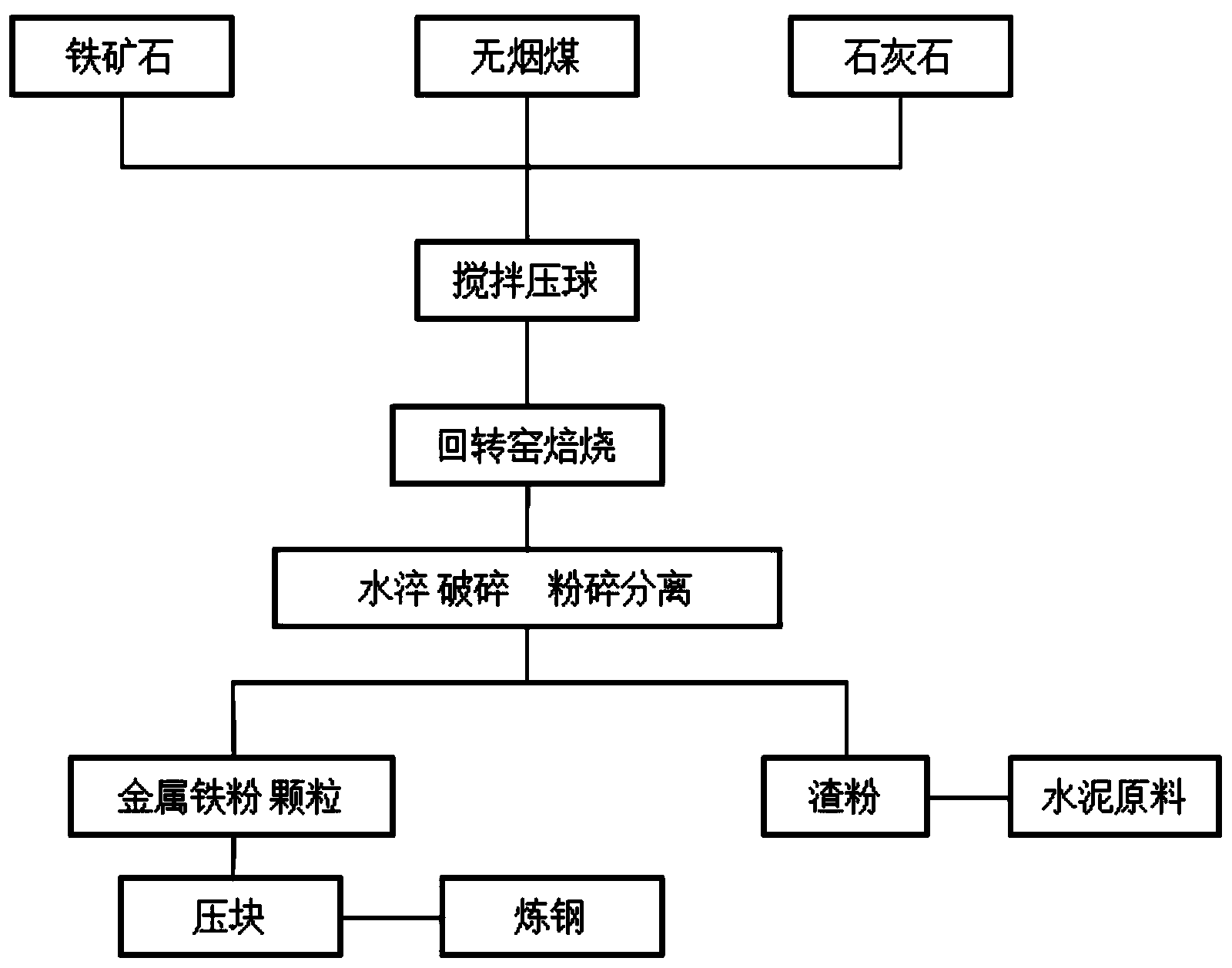

Method for producing metal iron powder by using deep reduction of rotary kiln

A rotary kiln and metal iron technology, applied in the direction of rotary drum furnace, furnace, furnace type, etc., can solve the problems of high price and high energy consumption, achieve good metallurgical performance, uniform particle size, and reduce dependence on coking coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The raw iron ore is, for example, oolitic limonite (grade 35%), which belongs to refractory iron ore. The raw ore is crushed to -20mm by a crusher, and then powdered to -5mm by a sander. Add 5% limestone powder (-100 mesh) of raw iron ore mass to iron ore powder as desulfurizer, add 15% raw ore mass of anthracite powder (C≥55%) as reducing agent, and mix the three materials and press balls. The pellets are dried after pressing. The dried pellets are sent to the rotary kiln for preheating. The preheating temperature is controlled at 400°C for about 1.5 hours. After preheating, it enters the reduction section for reduction. The temperature is controlled at 900°C and the reduction time is about 3 hours. The reduction section requires the iron reduction rate to reach over 92%. Then enter the deep reduction time for about 1.5 hours. Deep reduction temperature is 1300°C. After deep reduction, iron metal grains are formed (iron metal grain size 0.1-15mm). After deep reducti...

Embodiment 2

[0060] The raw iron ore is, for example, oolitic limonite (grade 40%), which belongs to refractory iron ore. The raw ore is crushed to -20mm by a crusher, and then powdered to -5mm by a sander. Add 5% limestone powder (-100 mesh) of raw iron ore mass to iron ore powder as desulfurizer, add 15% raw ore mass of anthracite powder (C≥55%) as reducing agent, and mix the three materials and press balls. The pellets are dried after pressing. The dried pellets are sent to the rotary kiln for preheating, the preheating temperature is controlled at 450°C, and the time is about 1 hour; after preheating, it enters the reduction section for reduction, the temperature is controlled at 1100°C, and the reduction time is about 3 hours. The reduction section requires the iron reduction rate to reach over 92%. Then enter the deep reduction time for about 1.5 hours. Deep reduction temperature is 1250°C. After deep reduction, iron metal grains are formed (iron metal grain size 0.1-15mm). After ...

Embodiment 3

[0062] Add 6% limestone desulfurizer of raw ore quality to raw iron ore such as oolitic limonite (grade 45%) and mix, grind to below 5mm, add coal powder with 15% of raw ore weight, and directly send it into the primary rotary kiln for pretreatment Thermal reduction, the preheating temperature is controlled at 400°C, and the time is, for example, 1h; the reduction temperature is, for example, 1000°C, and the smelting time is 3h. The hot air flow generated by the combustion of raw materials and coal moves countercurrently, and the raw materials generate Fe 2 o 3 , Fe and other metals. After further deep reduction, the temperature is controlled at 1250°C, and the melting time is 2 hours. All the reduction and smelting is completed, and the black pig iron is quenched by the cooling water of the second rotary kiln. The temperature in the kiln is controlled at 150-220°C. The iron separated by crushing and magnetic separation is sand-like particles with a diameter of 1 mm. The iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com