Patents

Literature

42results about How to "Realize automatic batching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

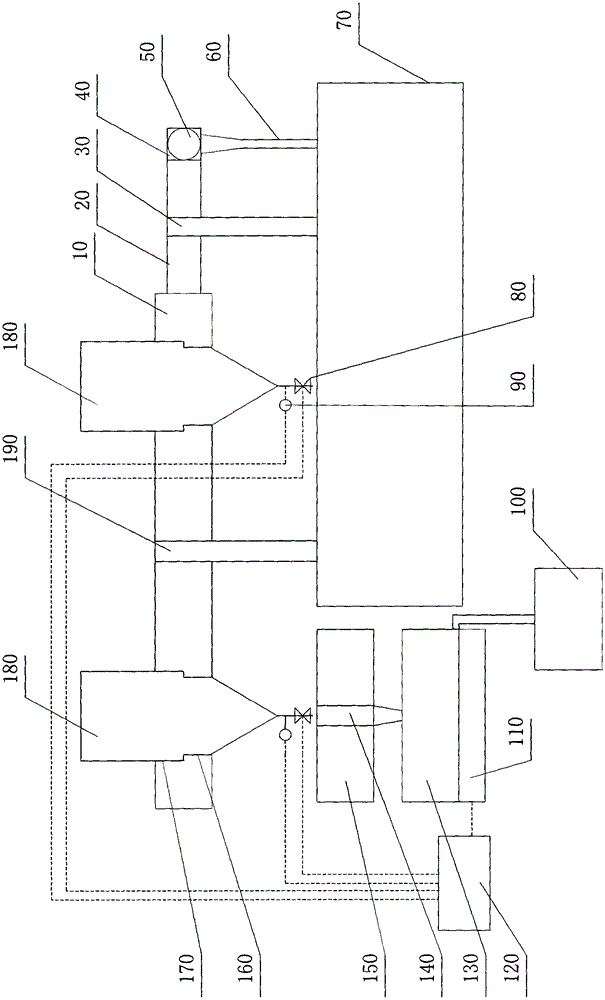

Premixing equipment for polyurethane polyol multi-component formula

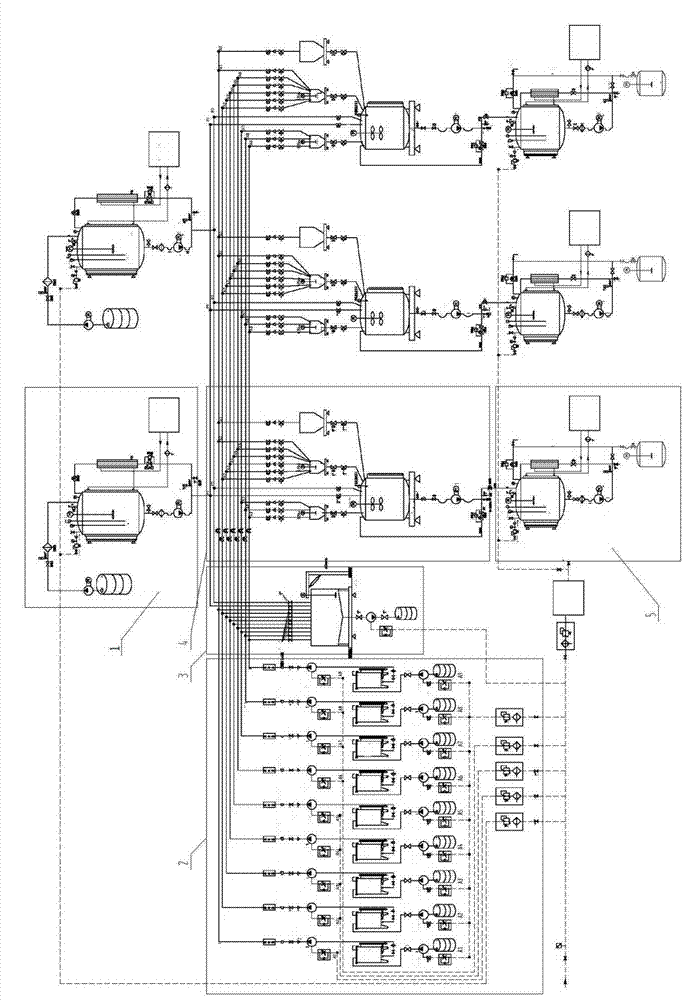

The invention provides premixing equipment for a polyurethane polyol multi-component formula. The premixing equipment comprises a polyether raw material storing system, a plurality of auxiliary material storing and conveying systems, a manual test mixing device, a mixing metering system and a mixed raw material storing and conveying system. A first conveying pump of the polyether raw material storing system is respectively connected with a manual test mixing tank of the manual test mixing device and a mixing metering tank of the mixing metering system; auxiliary material conveying pumps of the auxiliary material storing and conveying systems are respectively connected with the manual test mixing tank of the manual test mixing device; an auxiliary material A metering tank, an auxiliary material B metering tank and an auxiliary material C metering tank of the mixing metering system are respectively connected with the corresponding auxiliary material conveying pump of the auxiliary material storing and conveying systems, and the pipelines of the auxiliary material A metering tank, the auxiliary material B metering tank and the auxiliary material C metering tank are respectively provided with a flow proportional valve; and a mixing tank conveying pump of the mixing metering system is connected with a material storage tank of the mixed raw material storing and conveying system through a pipeline. According to the premixing equipment provided by the invention, automatic burdening can be performed according to the formula, therefore, the manpower is saved, and the polyurethane production cost is reduced.

