Patents

Literature

36results about How to "Fast homogenization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

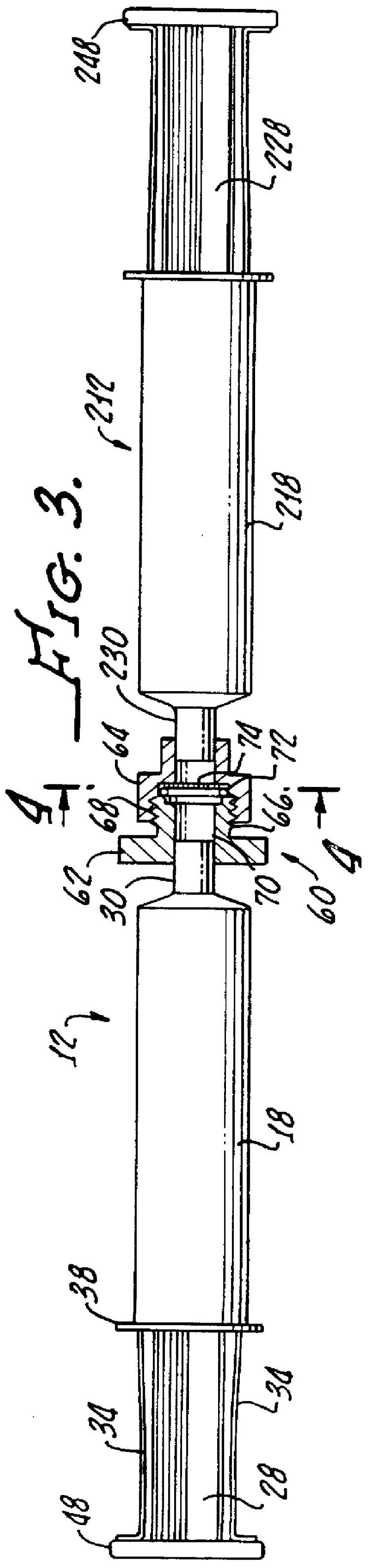

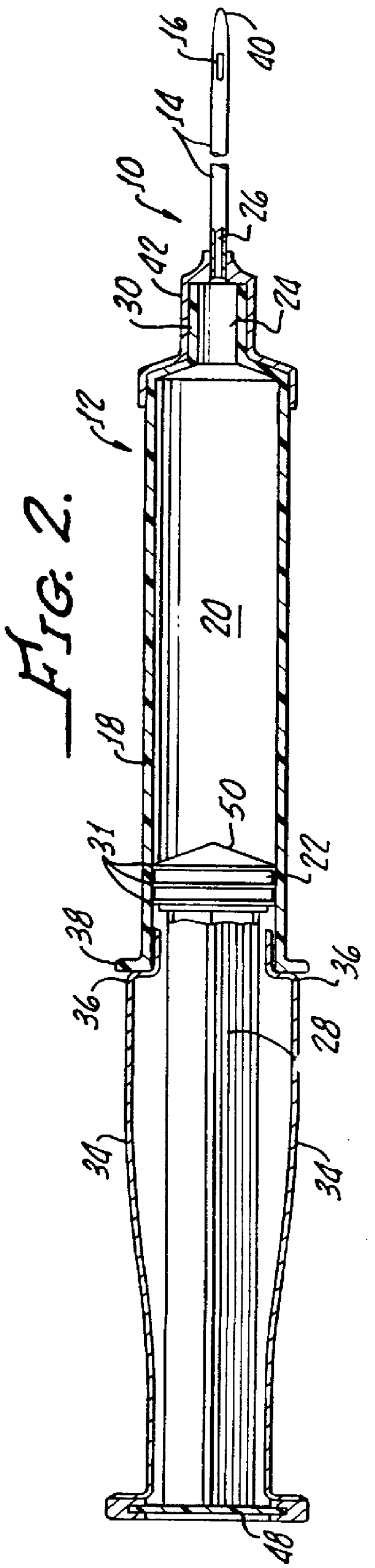

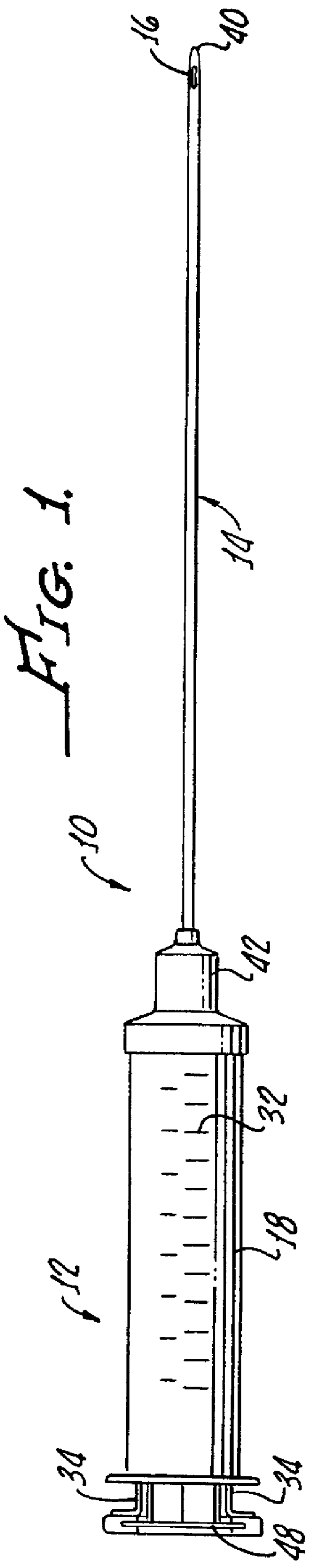

Devices for harvesting and homogenizing adipose tissue containing autologous endothelial cells

InactiveUS6020196AExpand the populationEasy to operateBioreactor/fermenter combinationsElectrotherapyAmbient pressureWhite adipose tissue

Disclosed herein are methods for harvesting adipose tissue so as to preserve an increased population of viable microvascular endothelial cells. Adipose tissue containing microvascular endothelial cells is harvested using a collection apparatus incorporating an elongate cannula having apertures with tissue cutting edges. A sub-ambient pressure is applied to a lumen in the cannula to draw the adipose tissue through the aperture where it is then severed using the cutting edge to disrupt the connective adipose matrix. This harvesting provides a cleaner, more homogeneous sample of adipose tissue, thereby increasing the population of viable microvascular endothelial cells obtained through further processing. Rapid and easy methods for the further homogenization of the harvested adipose tissue are also disclosed.

Owner:EDWARDS LIFESCIENCES CORP

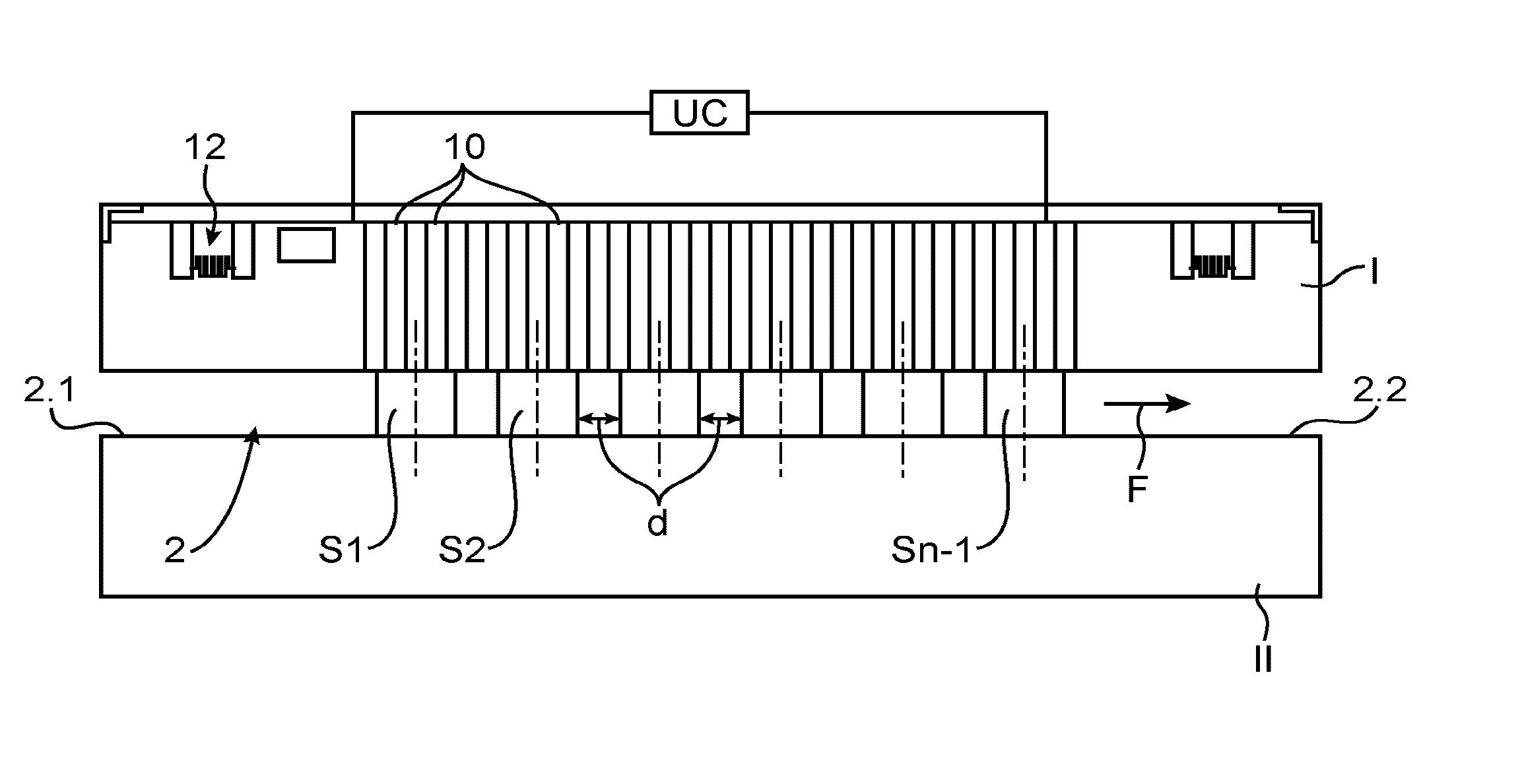

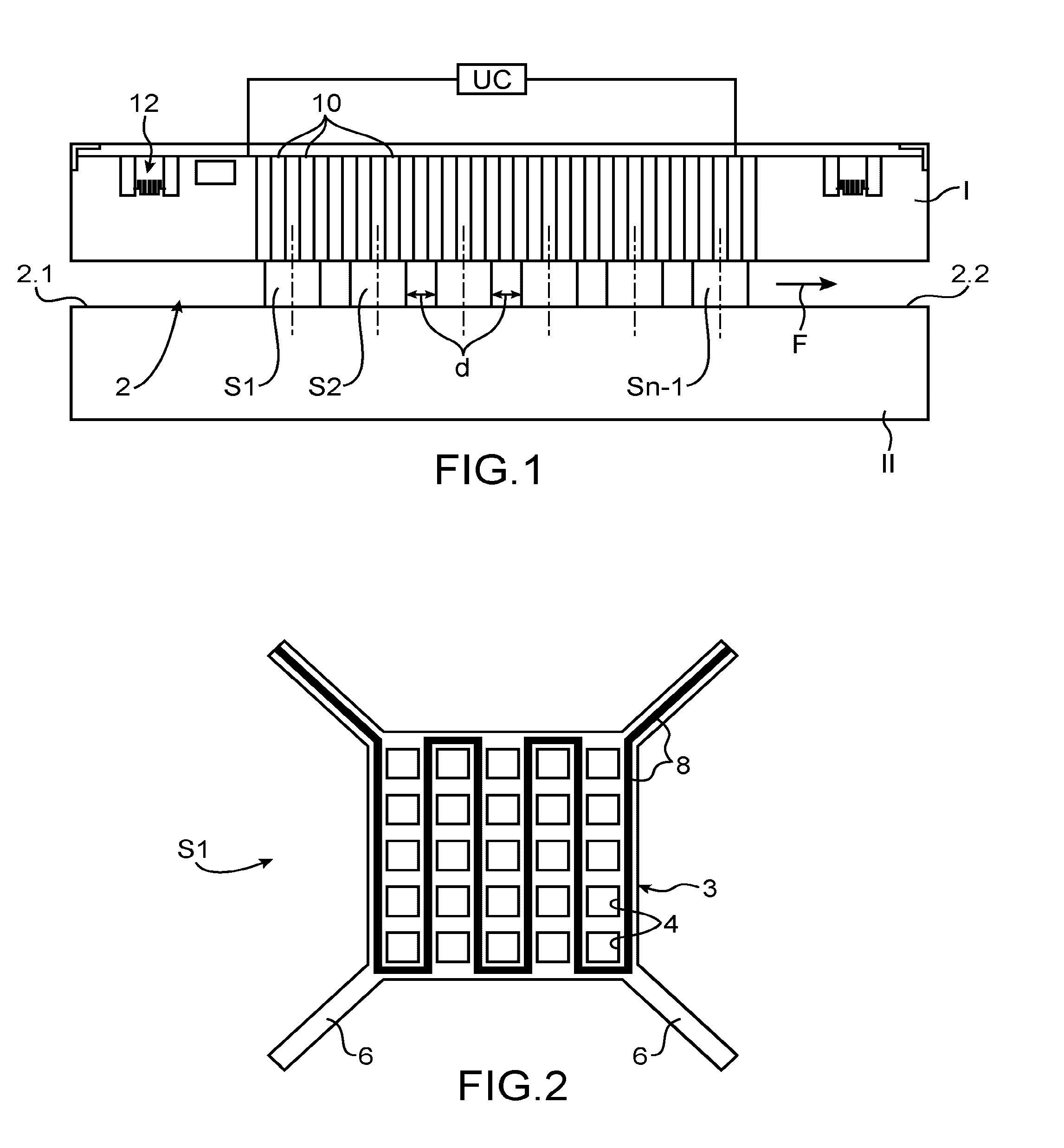

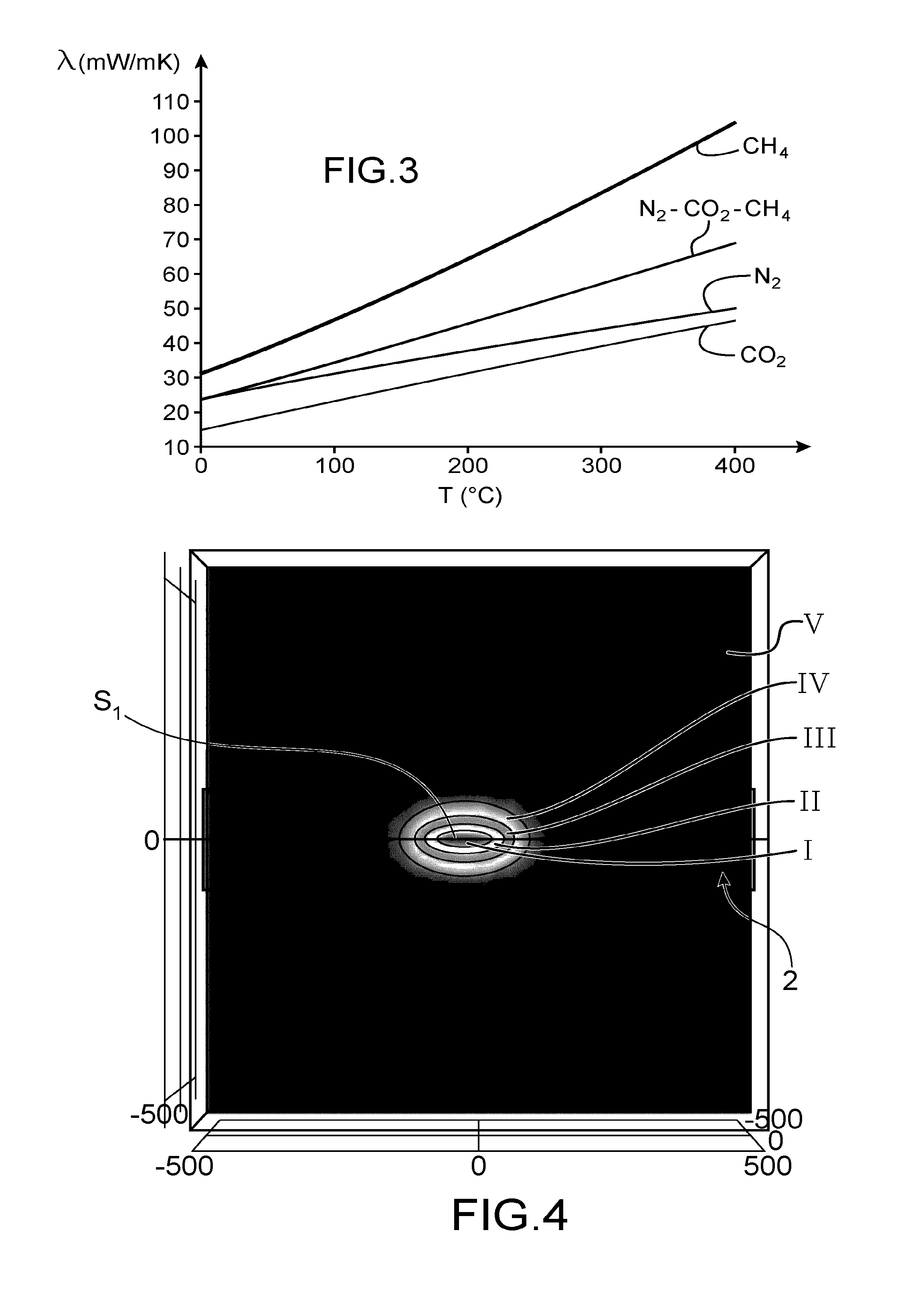

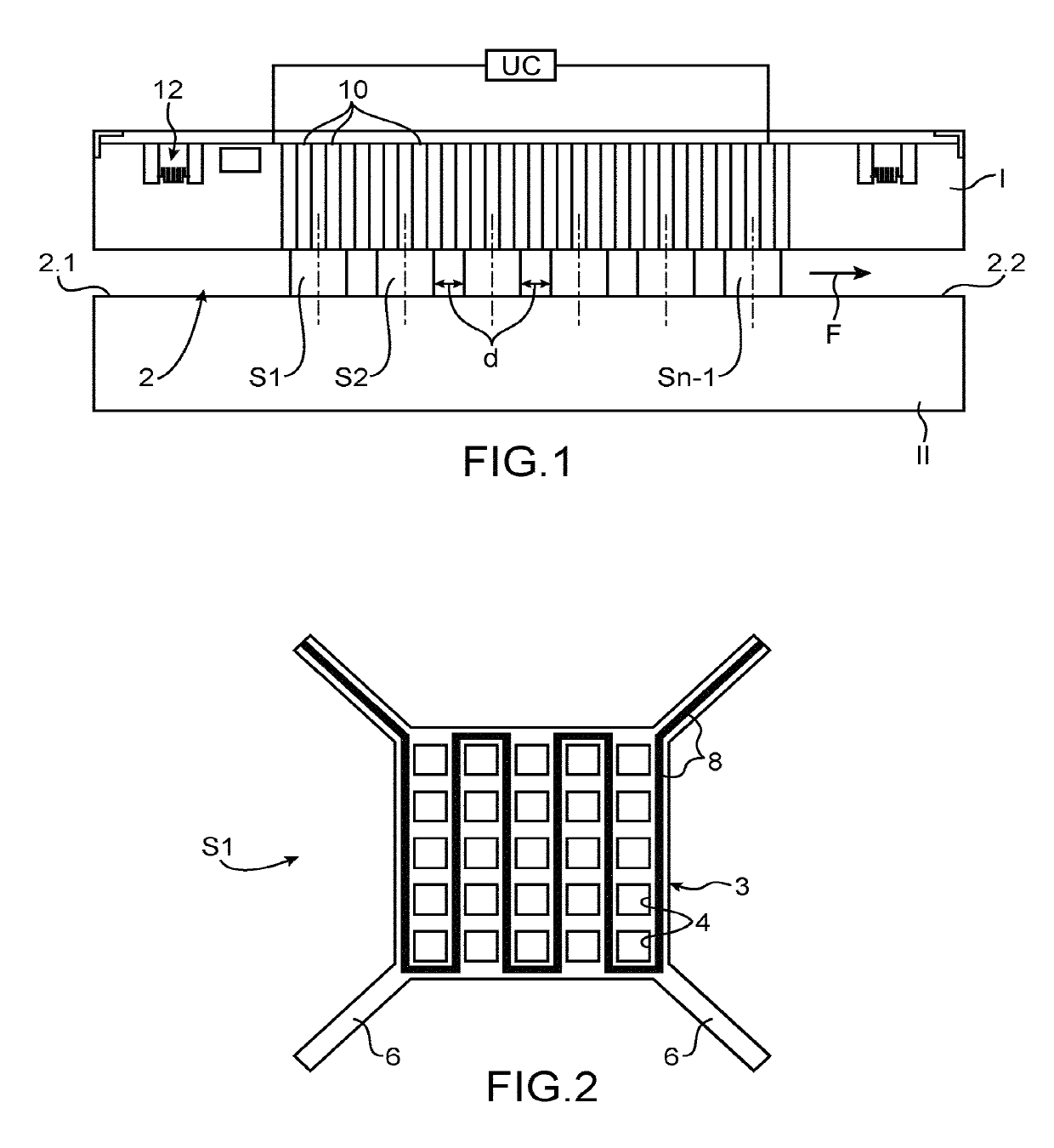

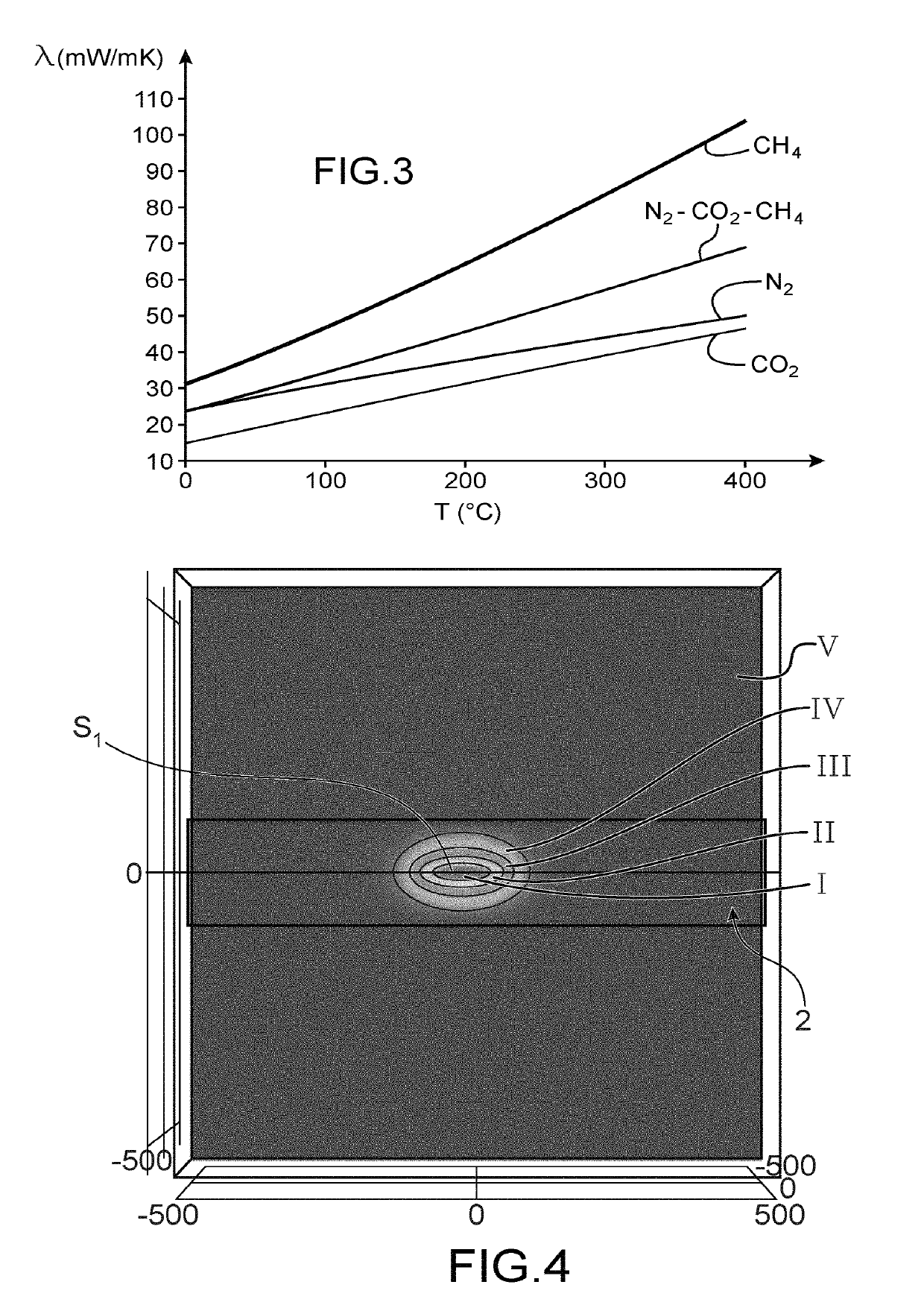

Device for analysis of mixtures of at least two gas

ActiveUS20170016840A1Quick analysisSmall sizeMaterial thermal conductivityAnalysing gaseous mixturesEngineeringMicrofluidic channel

Device for analysing a mixture of n gases, comprising a microfluidic channel (2) extending between a first end and a second end, at least n−1 suspended elements in the microfluidic channel (2), said n−1 elements (S1, S2 . . . Sn−1) succeeding one another from the first end of the microfluidic channel (2) to the second end of the microfluidic channel (2), heating means capable of heating a part at least of the gaseous mixture surrounding each suspended element (S1, S2 . . . Sn−1) to a given temperature different to those to which are heated the gaseous mixtures surrounding the other suspended elements (S1, S2 . . . Sn−1), means of measuring the temperature or the variation in temperature of the suspended elements (S1, S2 . . . Sn−1) and a control and measurement system (UC) connected to the heating means and to the measuring means.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

