A vertical clamping large-size tempered glass homogenization processing device

A technology for homogenizing and tempering glass, which is applied in the field of vertical clamping large-size tempered glass homogenizing processing device, which can solve the problems of glass damage, high energy consumption, and affecting the homogenization process, so as to improve the homogenization speed, The effect of reducing the probability of injury and raising the surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

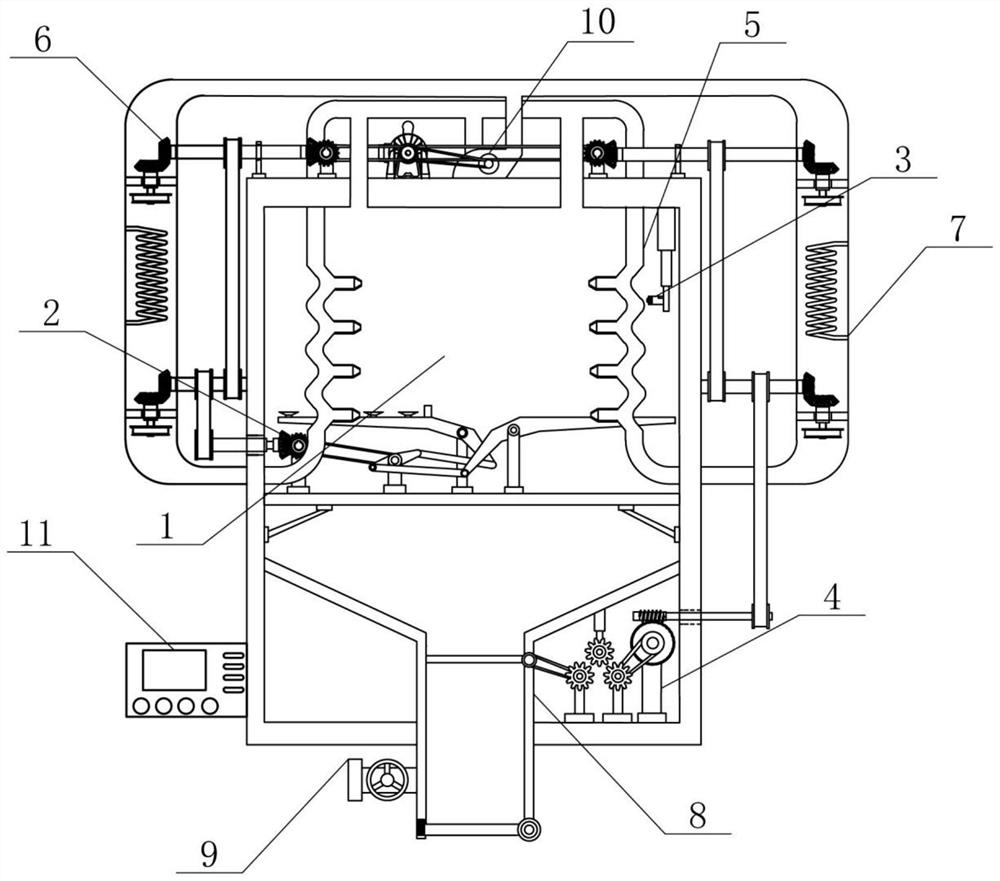

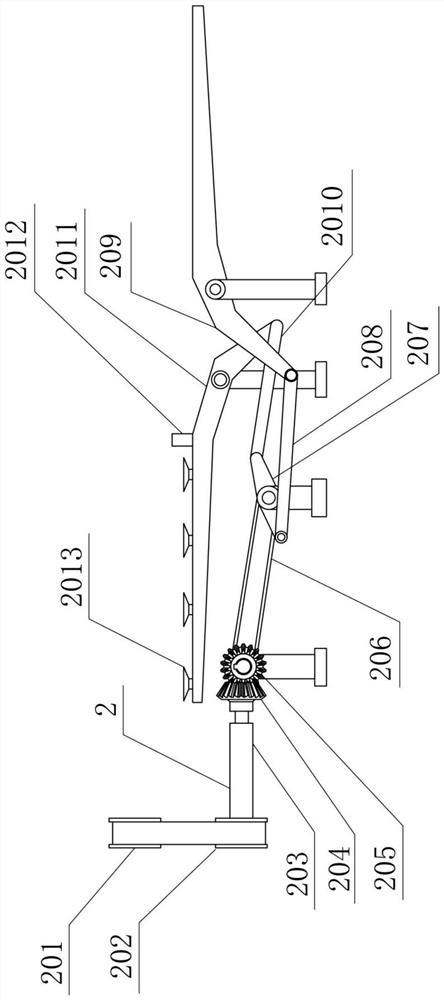

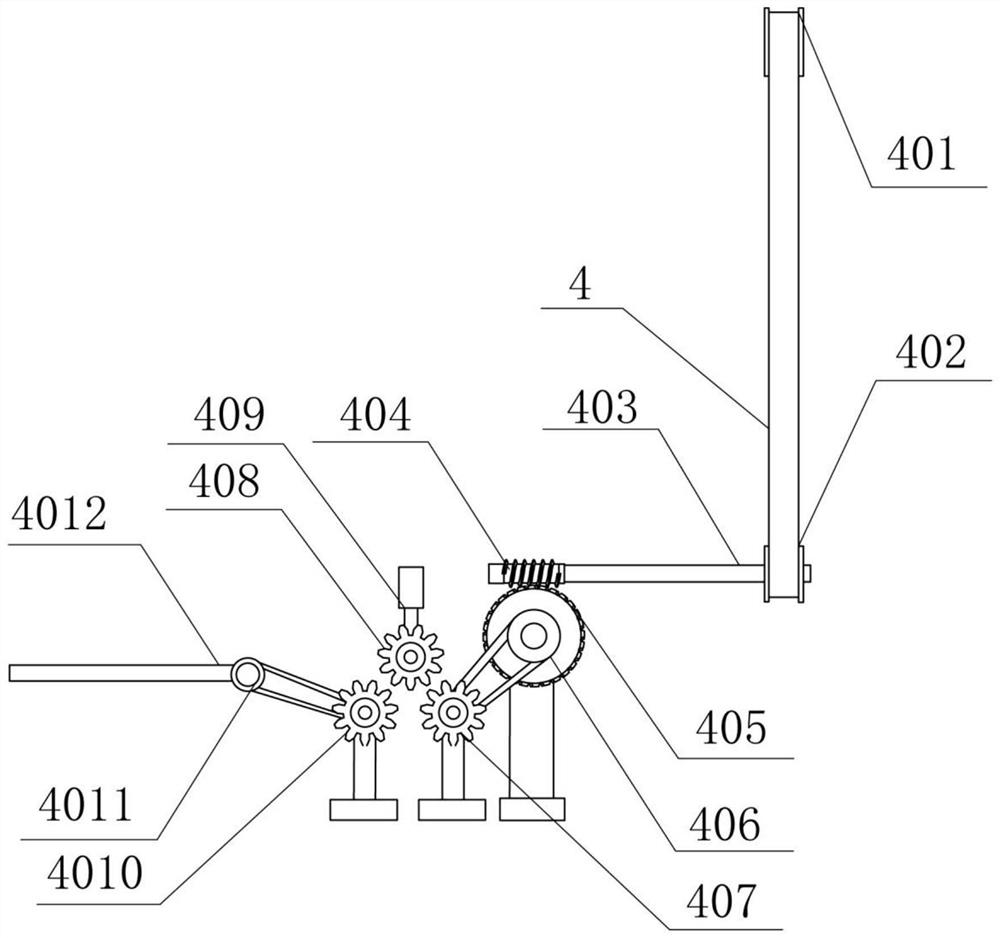

[0021] A vertical clamping large-size tempered glass homogenization processing device, such as Figure 1-4 As shown, it includes a homogeneous treatment chamber 1, a vertical clamping device 2, an infrared thermometer 3, a waste removal control device 4, an eruption gas circulation pipe 5, a gas push device 6, a heating wire 7, a waste temporary storage cabin 8, Pressure relief valve 9, high-temperature blower 10 and control panel 11; vertical clamping device 2 is installed in the middle of homogeneous processing chamber 1; infrared thermometer 3 is installed on the right side of the top of homogeneous processing chamber 1; homogeneous processing chamber 1 The right side of the inner bottom is connected to the waste material removal control device 4; the middle left part and the inner middle right part of the homogeneous treatment chamber 1 are provided with an eruption gas circulation pipe 5; Connection; the top and middle part of the homogeneous processing chamber 1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com