Self-cleaning waste water pipe rack

A self-cleaning, waste water technology, applied in the direction of pipe components, pipe heating/cooling, pipes/pipe joints/pipe fittings, etc., can solve the problems of weak dispersion and homogenization treatment capacity, blocked drainage channels, etc., and achieve good dispersion and homogenization effect , Improve work efficiency, expand the effect of strength and scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

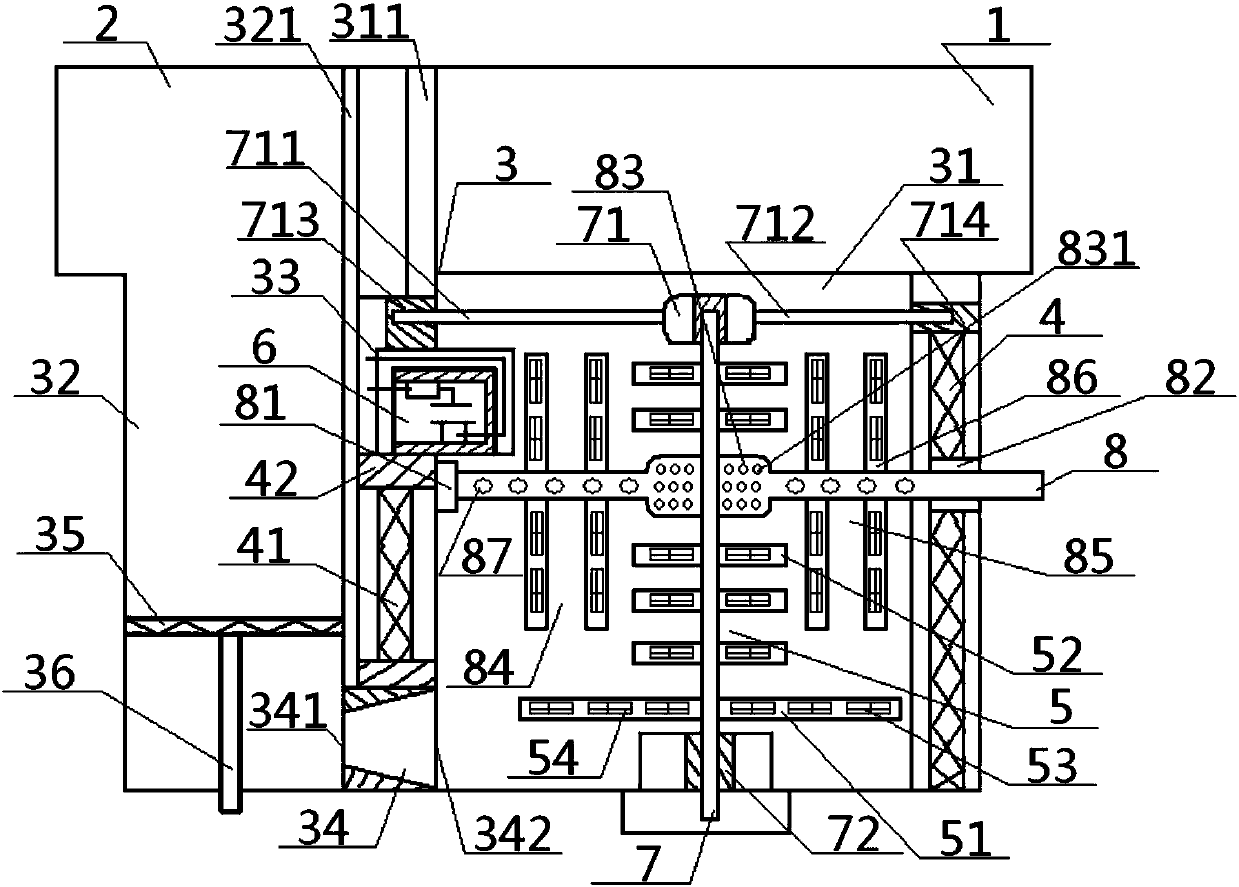

[0028] see Figure 1 to Figure 3 , a self-cleaning waste water pipe gallery, comprising a water inlet pipe 1, an outlet pipe 2 and a water treatment unit 3, the water inlet pipe 1 communicates with the water outlet pipe 2 through the water treatment unit 3, and is set in the water treatment unit 3 There is a stirring unit 5;