Owner:HUNAN JINGZHENG EQUIP MFG

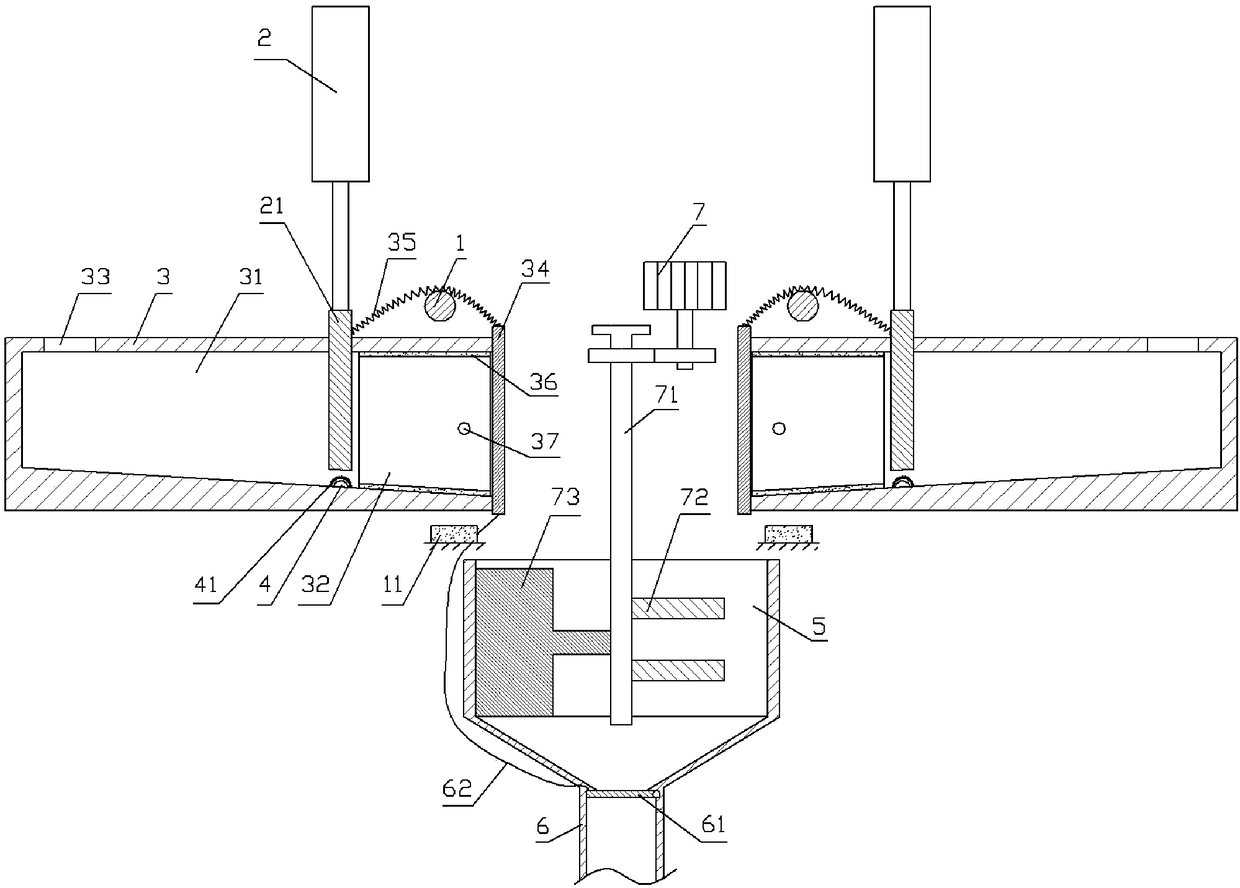

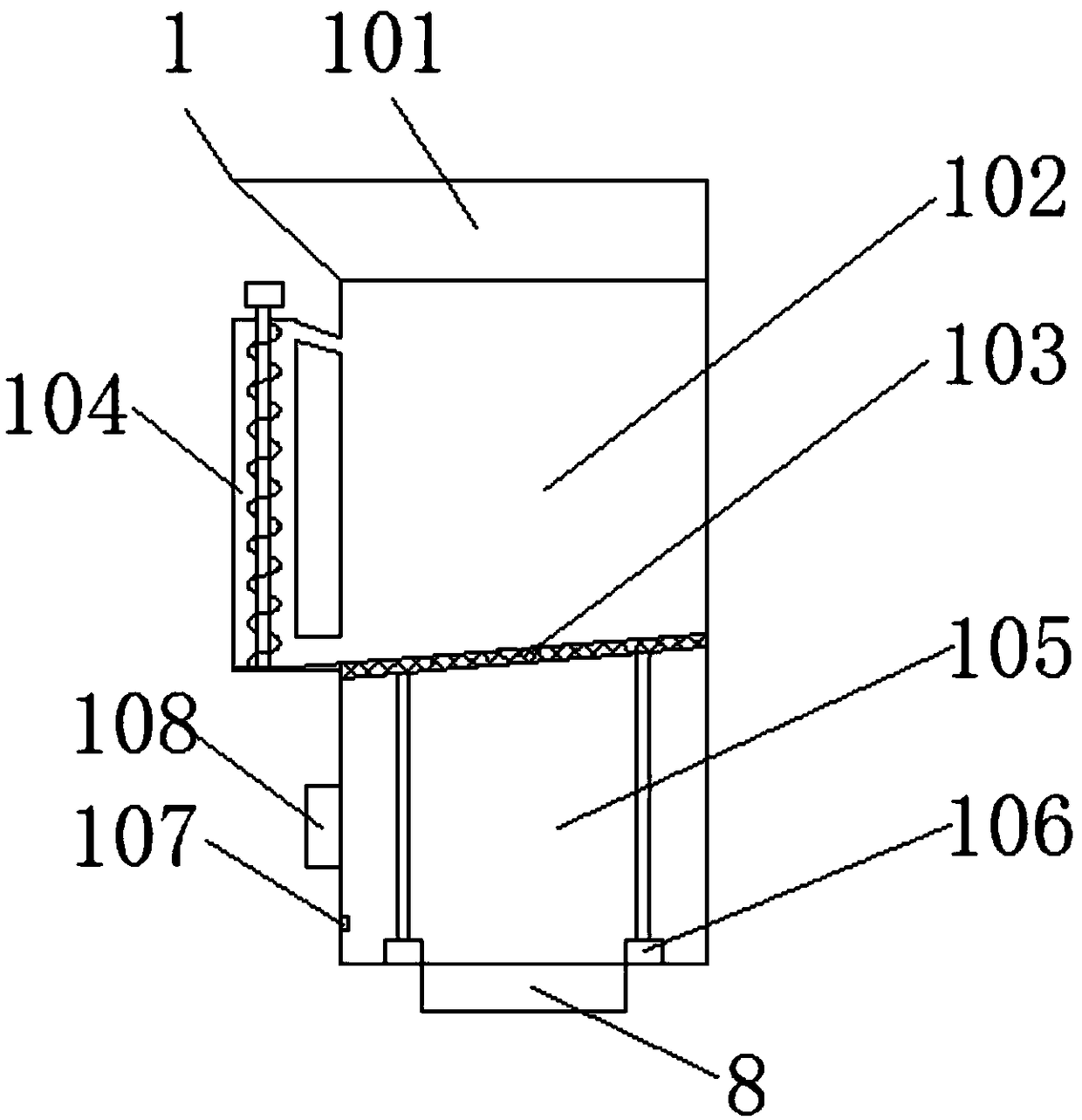

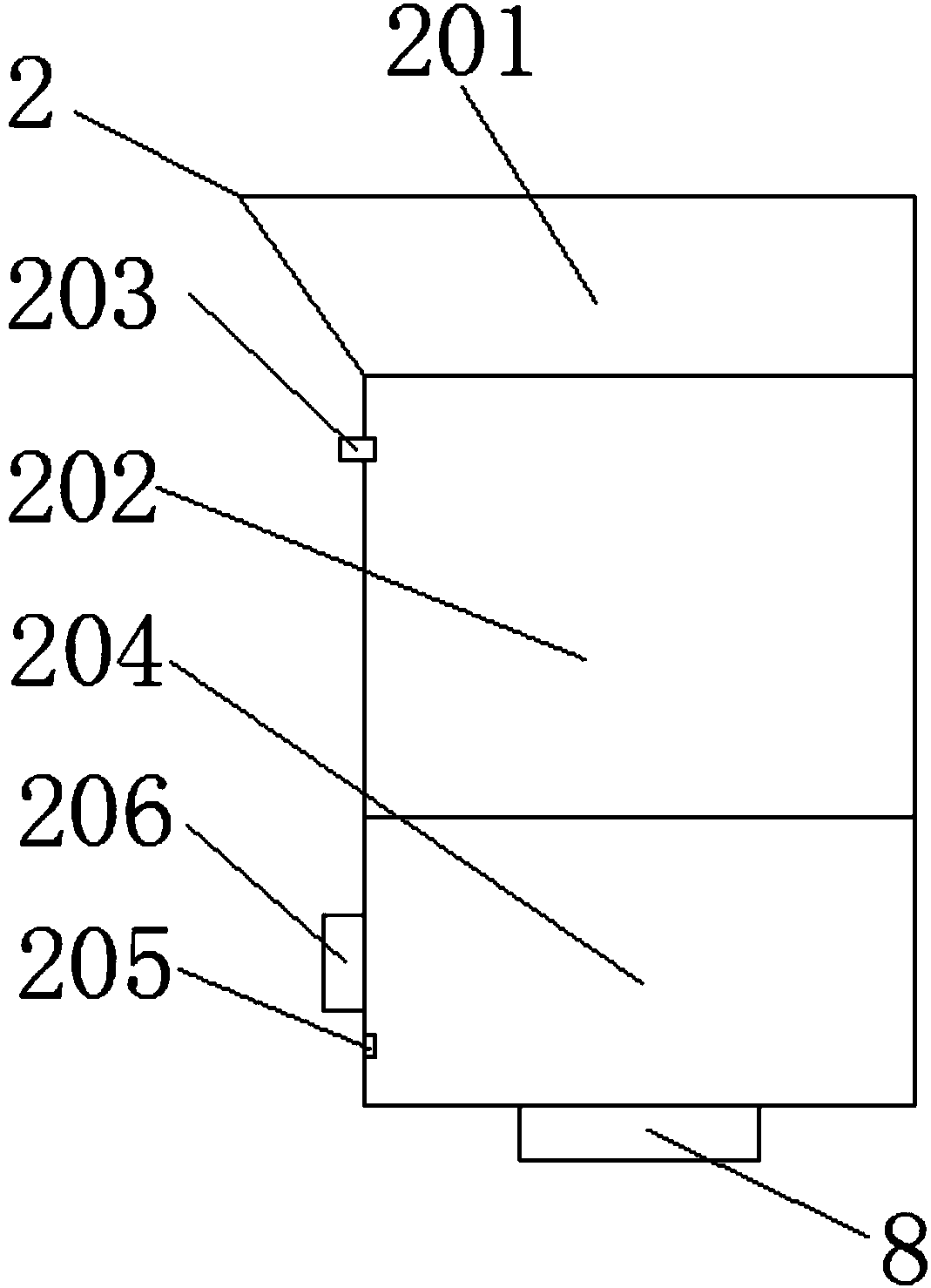

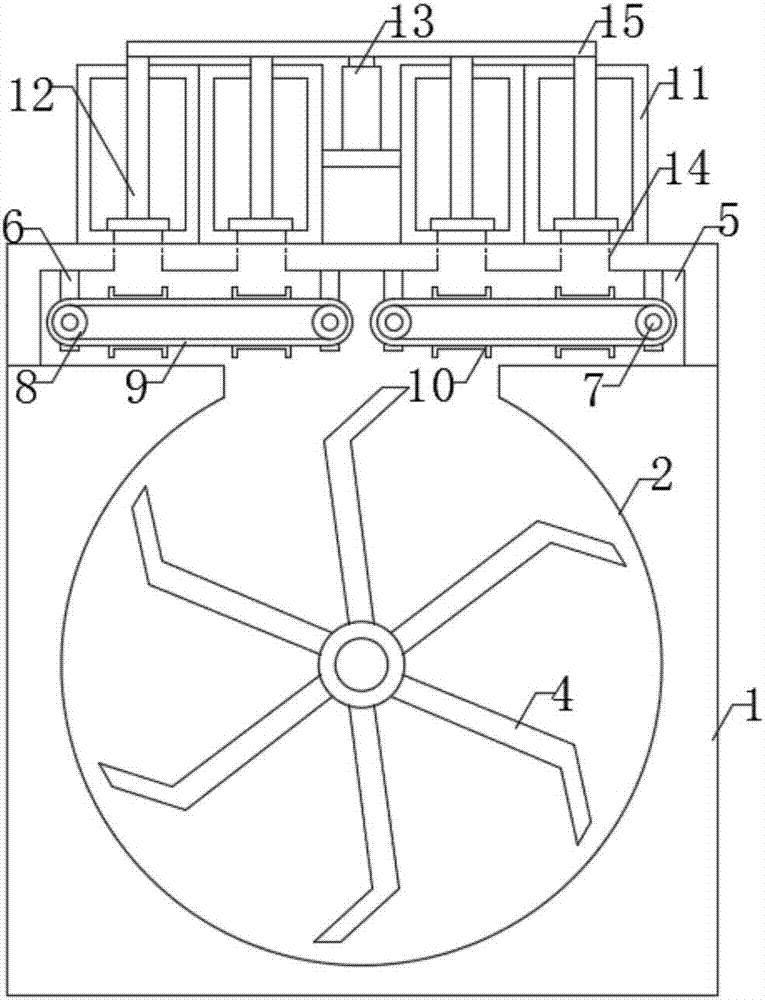

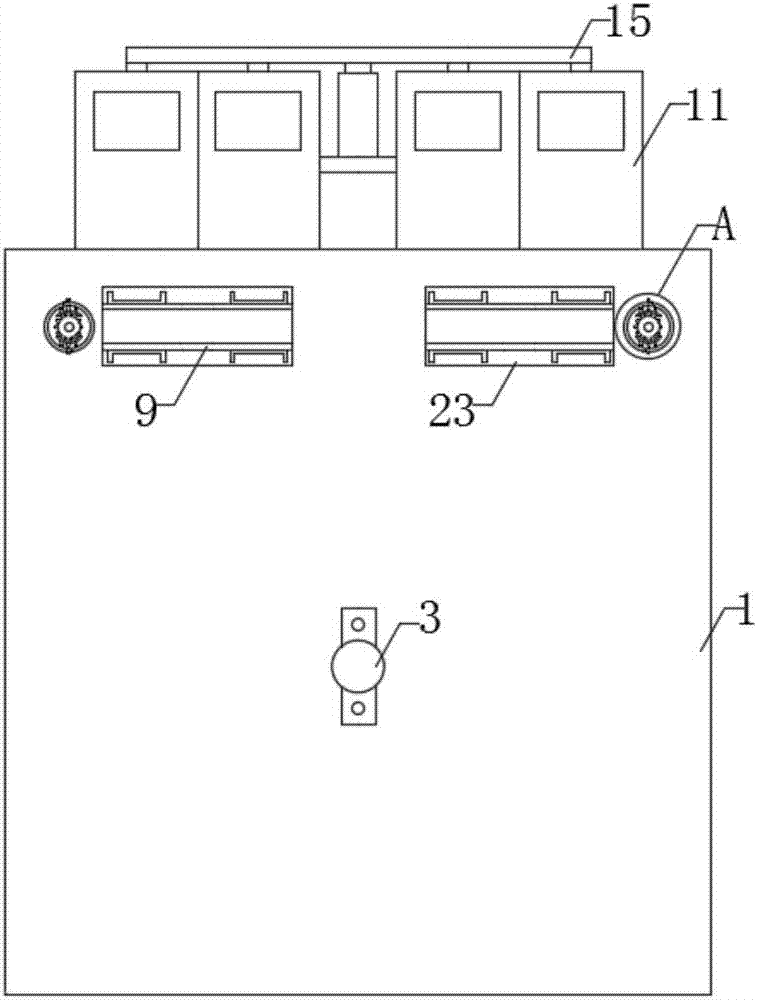

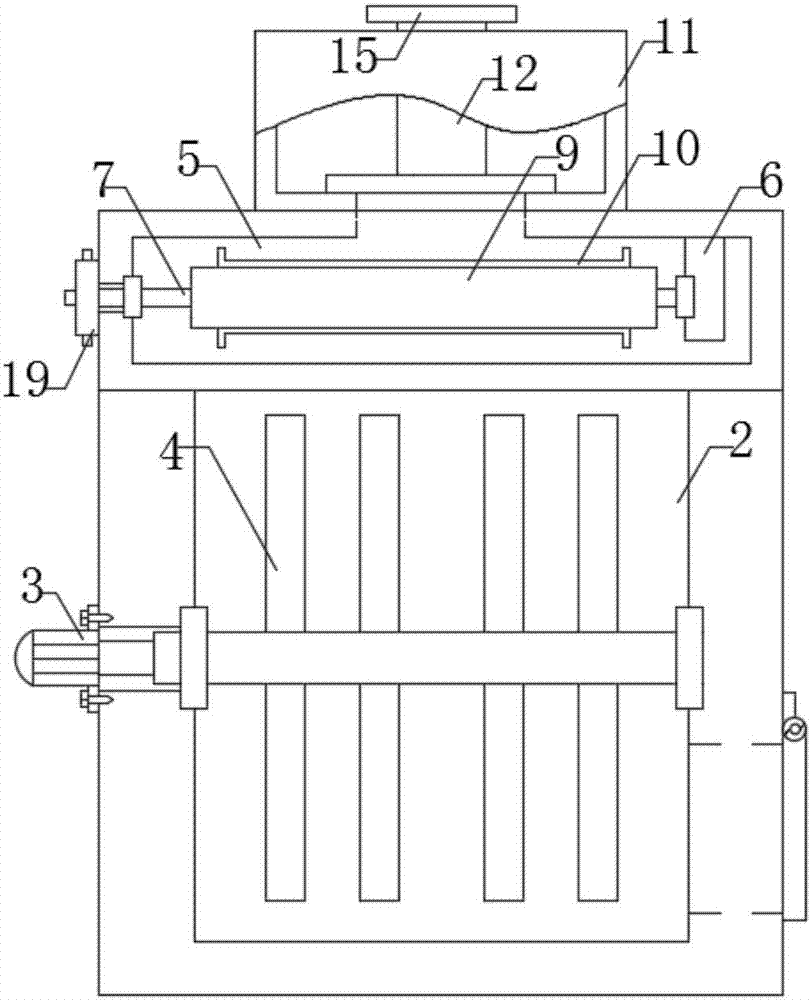

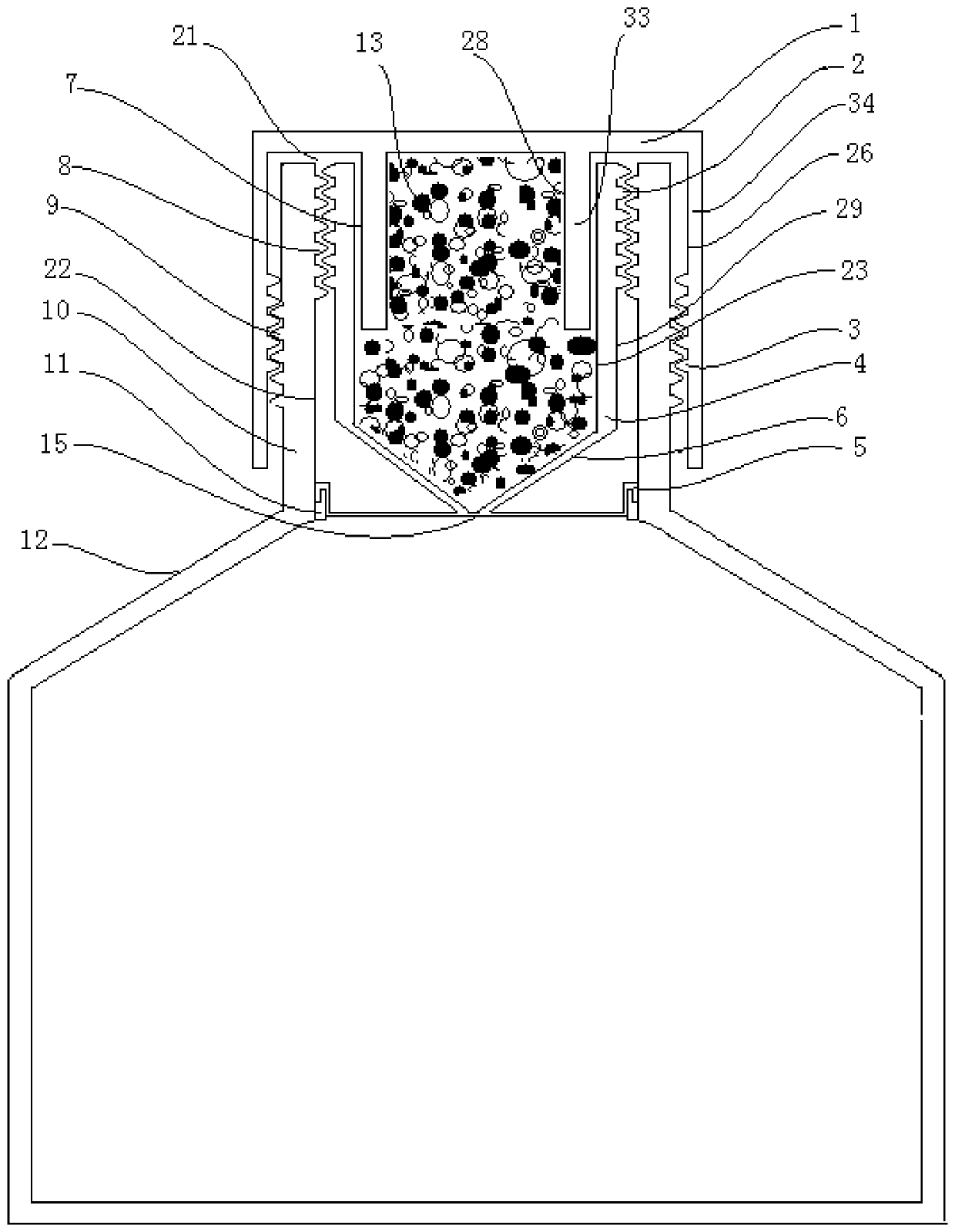

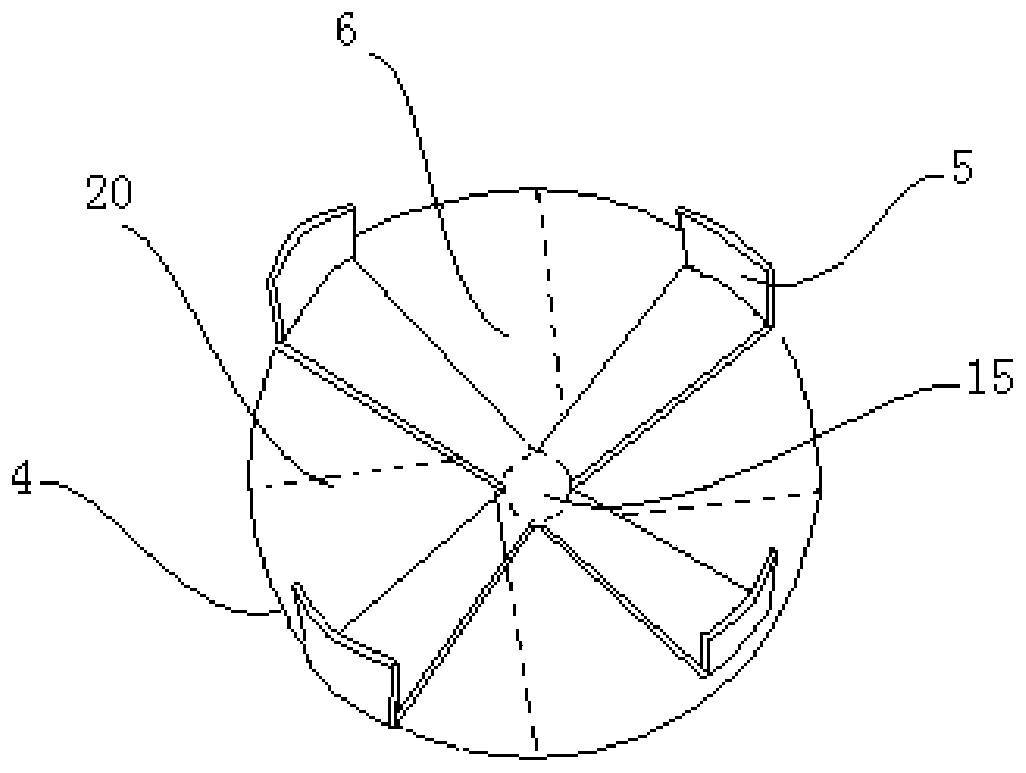

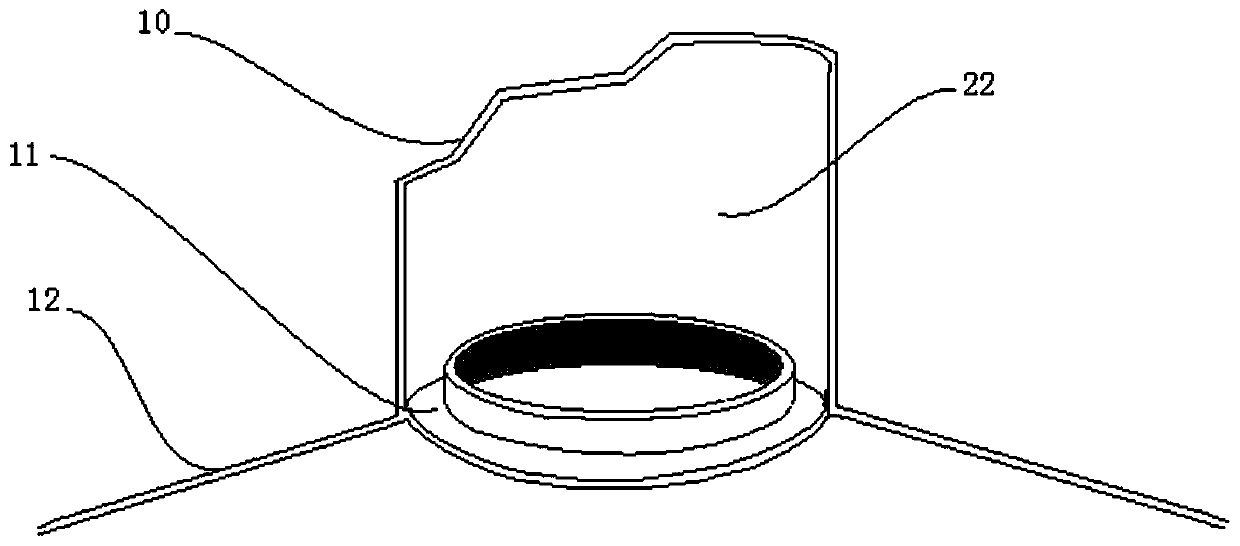

Automatic proportioning type cement hopper

