right-handed spiral belt; the inner and outer spiral belts are fixed on the stirring arm 7 connected to the stirring shaft at one end; a discharge door is provided at the bottom of the shell.

[0015] One end of the stirring arm is fixed on the stirring shaft, and the other end of the stirring arm passes through the hole 8 on the inner thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com