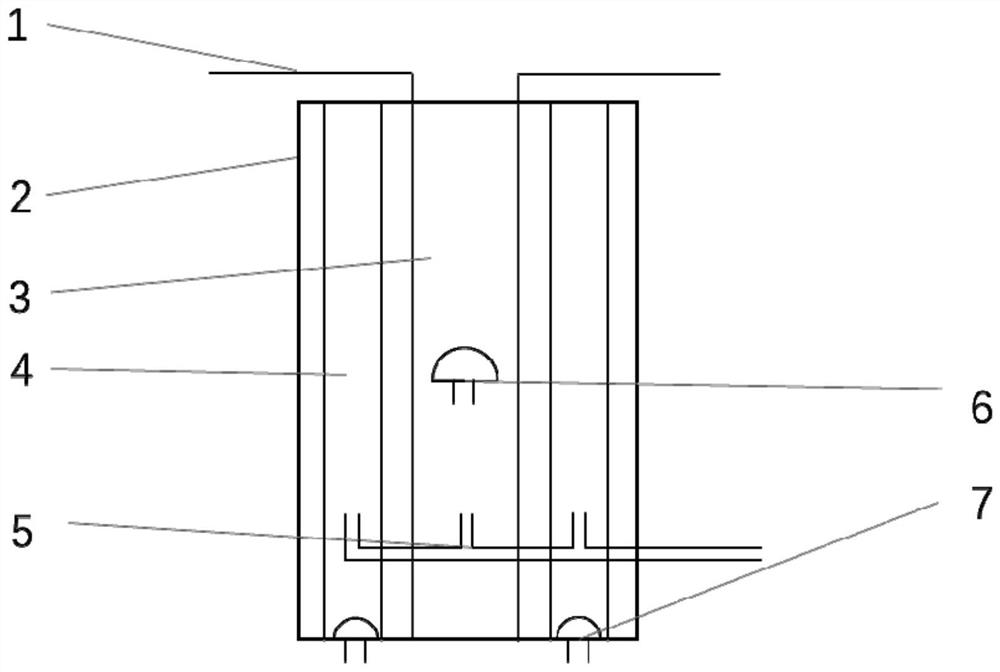

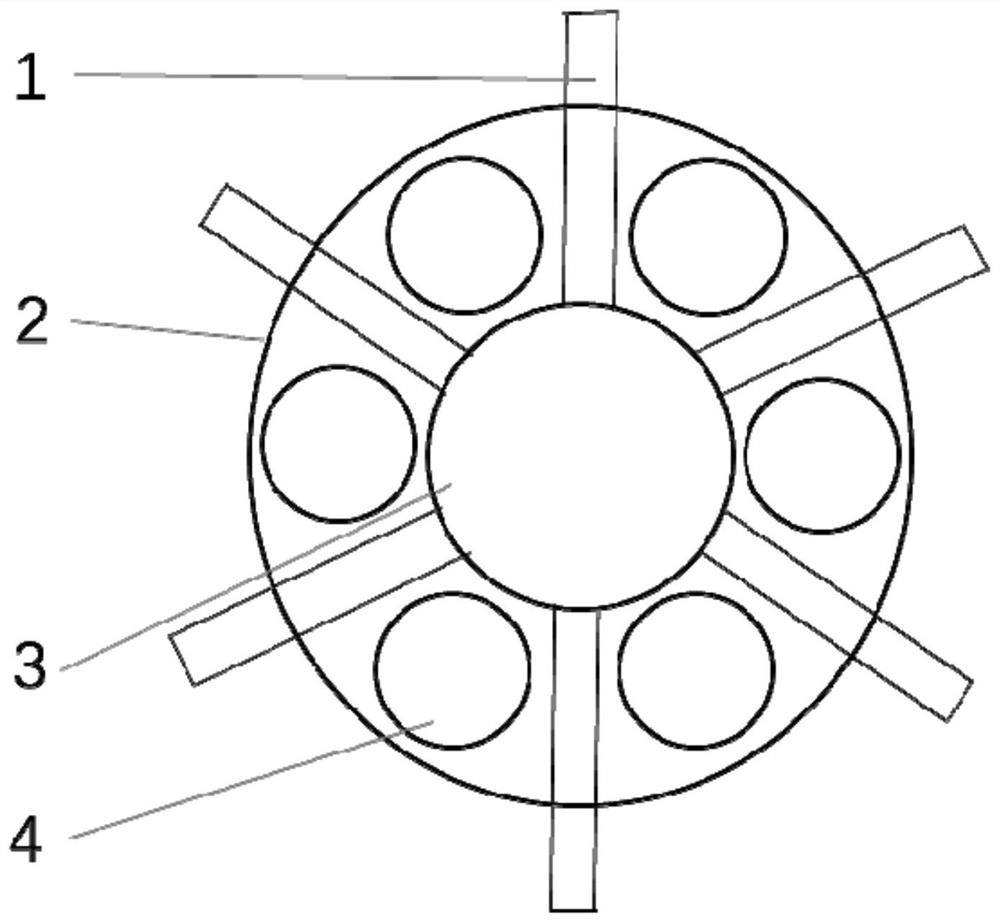

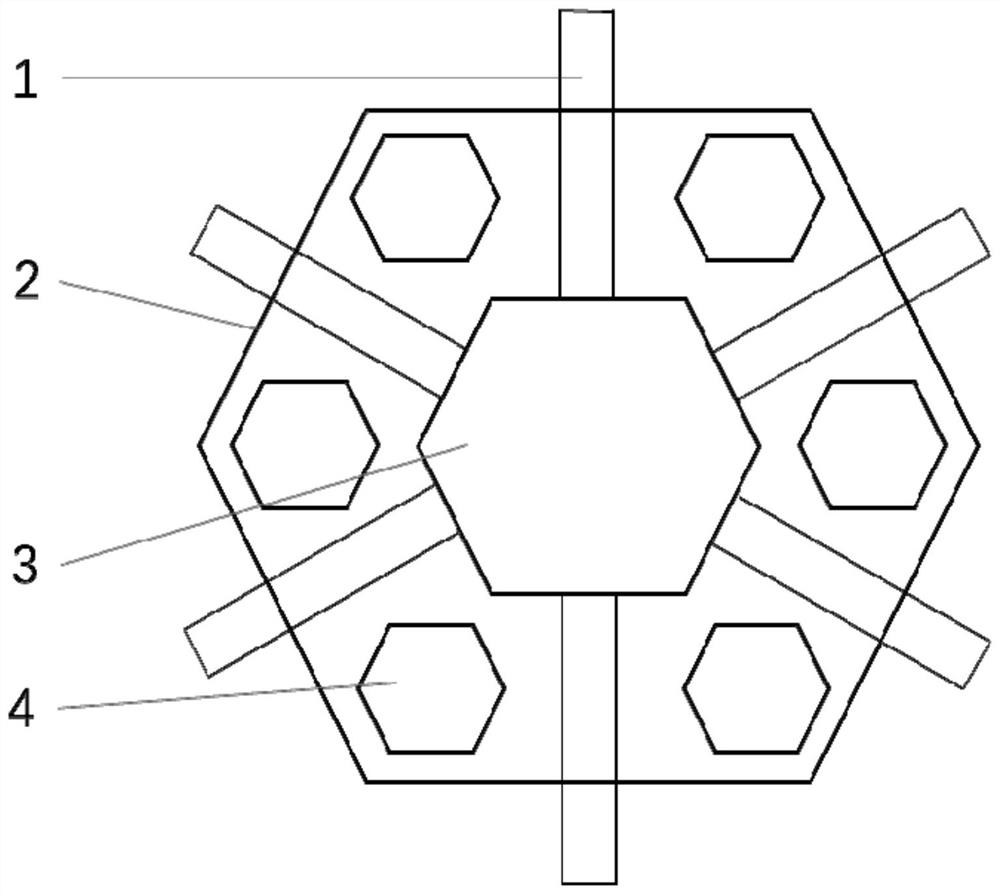

Internal component for strengthening refining wastewater biochemical mixed mass transfer reaction process

A technology for refining and chemical wastewater and internal components, which is used in natural water treatment, water treatment parameter control, sustainable biological treatment, etc. Contact area, improve oxygen utilization efficiency, and improve the effect of mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 The COD of a refinery wastewater is 8657mg / L, the pH is 8.21; after the operation is stable, the device load is 0.1m3 / d, the effluent COD is 562.7mg / L, and the removal efficiency is 93.50%.

Embodiment 2

[0026] Example 2 The COD of a refinery wastewater is 7954mg / L, the pH is 7.98; after the operation is stable, the device load is 0.1m3 / d, the effluent COD is 588.6mg / L, and the removal efficiency is 92.60%.

Embodiment 3

[0027] Example 3 The COD of a refinery wastewater is 9548mg / L, the pH is 8.49; after the operation is stable, the device load is 0.1m3 / d, the effluent COD is 750.5mg / L, and the removal efficiency is 92.14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com