Efficient gas-liquid reactor

A gas-liquid reaction, high-efficiency technology, applied in chemical methods, chemical/physical/physical-chemical stationary reactors, chemical instruments and methods for reacting liquids with gaseous media, etc. The problems of poor liquid mixing effect and incomplete reaction can improve the reaction effect, increase the reaction speed, and increase the chance of gas-liquid contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

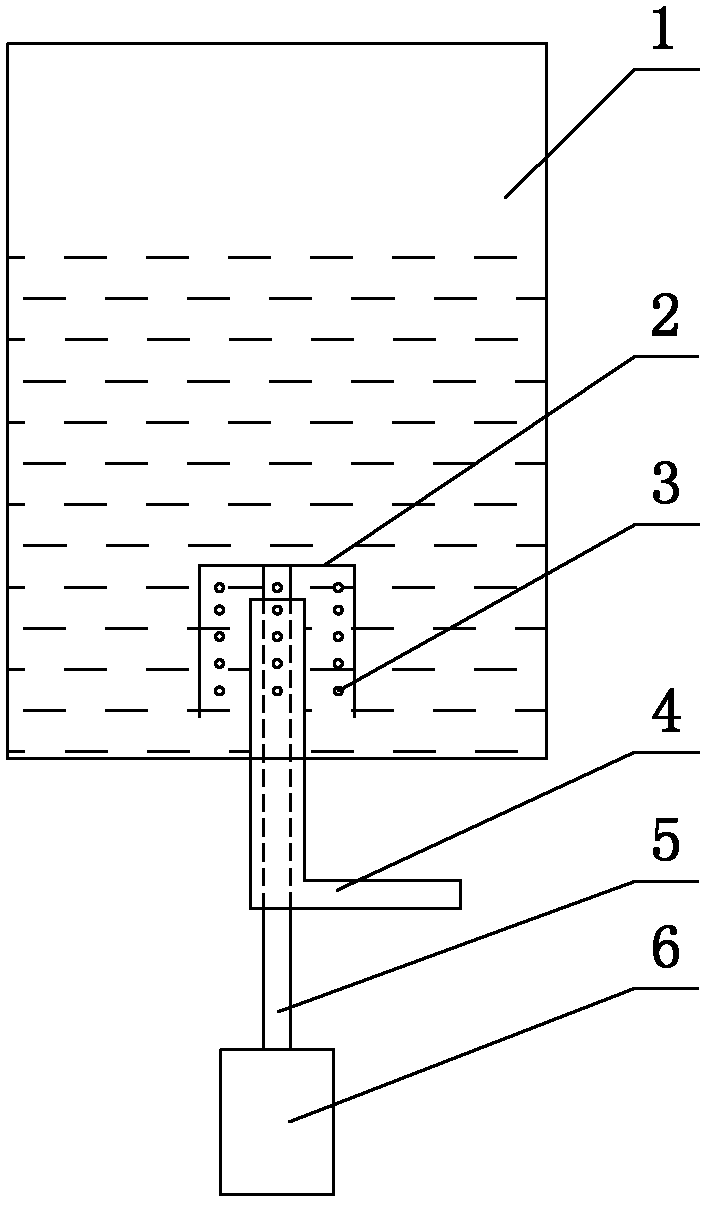

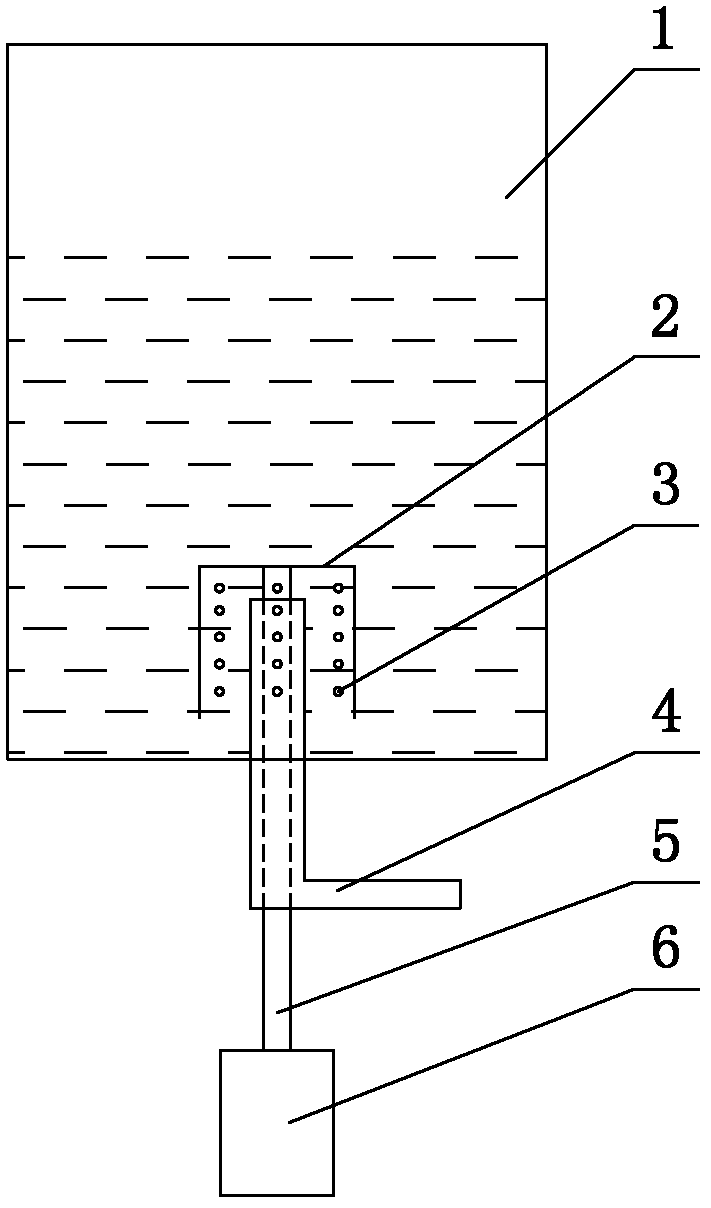

[0015] A high-efficiency gas-liquid reaction kettle includes a kettle body 1 and an air inlet pipe 4. Its innovation is that a stirring motor 6 is vertically arranged below the kettle body, and the stirring motor is a DC motor. The motor shaft 5 of this stirring motor stretches into the kettle body, and a cover-shaped rotating disk 2 positioned at the kettle body is installed on the upper end of the motor shaft. A group of air holes 3 are made on the side wall of the cover body of the cover-shaped turntable, the number of the air holes is not limited, and the diameter can be adjusted as required. The air intake pipe is coaxially set on the motor shaft. The air outlet of the air intake pipe is located in the cover-shaped turntable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com