Substrate cleaning device

A technology for cleaning devices and substrates, used in grinding machines, metal processing equipment, grinding/polishing equipment, etc., which can solve the problems of rapid wear of cleaning blades, frequent replacement, and poor cleaning ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

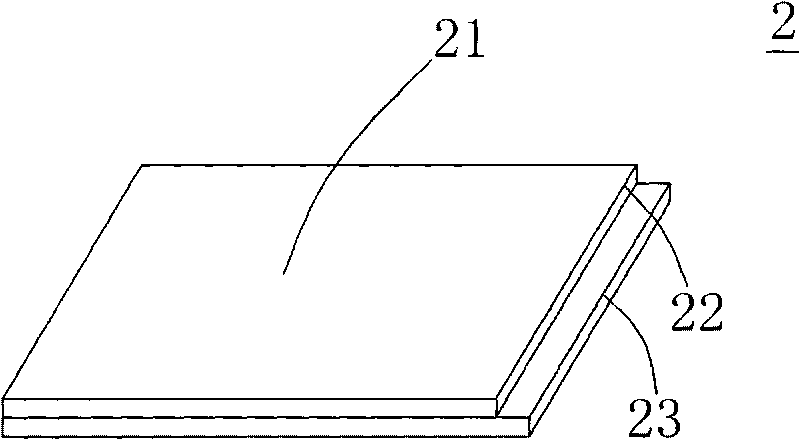

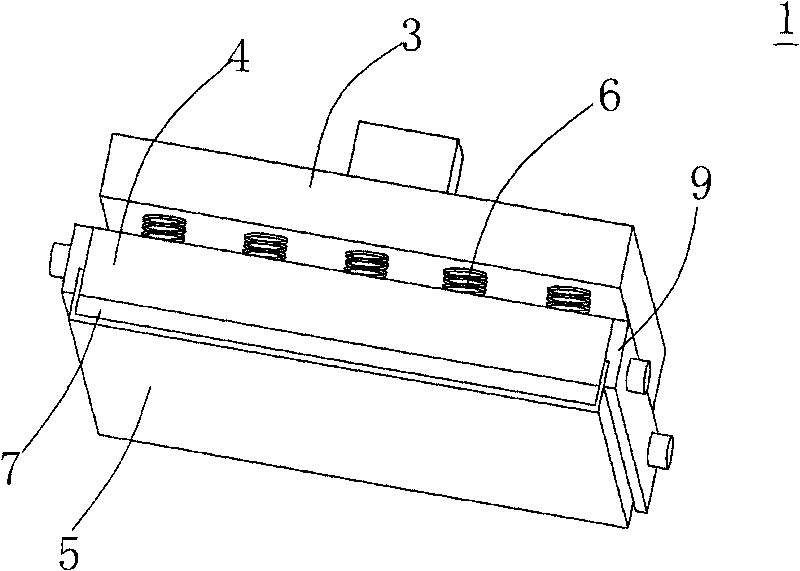

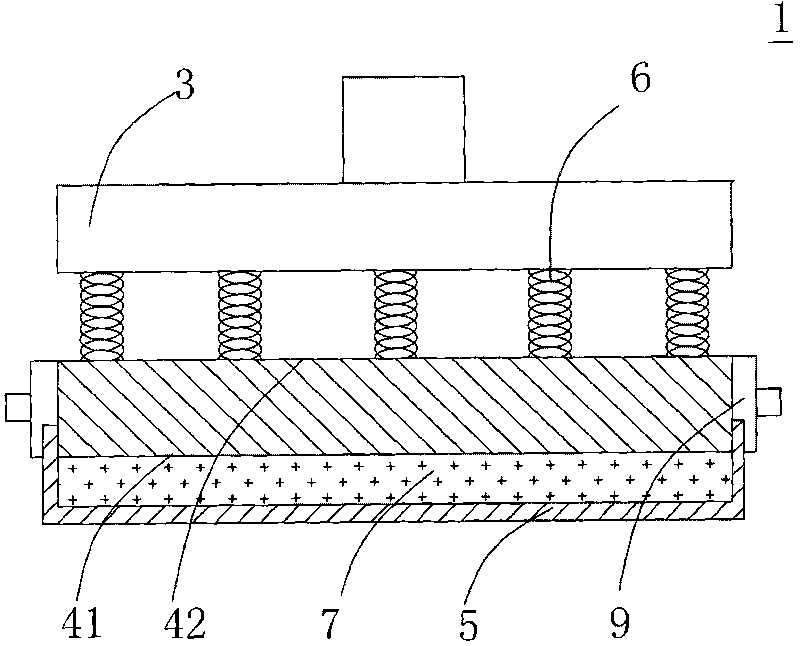

[0021] See figure 1 , figure 2 and image 3 , figure 1 Shown is a schematic diagram of a liquid crystal display panel, figure 2 Shown is a schematic perspective view of the cleaning device according to the present invention, image 3 shown as figure 2 Front view of the cleaning unit in . The substrate cleaning device 1 provided by the present invention is used to remove foreign matter on the surface 21 of a substrate 2, wherein the substrate 2 is, for example, glass or a display panel. In this embodiment, the substrate 2 is taken as an example of a liquid crystal display panel, the liquid crystal display panel 2 includes a color filter substrate 22 and a TFT array substrate 23 , and the surface 21 is located on the side of the color filter substrate 22 as an example. In the field of liquid crystal displays, in the manufacturing process of the liquid crystal display panel 2, before attaching the polarizer, the panel will be cleaned first. Glue or foreign matter will c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com