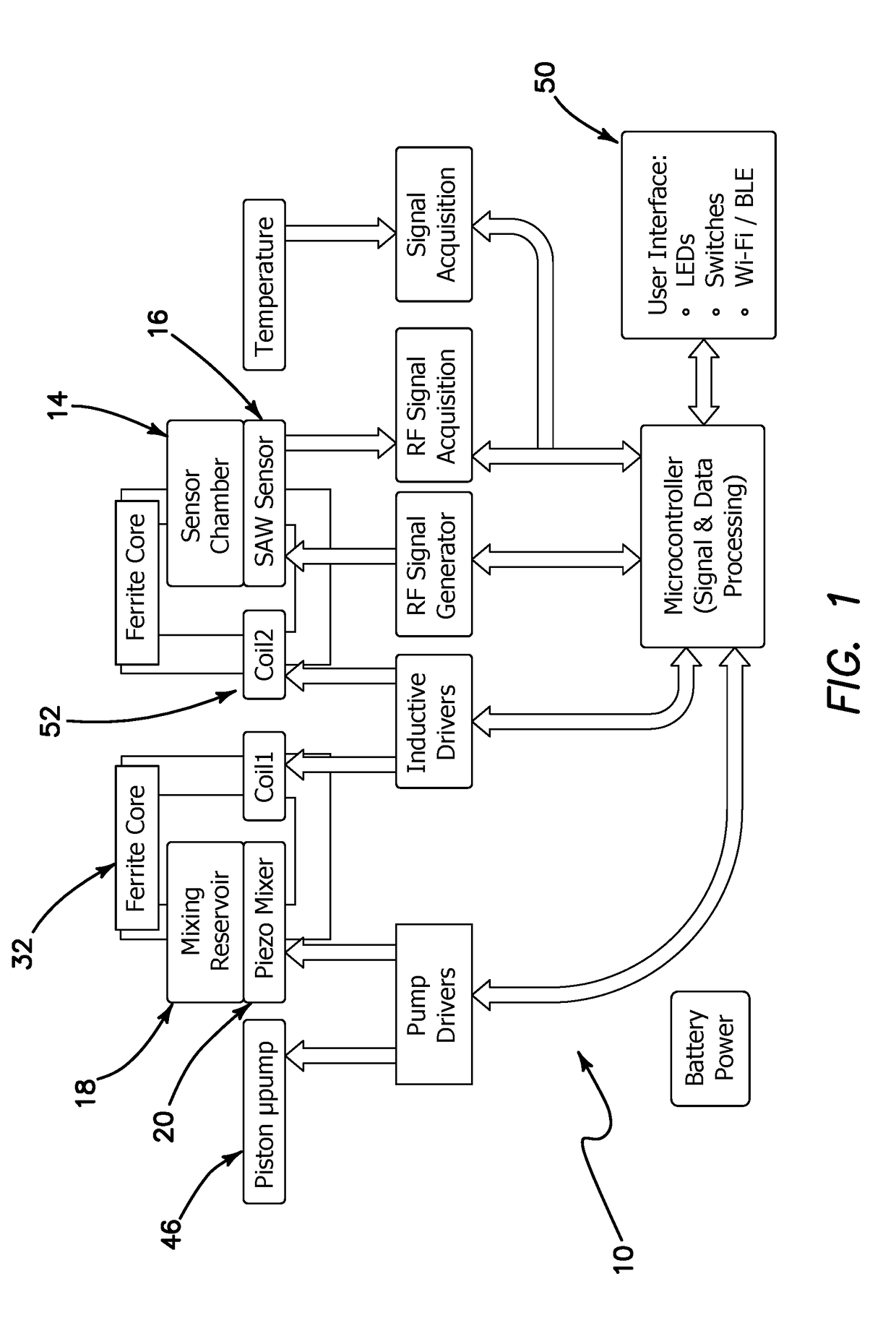

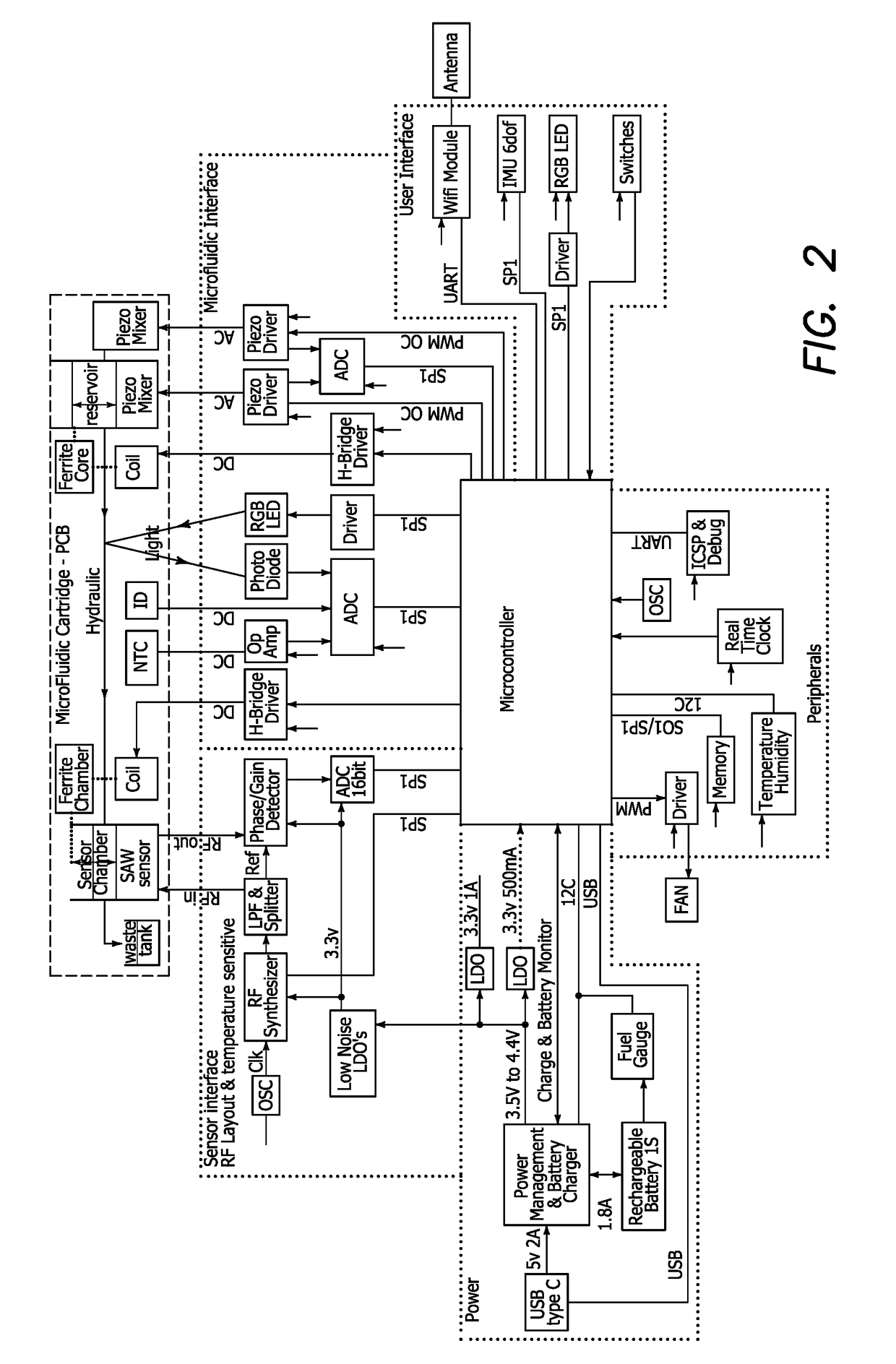

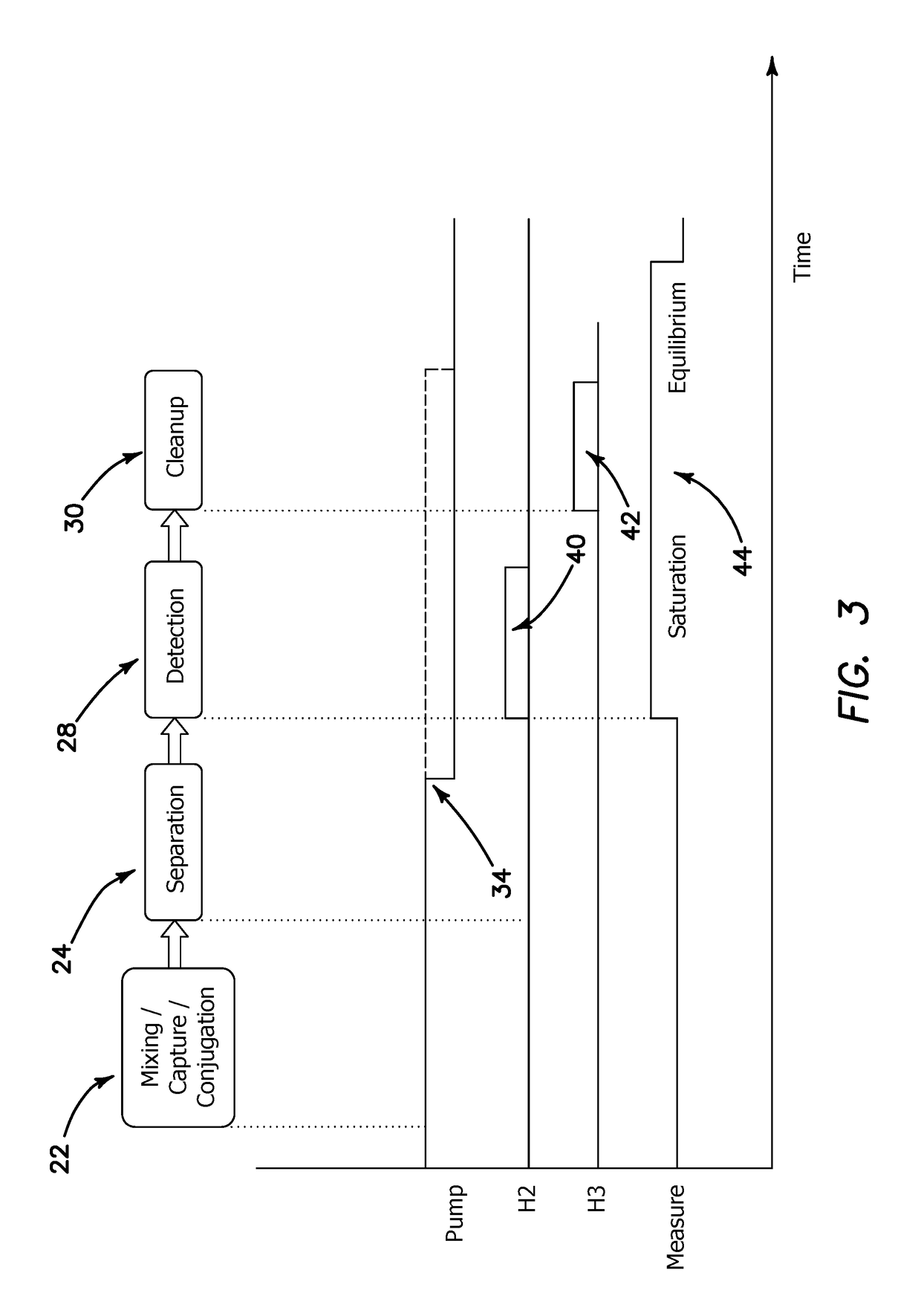

Apparatus for automatic sampling of biological species employing an amplification with a magnetic nanoparticle and propulsion method

ActiveUS20190030533A1Reduces diffusion coefficient penaltyReduce inconsistencyAnalysing fluids using sonic/ultrasonic/infrasonic wavesImpedence networksPhysicsMicro fluidic

An cartridge is combined with a smart device which is capable of communicating with a network to perform a portable, fast, field assay of a small sample biological analyte. A closed microfluidic circuit for mixes the analyte with a buffer with functionalized magnetic beads capable of being specifically combined with the analyte. A detector communicates with the microfluidic circuit in which the mixed analyte, buffer and combined functionalized magnetic beads are sensed. A microcontroller is coupled to detector for controlling the detector and for data processing an output assay signal from the detector. A user interface communicates with the microcontroller for providing user input and for providing user output through the smart device to the network.

Owner:SENSOR KINESIS

Method for preparing brick material of wall body with sludge compound mineralized refuse

ActiveCN108947483ARealize resource utilizationTurn waste into treasureSievingSludge treatment by de-watering/drying/thickeningBrickSludge

The invention discloses a method for preparing a brick material of a wall body with sludge compound mineralized refuse. The method comprises the following steps: homogenizing mineralized refuse powderand dried sludge powder in a horizontal homogenizer; adding a doping material, and mixing to obtain a mixed material; stirring the mixed material for three times, aging twice and extruding once to obtain a raw brick; and finally drying the raw brick in a drying kiln, and sintering and molding in a roasting kiln to obtain the brick material of a wall body. The brick material of a wall body sintered by the dried sludge powder, the mineralized refuse powder and the doping material has performance in conformity with national standard, the comprehensive resource utilization performance of sludge and mineralized waste can be improved, and the sludge homogenizing problem can be solved. The preparation method is simple in process and is favorable to popularization.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Wear resisting material and preparation method thereof

ActiveCN109868386AImprove wear resistanceImprove surface wear resistanceAnodisationOxide ceramicMicro arc oxidation

The invention discloses a wear resisting material. Aluminum nitride, aluminum oxide, molybdenum disilicide and graphite powder particles are uniformly distributed in an aluminum alloy basal body; a composite micro-arc oxidation layer is distributed on the surface of the aluminum alloy basal body; the aluminum nitride, the aluminum oxide and the molybdenum disilicide are high in hardness to prominently improve the hardness and the wear resistance of the material; and through graphite powder, the antifriction can be improved. Through the composite micro-arc oxidation layer on the surface, the alloy surface wear resistance and corrosion resistance can be effectively improved. Strengthening phases of such elements as Sn, Ru, Sr, Lu, Cu, Mn, Mg, Mo and Fe in an alloy are in dispersion strengthening to improve mechanical performances of the material. In a preparation method, through a mode of attaching mixed powder on a pure aluminum metal wire, the mixed powder is positioned in the center of mother alloy liquid during casting, so that the quick dispersion and the homogenization of micropowder particles are facilitated, and the production efficiency is improved; and micro-arc oxidation film forming parameters and conditions are optimized, so that the hardness and the smoothness degree of oxide ceramic films are improved, the film thickness is reduced, and the wear resistance of the material is effectively improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

