Environment-friendly refuse treatment tank

A garbage disposal box, an environment-friendly technology, applied in trash cans, garbage collection, waste collection and transfer, etc., can solve the problems of long garbage disposal cycle, ventilation, deodorization defects, inability to guarantee composting effect, etc., and achieve fast fermentation time. , high reliability, shortened cycle operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

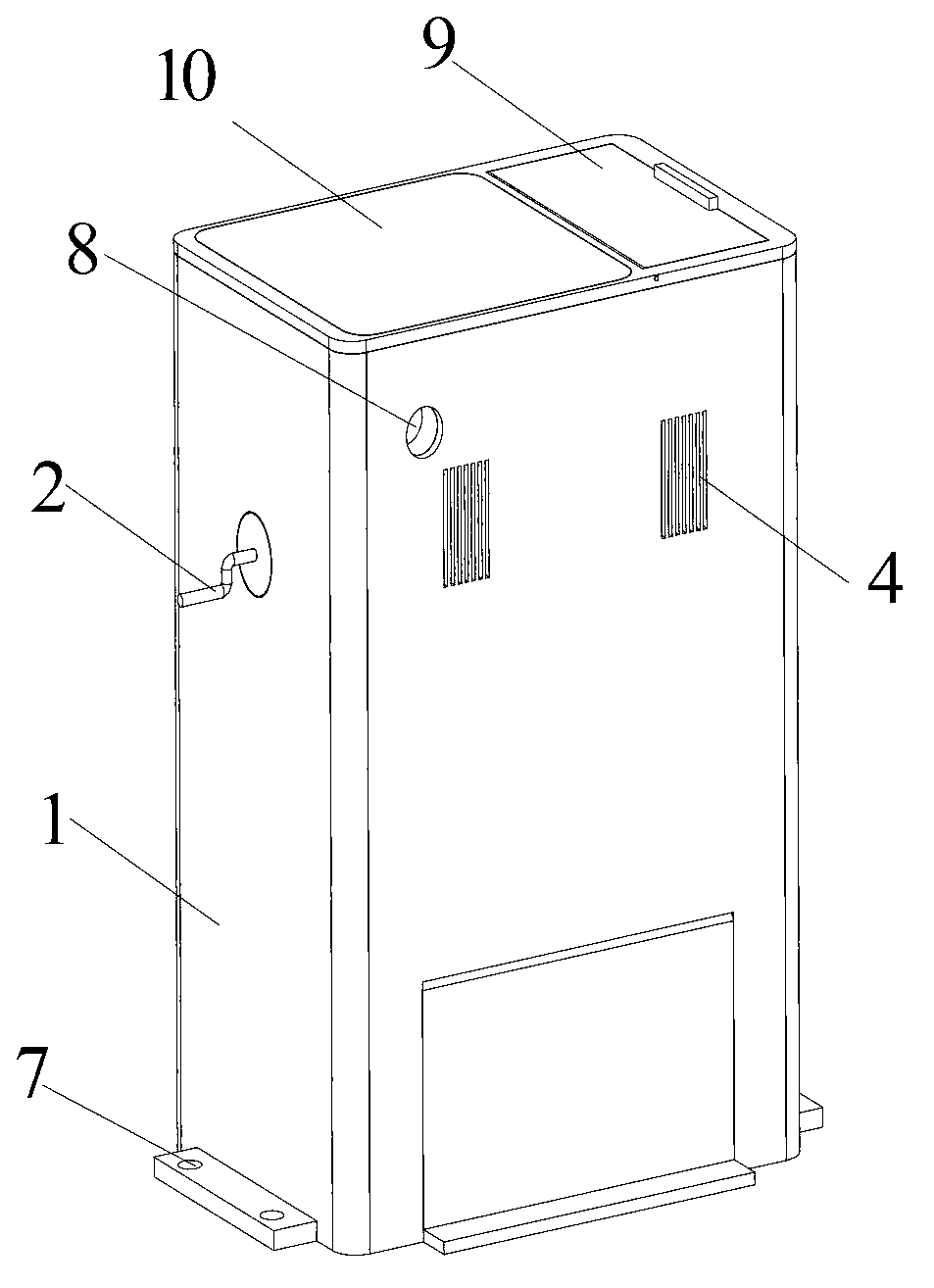

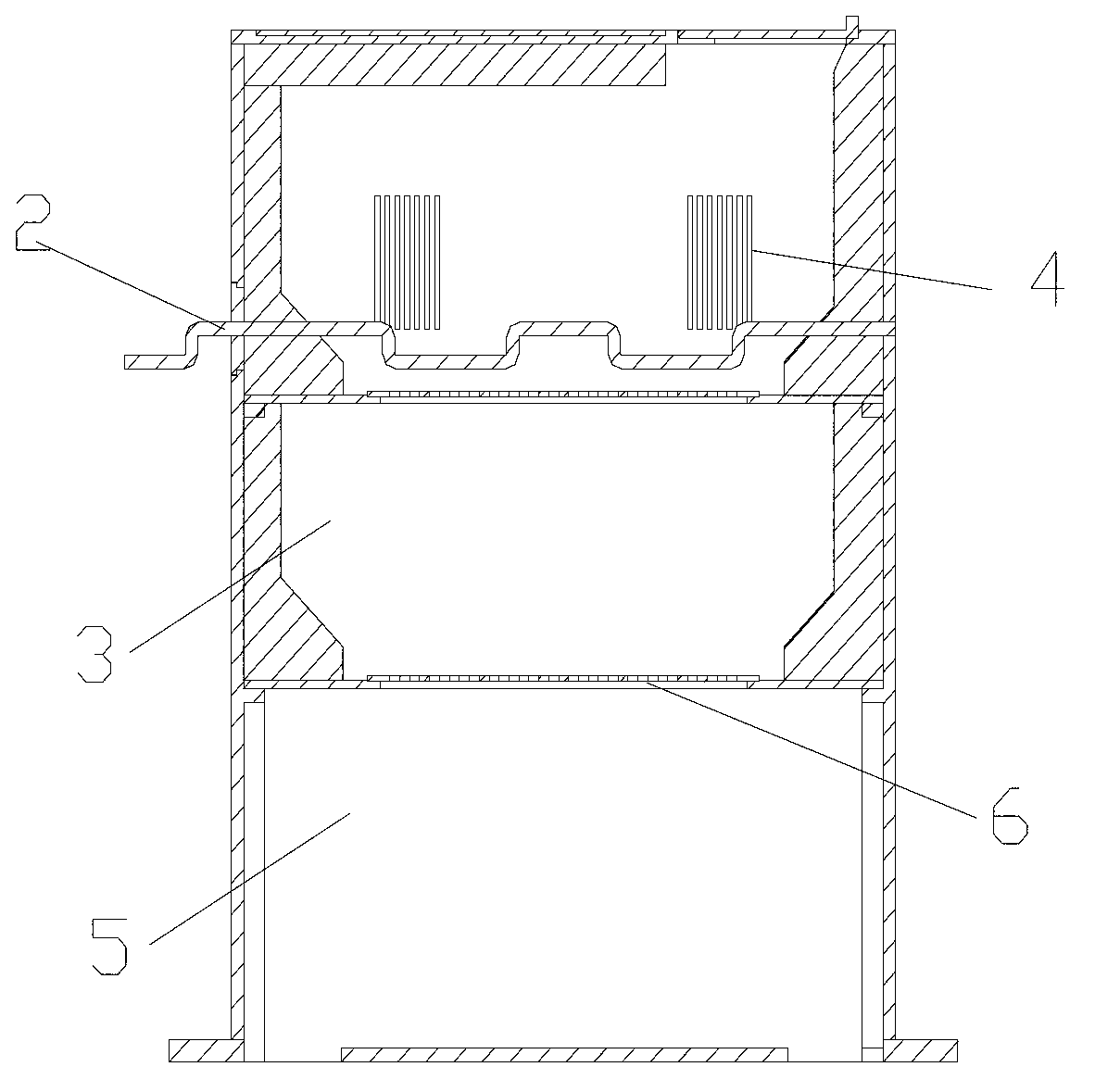

