Manufacturing method of functional area tooth preparation guide plate and detachable drill limiter

A manufacturing method and technology of a limiter, which are applied to dental prostheses, dentistry, dentures, etc., can solve the problems of complicated design and manufacture, high application cost, unfavorable popularization, etc., so as to avoid excessive opening requirements and reduce soft tissues such as gums. and adjacent tooth damage probability, and the effect of improving clinical practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

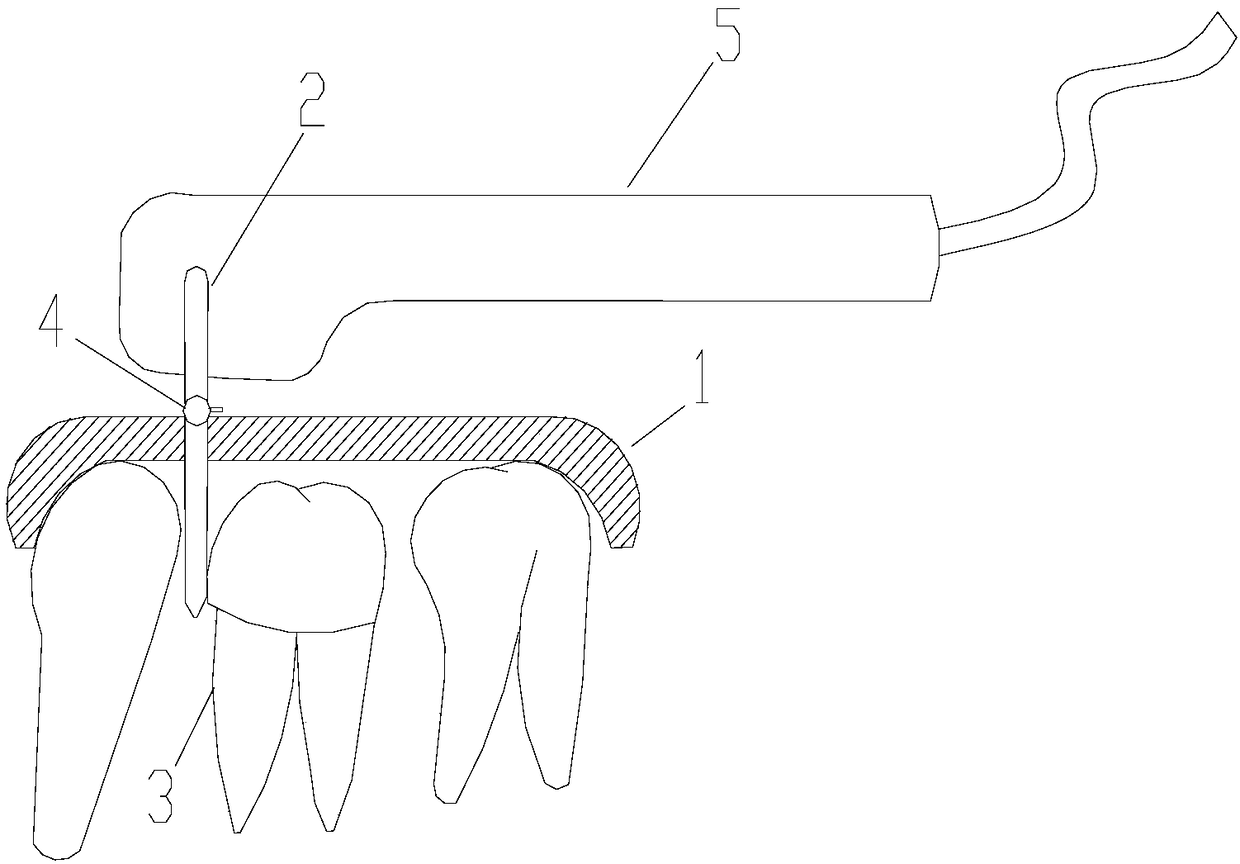

[0021] see figure 1 According to the present invention, a method for making a functional area tooth preparation guide plate and a detachable bur stopper of the present invention has the following steps:

[0022] (1) Scan the teeth and adjacent teeth that need to be prepared, and save the scanned data in STL format for future use;

[0023] (2) Design the three-dimensional shape of the tooth preparation with three-dimensional reverse engineering software;

[0024] (3) According to the shape of the tooth preparation described in step (2), it is designed that when the functional area is prepared, the guide plate is provided with a guide groove that can guide the movement path of the dental bur throughout the entire process, and the axis of the guide groove is in line with the The gingival margin line or the outer edge line of the tooth p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com