Method for preventing self-fluxed pellets from bonding in roasting

A technology of self-melting and pelletizing, which is applied in the field of ironmaking raw material production, can solve the problem of high alkalinity pellet cohesiveness and other problems, so as to achieve not easy bonding, increase the proportion of furnace, and optimize the furnace charge structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Describe below in conjunction with specific embodiment:

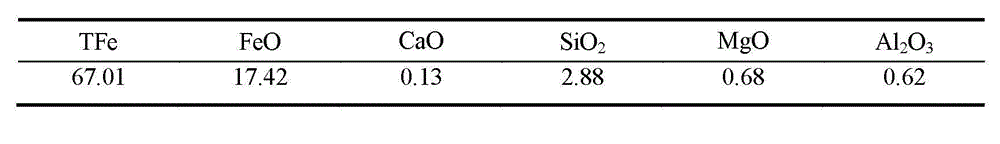

[0022] The mixed ore was used to carry out the self-melting pelletizing test, and the composition of the mixed ore is shown in Table 1.

[0023] Table 1 Mass percentage of mixed ore components

[0024]

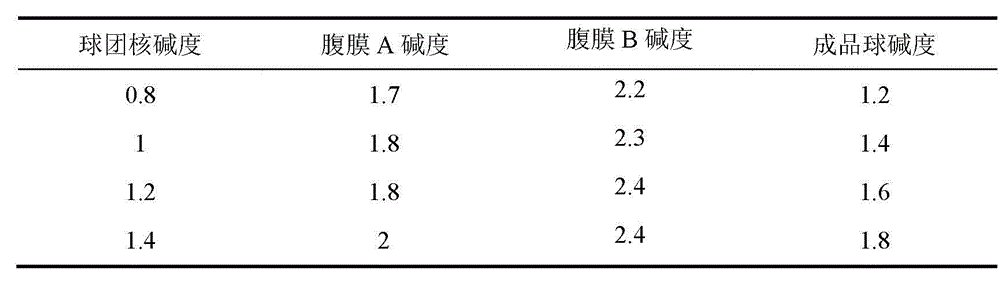

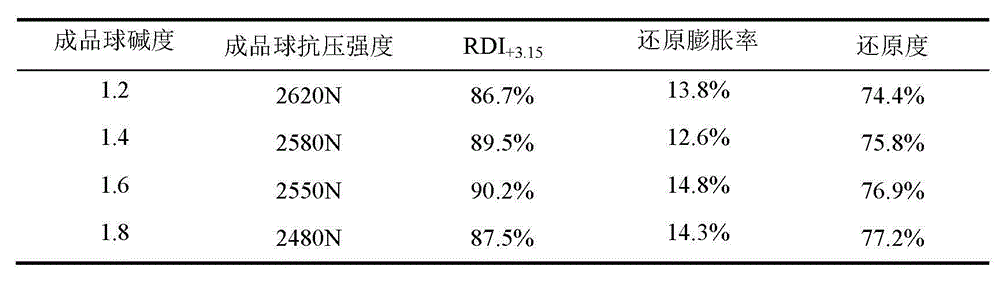

[0025] Fix the iron material, add flux and binder to make a mixture, the flux in the mixture is magnesite and lime powder, and the mass fraction of magnesite is 2%; the binder is bentonite; adjust the lime powder content so that The alkalinity of the mixture is 0.8, mix the mixture evenly, and pile it up for 30~40 hours. Then use a pelletizing machine to make the mixture into a self-fluxing pellet core with a particle size of 8-10mm.

[0026] Mix dolomite powder and iron boron fine powder evenly to make anti-adhesion peritoneum A, wherein the alkalinity of anti-adhesion peritoneum A is adjusted to 1.7 according to the alkalinity of the self-fluxing pellet core; lime powder, iron phosphorus and carboxymethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com