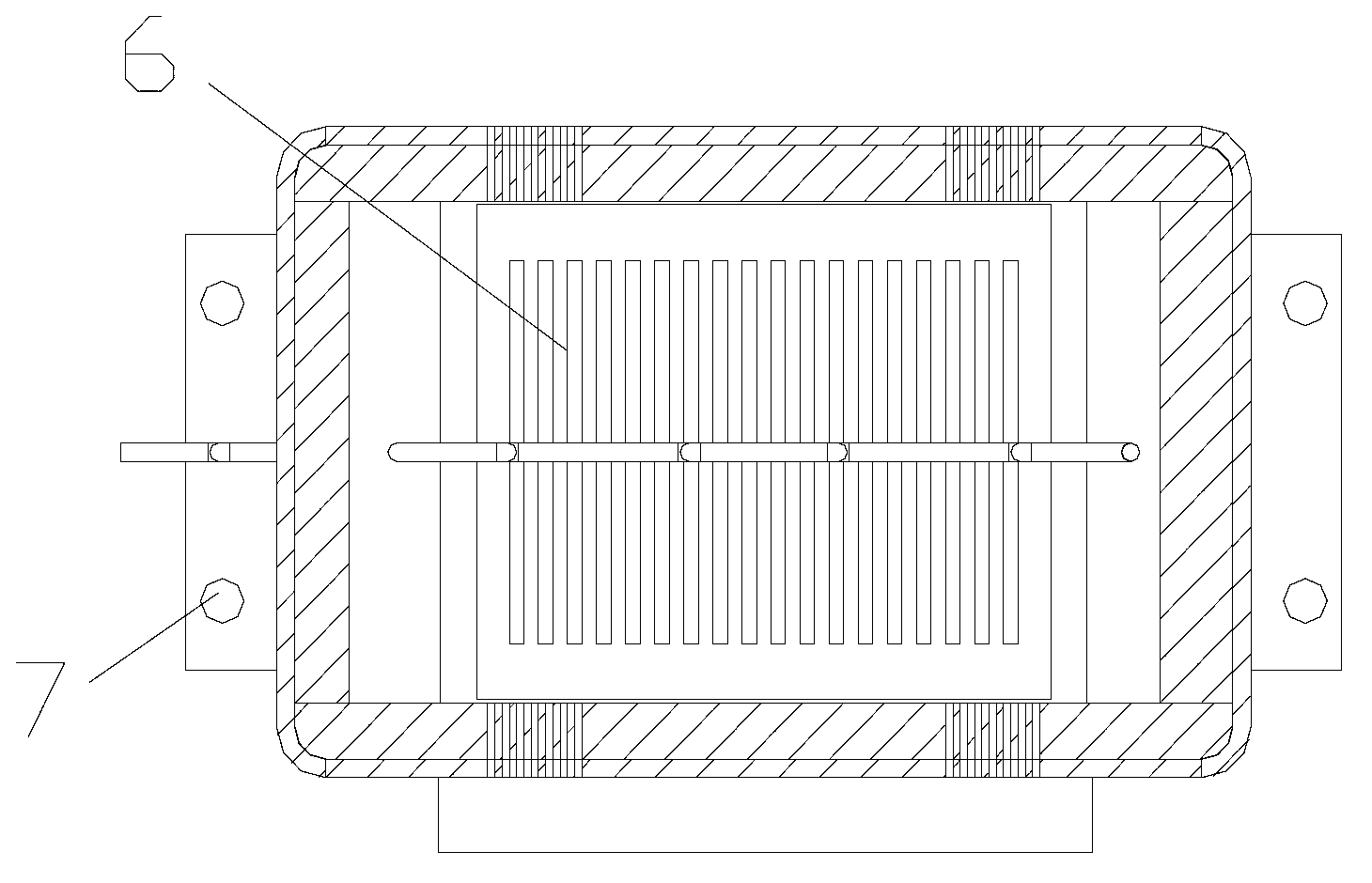

[0034] Such as Figure 1~3 As shown, an environment-friendly garbage disposal box includes a box shell 1, an agitator 2, a thermal insulation liner 3, and a fertilizer collection box 5. The thermal insulation liner 3 and the fertilizer collection box 5 are arranged on the box shell 1 up and down. Inside, a double-layer filter plate 6 is arranged at the bottom of the thermal insulation liner, the box shell 1 is made of engineering plastics, the thermal insulation liner 3 is made of foam material, the agitator 2 is a stirring rod with sawtooth, and its two ends Rotately connected with the box, the agitator 2 is arranged on the upper part of the thermal insulation liner 3, and the thermal insulation liner 3 and the side of the box shell 1 are provided with corresponding exhaust vents 4, and the inside of the exhaust vent 4 Adsorption activated carbon is set, the top of the box shell is provided with a fertilizer inlet, and the side wall of the fertilizer collection box is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com