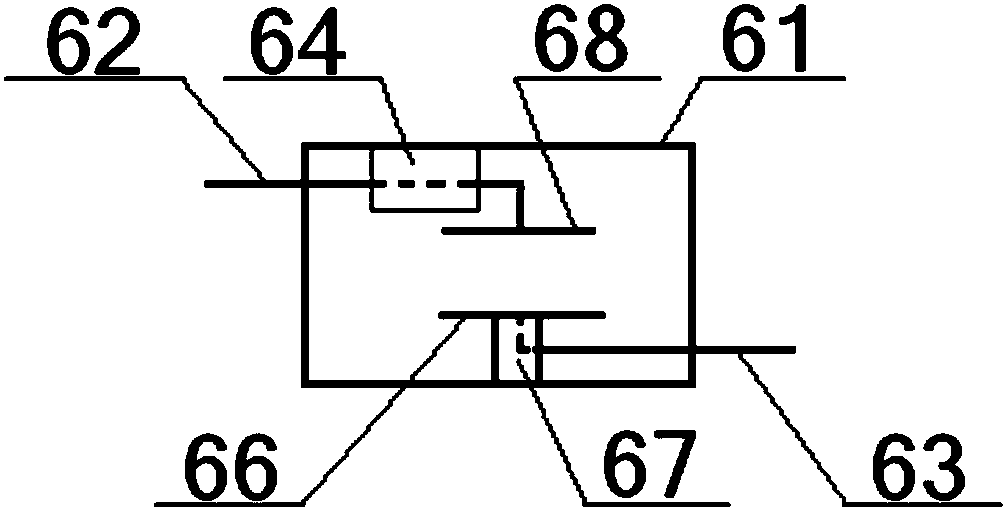

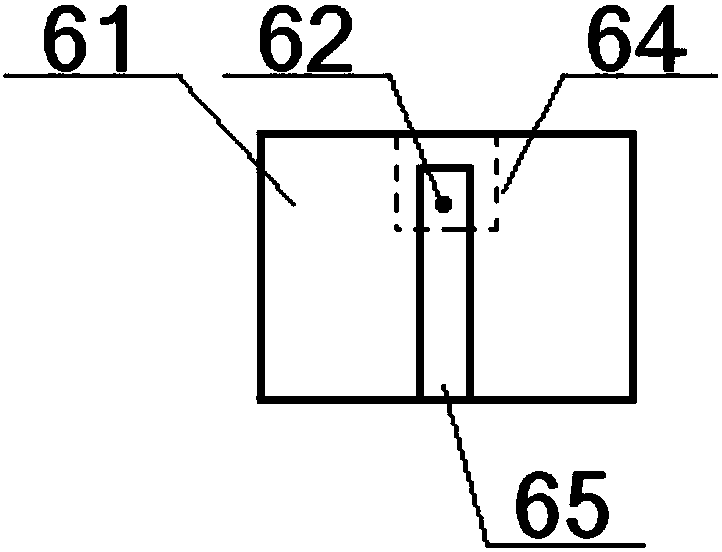

[0029]The water treatment unit 3 includes a stirring room 31, a communication room 32, a stirring unit 5 and a stirring main shaft 7. The inside of the stirring room 31 is provided with a stirring unit 5, and the middle part of the stirring unit 5 passes through and has a stirring main shaft 7. The top end and the bottom end of the main shaft 7 are respectively connected with the middle part of the top bearing 71 and the bottom bearing 72, and the side wall of the top bearing 71 is connected with the left suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com