InactiveCN108312356ARealize automatic batchingChange the ratioDischarging apparatusMixing operation control apparatusAgricultural engineeringAirbag

The invention relates to the field of buildings and in particular discloses an automatic proportioning type cement hopper. The automatic proportioning type cement hopper comprises a rack, a stirring mechanism, a feeding hopper and a proportioning mechanism, wherein the feeding holler comprises a feeding part and a discharging pipe; a sealing plate is hinged to the upper part of the discharging pipe; a pull rope is fixed on the sealing plate; the stirring mechanism comprises a motor, a stirring shaft and stirring blades; one end of the stirring shaft and the stirring blades are arranged in thefeeding part; the proportioning mechanism comprises an extension spring, a separating plate, a hydraulic jacking device, an electromagnet, a proportioning box and a baffle plate; the pull rope is fixedly arranged on the baffle plate; the proportioning box is divided into a proportioning cabin and a feeding cabin by the separating plate; two ends of the extension spring are fixedly arranged on thebaffle plate and the separating plate respectively; the bottom of the proportioning box is an inclined surface; the electromagnet can adsorb the baffle plate; a switch is arranged on an inner wall ofthe proportioning box; the separating plate can press the switch; an airbag is fixedly arranged at the bottom of the proportioning cabin; an air inlet is formed in the airbag; a feeding opening is formed in a lateral wall of the feeding cabin. By adopting the automatic proportioning type cement hopper provided by the invention, the quantity of entered raw materials can be controlled.