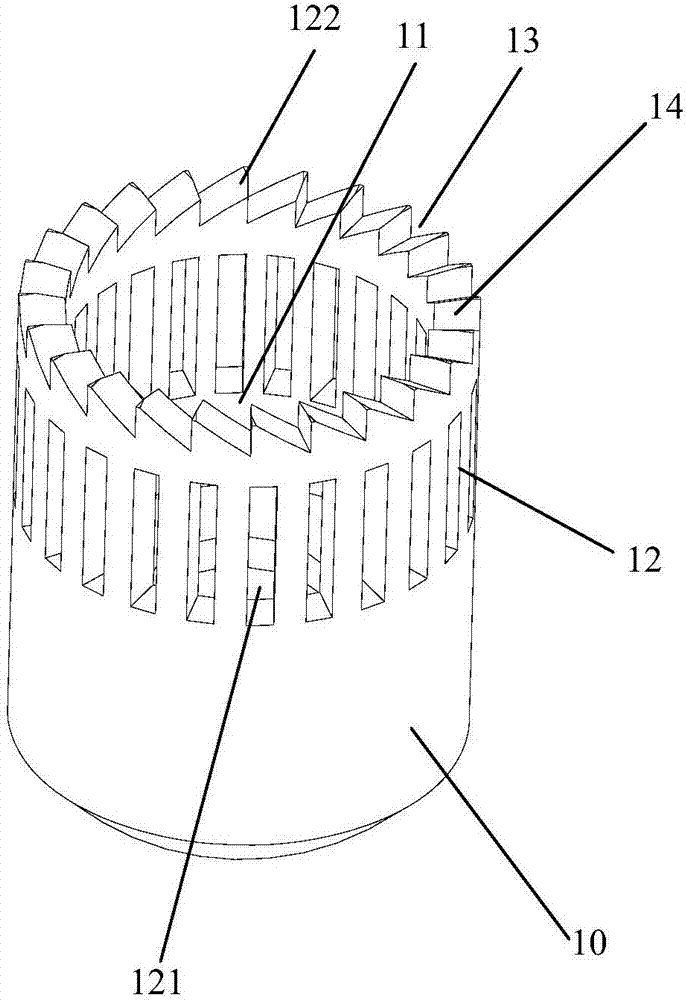

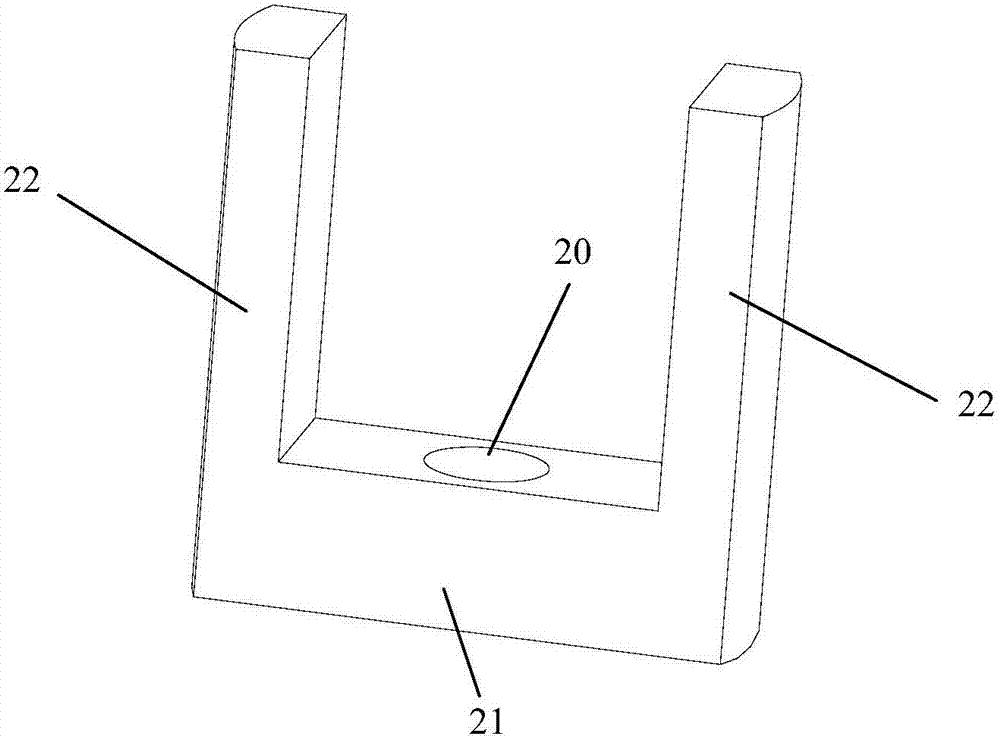

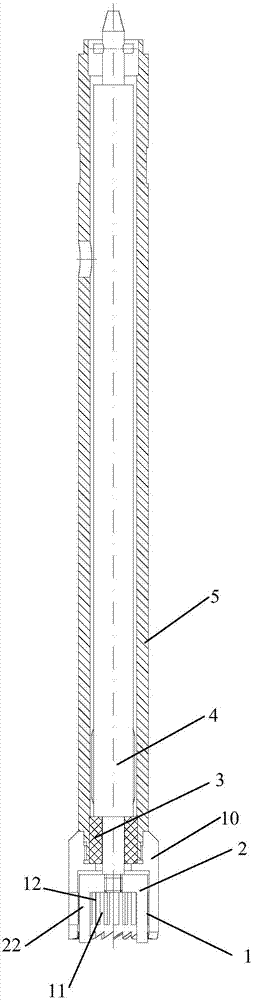

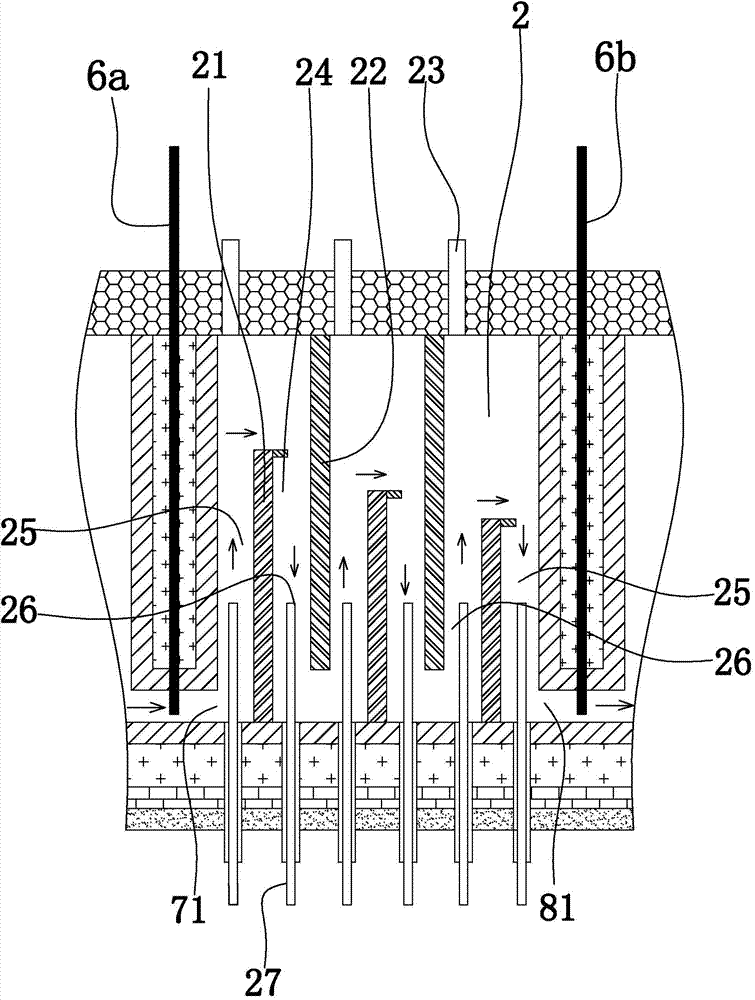

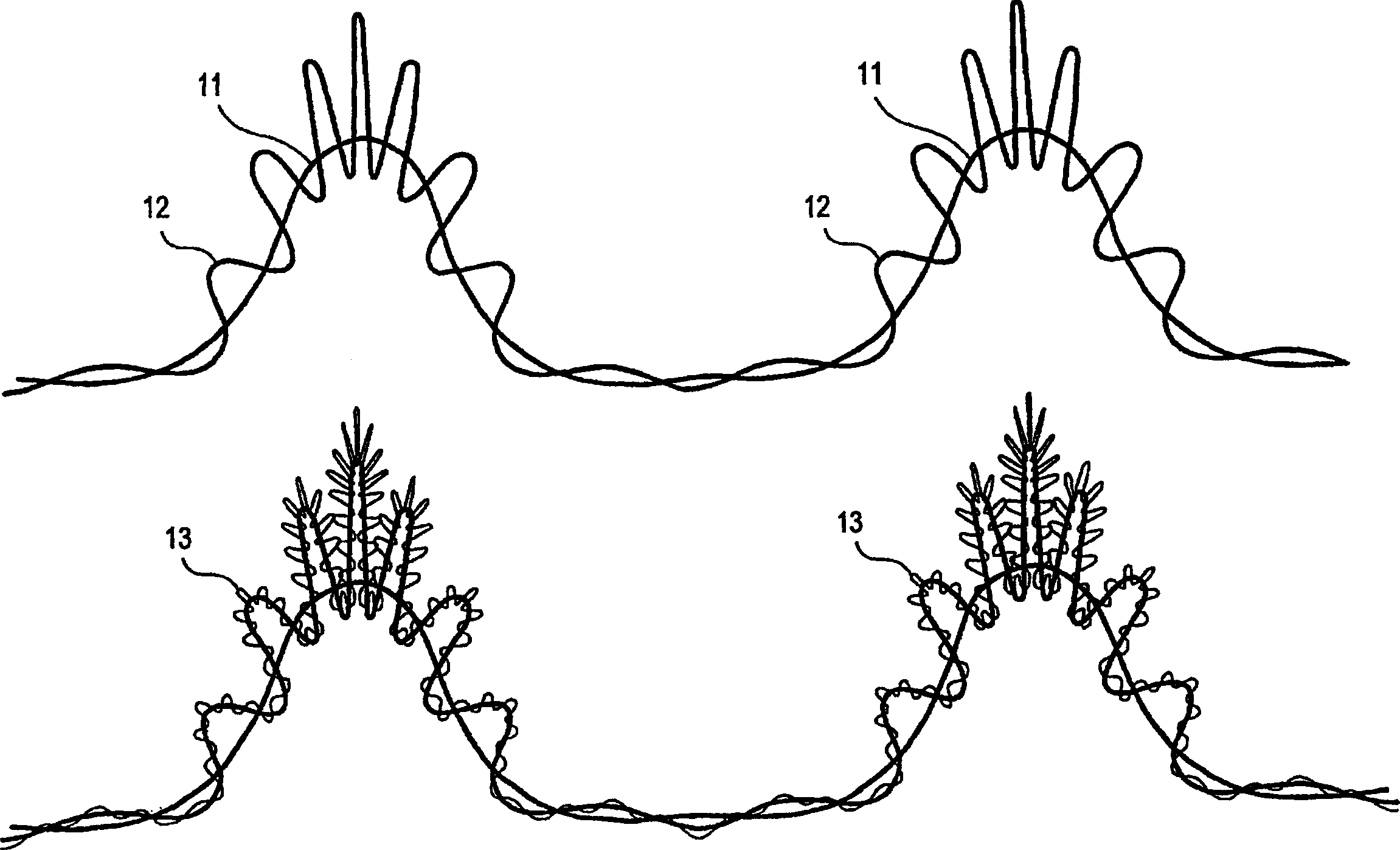

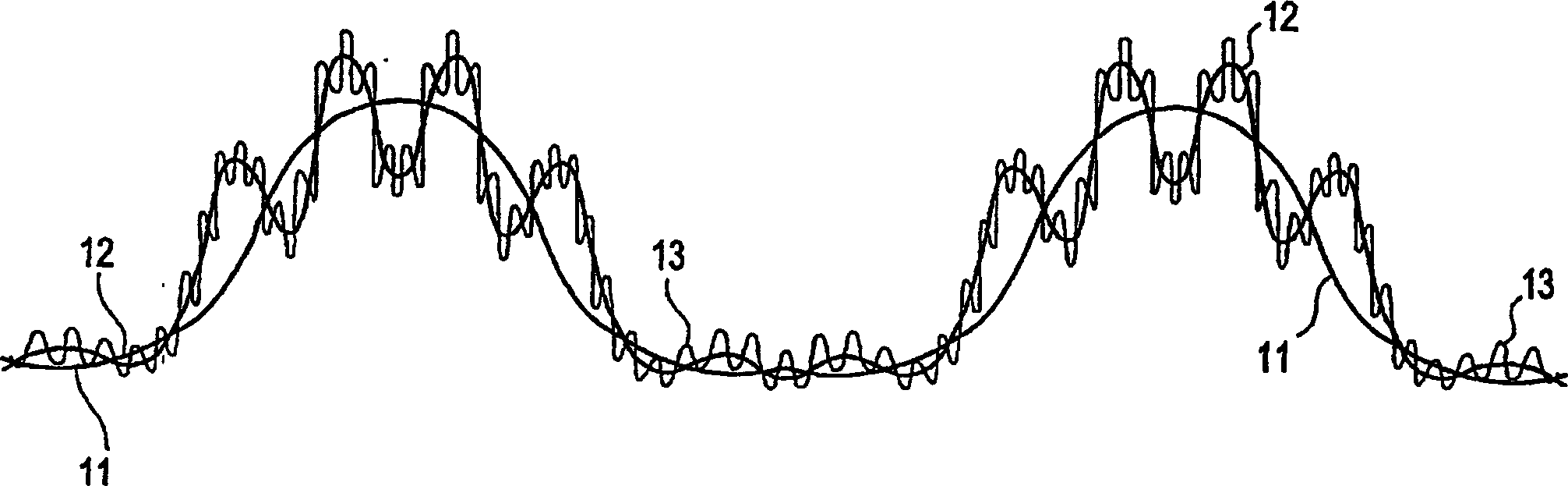

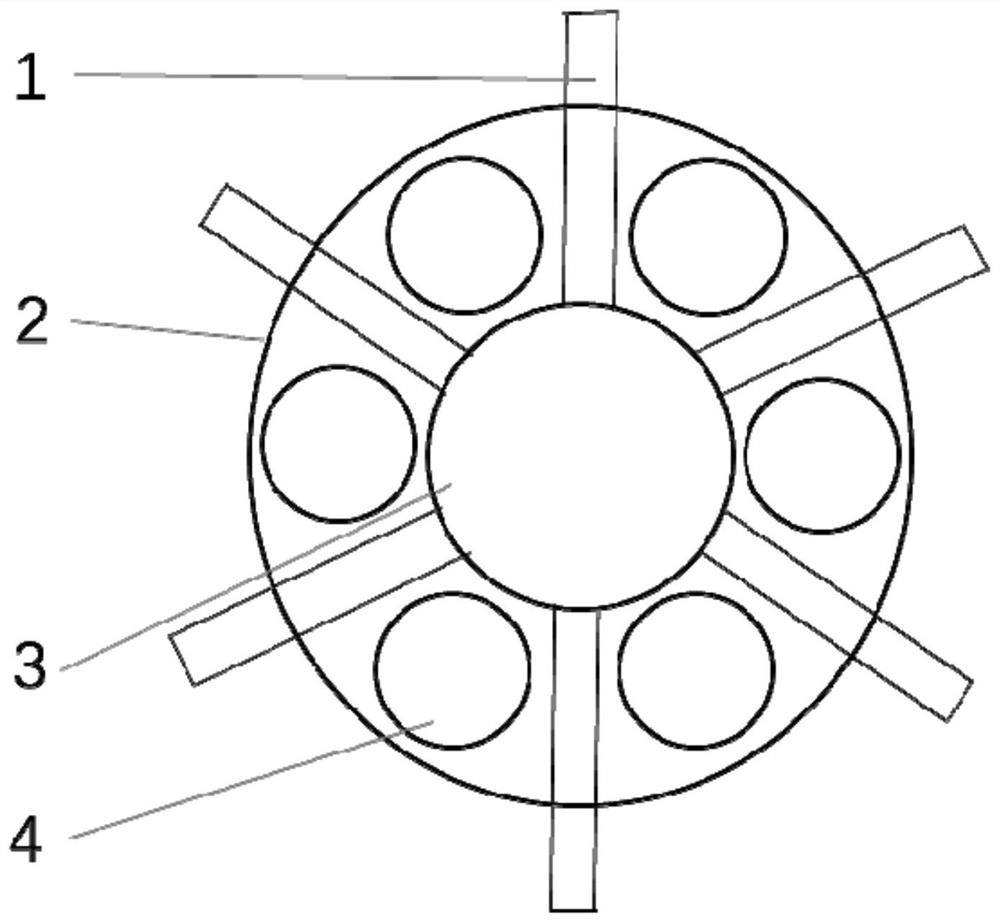

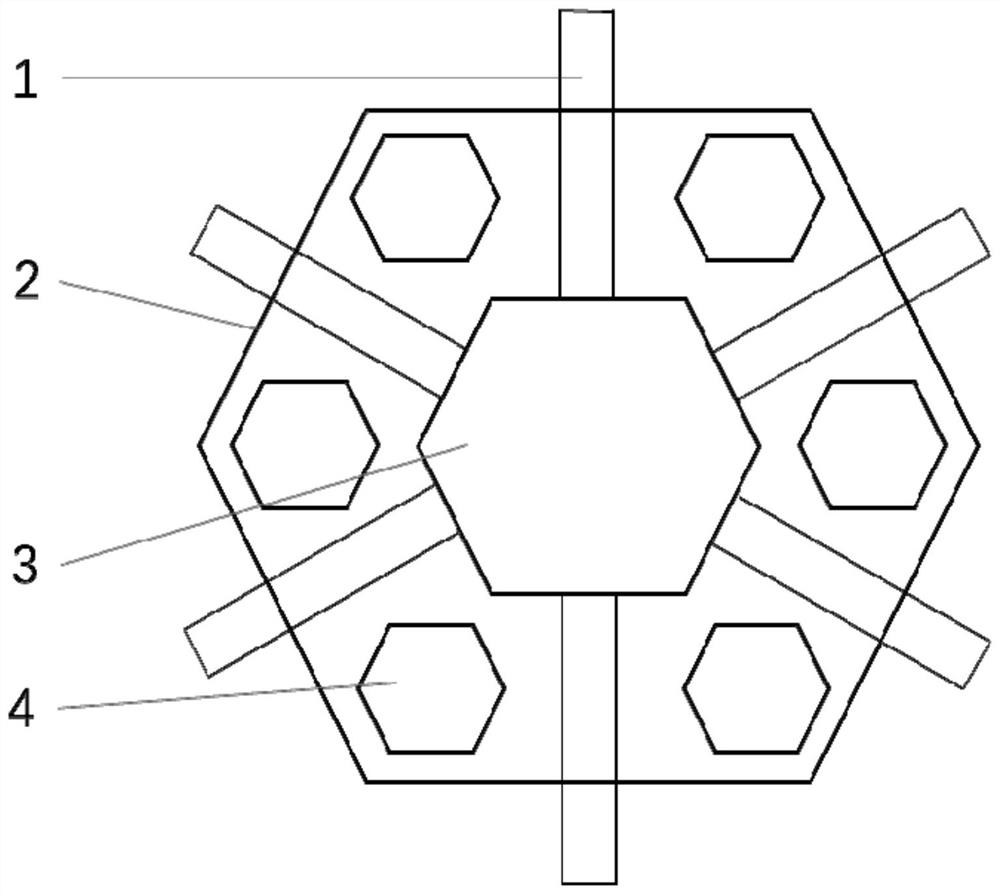

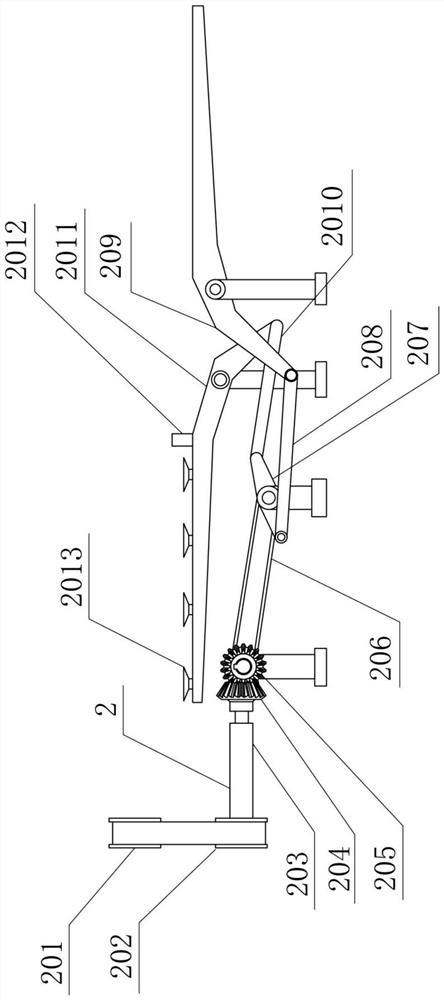

Animal and plant tissue homogenate dispersion machine and working head thereof

PendingCN107441975AQuick breakFast homogenizationRotary stirring mixersTransportation and packagingPlant tissueEmulsion

The invention discloses an animal and plant tissue homogenate dispersion machine and a working head thereof, and is applicable for animal and plant tissue homogenization and dispersion and preparation of a suspending agent and an emulsion. The working head of the animal and plant tissue homogenate dispersion machine comprises a rotor and a stator, wherein the rotor comprises a cross arm and stirring arms extending at two ends of the cross arm in parallel; the stator comprises a base part and a plurality of sawteeth annularly distributed from one side of the base part, the sawteeth are provided with inclined surfaces on two sides in circumferential direction, the sawteeth form a stator cavity, the rotor is arranged inside the stator cavity, and the stirring arms are positioned on the inner sides of the sawteeth.

Owner:SHANGHAI FLUKO TECH DEV

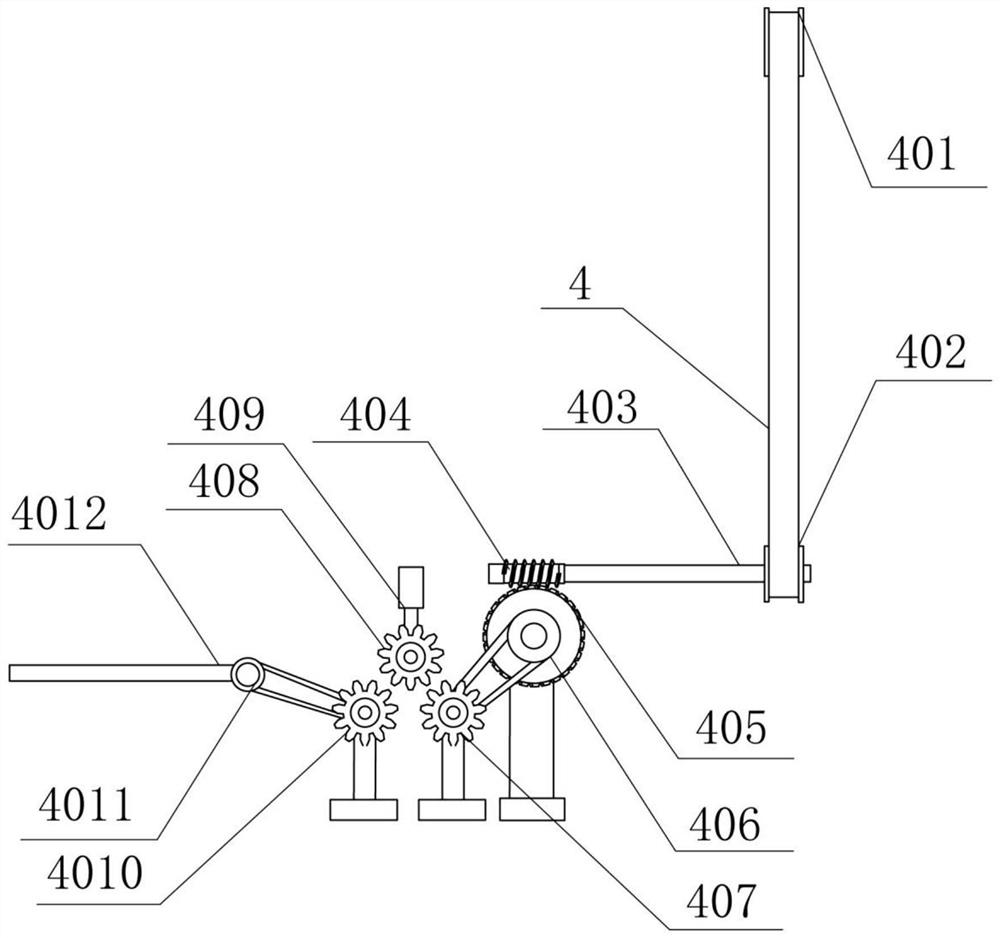

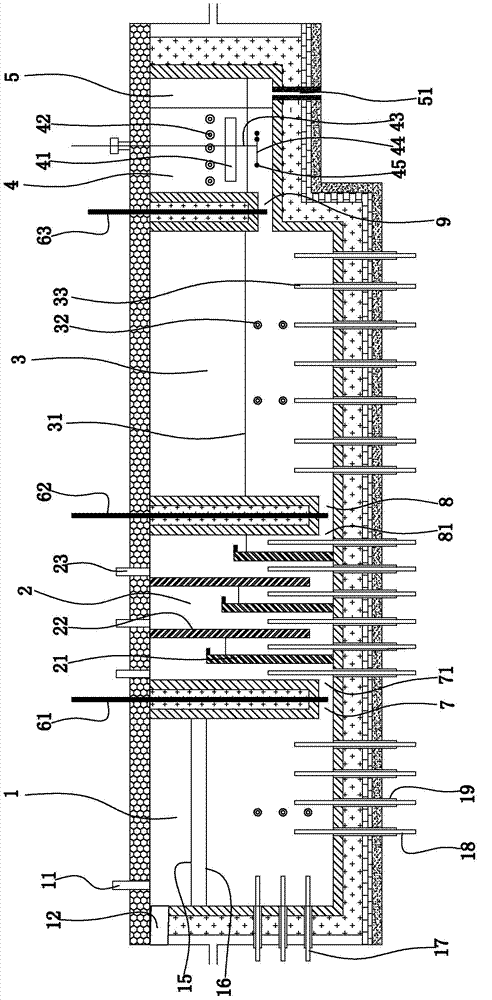

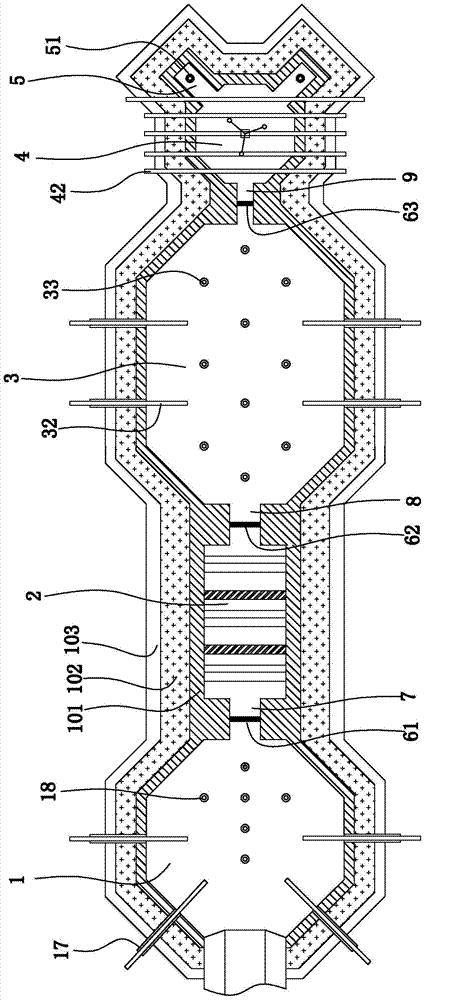

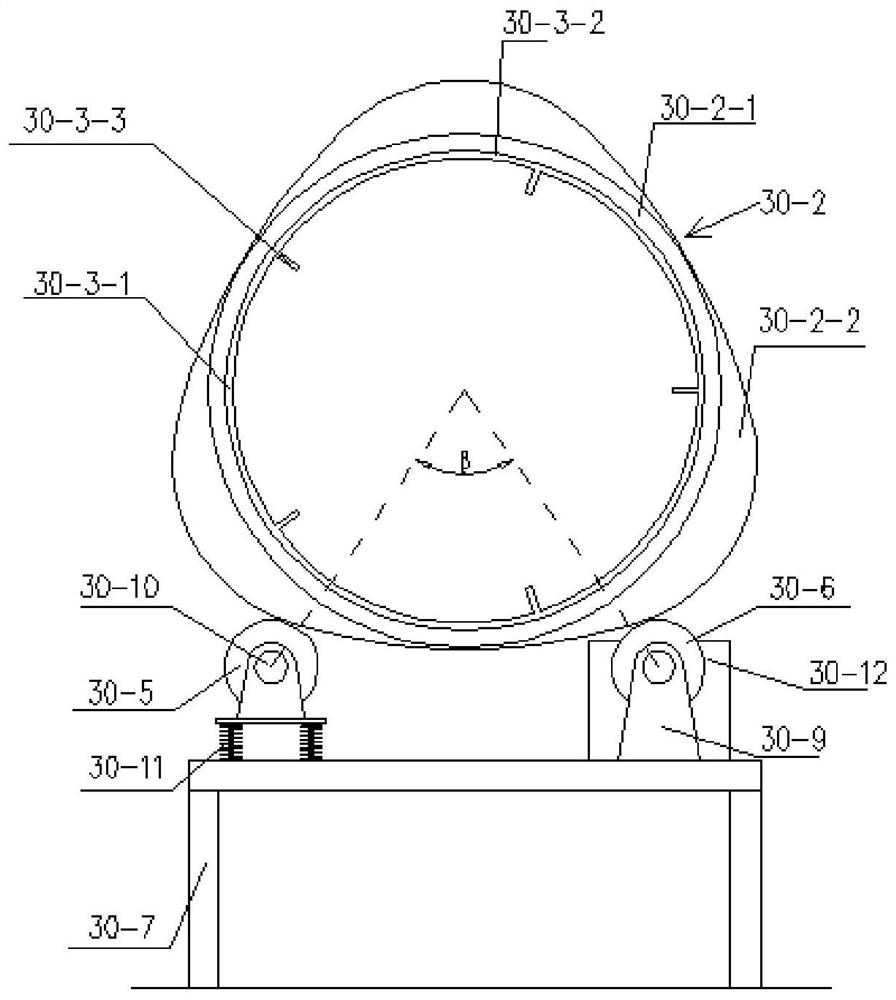

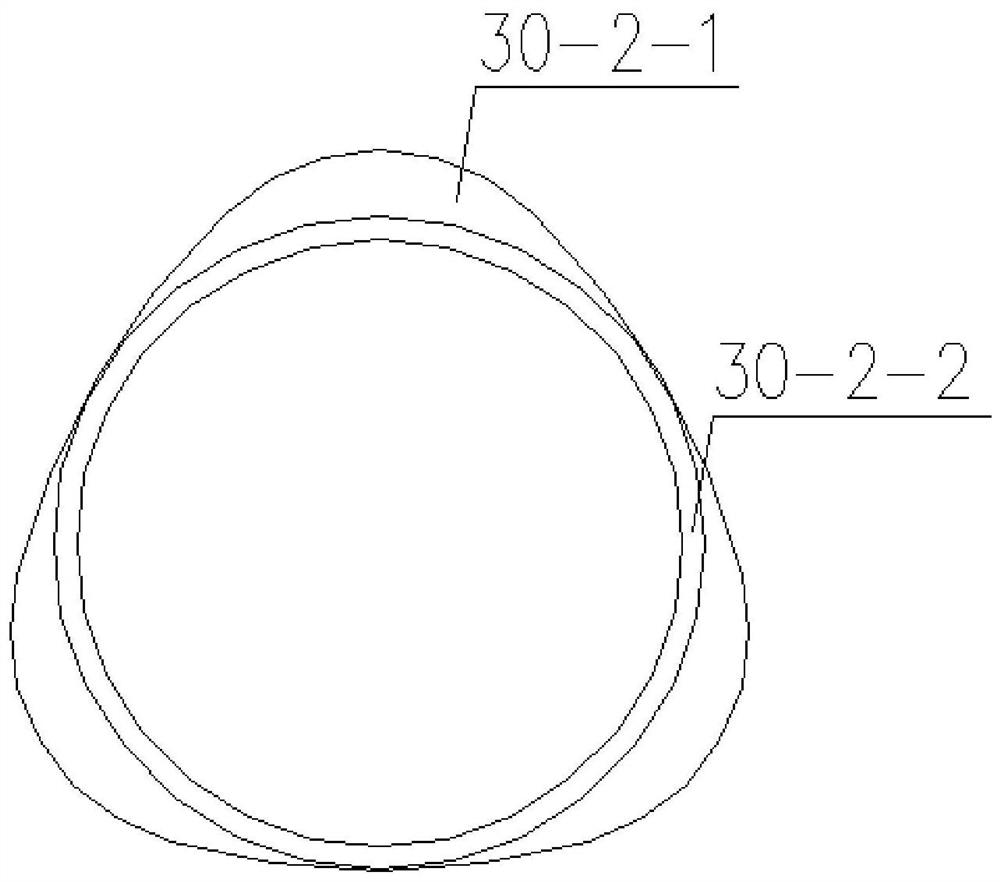

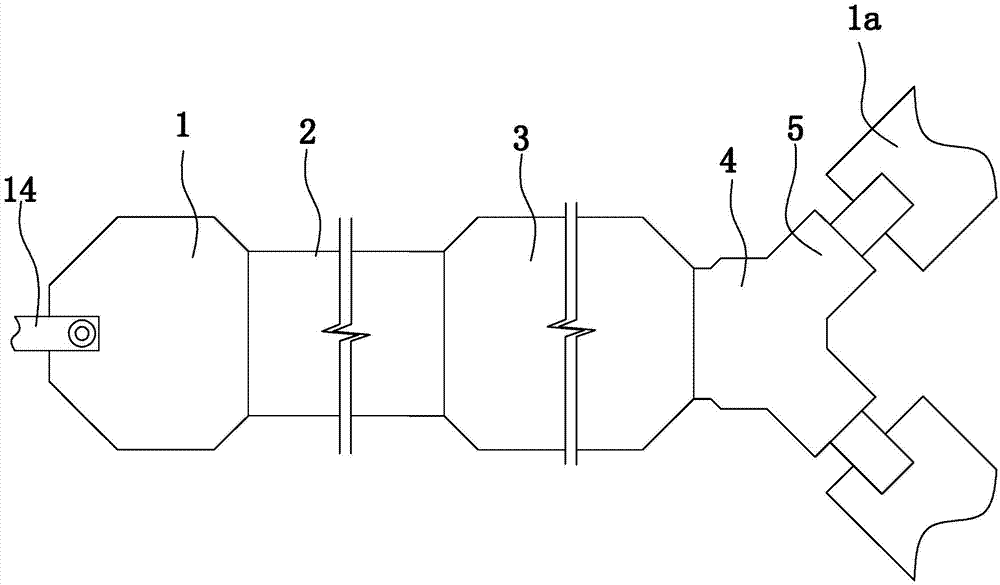

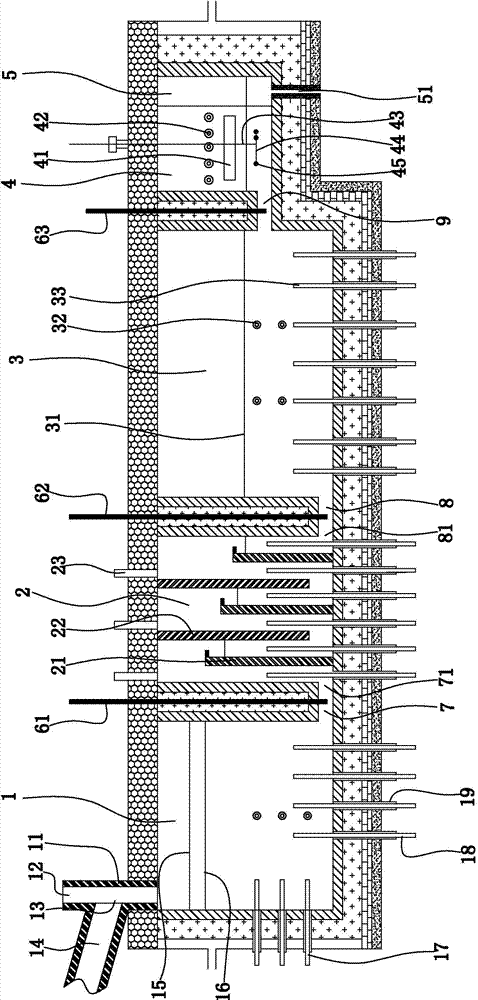

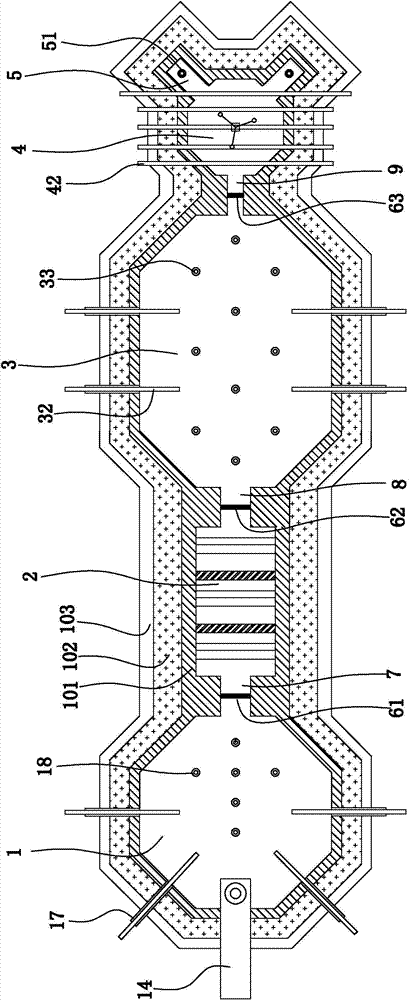

Slag furnace for treating blast furnace thermal-state slag

InactiveCN104326652ASimple structureFast homogenizationGlass making apparatusMelting tankVitrification

The invention discloses a slag furnace for treating a blast furnace thermal-state slag and aims to provide the slag furnace which not only can fully utilize residual heat resources in the blast furnace thermal-state slag and is energy-saving and environmental-protective but also can enable a melt in the slag furnace to be melted uniformly, a vitrification degree to be high and a fiber-forming ratio and quality of mineral wool to be improved. The slag furnace includes a feeding tank, a homogenizing tank, a melting tank, a clarifying tank and at least two material paths. A slag flow inlet and a main modulating material feeding port are arranged on an upper part of the feeding tank. The bottom of the feeding tank is connected to the bottom of the homogenizing tank through a first liquid flowing path. The bottom of the homogenizing tank is communicated with the bottom of the melting tank through a second liquid flowing path. The clarifying tank is communicated with the melting tank through a third liquid flowing path. One end of each material path is communicated with the clarifying tank and the other end of each material path is closed. In addition, material outlet ports are arranged at the bottoms of the material paths.

Owner:宝钢矿棉科技(宁波)有限公司

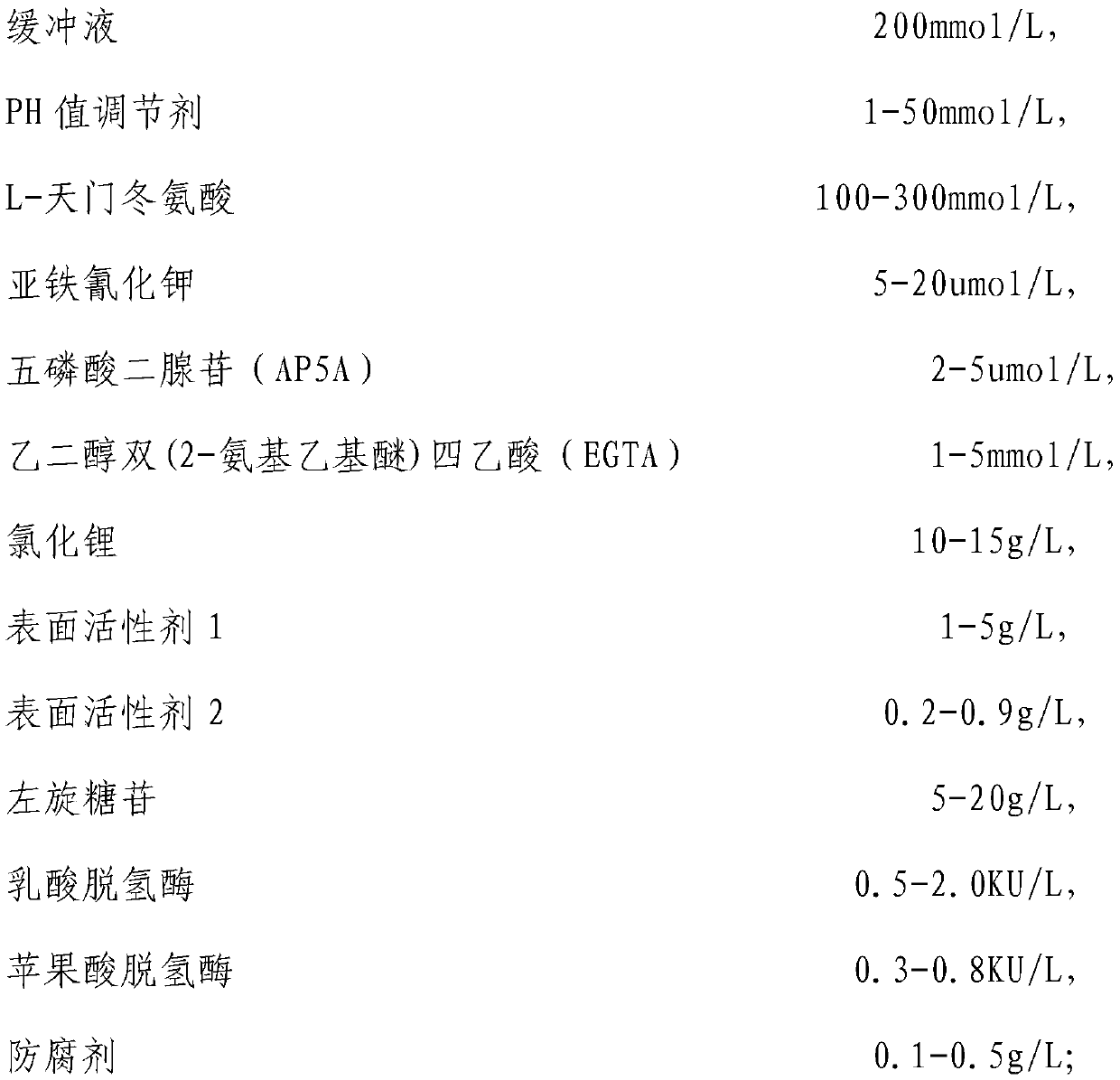

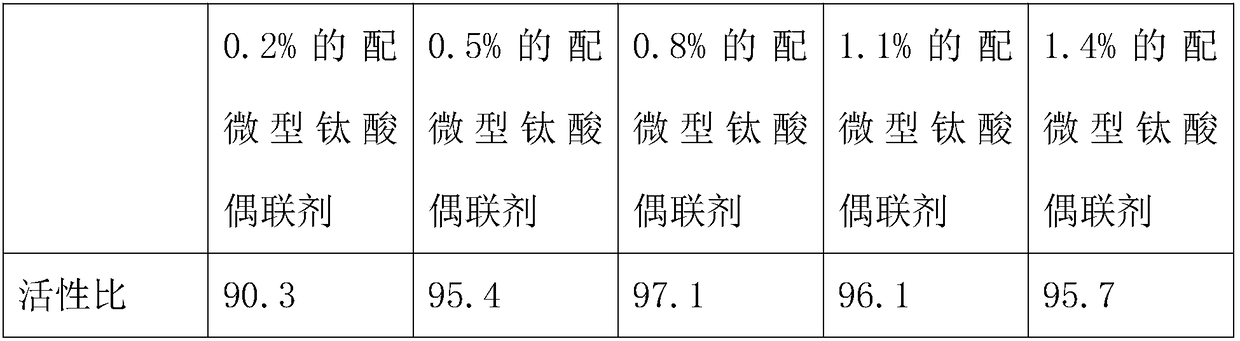

Detection kit for aspartate aminotransferase with good repeatability

InactiveCN109724933AHigh activityEliminate distractionsColor/spectral properties measurementsLactate dehydrogenaseLithium chloride

The invention relates to the technical field of biochemical detection, in particular to a detection kit for aspartate aminotransferase with good repeatability and a preparation and application methodthereof. The kit comprises a reagent R1 and a reagent R2. The reagent R1 comprises a buffer solution, a PH value adjusting agent, L-aspartic acid, potassium ferrocyanide, an AP5A, an EGTA, lithium chloride, a surfactant, levoglucosides, lactate dehydrogenase, malate dehydrogenase, and a preservative component. The reagent R2 comprises a buffer solution, a PH value adjusting agent, a BSA, a preservative, a-ketoglutarate, and NADH components. The kit is optimized in terms of removing reflection interference, increasing the activity of the reacted enzyme, improving the uniformity of the reactionsystem, and preferably selecting the excellent sub-wavelength. The kit remarkably improves the repeatability of reagents, especially the repeatability of low-value samples so as to improve the accuracy of clinical diagnosis results and achieve great clinical practical value.

