Automatic application hand brake

a hand brake and automatic technology, applied in the direction of mechanical equipment, brake systems, transportation and packaging, etc., can solve the problems of high force, shock, and high force on the hand brake mechanism, and achieve the effect of reducing time and effort, convenient use, and safe use by the operator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

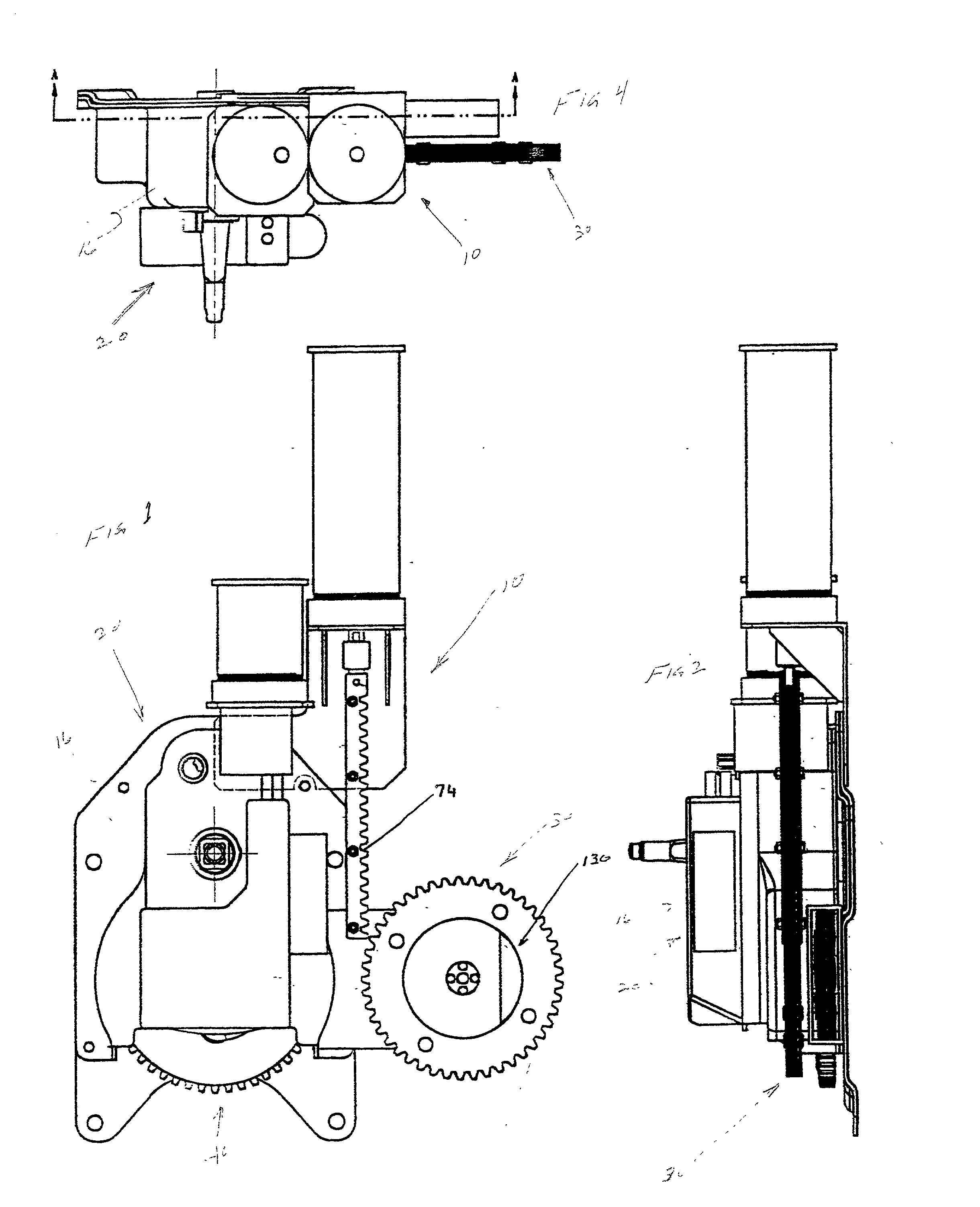

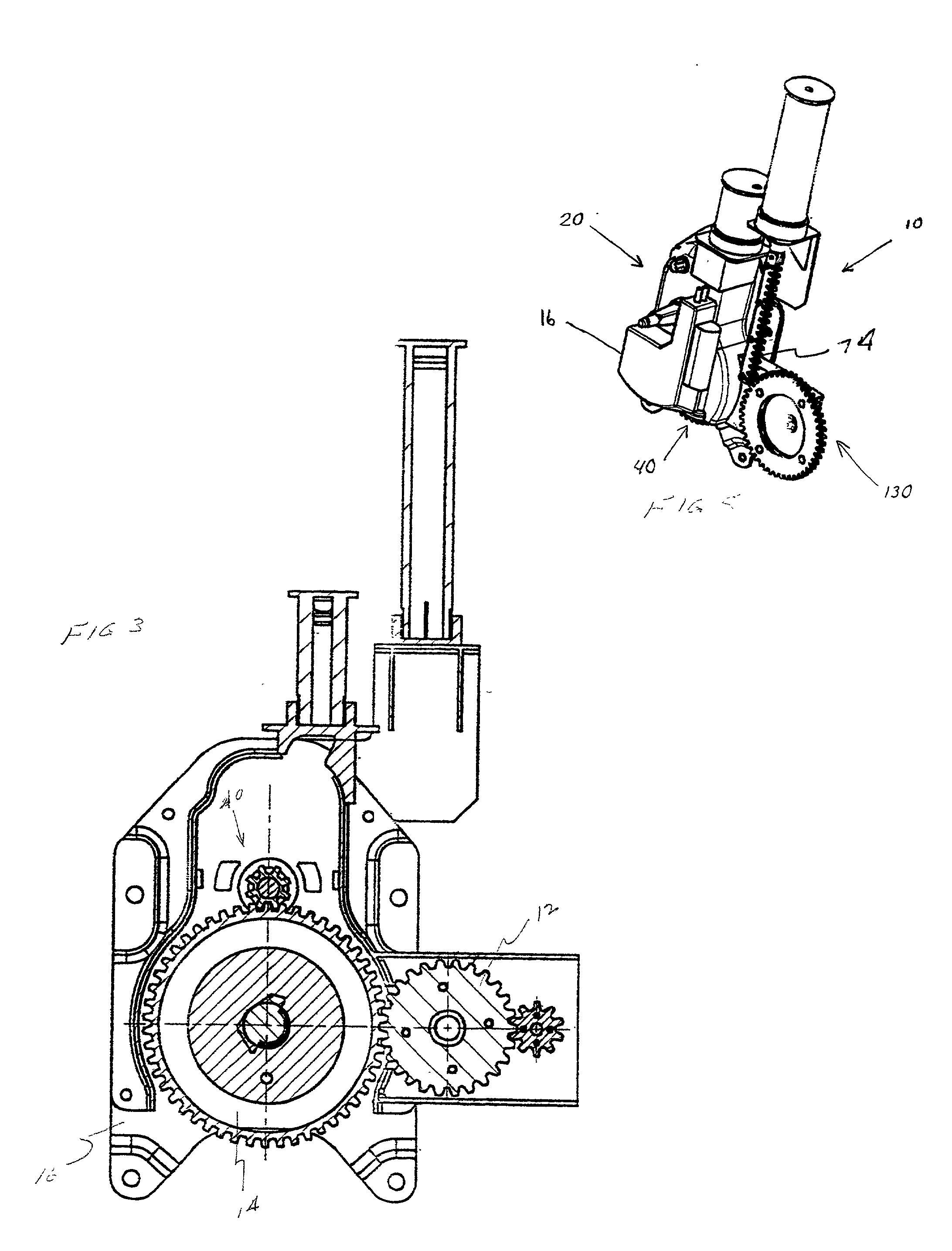

[0039] Prior to proceeding to the more detailed description of the various embodiments of the present invention, for the sake of clarity and understanding of such invention, it should be noted that identical components having identical functions have been identified with identical reference numerals throughout each of the figures illustrated herein.