Owner:苏州相城埭辰科技产业发展有限公司

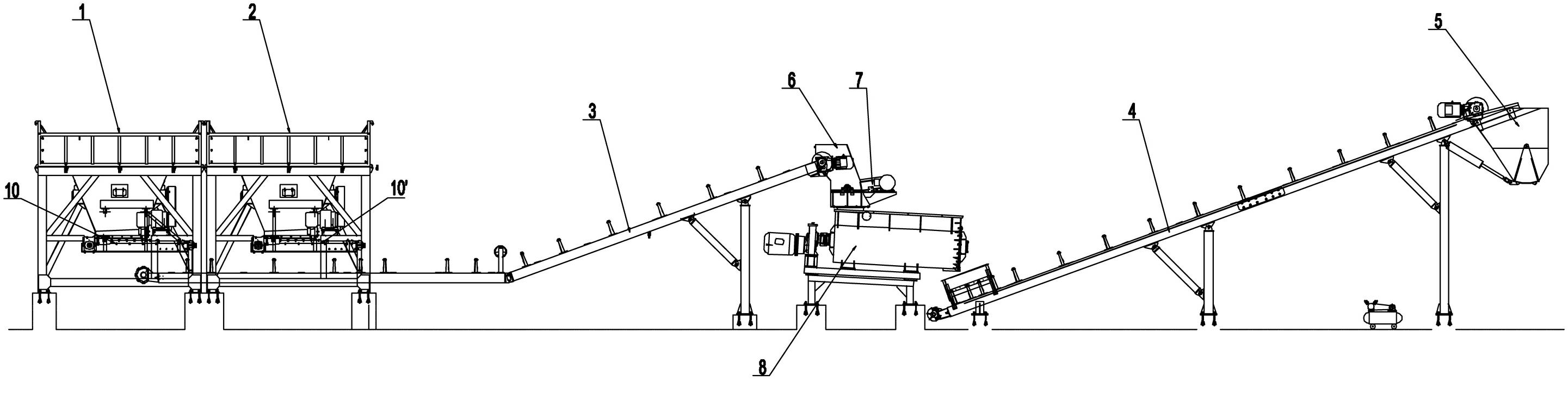

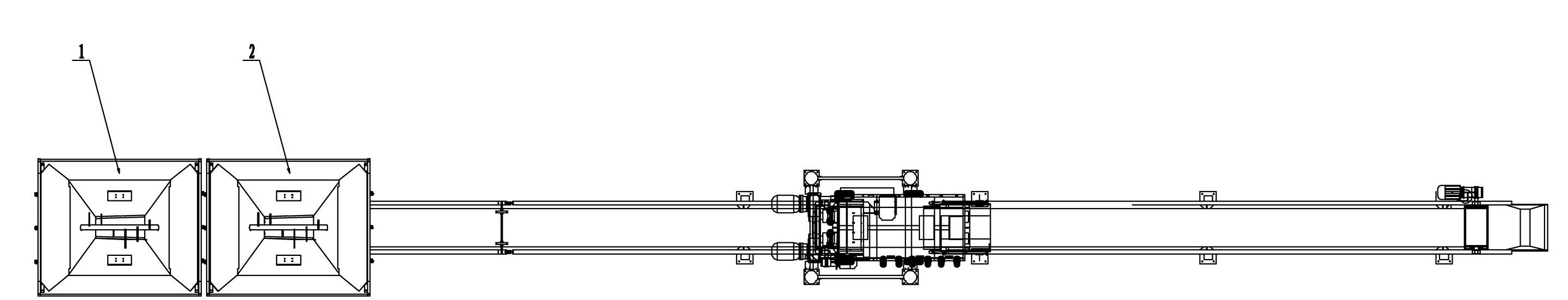

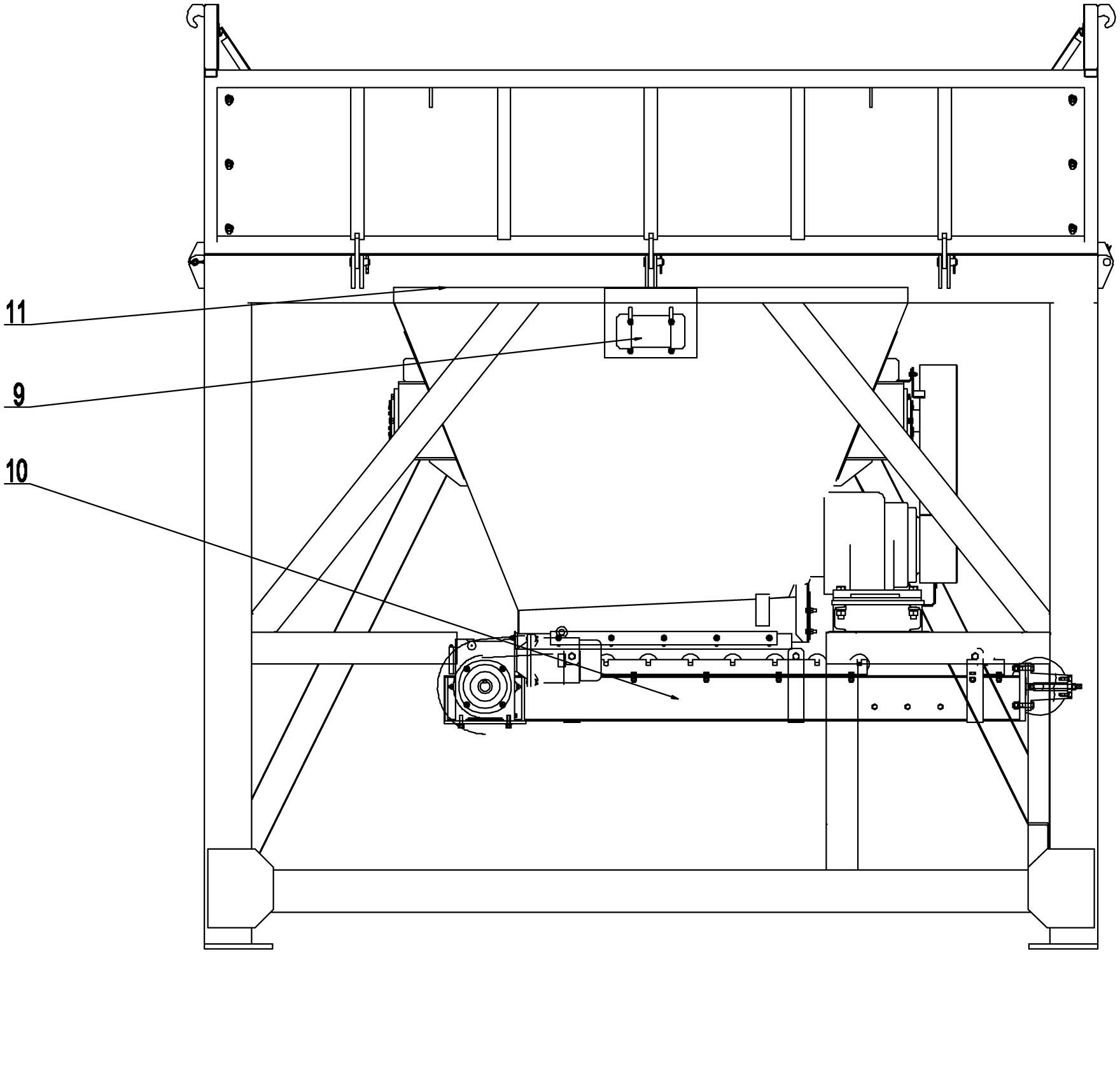

Continuous mixing system for preparing impervious soil and control method

InactiveCN102152400ARealize automatic batchingSave equipmentClay mixing apparatusControl apparatusEngineeringContinuous mixing

The invention provides a continuous mixing system for preparing impervious soil. A collecting and distributing belt conveyor is arranged under a clay hopper and a gravel hopper, and is connected with a measuring hopper, a continuous mixer is arranged under the measuring hopper, a hoisting discharge belt conveyor is arranged under the discharge port