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

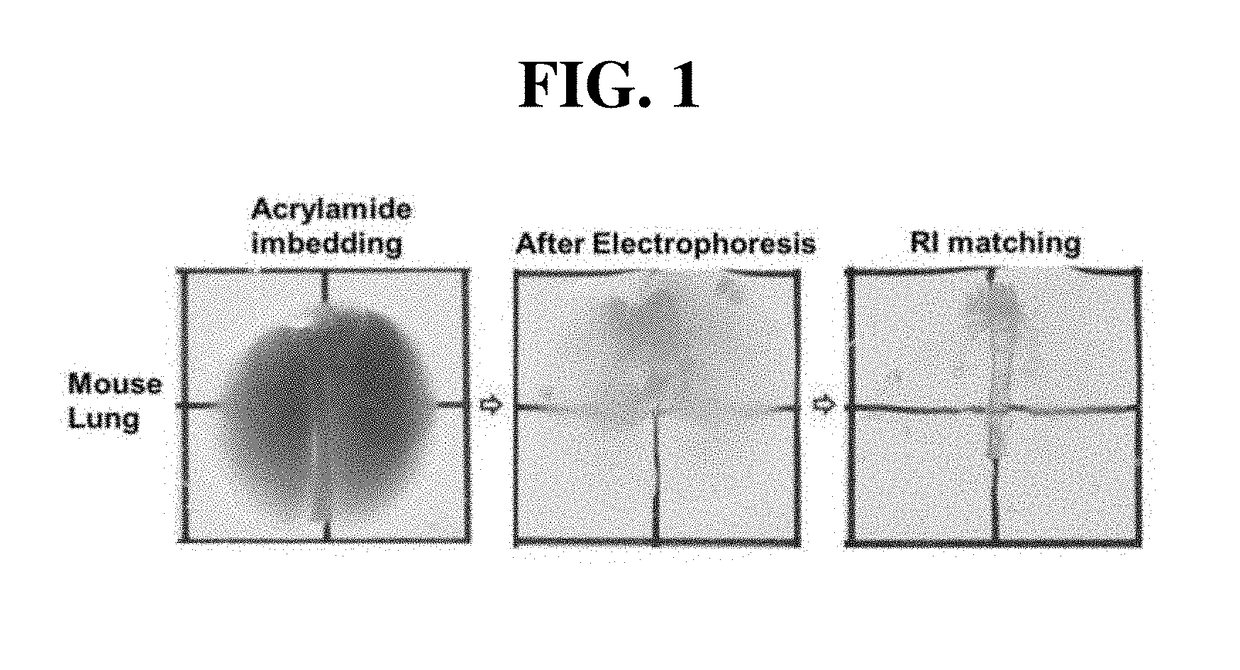

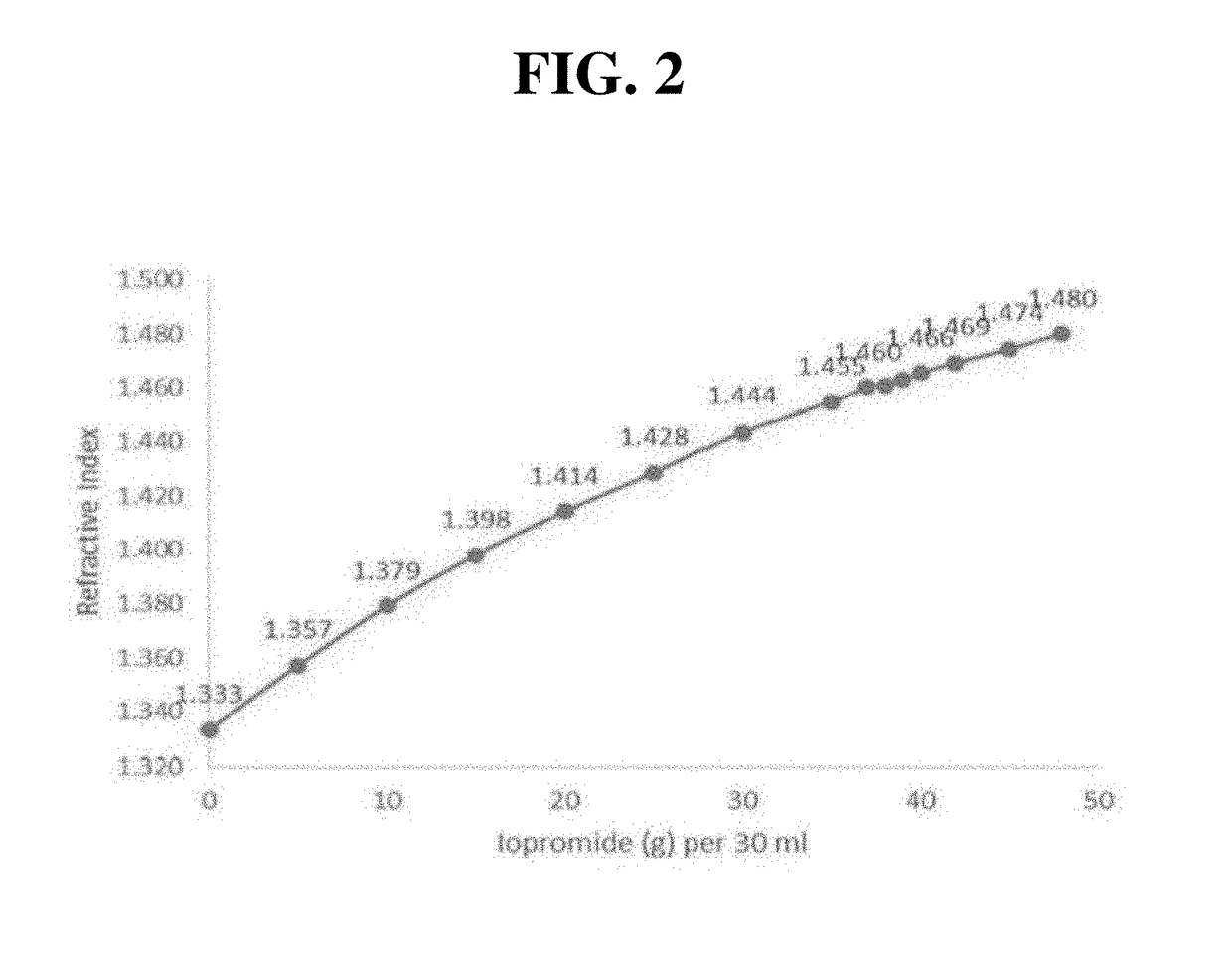

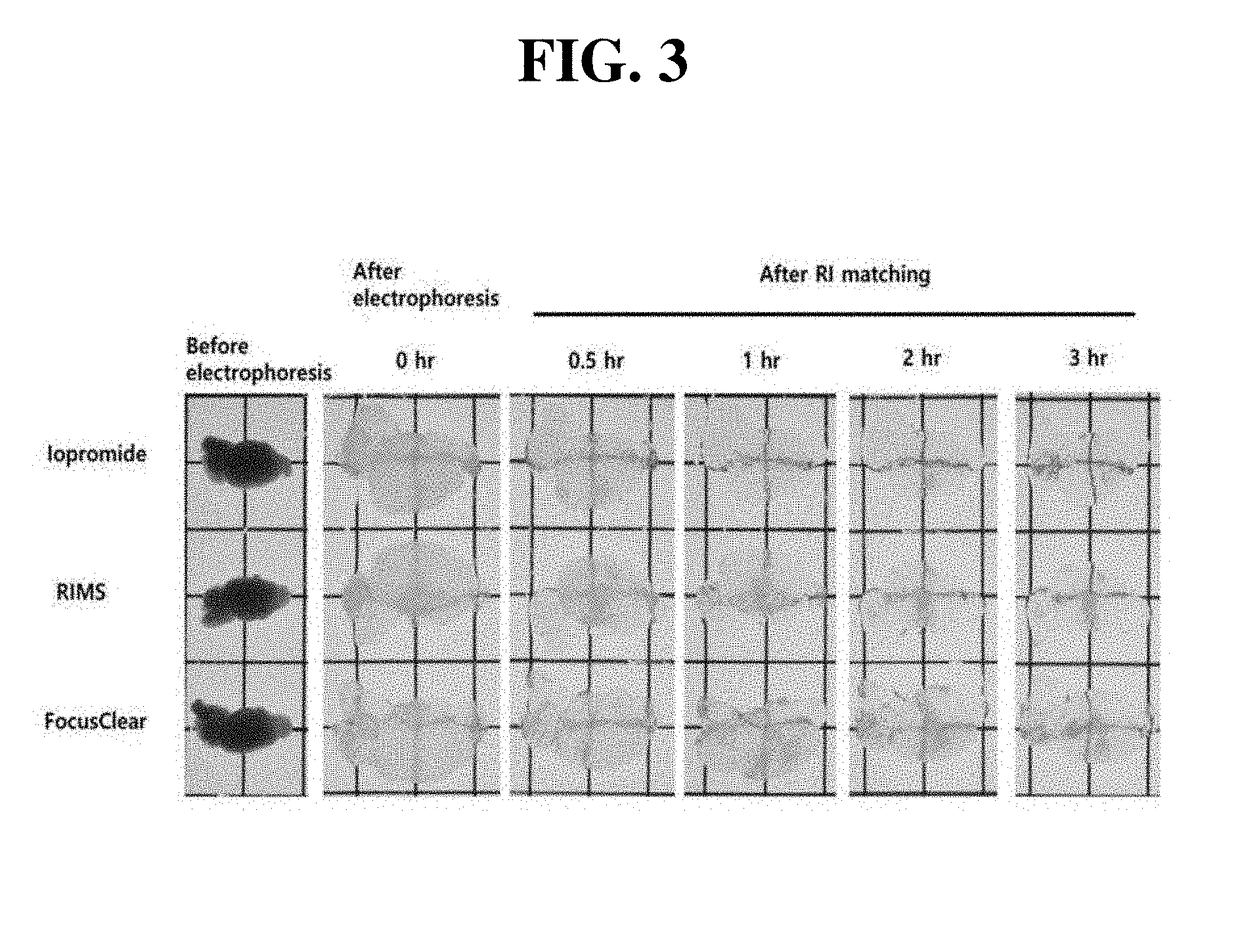

Refractive index matching composition for biological tissue

InactiveUS20170307485A1Excellent refractive index matching effectRemarkable fluorescent signal preservation abilityOrganic chemistryWithdrawing sample devicesFluorescenceBiological tissue

The present invention is about biological tissue refractive index (RI) matching composition and the method for clearing biological tissue. Specifically, the RI matching composition of the present invention shows remarkable RI matching effects when clearing biological tissue, and has excellent fluorescent signal preservation, and can be used for long-term storage of biological tissue since the biological tissue remains clear during in low temperature storage.

Owner:LOGOS BIOSYST

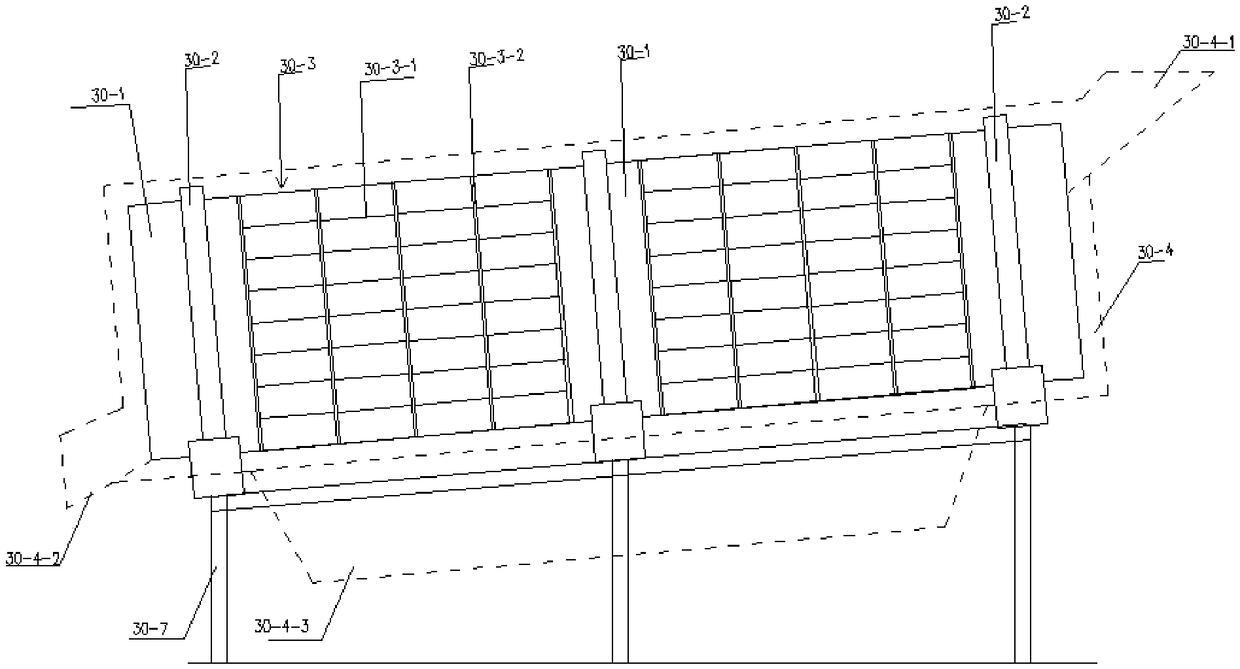

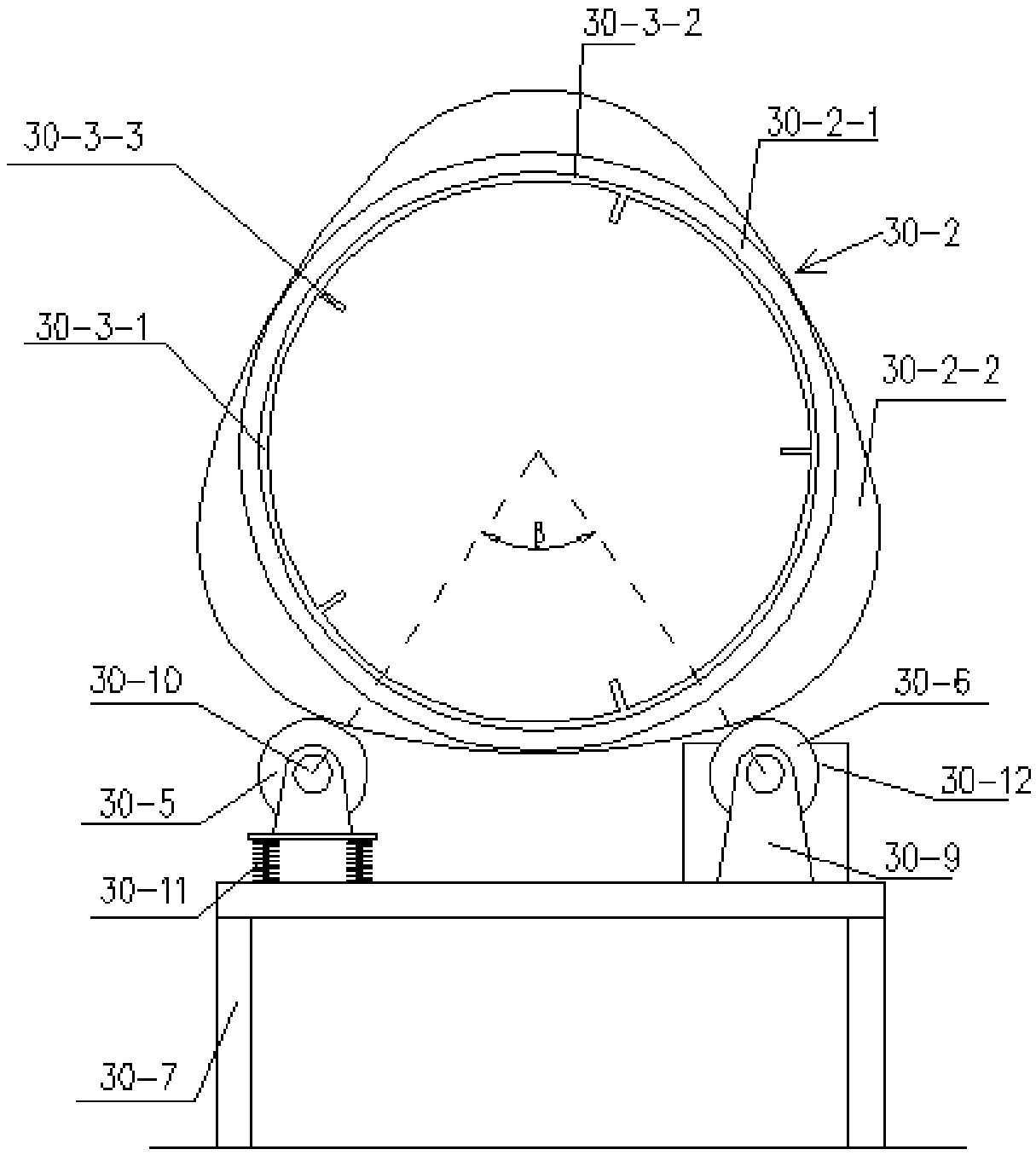

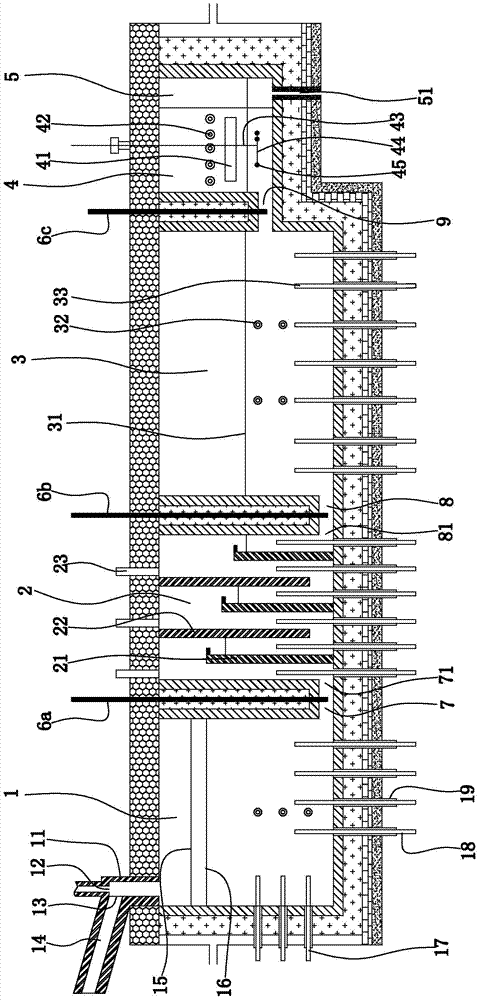

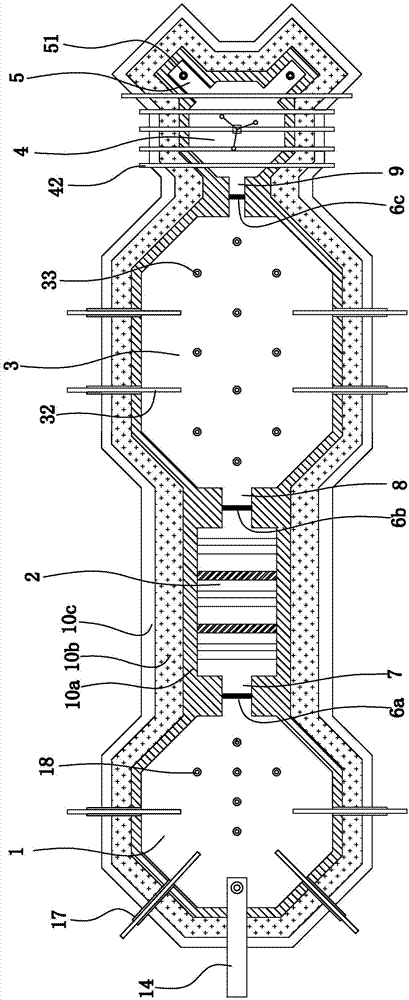

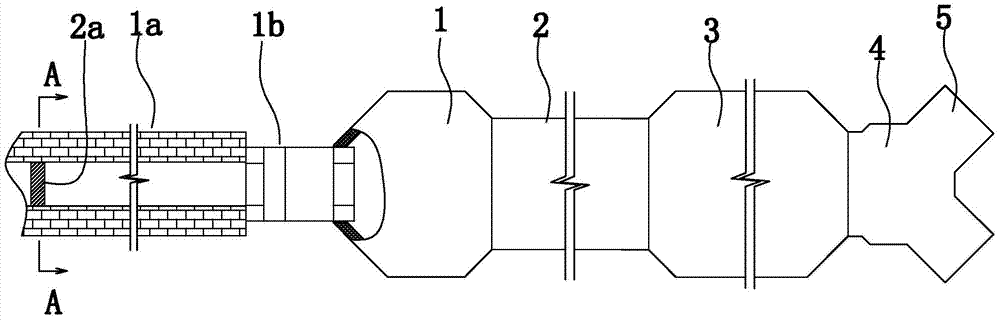

Blast furnace thermal-state slag mineral wool producing device

The invention discloses a blast furnace thermal-state slag mineral wool producing device and aims to provide the blast furnace thermal-state slag mineral wool producing device which not only can fully utilize residual heat resources in blast furnace thermal-state slag and is energy-saving and environmental-protective but also can enable a melt in a slag furnace to be melted uniformly, a vitrification degree to be high and a fiber-forming ratio and quality of mineral wool to be improved. The device includes a slag-obtaining trough used for guiding a blast furnace thermal-state slag flow, a feeding chute apparatus, a slag furnace and at least two centrifugal machines. The slag furnace successively includes a feeding tank, a homogenizing tank, a melting tank, a clarifying tank and at least two material paths. A slag flow inlet and a main modulating material feeding port are arranged on an upper part of the feeding tank. The bottom of the feeding tank is connected to the bottom of the homogenizing tank through a first liquid flowing path. The bottom of the homogenizing tank is communicated with the bottom of the melting tank through a second liquid flowing path. The clarifying tank is communicated with the melting tank through a third liquid flowing path. One end of each material path is communicated with the clarifying tank and the other end of each material path is closed. In addition, material outlet ports are arranged at the bottoms of the material paths.

Owner:宝钢矿棉科技(宁波)有限公司

Process for producing rock/slag wool products by using iron-making blast furnace hot slag and electric-arc furnace

InactiveCN110540360AMelting fastMeet quality requirementsGlass making apparatusElectric arc furnaceSlag

The invention provides a process for producing rock / slag wool products by using iron-making blast furnace hot slag and an electric-arc furnace. The process comprises the following steps of: adding quartz sand tailings during slag receiving of a slag ladle, and partially melting quartz sand by using impact force in slag tapping and heat of blast furnace slag; conveying fly ash into electric furnaceslag by using a gas injection method, and carrying out rapid melting; adding quartz sand and a small amount of a magnesium hardening and tempering material; increasing the current of the electric arcfurnace, and carrying out stirring by using high-current and nitrogen stirring so as to allow the hardening and tempering material to be fully melted and homogenized; pouring slag in the slag ladle into the electric arc furnace, and allowing the slag just poured into the electric arc furnace and the slag provided in the furnace body to be fully molten through nitrogen stirring; and increasing thecurrent and carrying out stirring through a current loop generated by the current of the electric arc furnace so as to realize further homogenization of the slag. The process provides a new way for utilizing the blast furnace slag, increases the additional value of the utilization of blast furnace slag, and realizes high-additional-value utilization of fly ash.

