Fill-automatic milk tea production device and method

A production device, fully automatic technology, applied in beverage preparation devices, packaging, instruments, etc., can solve the problems of long waiting time for customers, short supply of production, long delay time, etc., to reduce the number of employees, compact structure, and increase the stirring function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

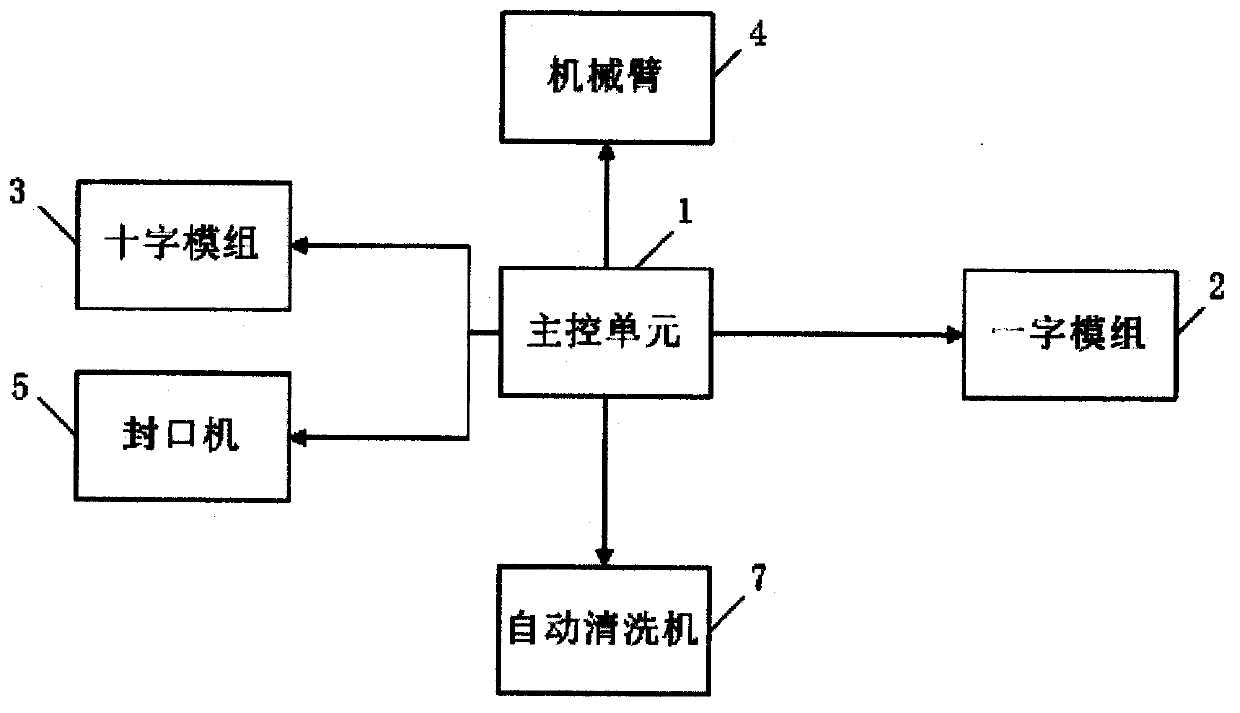

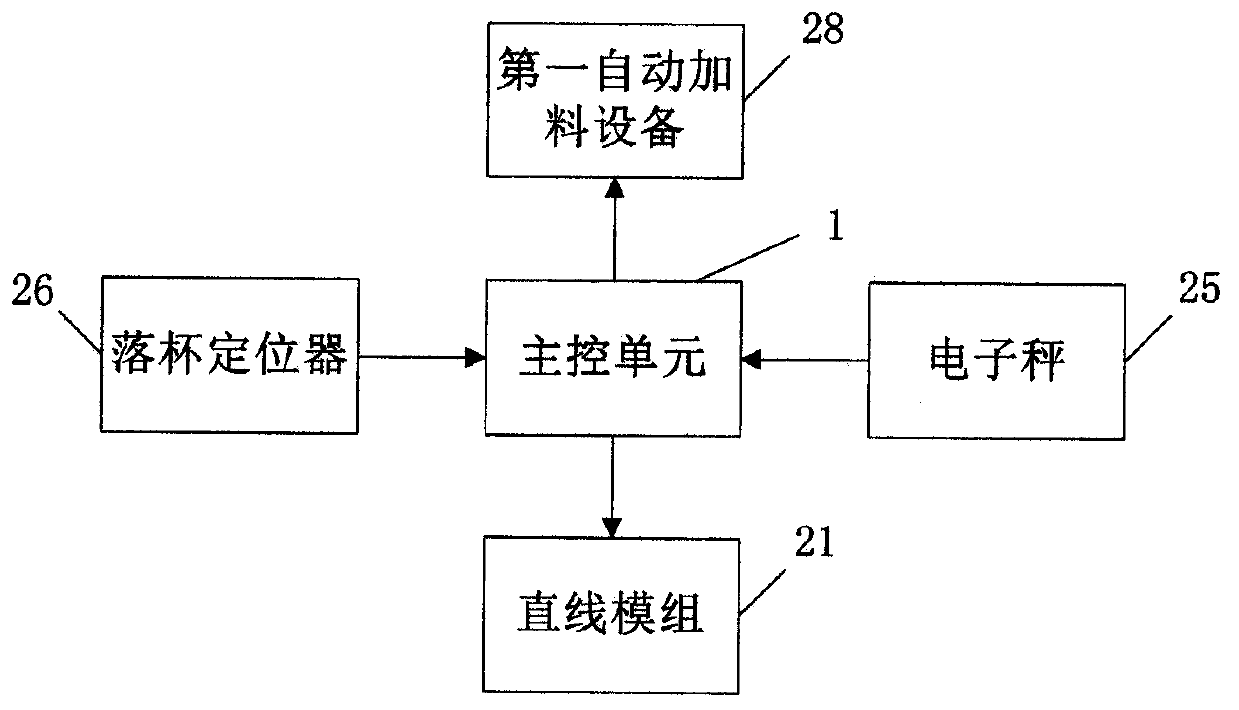

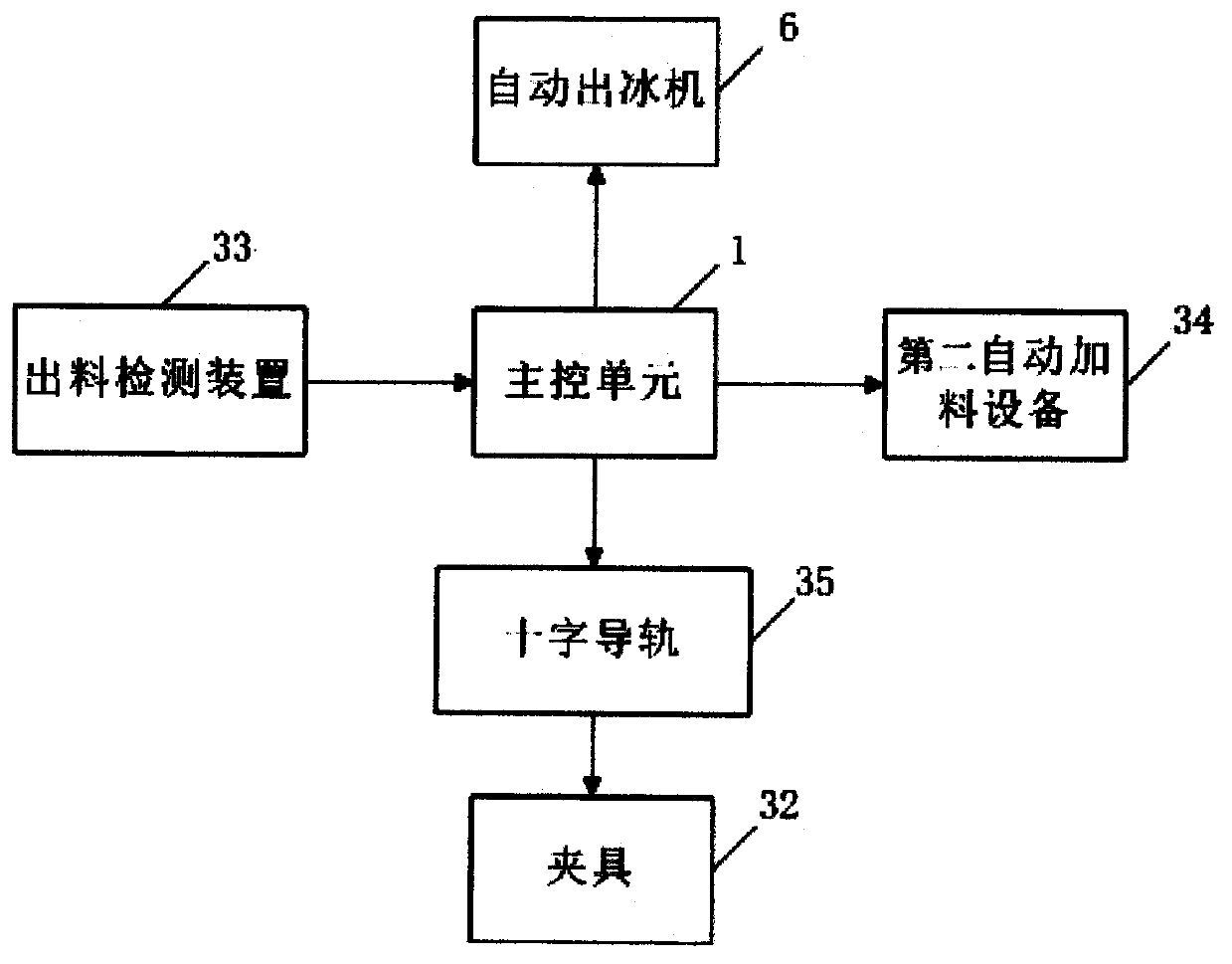

[0062] figure 1 It is a control block diagram of the automatic milk tea production device of the present invention. like figure 1 As shown, the present invention provides a fully automatic milk tea production device, comprising: a main control unit 1, a straight module 2, a cross module 3, a mechanical arm 4, a sealing machine 5, an automatic ice dispenser 6 and an automatic cleaning machine 7 , the main control unit 1 is a PLC controller. The main control unit 1 controls the one-character module 2 to obtain the finished cup and quantitatively add materials to the finished cup, and the main control unit 1 controls the cross module 3 to obtain the snow cup and quantitatively add materials to the finished cup. The cross module 3 moves the snow cup to the automatic ice dispenser 6, and the automatic ice dispenser 6 discharges ice into the snow cup according to the set amount of ice; the mechanical arm 4 adds the materials in the snow cup to the After the finished cup is filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com