Systems and methods of electromagnetic influence on electroconducting continuum

A current and magnetic field technology, applied in the field of deep strengthening of metallurgical process, can solve the problems of hindering capacity, low melt stirring intensity, increasing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] introduction

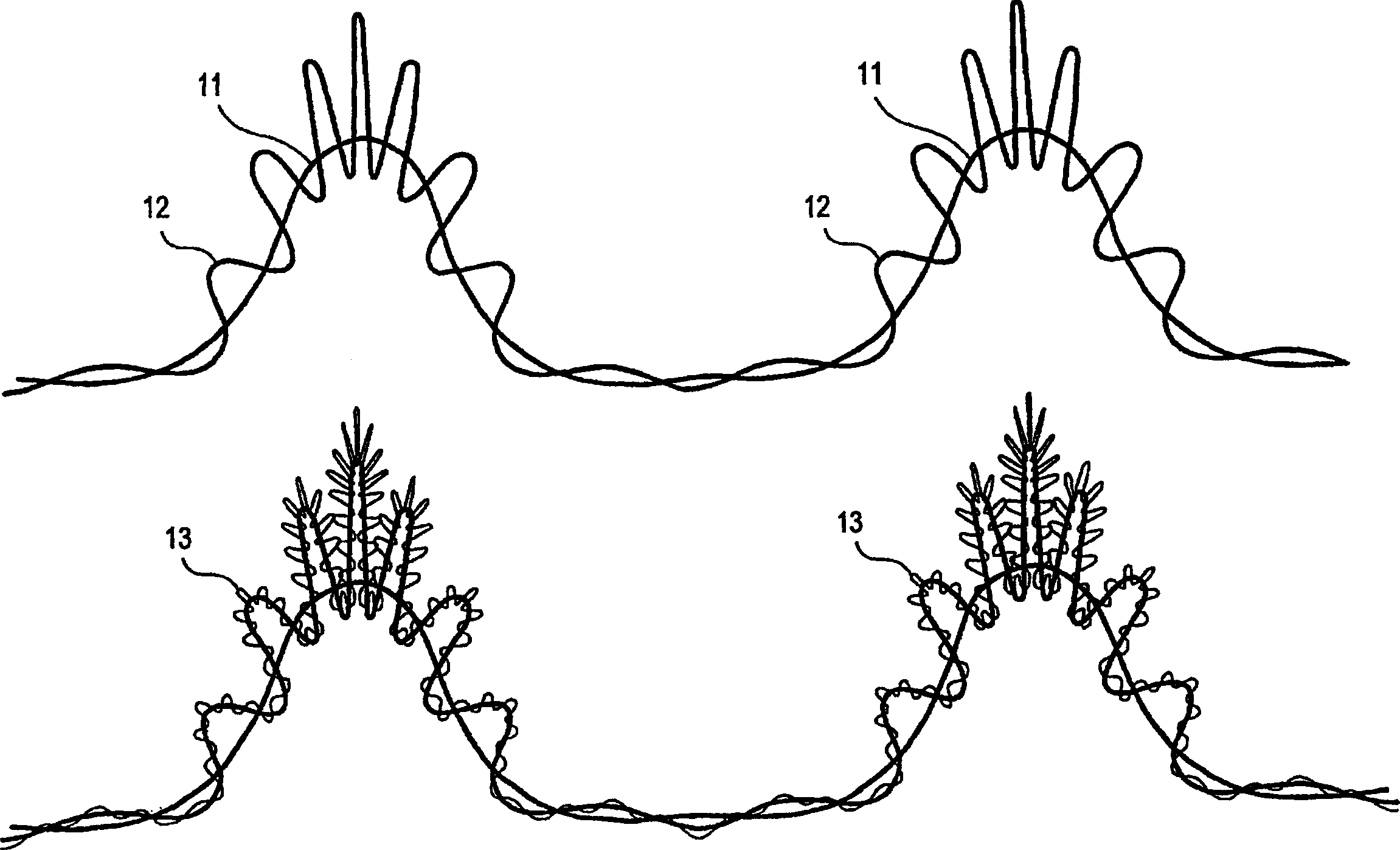

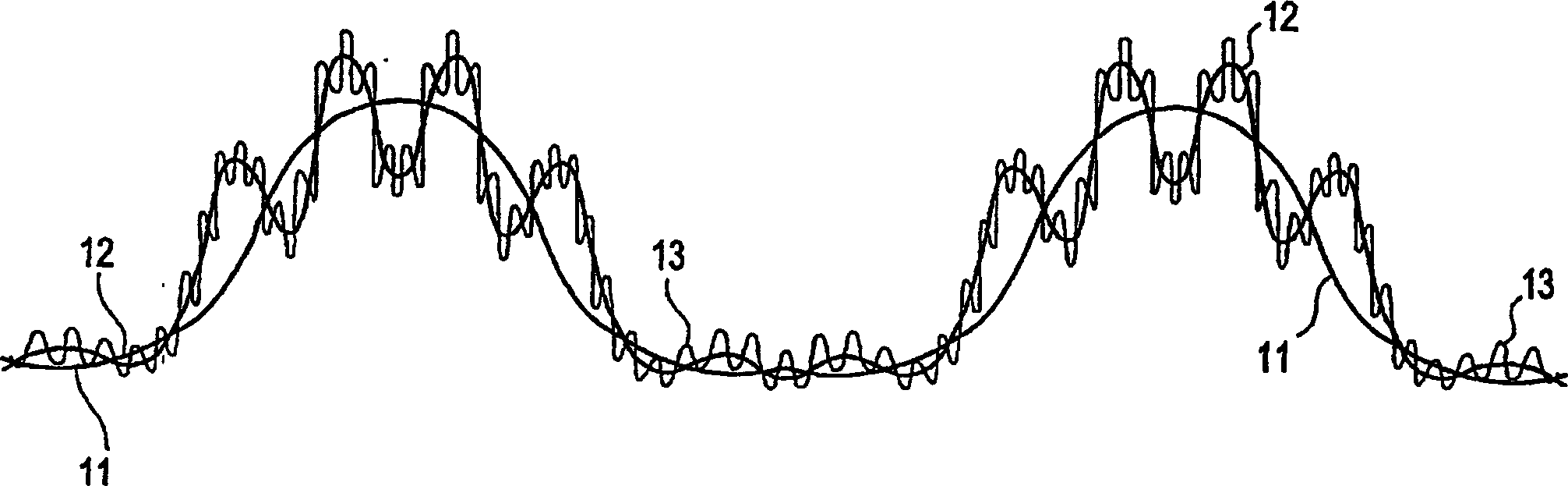

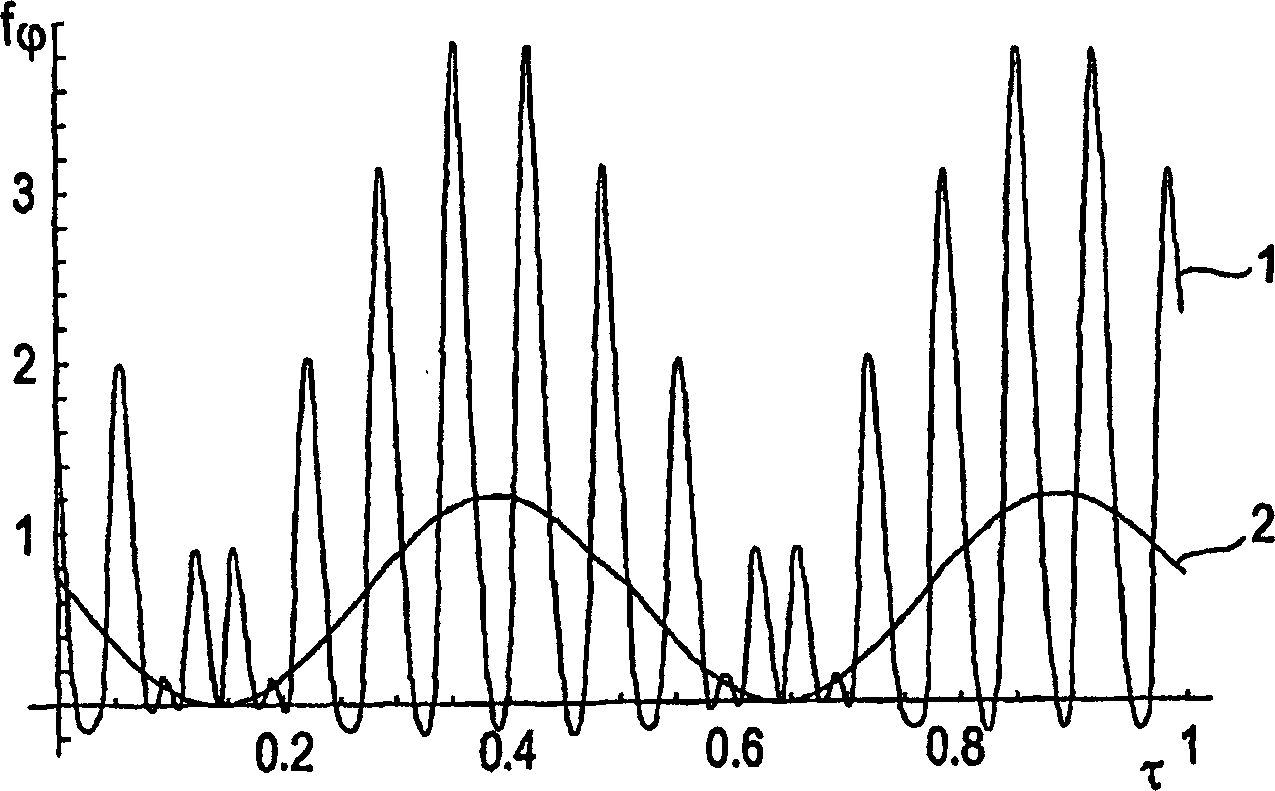

[0048] This article includes a method for speeding up technological processes and improving product quality in the metallurgical, foundry and chemical industries. The method is based on intensified agitation by applying moving magnetic fields that follow the superwave pattern based on superwave activity described in a new theory by Irving I. Darkik in the article "The Great Law of the Universe", which Article published in the March / April 1994 issue of "Cycles" magazine (V.44, No.5). See also Irving I. Dardik's article "The Law of Waves" in "Cycles" Magazine V.45, No.3, 1995 and his "Superwaves: The Law of Waves" at www.dardikinstitute.org, 2002 Reality that is Existence". Each of these articles is included as a reference in its entirety.

[0049] As pointed out in Dardik's article, it is generally accepted in science that everything in nature is made of atoms that move around in perpetual motion, attracting each other when the atoms are small in dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com