Owner:潍坊奥华环保新材料科技有限公司

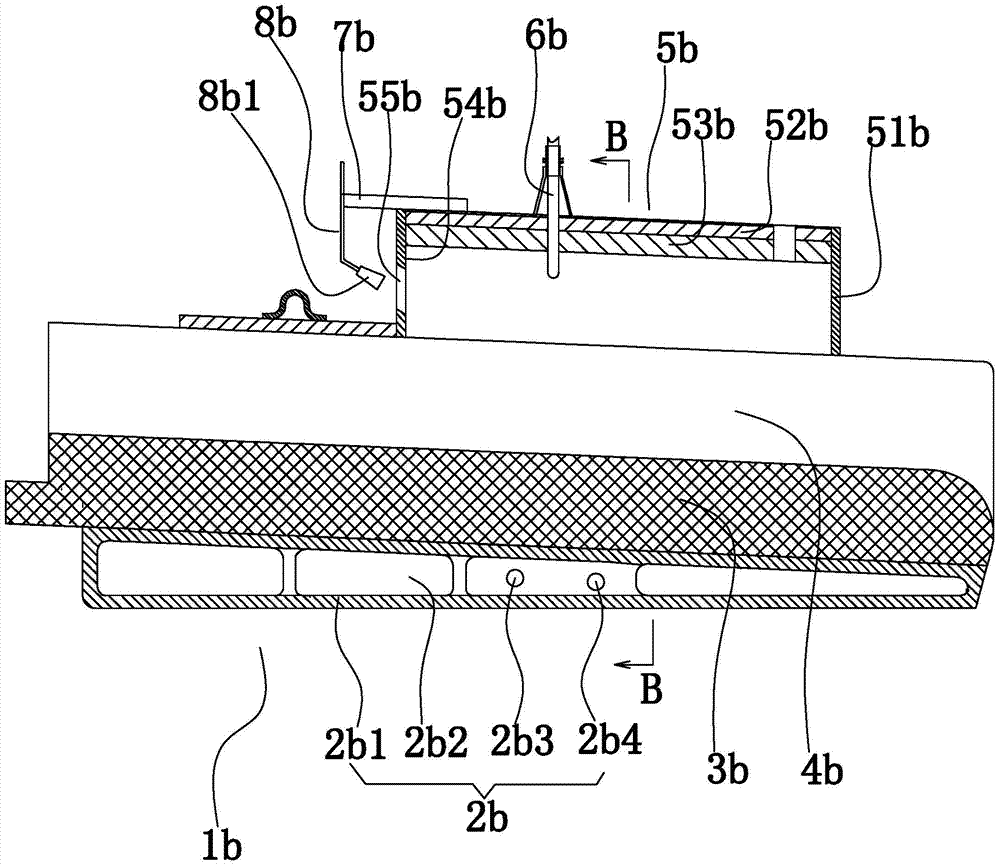

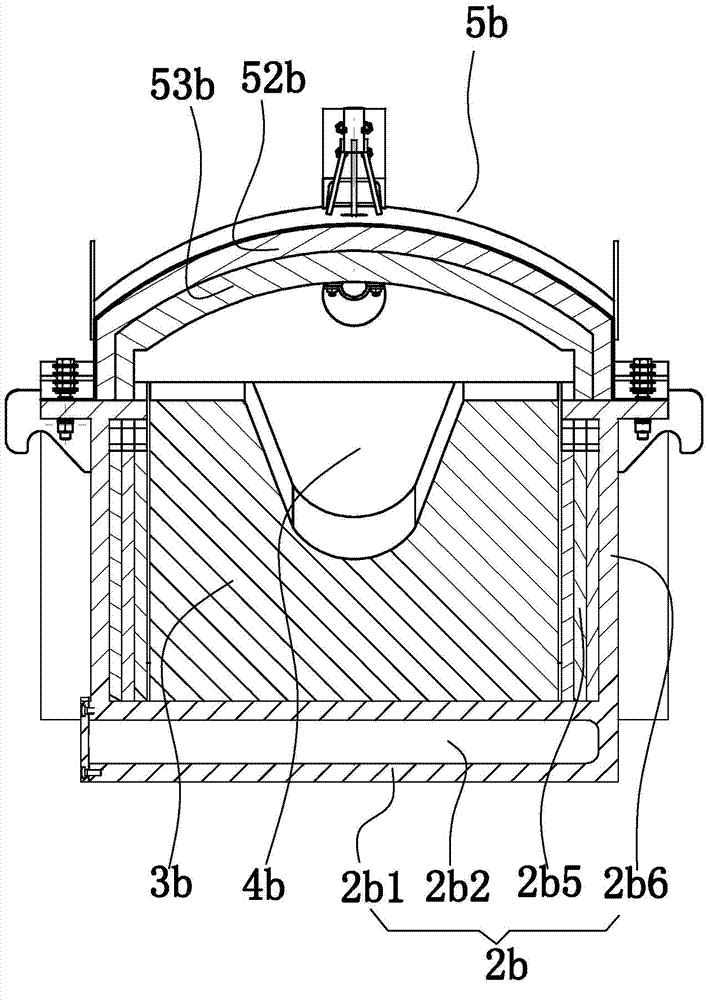

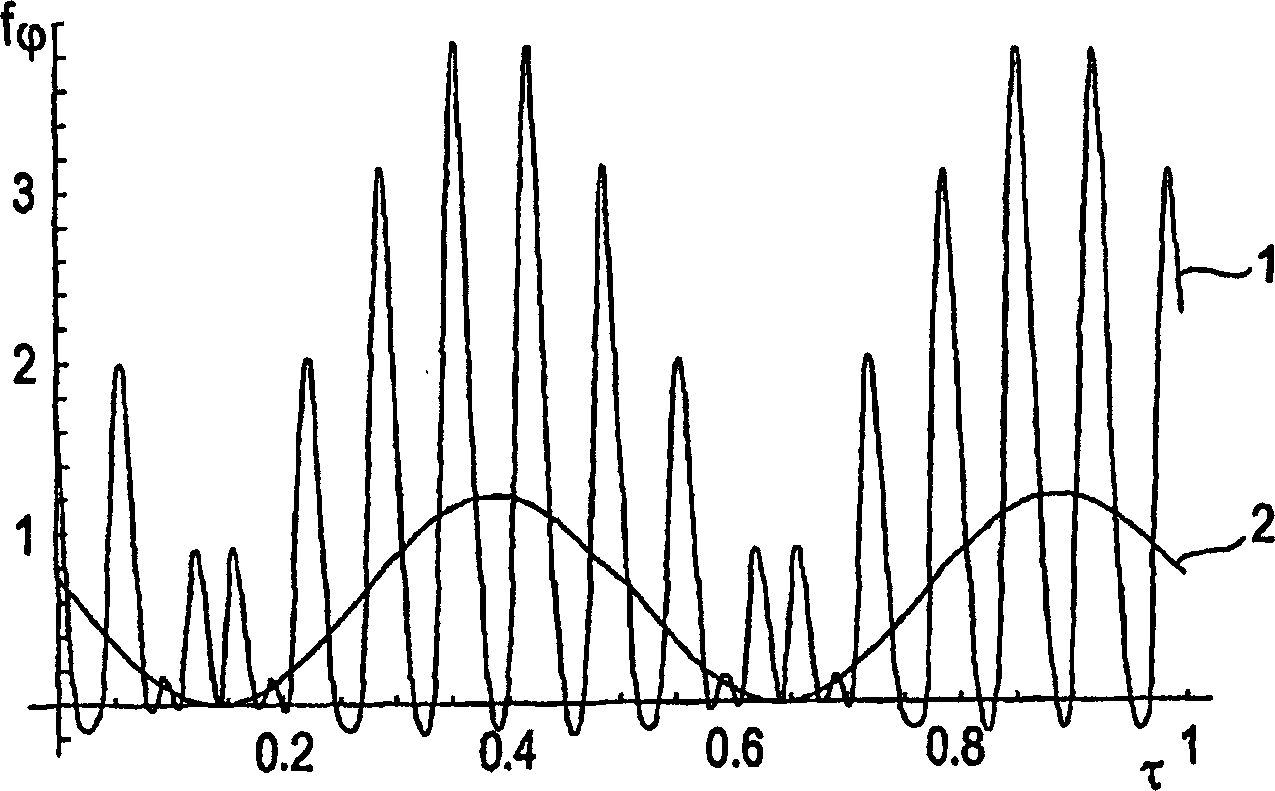

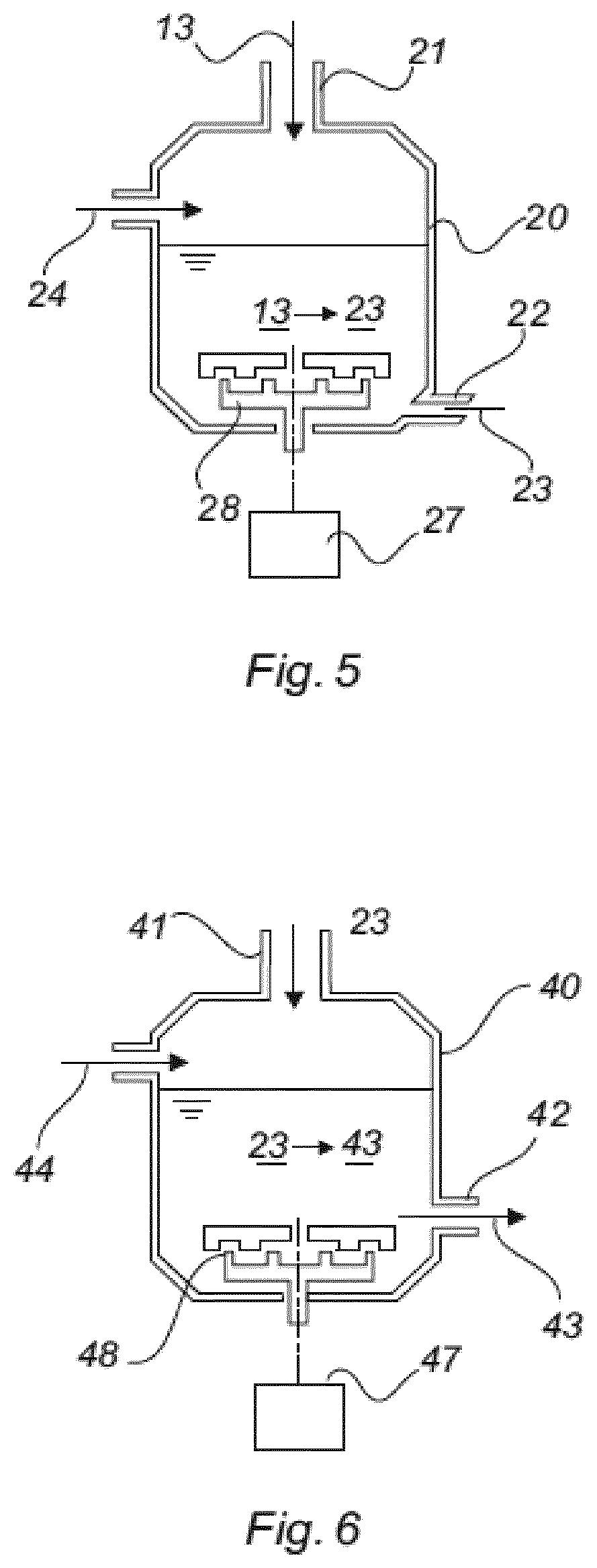

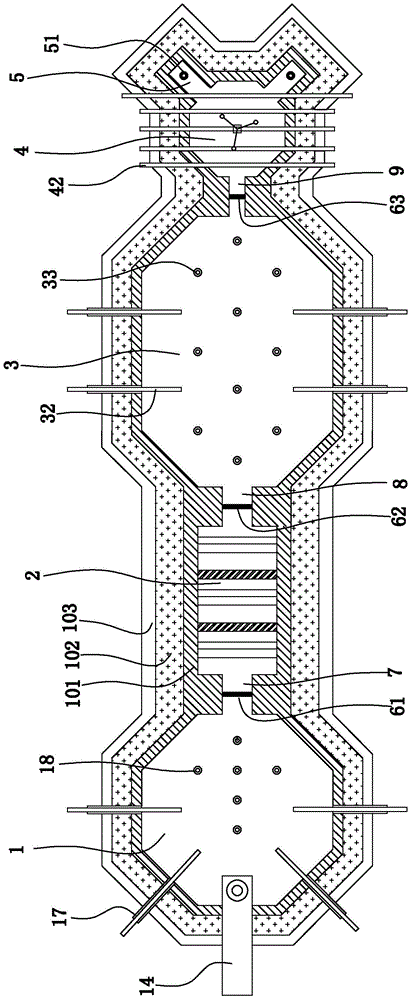

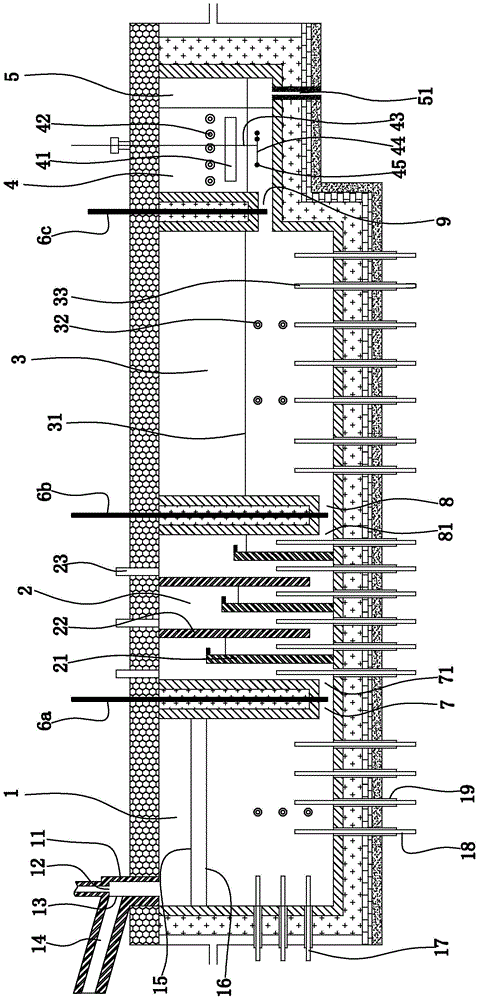

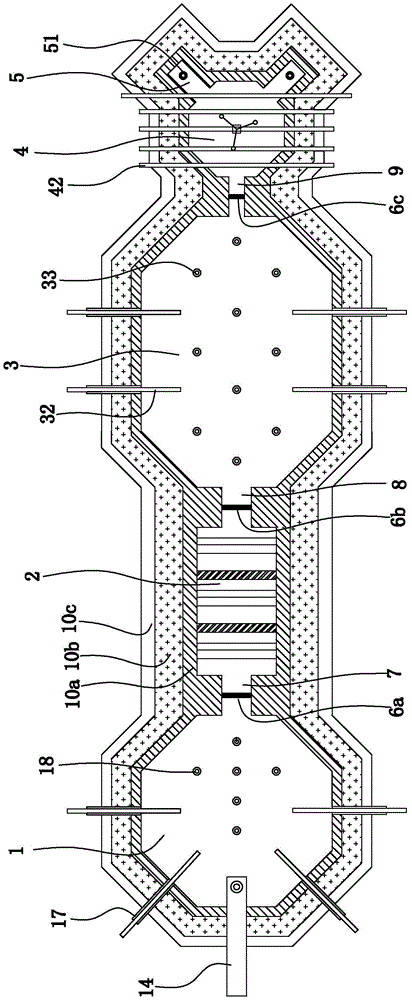

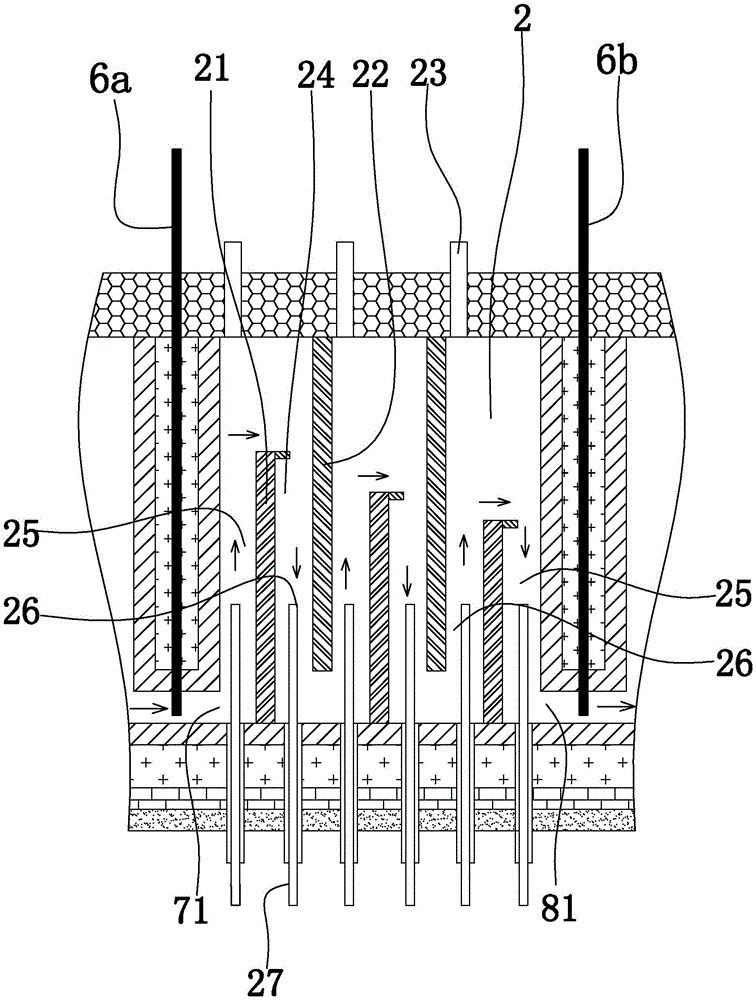

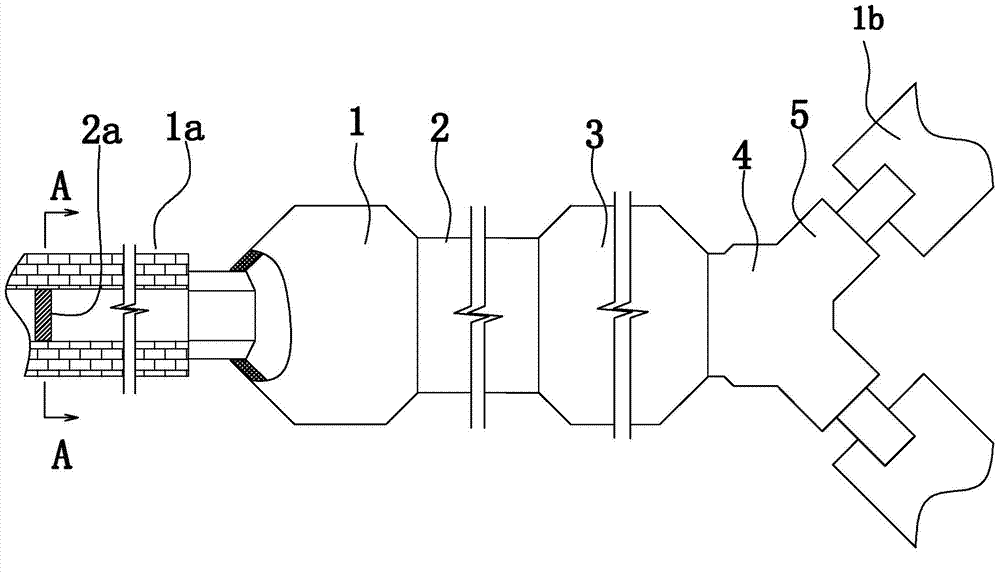

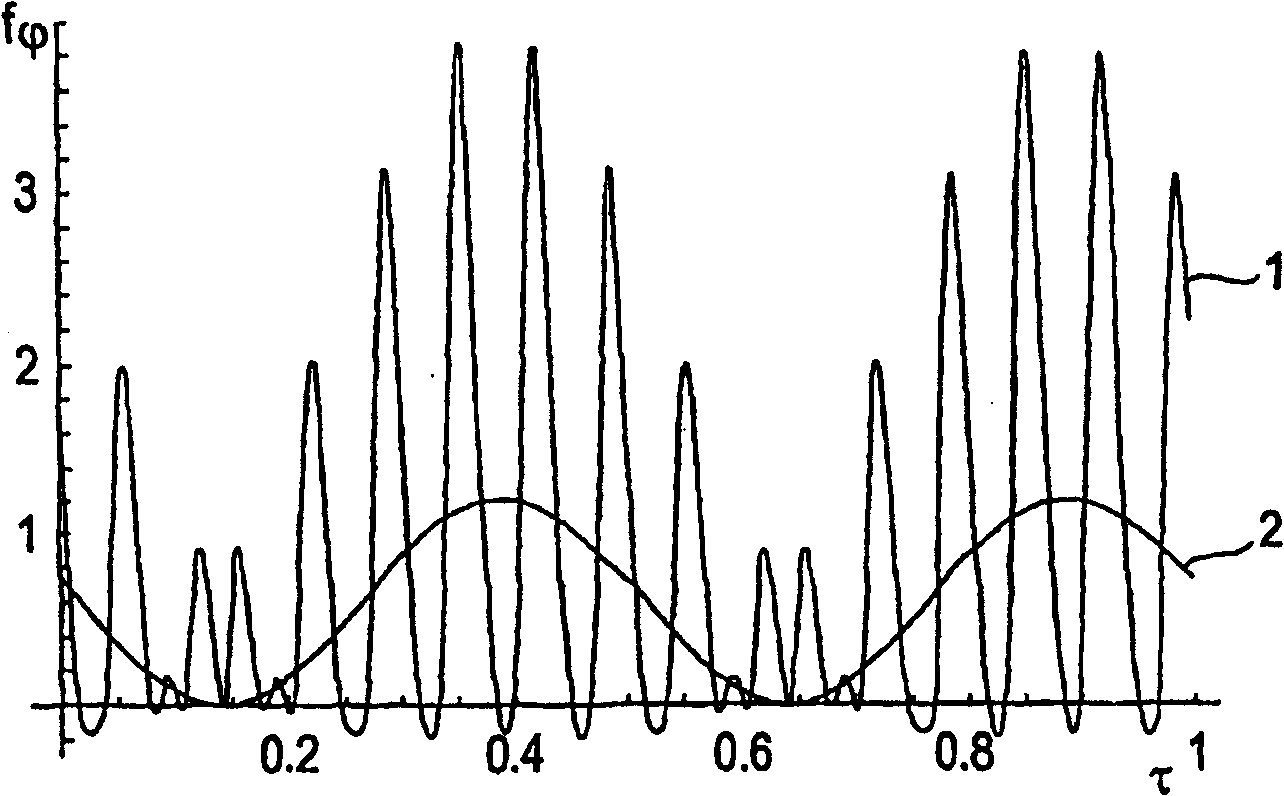

Systems and methods of electromagnetic influence on electroconducting continuum

InactiveCN1744960ARaise the unstable componentFast homogenizationMechanical apparatusStirring devicesFoundryDecreased energy

Thus, as shown by an exact electrodynamic computation of EMBF and the estimations described above of the velocity of turbulent flows arising due to their effect, application of amplitude- and frequency-modulated helically traveling (rotating and axially traveling) electromagnetic fields in metallurgical and chemical technologies and foundry can considerably increase the hydraulic efficiency of MHD facilities, intensify the processes of heat and mass transfer in technological plants, significantly increase their productivity, considerably decrease energy consumption for the production of metals, alloys, cast articles, and chemical products, and improve their quality.

Owner:ENERGETICS TECH

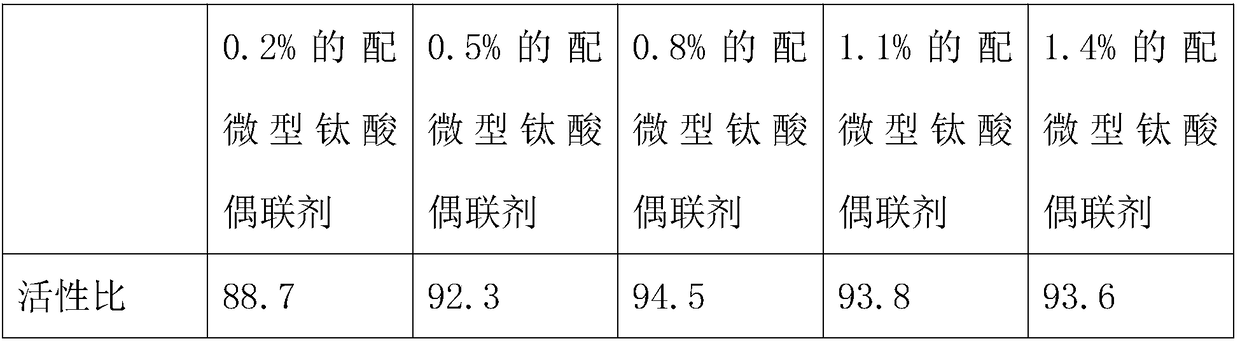

Preparation method of ultra-fine active heavy calcium carbonate

InactiveCN108102430AFast homogenizationReduce frictionPigment treatment with non-polymer organic compoundsAlcoholUltra fine

The invention discloses a preparation method of ultra-fine active heavy calcium carbonate and belongs to the technical filed of heavy calcium carbonate. The ultra-fine active heavy calcium carbonate is prepared by mixing a heavy calcium carbonate powder, absolute ethyl alcohol, a titanate coupling agent and calcium chloride by adopting a wet process and modified by adopting a wet grinding method,so that the affinity of the heavy calcium carbonate and an organic high polymer is improved, and the dispersibility of the heavy calcium carbonate in the organic high polymer is improved. The preparation method disclosed by the invention has the benefits that through the modification of the heavy calcium carbonate, the filling quantity of the heavy calcium carbonate is improved, and the product performance is improved.

Owner:XUANCHENG XINTAO CALCIUM CARBONATE

Internal component for strengthening refining wastewater biochemical mixed mass transfer reaction process

ActiveCN113184980AQuick mixMixed mass transfer is fastWater treatment parameter controlSpecific water treatment objectivesProcess engineeringMass transfer rate

The invention relates to an internal component for strengthening a refining wastewater biochemical mixing mass transfer reaction process. The internal component comprises a barrel body and a water and gas distribution structure. The internal component is characterized in that the water and gas distribution internal component mainly comprises a transmission internal component and a mass transfer internal component. The transmission internal component is composed of a hydraulic lifting device, a central circulating cylinder and a water distributor; and the mass transfer internal component is composed of an auxiliary cylinder and a pressure air releaser. The internal component can realize gas-liquid-solid high-strength mixing, has the characteristics of uniform mixing, high mass transfer rate and high oxygen dissolving efficiency, can adjust the radius of reflux circulating water, remarkably strengthens the mixing and mass transfer effects of biochemical reaction, shortens the hydraulic retention time, can be used for a deep water biochemical device, and reduces the occupied area of the biochemical device.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

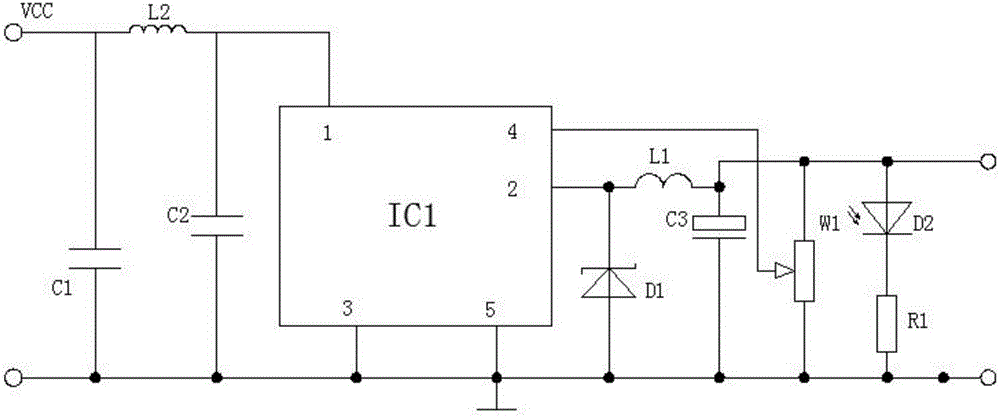

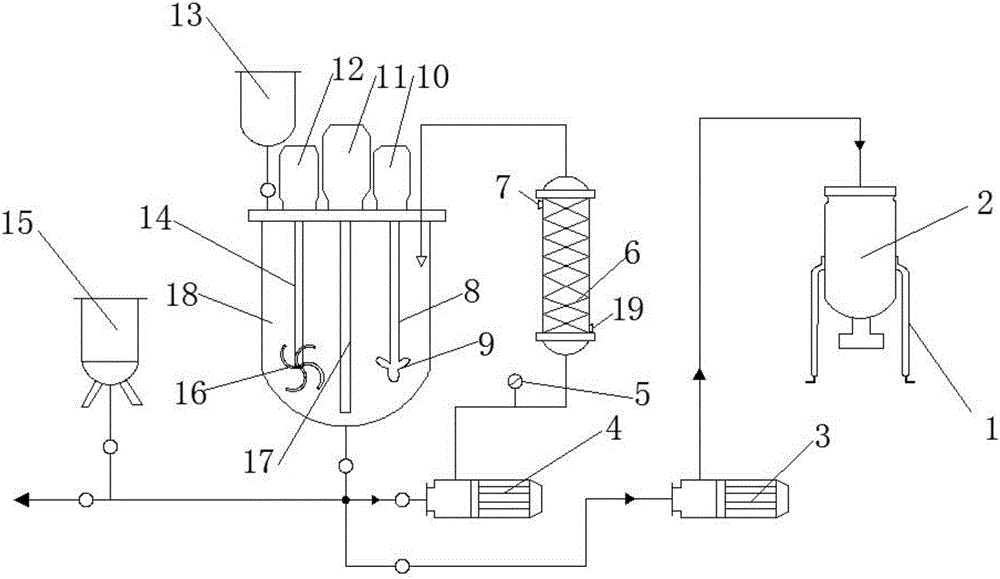

Multi-stirring-mode paint production system powered by adjustable stabilized voltage source

InactiveCN106422938AAchieving Power ReliabilityImprove stabilityTransportation and packagingMixer accessoriesImpellerLow speed

The invention discloses a multi-stirring-mode paint production system powered by an adjustable stabilized voltage source. The paint production system comprises a multi-stirring-system reaction kettle, a liquid raw material loading equipment loading facility, a static mixing system and a stabilized-voltage power supply circuit, wherein the stabilized-voltage power supply circuit is connected with the multi-stirring-system reaction kettle; the multi-stirring-system reaction kettle is provided with a spiral line stirring mechanism, a low-speed dispersion mechanism and a tri-impeller dispersion mechanism; an LC pi-type power filter, an adjustable power stabilized-voltage chip circuit and an indicator lamp circuit are arranged in the stabilized-voltage power supply circuit; the LC pi-type power filter is connected with the adjustable power stabilized-voltage chip circuit; and the adjustable power stabilized-voltage chip circuit is respectively connected with a control circuit of the spiral line stirring mechanism, a control circuit of the low-speed dispersion mechanism and a control circuit of the tri-impeller dispersion mechanism. One adjustable stabilized-voltage source is utilized to simultaneously supply power to the control circuits of the three different stirring mechanisms (dispersion mechanisms), thereby implementing reliable power supply of the control circuit of the multi-stirring-system reaction kettle.

