Method and device for realizing photoelectrochemical micro-etch processing of masked electrode

A photoelectrochemical and processing method technology is applied in the field of photoelectrochemical micro-etching processing methods and devices for mask electrodes, and can solve the problem that the substrate cannot be directly illuminated, the processing fineness is restricted, and the fabrication accuracy of the microprobe electrode affects the substrate. Processing and other problems, to achieve the effect of favorable exclusion, high degree of fineness, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

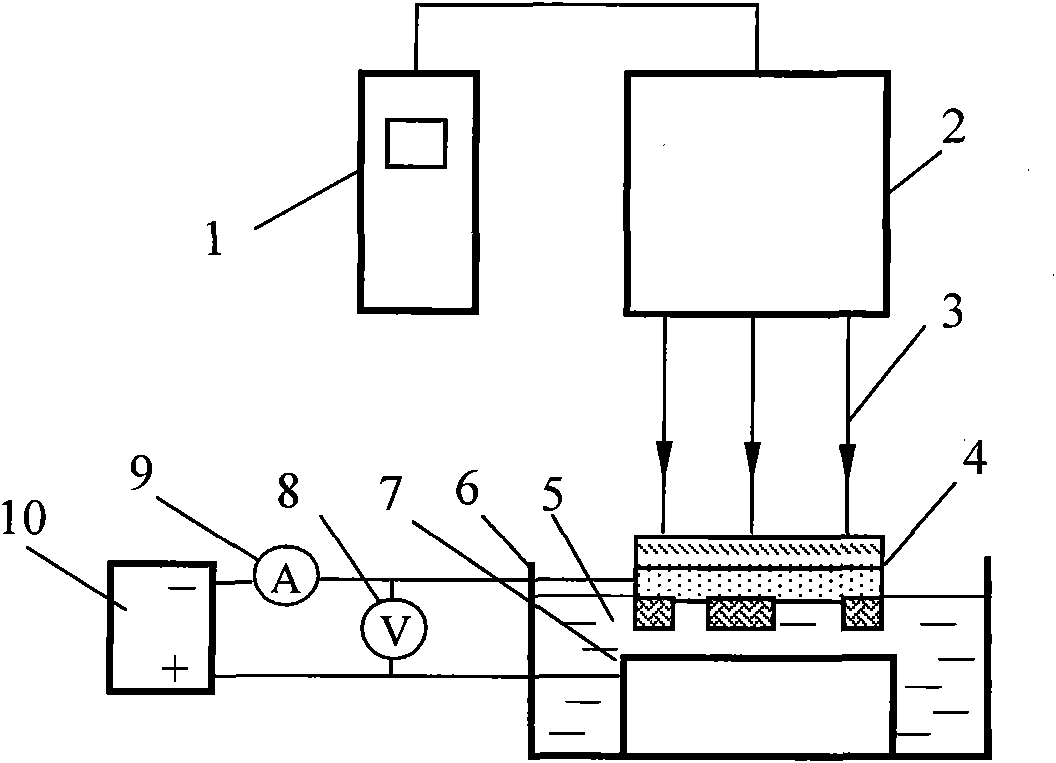

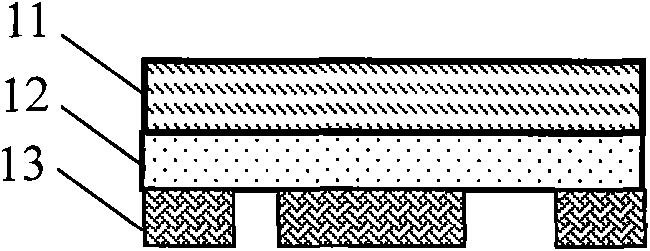

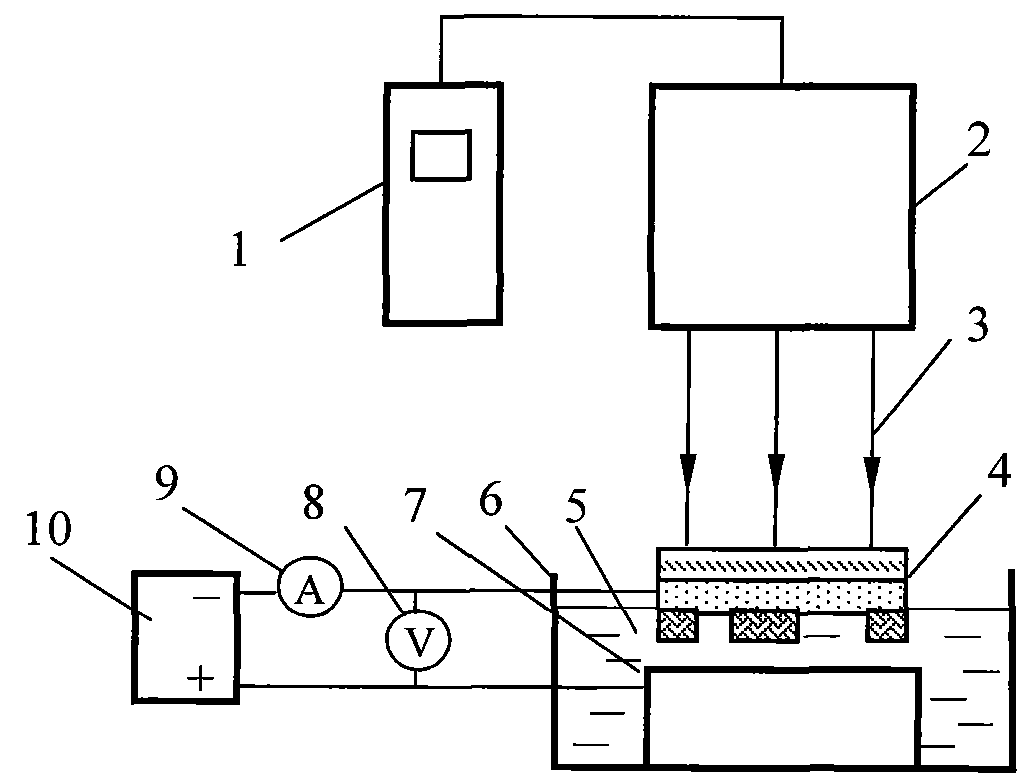

[0026] Embodiment 1: This embodiment is a photoelectrochemical micro-etching processing method of a mask electrode. The first step is to make a mask electrode with a micro-pattern structure. Choose glass with high laser transmittance as the substrate, or coat the upper surface of the glass with an optical antireflection film to make the laser transmittance greater than 95%. The transmittance of the conductive light-transmitting indium tin oxide layer to the laser is greater than 90%, and the resistivity is 1~5×10 -4 Ω / cm. The photoresist layer is mainly composed of photosensitive resin, sensitizer and solvent. The transmittance of the laser beam for processing is less than 15%, and the required fine structure is processed by the photolithography process to serve as a beam mask and The role of electric field masks.

[0027] The laser generates a laser beam 3 with a pulse time of 10 nanoseconds, the laser wavelength is 532 nanometers, the spot mode can be fundamental mode or mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com