Blast furnace thermal slag-to-mineral wool preparation system

A technology of hot slag and preparation system, which is applied in the direction of glass manufacturing equipment, manufacturing tools, etc., to achieve the effect of promoting formation, improving fiber formation rate and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

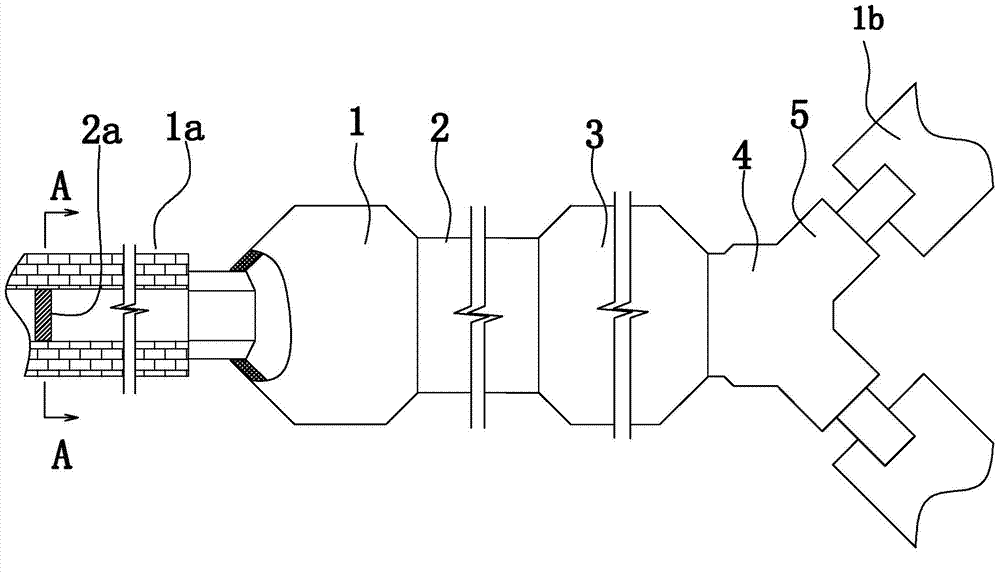

[0056] like figure 1 As shown, a blast furnace hot slag mineral wool preparation system includes a slag taking ditch 1a for diverting the blast furnace hot slag, a slag furnace and two or three or four centrifuges. There are two centrifuges in this embodiment.

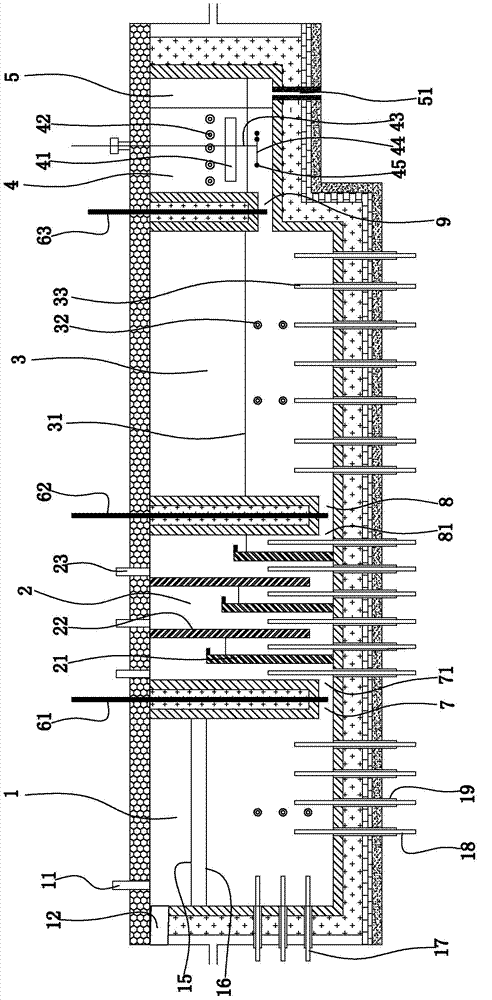

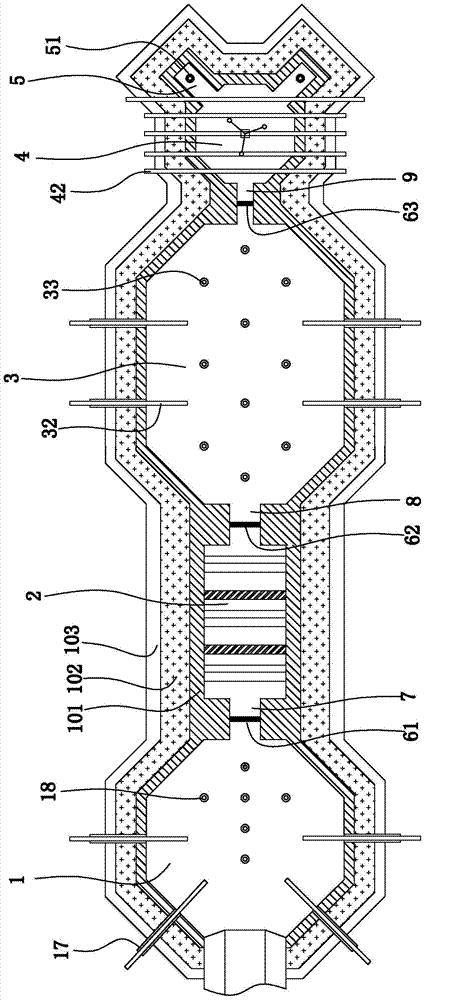

[0057] like figure 1 , figure 2 , image 3 As shown, the slag furnace includes a charging pool 1, a homogenization pool 2, a melting pool 3, a purification pool 4 and two or three or four forehearths 5 in sequence. There are two forehearths in this embodiment. The number of centrifuges corresponds to the number of channels (ie the same). The bottom of the feeding tank and the bottom of the homogenization tank are connected through the first liquid flow channel 7 . The bottom of the homogenization tank and the bottom of the melting tank are communicated through the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com