Owner:CHONGQING RYAN PAINT CO LTD

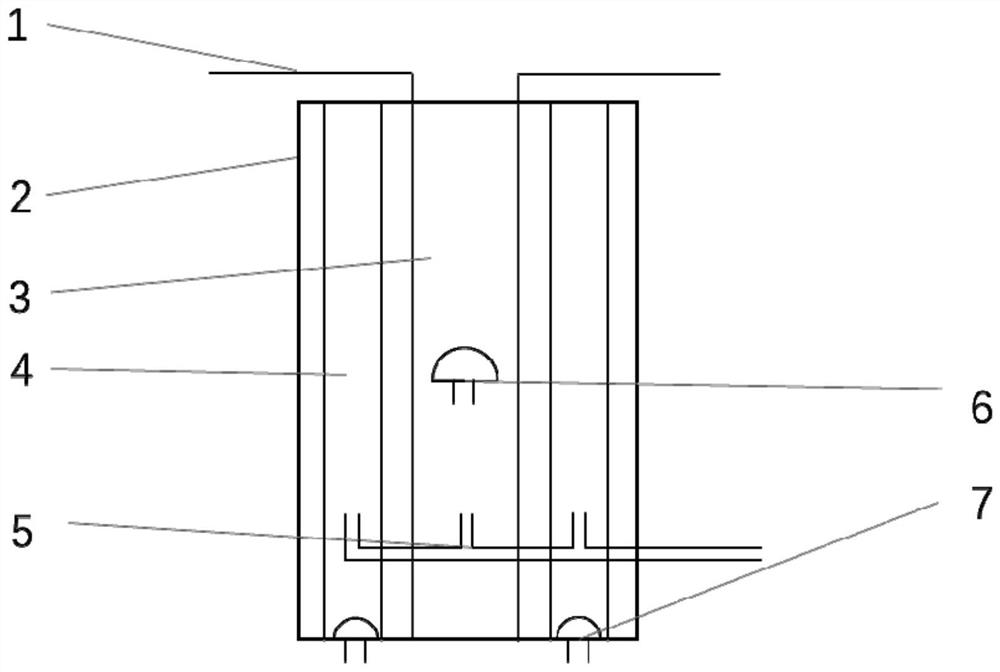

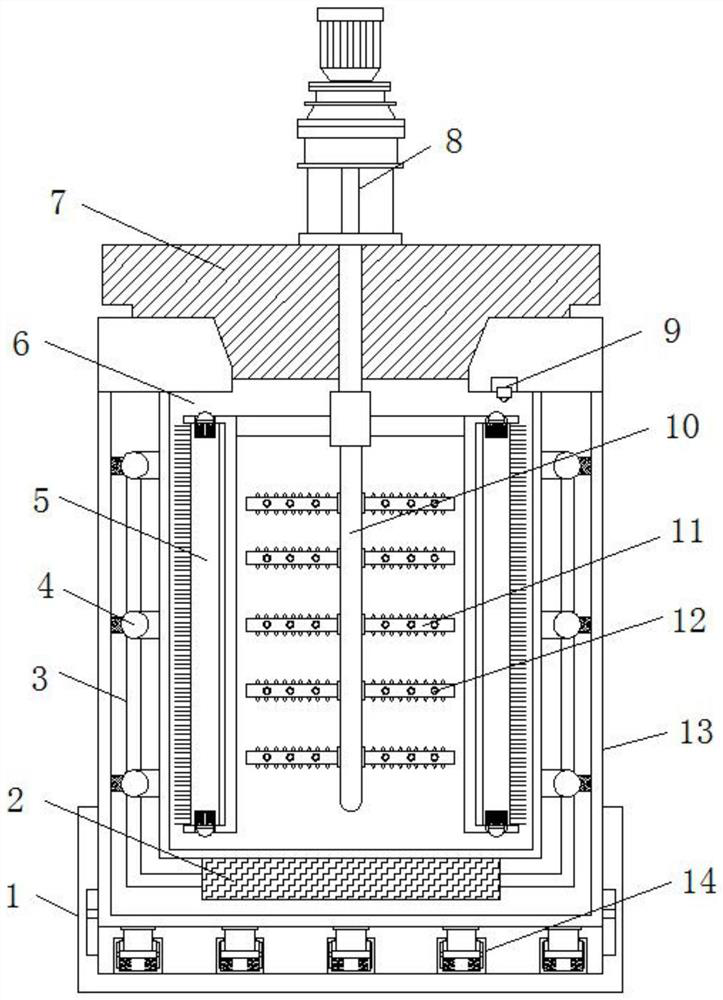

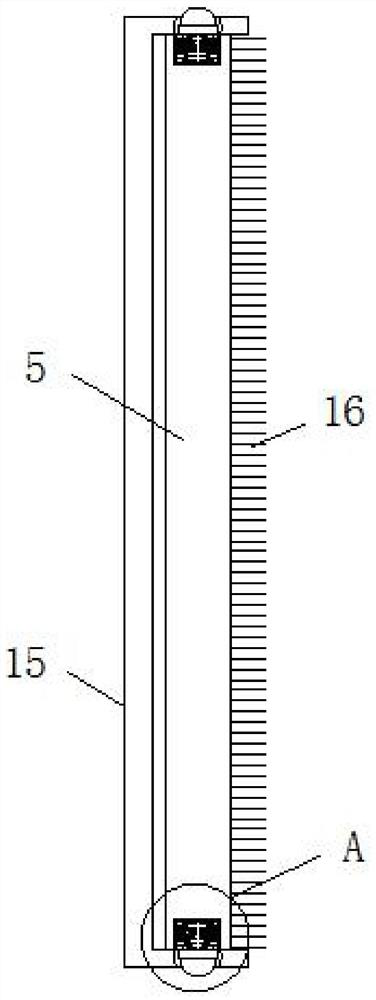

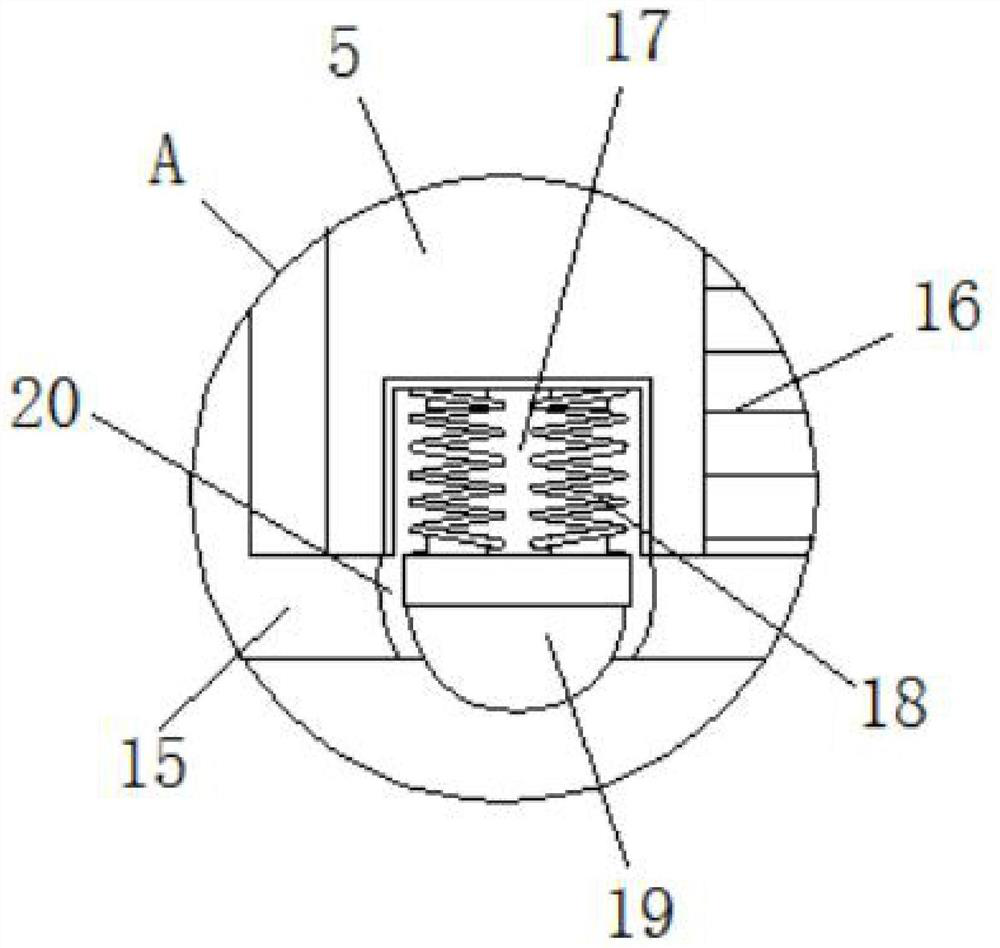

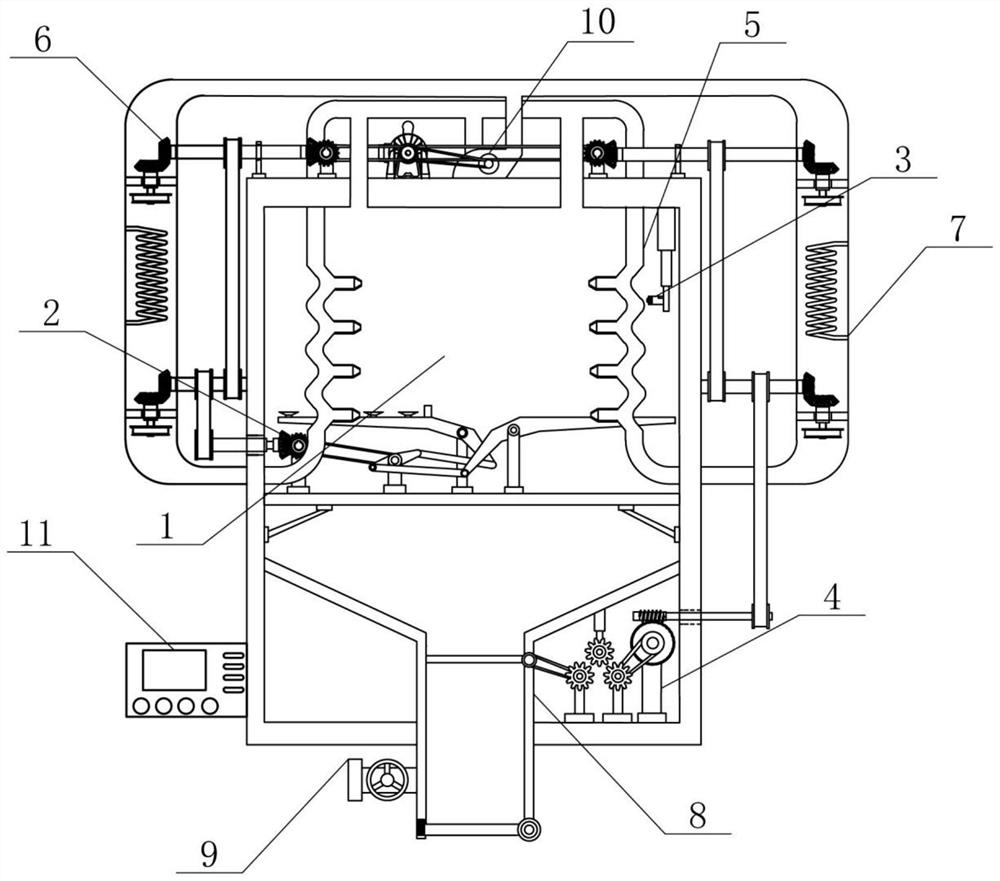

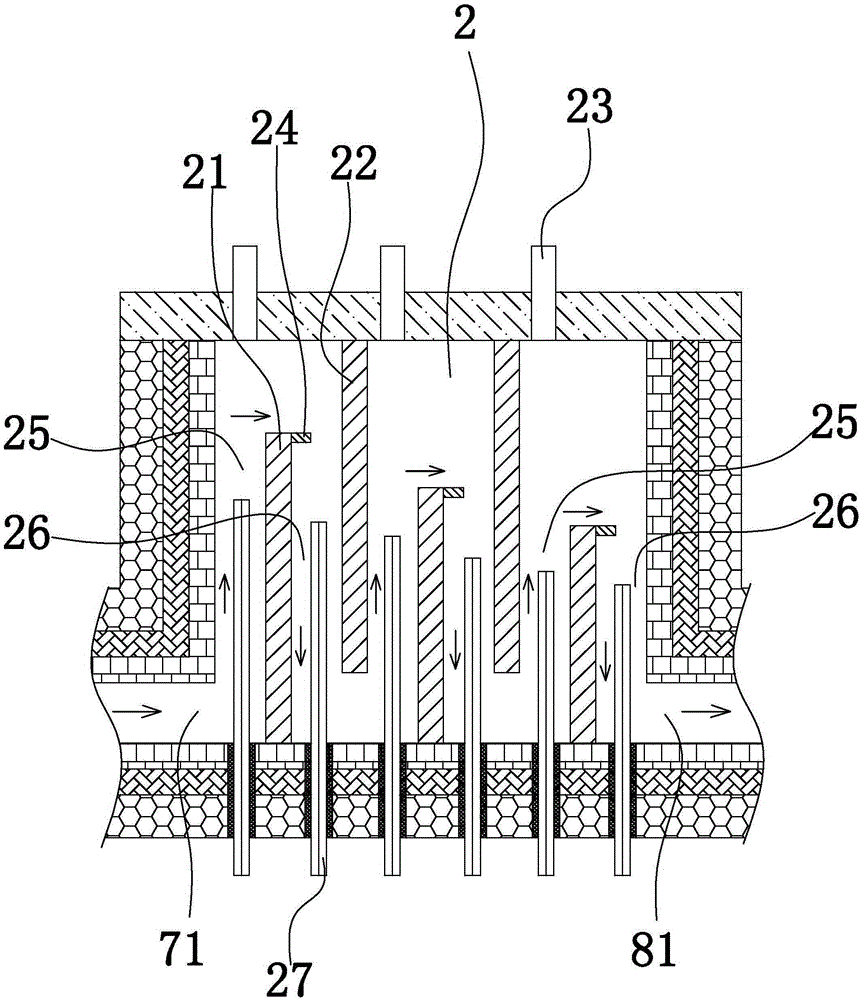

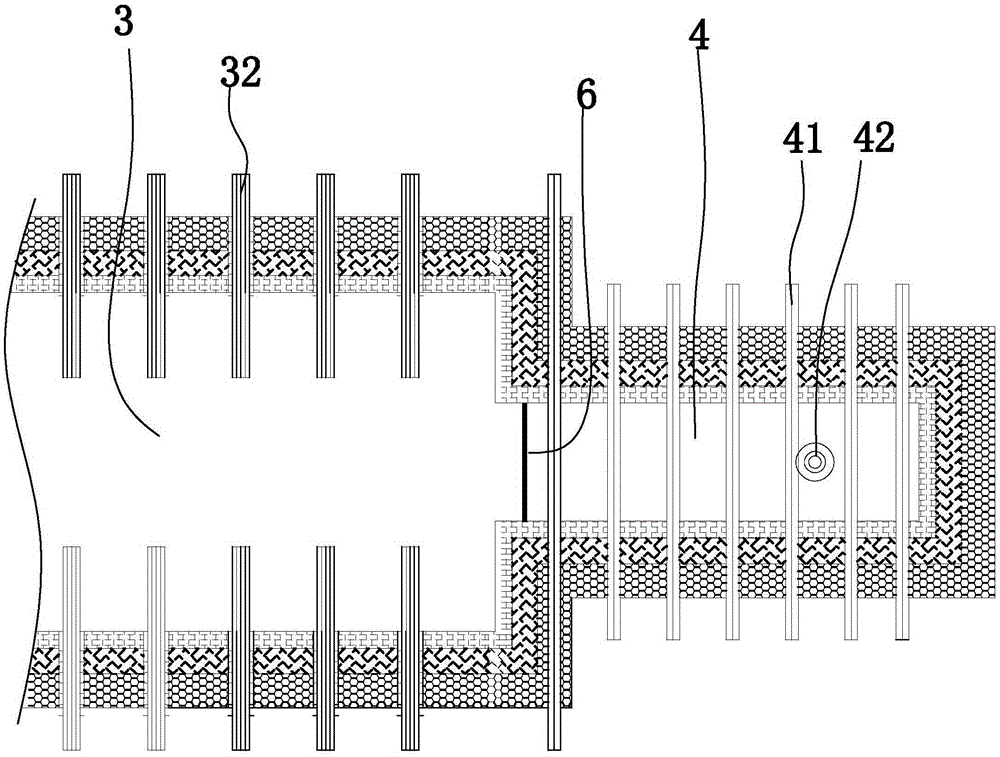

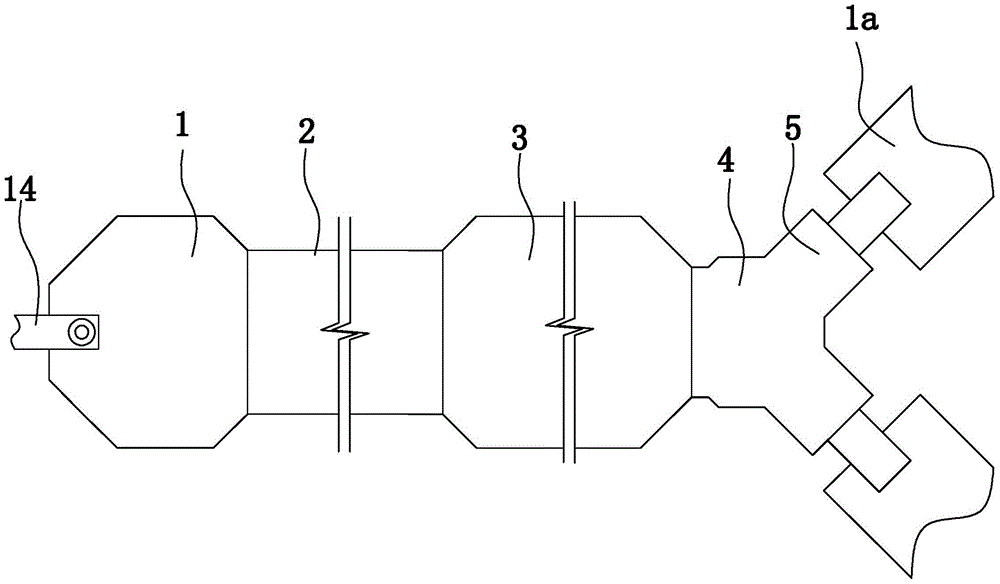

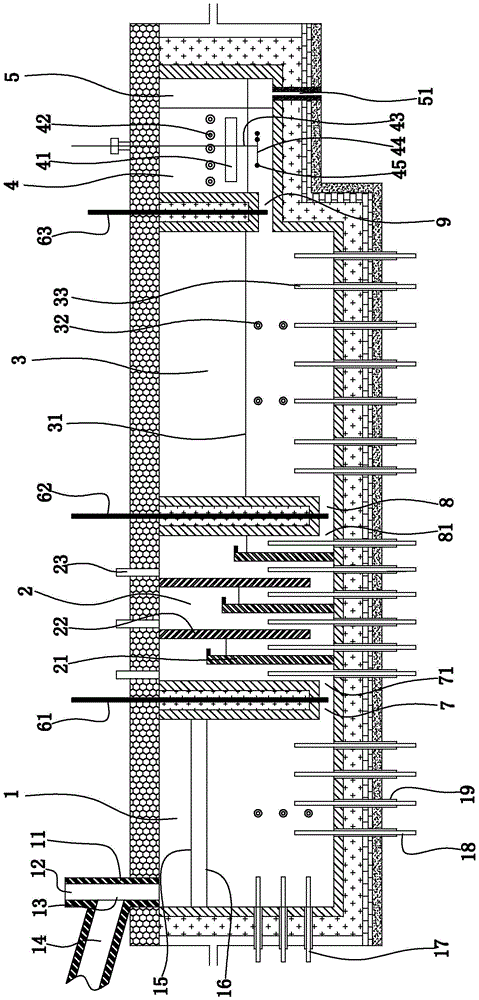

Rapid homogenizing device for chemical high polymer material

PendingCN112774507AEvenly heatedFast homogenizationRotary stirring mixersTransportation and packagingChemistryHigh polymer

The invention discloses a rapid homogenizing device for a chemical high polymer material, which comprises a base, a homogenizing chamber, a stirring piece and a tank body, wherein the tank body is arranged in the base, the homogenizing chamber is arranged in the tank body, a temperature sensor is arranged at the top end in the homogenizing chamber, a cover body is arranged at the top end of the tank body, a motor is fixed to the top end of the cover body, a rotating shaft is arranged at the output end of the motor and extends into the homogenizing chamber, fixing frames are fixed to the two sides of the rotating shaft, mounting pieces are arranged in the fixing frames, and stirring pieces are evenly arranged on the two sides of the rotating shaft. By installing the tank body, the homogenizing chamber, a heating resistor, a heat transfer rod, a heat transfer ring, the motor, the rotating shaft, the stirring pieces and the temperature sensor, the chemical polymer material in the homogenizing chamber can be uniformly heated, and the homogenizing speed is increased.

Owner:常州大连理工大学智能装备研究院

Device for analysis of mixtures of at least two gases

ActiveUS10247690B2Quick analysisSmall sizeMaterial thermal conductivityAnalysing gaseous mixturesEngineeringMicrofluidic channel

Device for analyzing a mixture of n gases, comprising a microfluidic channel (2) extending between a first end and a second end, at least n−1 suspended elements in the microfluidic channel (2), said n−1 elements (S1, S2 . . . Sn−1) succeeding one another from the first end of the microfluidic channel (2) to the second end of the microfluidic channel (2), heating means capable of heating a part at least of the gaseous mixture surrounding each suspended element (S1, S2 . . . Sn−1) to a given temperature different to those to which are heated the gaseous mixtures surrounding the other suspended elements (S1, S2 . . . Sn−1), means of measuring the temperature or the variation in temperature of the suspended elements (S1, S2 . . . Sn−1) and a control and measurement system (UC) connected to the heating means and to the measuring means.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

