Preparation method of ultra-fine active heavy calcium carbonate

A technology of heavy calcium carbonate and heavy calcium carbonate powder, applied in chemical instruments and methods, inorganic pigment treatment, dyeing low-molecular organic compound treatment, etc., can solve the problems of increasing product volume, reducing production cost, and poor affinity , to speed up stirring speed, improve modification efficiency and quality, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, one part of modified heavy calcium carbonate is made of following material components under normal pressure: heavy calcium carbonate 82%, calcium chloride 5, all the other are dehydrated alcohol and mix miniature titanic acid coupling agent the mixture formed;

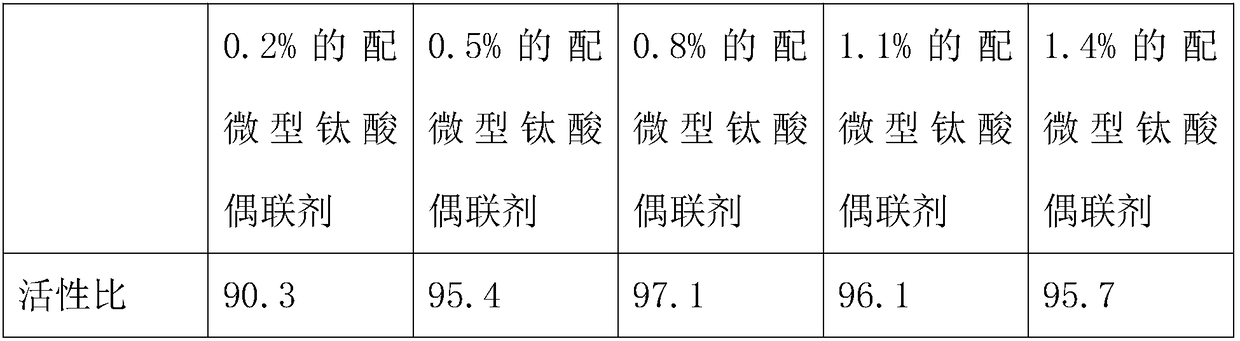

[0024] Among them, 0.2%, 0.5%, 0.8%, 1.1% and 1.4% of micro-titanic acid coupling agents are respectively selected, and the corresponding rest is absolute ethanol. First, heavy calcium carbonate fine powder and calcium chloride powder are evenly sealed and stirred , lasted for 30 minutes, gradually added 0.2% combined solution of micro titanic acid coupling agent and absolute ethanol 11.8% during the stirring process, and gradually raised its temperature within 5-20 minutes during the stirring process, the highest temperature At 70°C, select 0.5%, 0.8%, 1.1%, and 1.4% micro-titanic acid coupling agents according to the above, and the rest are absolute ethanol for proportioning solutions, and add he...

Embodiment 2

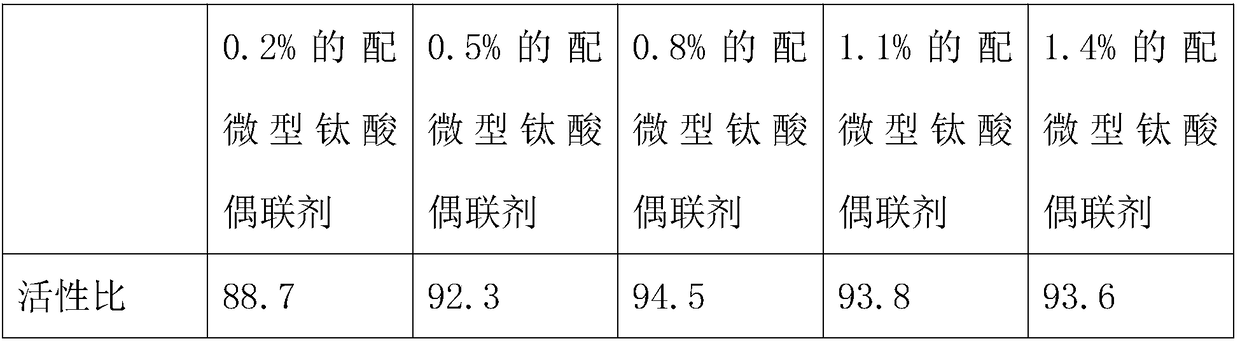

[0028] Embodiment 2, one part of modified heavy calcium carbonate is made of the following material components at normal temperature and pressure: heavy calcium carbonate 86%, calcium chloride 2, and the rest is dehydrated alcohol and micro titanic acid coupling The solution of the agent, wherein first heavy calcium carbonate fine powder and calcium chloride powder are uniformly sealed and stirred for 30 minutes, and gradually add 0.2% of the combination of micro titanic acid coupling agent and absolute ethanol 11.8% during the stirring process solution, and gradually heat it up within 5-20 minutes during the stirring process, the highest temperature is at 70°C, and then select 0.5%, 0.8%, 1.1%, and 1.4% of the matching micro-titanic acid coupling agent, the rest is anhydrous ethanol for proportioning solution, adding a mixture of heavy calcium carbonate 83% and calcium chloride 5 and stirring for 30 minutes, and at least 5% of each component is prepared.

[0029] The above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com