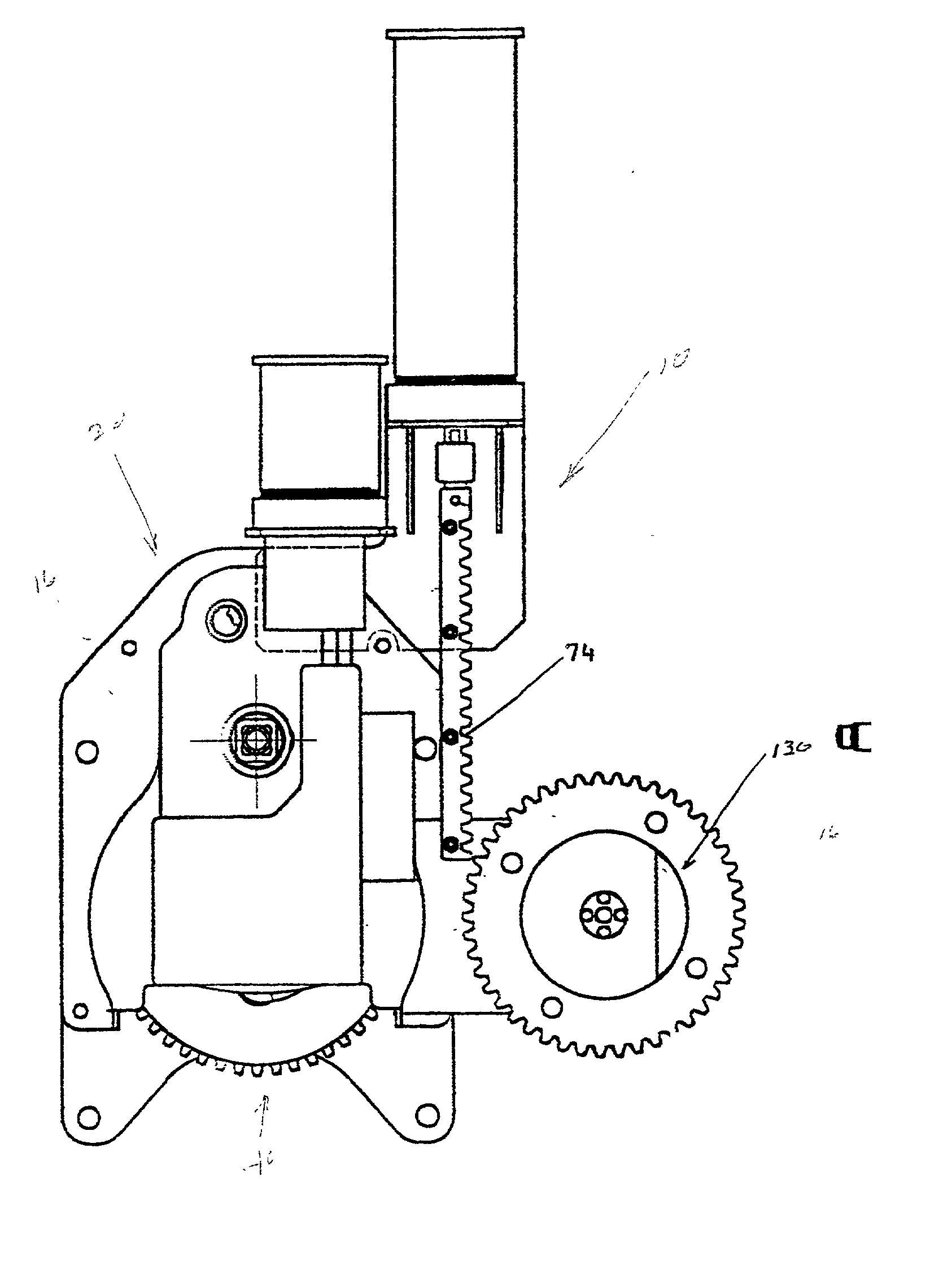

[0040] Refer now, more particularly, to FIGS. 1 through 6 of the drawings. Illustrated therein is an apparatus, generally designated 10, which is engageable with a hand brake assembly, generally designated 20, for automatically applying at least one brake means (not shown) secured to a railway vehicle (not shown) with such hand brake assembly 20.

[0041] Such apparatus 10 includes an operating means, generally designated 30. Operating means 30 has at least a portion thereof, i.e., gear 12, engageable with at least one gear 14 of a hand brake gear assembly, generally designated 40, disposed in a housing member 16 of such hand brake assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com