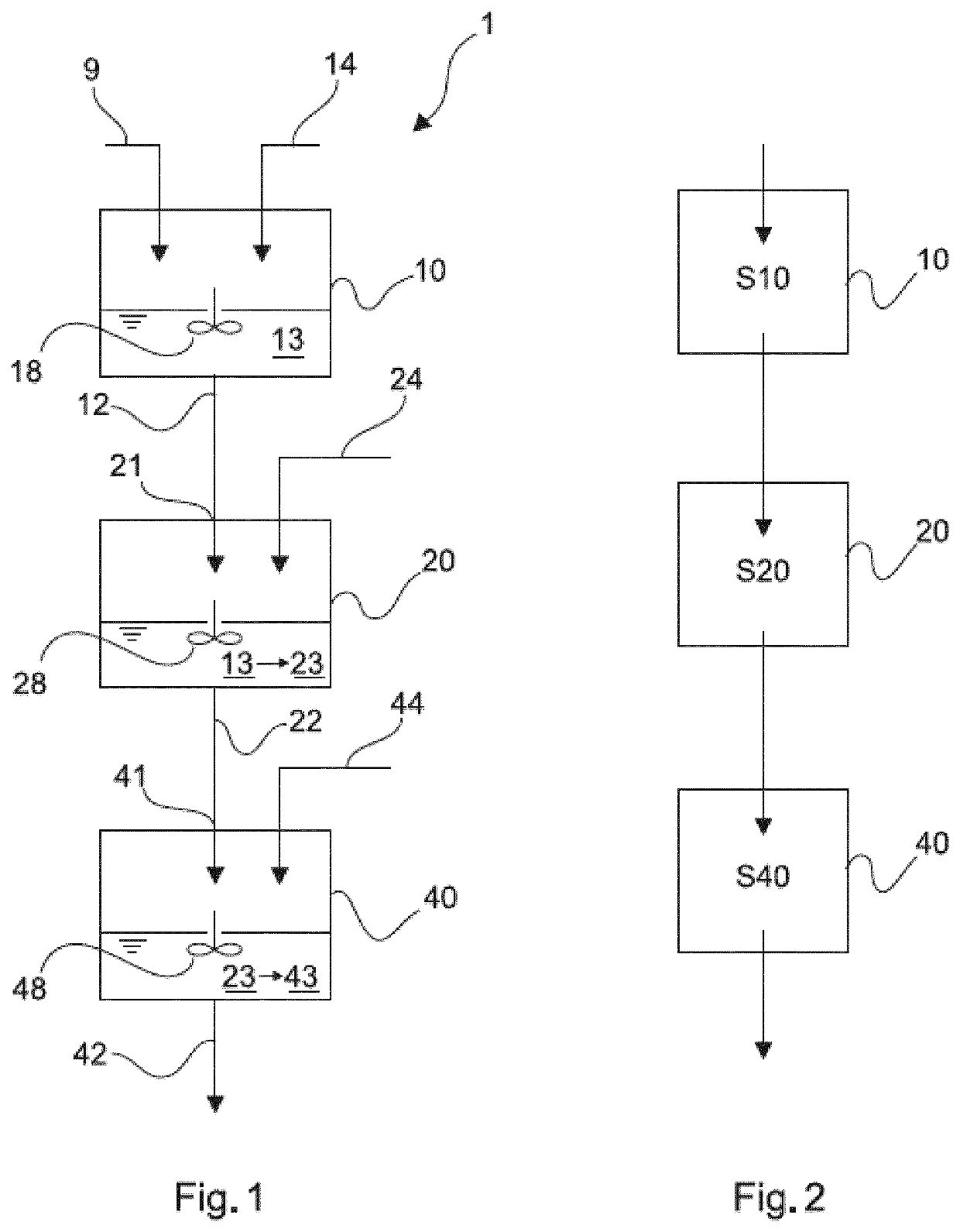

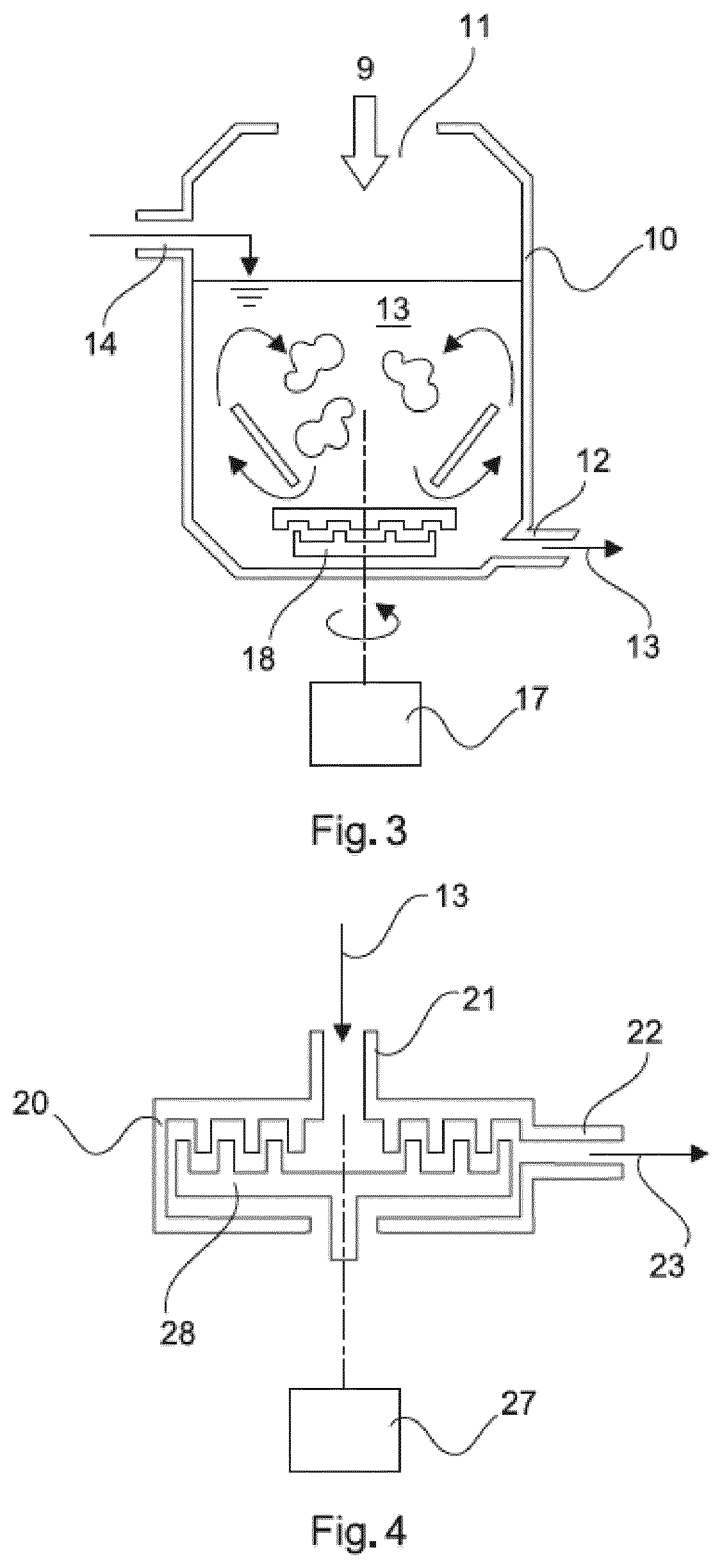

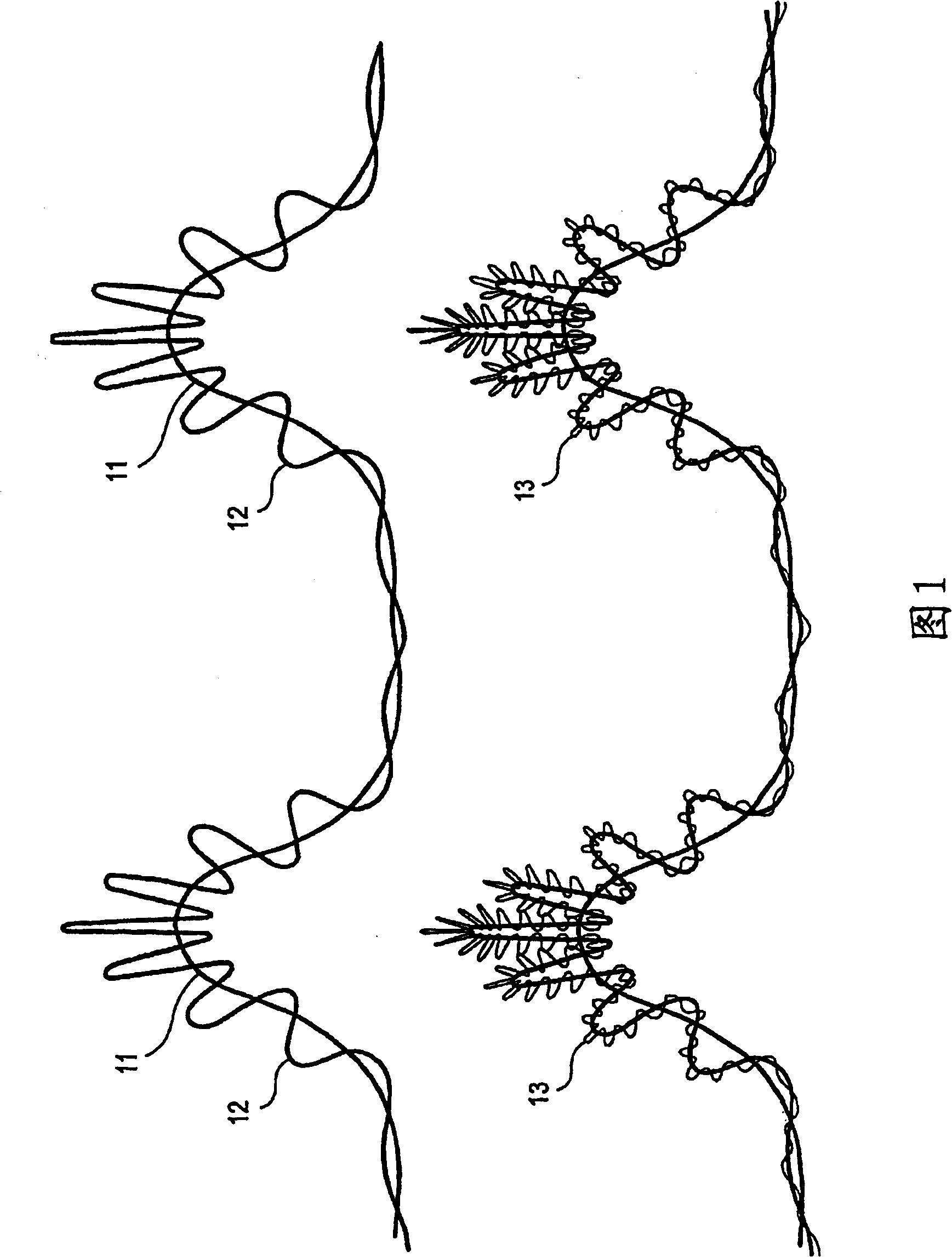

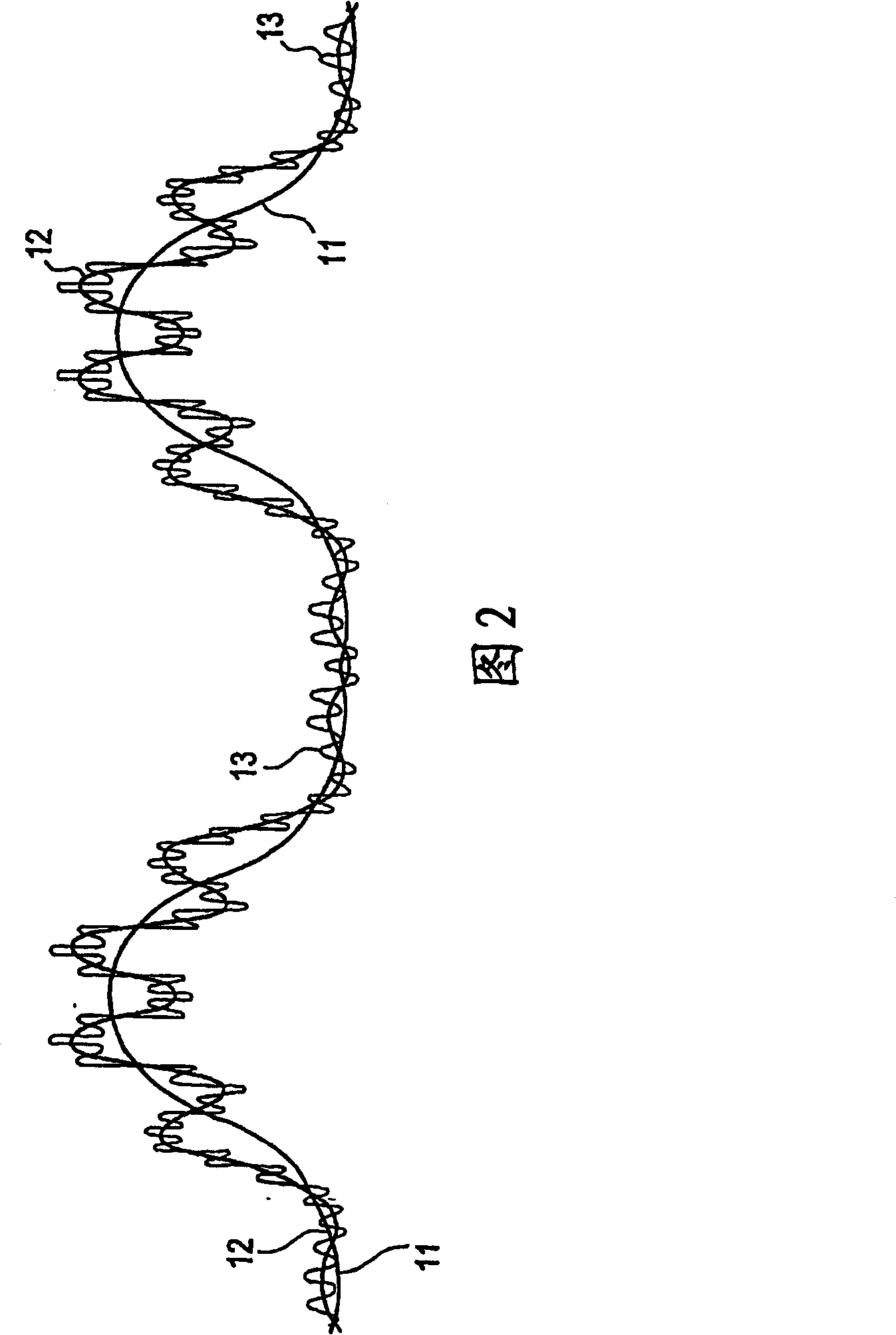

Redispersion of schizophyllan

The present invention relates to a method for preparing a concentrated polysaccharide mass, in particular a method for preparing concentrated glucan or schizophyllan, in particular a method for redispersing glucan or schizophyllan for producing a ready-to-use mass.

Owner:WINTERSHALL HLDG

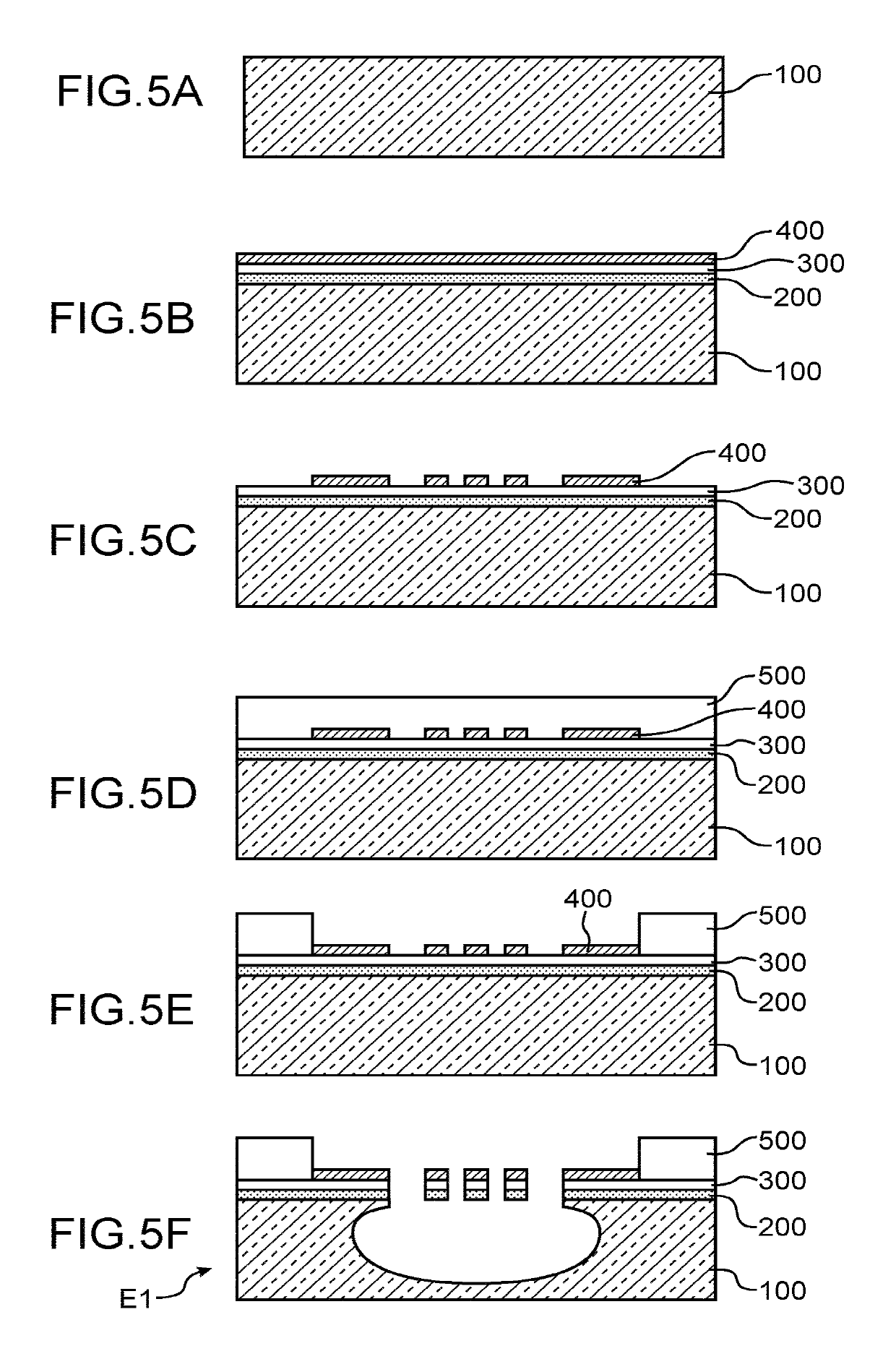

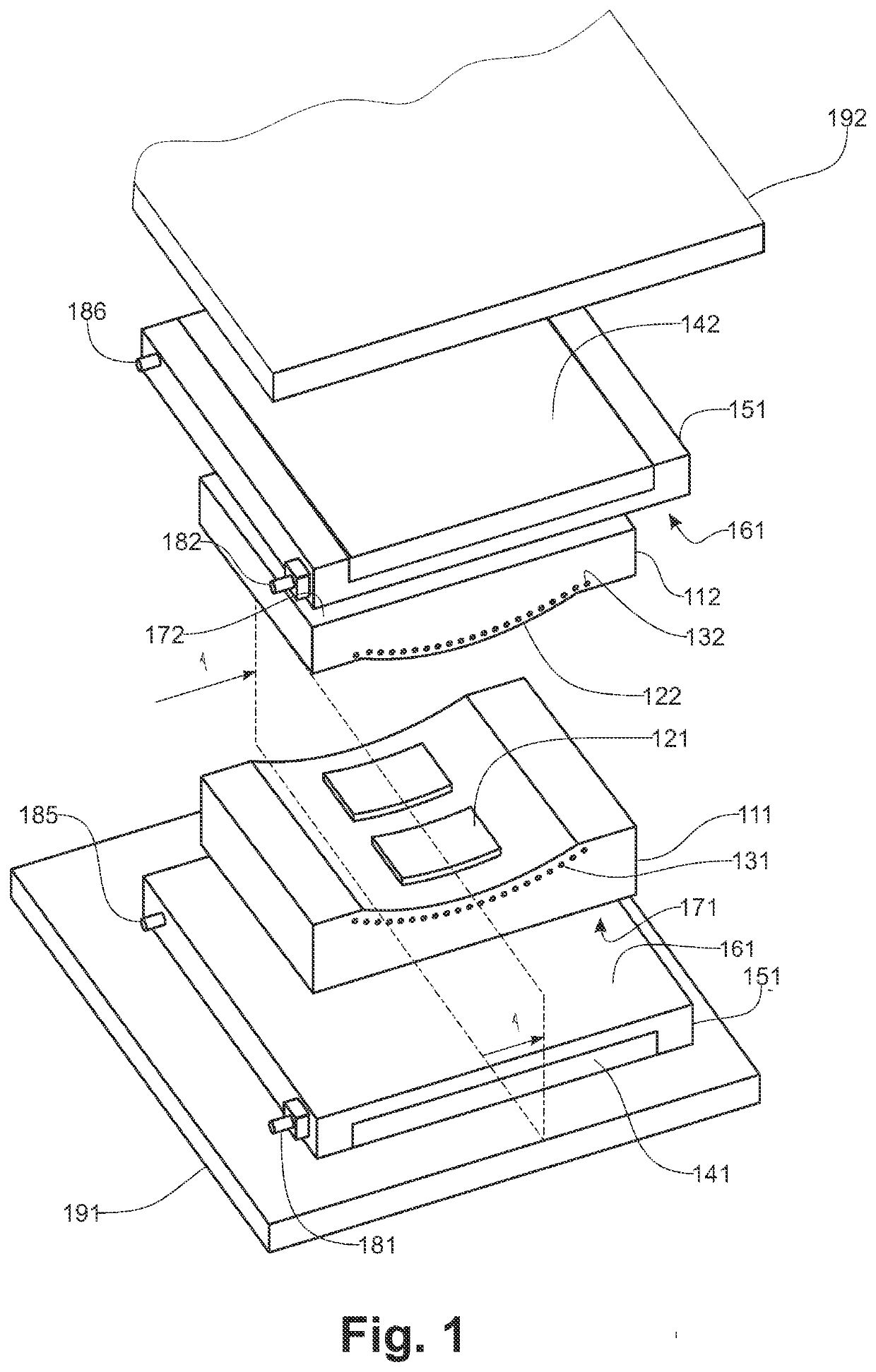

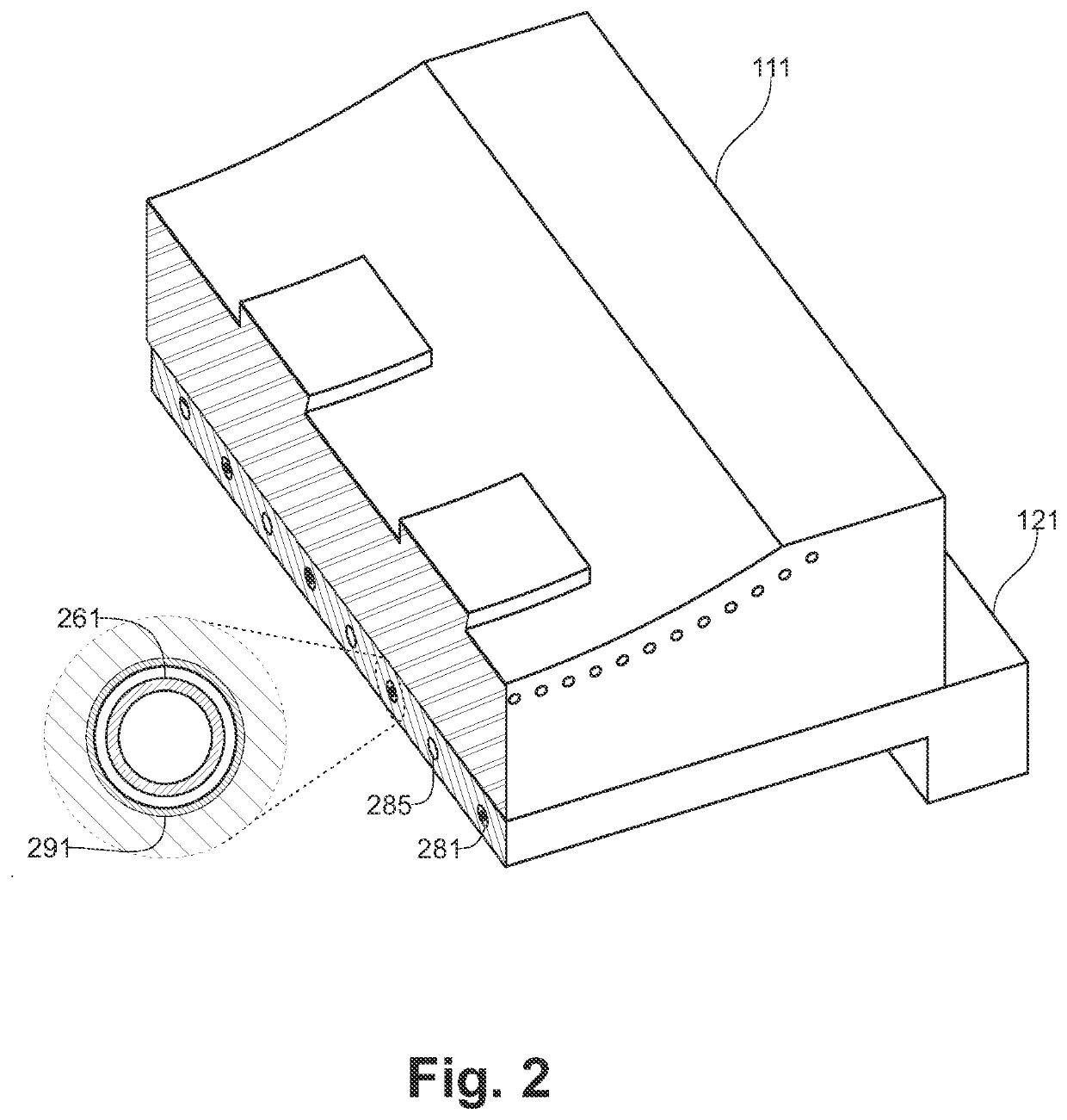

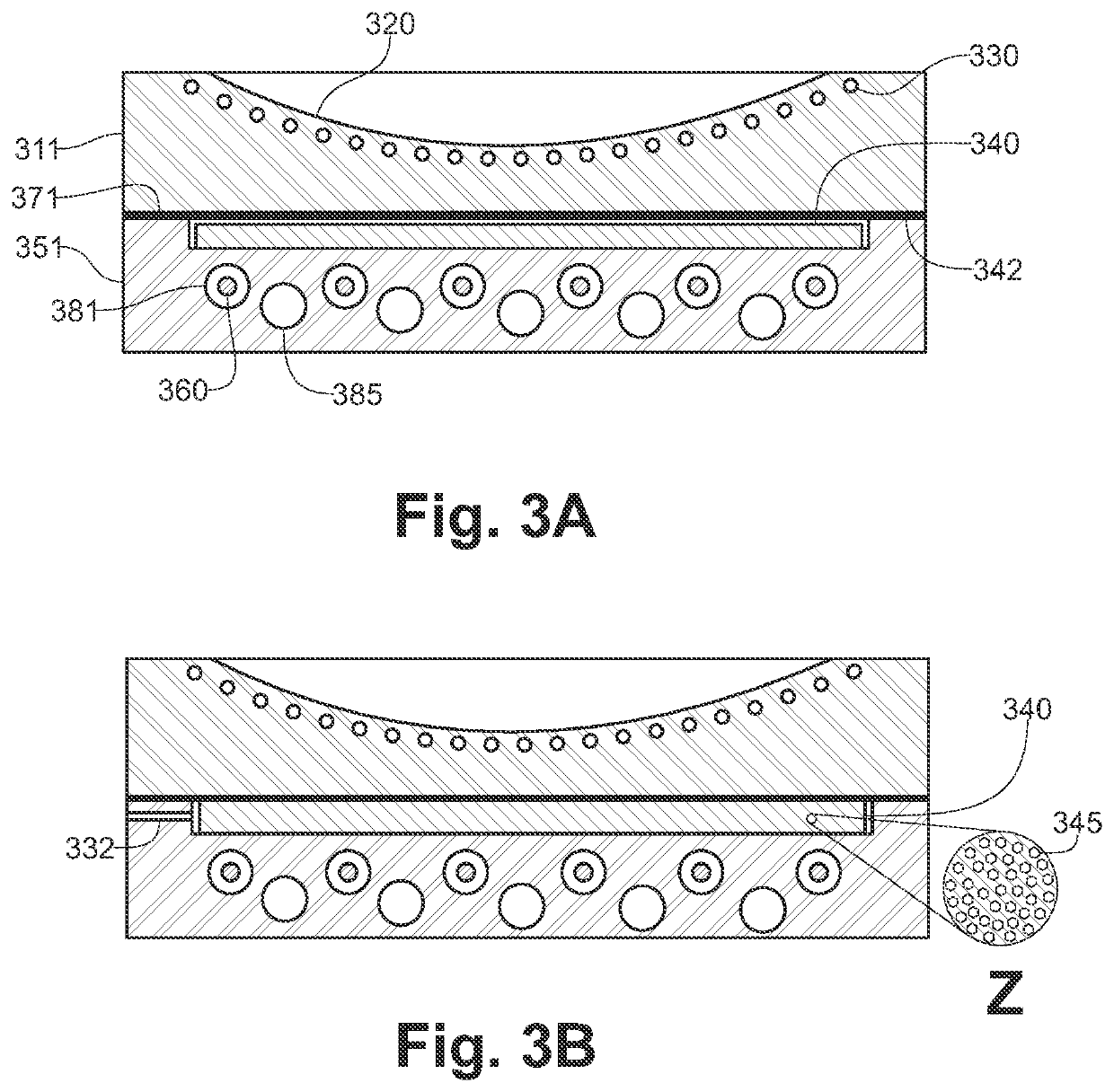

Method and device for heating a mould

PendingUS20220088838A1Reduce thermal resistanceImprove heat transfer performanceHeat transfer fluidFerroics

A mold to shape a material having a polymer matrix. The mold includes a first and a second die having molding surfaces. The molding surfaces delimit a molding cavity configured to shape the material when the first and the second dies are brought in contact with each other and the mold is closed. The heating plates include a ferromagnetic material configured to be heated by induction, and to transfer heat from a heat transfer surface of the heating plate to a receiving surface of the dies, other than the molding surfaces. The heating plates include heating and cooling channels. The heating channels of the heating plates have an inductor. The cooling channels of the heating plates are configured to circulate a heat transfer fluid.

Owner:ROCTOOL SAS

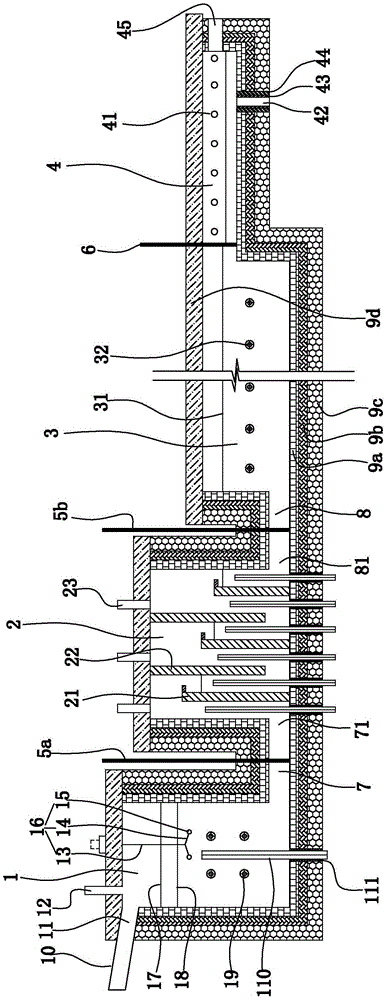

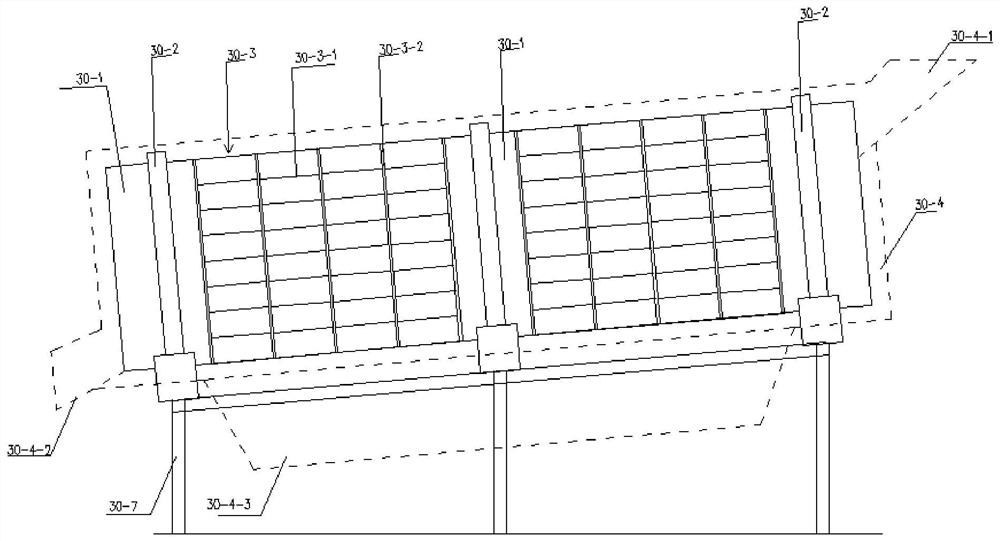

A vertical clamping large-size tempered glass homogenization processing device

The invention relates to a glass processing device, in particular to a vertical clamping large-size tempered glass homogenization processing device. The technical problem to be solved by the present invention is to provide a vertically clamped large-size tempered glass homogenization processing device. A vertical clamping large-size tempered glass homogenization treatment device, including a quality treatment chamber, a vertical clamping device, an infrared thermometer, a waste removal control device, an eruption gas circulation pipe, a gas push device, an electric heating wire, a waste temporary Storage cabin, high-temperature blower and control panel; an infrared thermometer is installed on the top right side of the homogeneous treatment chamber; the bottom right side of the homogeneous treatment chamber is connected to the waste discharge control device; circulation tube. The invention achieves the effects of spraying hot air on the glass surface to directly heat, increasing the homogenization speed; increasing the glass surface temperature first, shortening the processing time, and reducing the probability of glass injury; and automatically processing glass fragments to prevent the effect of affecting the homogenization process.

Owner:深圳市唛壳科技有限公司

a slag furnace

InactiveCN104328232BPrevent floatingHigh fiber rateRecycling and recovery technologiesVitrificationMelting tank

The invention discloses a slag furnace and aims to provide the slag furnace which not only can fully utilize residual heat resources in blast furnace thermal-state slag and is energy-saving and environmental-protective but also can enable a melt in a slag furnace to be melted uniformly, a vitrification degree to be high and a fiber-forming ratio and quality of mineral wool to be improved. The slag furnace successively includes a feeding tank, a melting tank and a material path. A slag flow inlet and a main modulating material feeding port are arranged on an upper part of the feeding tank. The feeding tank is connected to the melting tank through a first liquid flowing path. One end of the material path is communicated with the melting tank and the other end of the material path is closed. In addition, a material outlet port is arranged at the bottom of the material path. A first flow-controlling gate board device is disposed at the first liquid flowing path and is used for controlling the flow rate of the first liquid flowing path. A material path flow-controlling gate board device is disposed at the material path and is used for controlling the flow rate of the material path. The material path flow-controlling gate board device is arranged between the melting tank and the material outlet port and is closed to the melting tank.

Owner:宝钢矿棉科技(宁波)有限公司

An energy-saving mineral wool preparation system using hot slag

InactiveCN104326660BTake advantage ofFast homogenizationGlass making apparatusMelting tankVitrification

The invention discloses an energy-saving mineral wool preparation system with a thermal-state slag and aims to provide the energy-saving mineral wool preparation system which not only can fully utilize residual heat resources in blast furnace thermal-state slag and is energy-saving and environmental-protective but also can enable a melt in a slag furnace to be melted uniformly, a vitrification degree to be high and a fiber-forming ratio and quality of mineral wool to be improved. The device includes a slag furnace and at least two centrifugal machines. The slag furnace successively includes a feeding tank, a homogenizing tank, a melting tank, a clarifying tank and at least two material paths. A slag flow inlet and a main modulating material feeding port are arranged on an upper part of the feeding tank. The bottom of the feeding tank is connected to the bottom of the homogenizing tank through a first liquid flowing path. The bottom of the homogenizing tank is communicated with the bottom of the melting tank through a second liquid flowing path. The clarifying tank is communicated with the melting tank through a third liquid flowing path. One end of each material path is communicated with the clarifying tank and the other end of each material path is closed. In addition, material outlet ports are arranged at the bottoms of the material paths.

Owner:宝钢矿棉科技(宁波)有限公司

A slag furnace for processing blast furnace hot slag

InactiveCN104326652BSimple structureFast homogenizationGlass making apparatusVitrificationMelting tank

The invention discloses a slag furnace for treating a blast furnace thermal-state slag and aims to provide the slag furnace which not only can fully utilize residual heat resources in the blast furnace thermal-state slag and is energy-saving and environmental-protective but also can enable a melt in the slag furnace to be melted uniformly, a vitrification degree to be high and a fiber-forming ratio and quality of mineral wool to be improved. The slag furnace includes a feeding tank, a homogenizing tank, a melting tank, a clarifying tank and at least two material paths. A slag flow inlet and a main modulating material feeding port are arranged on an upper part of the feeding tank. The bottom of the feeding tank is connected to the bottom of the homogenizing tank through a first liquid flowing path. The bottom of the homogenizing tank is communicated with the bottom of the melting tank through a second liquid flowing path. The clarifying tank is communicated with the melting tank through a third liquid flowing path. One end of each material path is communicated with the clarifying tank and the other end of each material path is closed. In addition, material outlet ports are arranged at the bottoms of the material paths.

Owner:宝钢矿棉科技(宁波)有限公司

Blast furnace thermal slag-to-mineral wool preparation system

InactiveCN104496169APromote formationImprove fiber formation rate and qualityGlass making apparatusSlagFiber

The invention discloses a blast furnace thermal slag-to-mineral wool preparation system, and aims to provide the blast furnace thermal slag-to-mineral wool preparation system that not only can make full use of the residual heat resources in blast furnace thermal slag, is environment-friendly, but also can achieve uniform melt melting in a slag melting furnace and high vitrification degree, and effectively improve the fiber forming rate and quality of mineral wool. The system includes: a slag fetching ditch for diversion of blast furnace thermal slag, a slag melting furnace and at least two centrifuges. The slag melting furnace comprises, in order, a charging pool, a homogenization pool, a melting pool, a purification pool and at least two material channels. The upper part of the charging pool is provided with a slag inflow port and a main tempering material adding port. The bottom of the charging pool and the bottom of the homogenization pool are connected through a first liquid flow channel, the bottom of the homogenization pool and the bottom of the melting pool are communicated through a second liquid flow channel, and the purification pool and the melting pool are communicated through a third liquid flow channel. One end of each of the material channels is communicated with the purification pool, the other end is sealed, and the bottom of each material channel is provided with a discharge port.

Owner:宝钢矿棉科技(宁波)有限公司

A method for preparing wall bricks from sludge composite mineralized garbage

ActiveCN108947483BRealize resource utilizationTurn waste into treasureSievingSludge treatment by de-watering/drying/thickeningBrickSludge

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

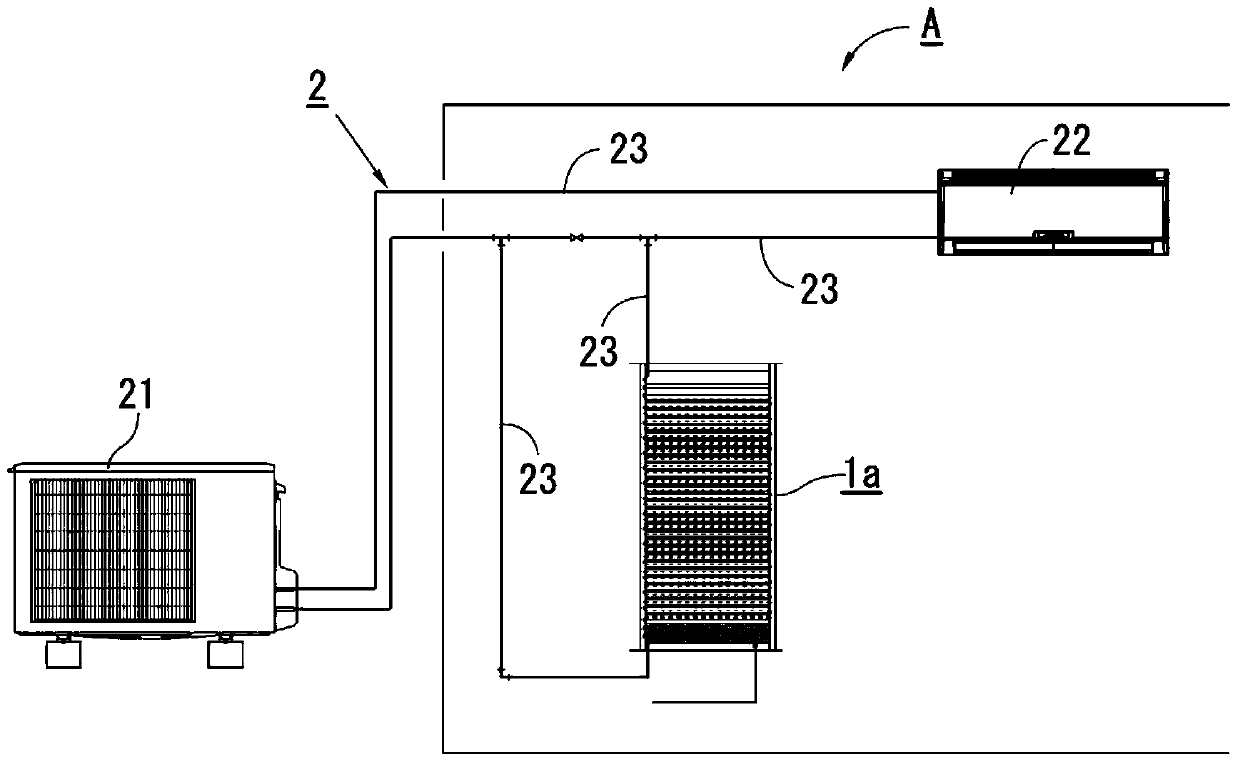

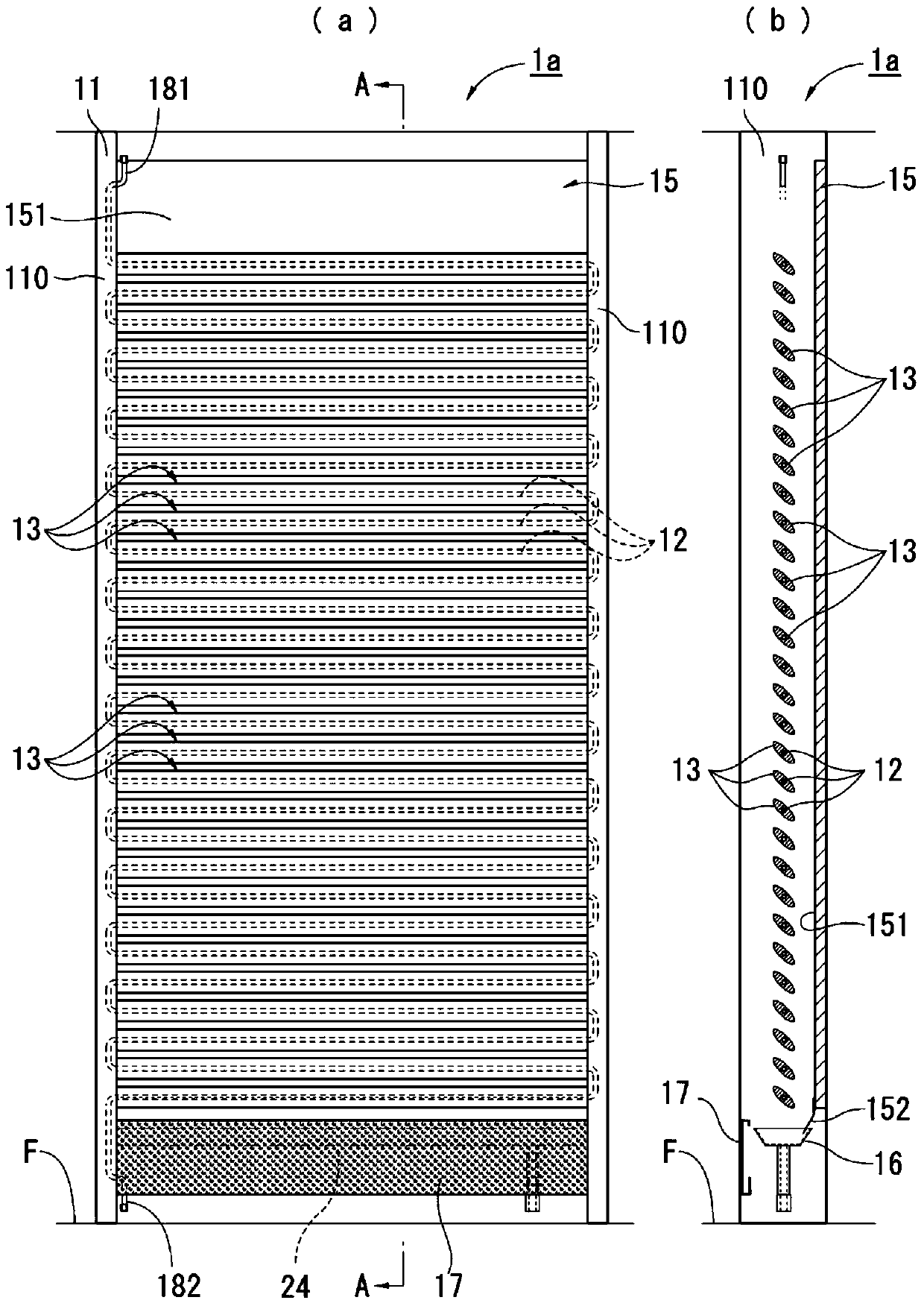

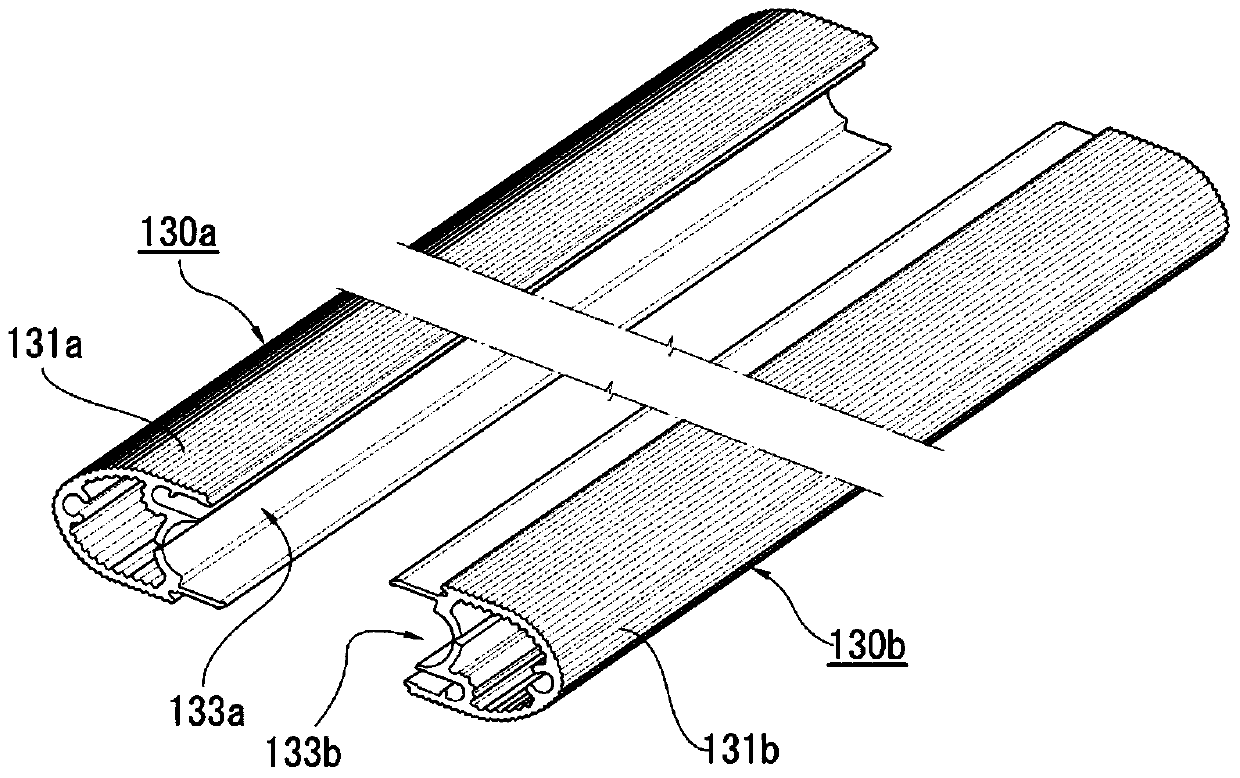

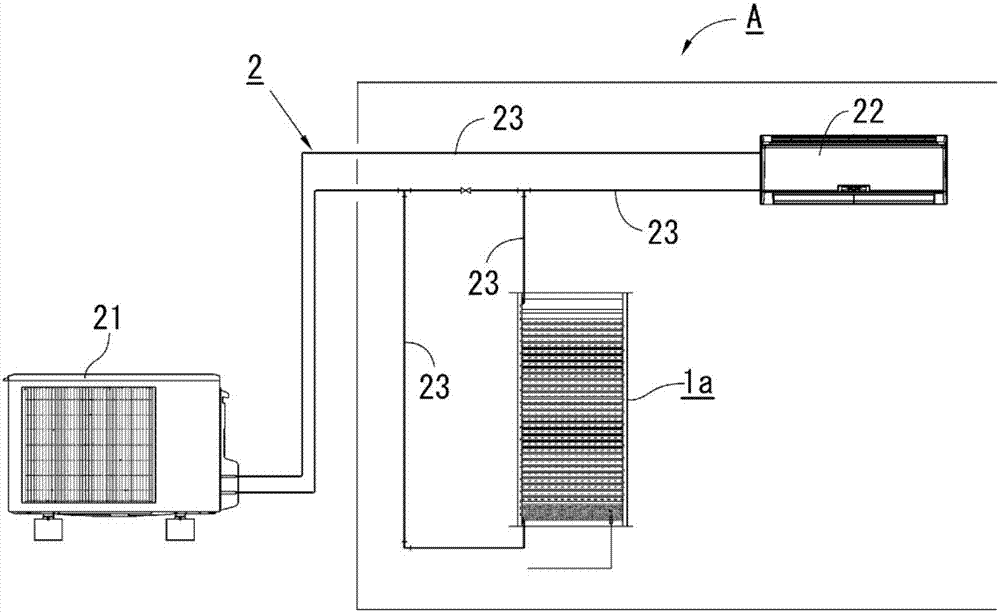

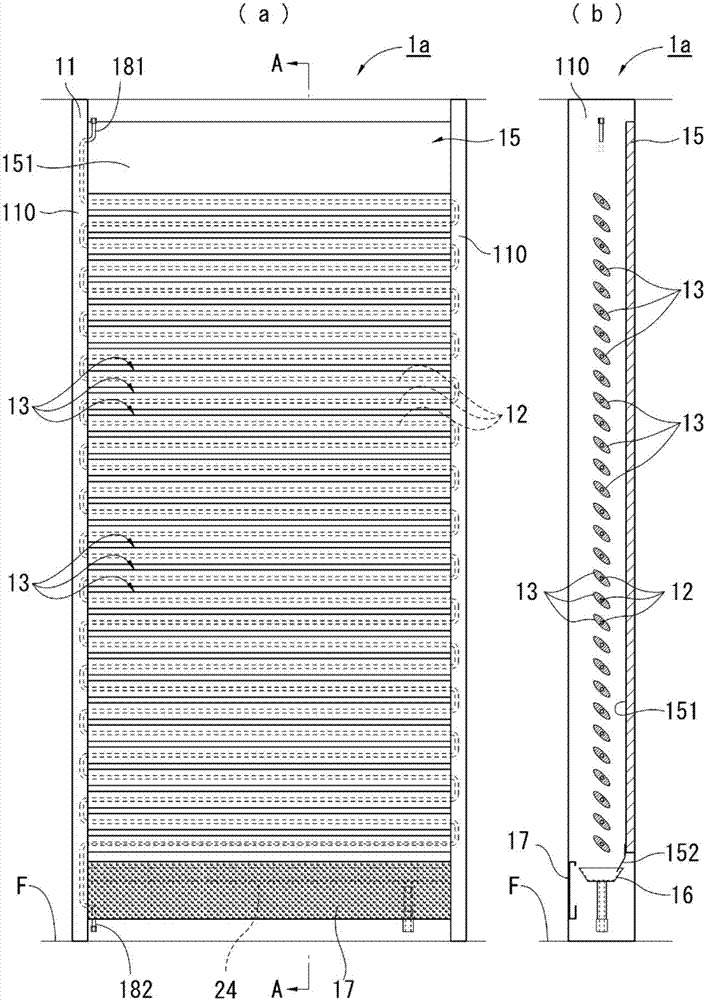

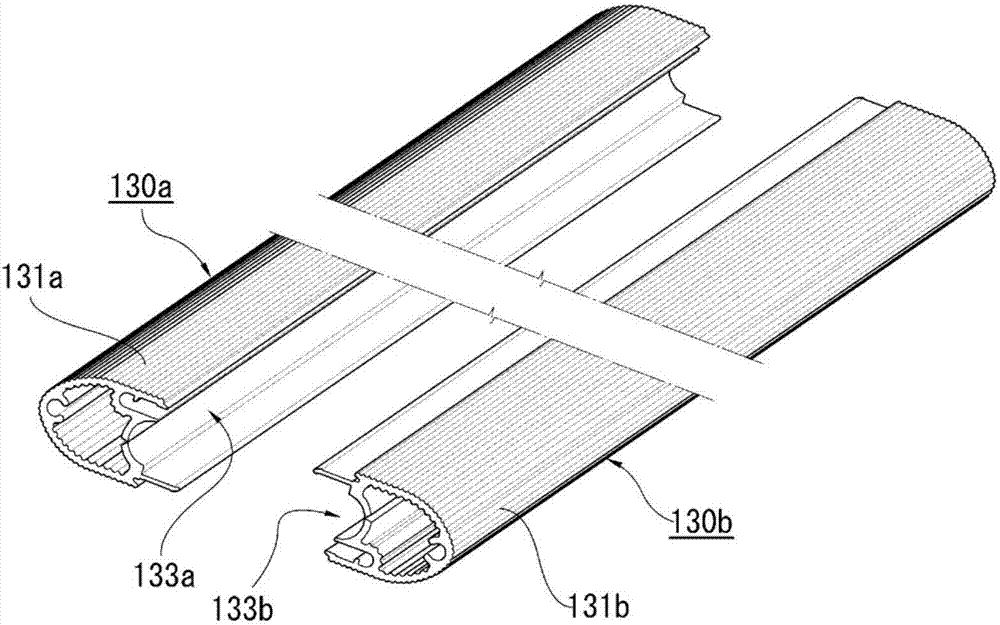

Heating body cover parts, heating body cover, radiant cooling and heating machine and air conditioning system

ActiveCN107407486BThermally conductiveImprove cooling effectHeat exhanger finsAir conditioning systemsEngineeringAir conditioning

The heating body cover part (130a) has: a shell part (131a), which has required rigidity and thermal conductivity, and has a space (132) with a required length; a substantially bisected pipe-shaped contact part (134a), It is formed at a desired position on the outer side of the case part (131a) with a required thickness parallel to the longitudinal direction of the case part (131a), has flexibility and thermal conductivity, and is formed over the entire length in parallel with the above-mentioned longitudinal direction. There is a slit (135a) penetrating in the thickness direction; a connecting part (136), which has flexibility and thermal conductivity, connects the edges of the two sides parallel to the longitudinal direction of the abutting part (134a) to the shell part (131a) and an engaging part, which is configured to be arranged at a line-symmetrical position with a straight line in the longitudinal direction in the middle of the width direction of the above-mentioned abutting part (134a) as the axis of symmetry and a pair of engaging parts that can engage with each other is also That is, the protruding piece (138a) and the protruding piece embedded part (140a) are constituted.

Owner:ECO FACTORY CO LTD

Heating element cover component, heating elelment cover, radiation cooling and heating equipment, and air-conditioning system

ActiveCN107407486AReduce thicknessEasy to liftHeat exhanger finsAir conditioning systemsAir conditioningRadiation

A heating element cover component 13a is equipped with: a shell portion 131a which has required rigidity and heat conductivity and has a space 132 having a required length; an approximately-half-tube-shaped abutment portion 134a which is formed at a required place on the outside of the shell portion 131a so as to be parallel to the longitudinal direction of the shell portion 131a and have a required thickness, and which has flexibility and heat conductivity and is formed with a slit 135a penetrating the abutment portion in the thickness direction, the slit being formed parallel to the longitudinal direction over the entire length thereof; connection portions 136 which have flexibility and heat conductivity, and connect both edges parallel to the longitudinal direction of the abutment portion 134a to the shell portion 131a; and an engagement portion that is composed of a protruding piece 138a and a protruding piece fitting portion 140a, which are a pair of engagement elements arranged symmetrically across the longitudinal line located midway in the width direction of the abutment portion 134a, and having structures engageable with each other.

Owner:ECO FACTORY

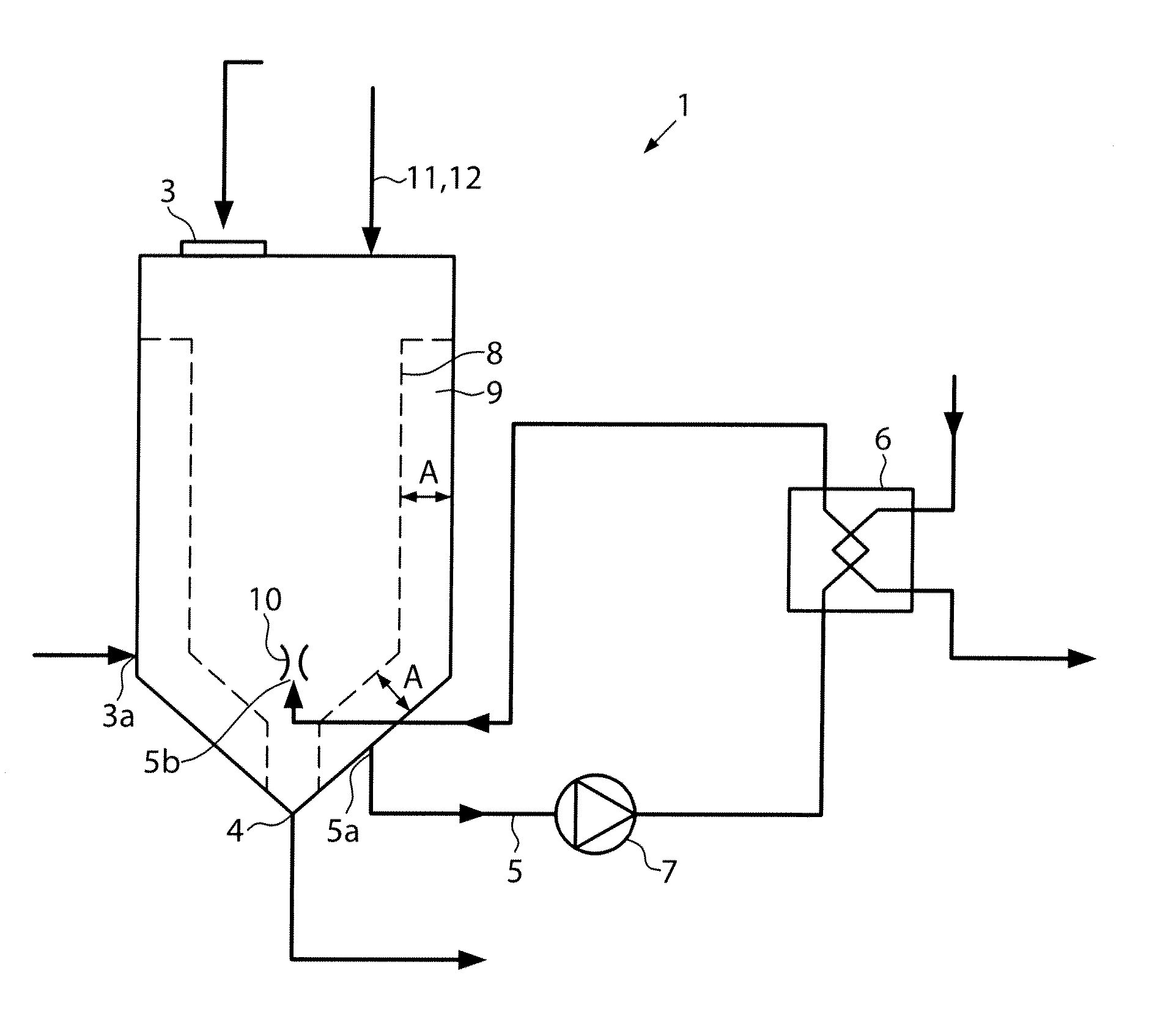

Device for tempering

InactiveUS20120006817A1Fast and deep mixingRapid temperature measurementFood preservationRigid containersEngineeringExit point

A device for tempering a mixture of a solid and a liquid phase, particularly a liquid containing fruit particles, having a container that is connected to a heat exchanger via a circulation line where the circulation line has an entry point and exit point in the container. So that the device is gentler on the product, blocks the exit point of the circulation line from the solid phase is arranged in the container.

Owner:KRONES AG

Systems and methods of electromagnetic influence on electroconducting continuum

InactiveCN100421838CRaise the unstable componentFast homogenizationMechanical apparatusStirring devicesFoundryChemical products

Thus, as shown by an exact electrodynamic computation of EMBF and the estimations described above of the velocity of turbulent flows arising due to their effect, application of amplitude- and frequency-modulated helically traveling (rotating and axially traveling) electromagnetic fields in metallurgical and chemical technologies and foundry can considerably increase the hydraulic efficiency of MHD facilities, intensify the processes of heat and mass transfer in technological plants, significantly increase their productivity, considerably decrease energy consumption for the production of metals, alloys, cast articles, and chemical products, and improve their quality.

Owner:ENERGETICS TECH

Energy-saving mineral wool preparation system with thermal-state slag

InactiveCN104326660ATake advantage ofFast homogenizationGlass making apparatusMelting tankVitrification

The invention discloses an energy-saving mineral wool preparation system with a thermal-state slag and aims to provide the energy-saving mineral wool preparation system which not only can fully utilize residual heat resources in blast furnace thermal-state slag and is energy-saving and environmental-protective but also can enable a melt in a slag furnace to be melted uniformly, a vitrification degree to be high and a fiber-forming ratio and quality of mineral wool to be improved. The device includes a slag furnace and at least two centrifugal machines. The slag furnace successively includes a feeding tank, a homogenizing tank, a melting tank, a clarifying tank and at least two material paths. A slag flow inlet and a main modulating material feeding port are arranged on an upper part of the feeding tank. The bottom of the feeding tank is connected to the bottom of the homogenizing tank through a first liquid flowing path. The bottom of the homogenizing tank is communicated with the bottom of the melting tank through a second liquid flowing path. The clarifying tank is communicated with the melting tank through a third liquid flowing path. One end of each material path is communicated with the clarifying tank and the other end of each material path is closed. In addition, material outlet ports are arranged at the bottoms of the material paths.

Owner:宝钢矿棉科技(宁波)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com