of the continuous mixer, and is connected with a discharge hopper, and a water supply device is further arranged on the continuous mixer. The continuous mixing system can realize control functions of automatic distribution, automatic measurement and water addition, continuous mixing, automatic or manual discharging and loading and the like with the methods of quantitative feeding, measured conveying and forced mixing. Compared with a traditional mixing method for preparing the impervious soil, the cost for equipment and site in the invention is saved by 50%, and the efficiency is 150% of that of the traditional mixing method.

Owner:HUBEI GEZHOUBA TESTING

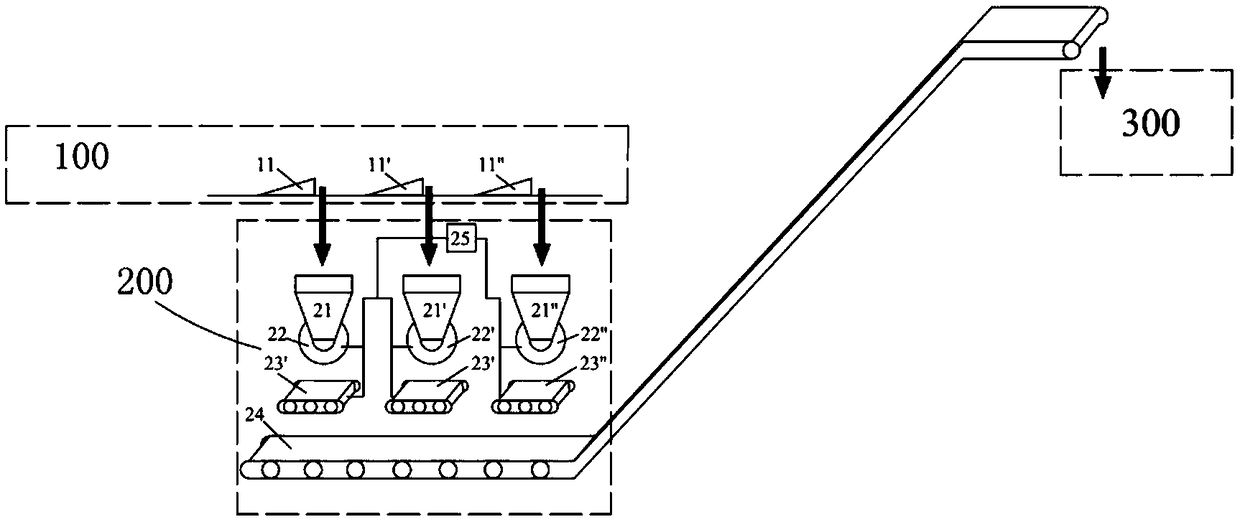

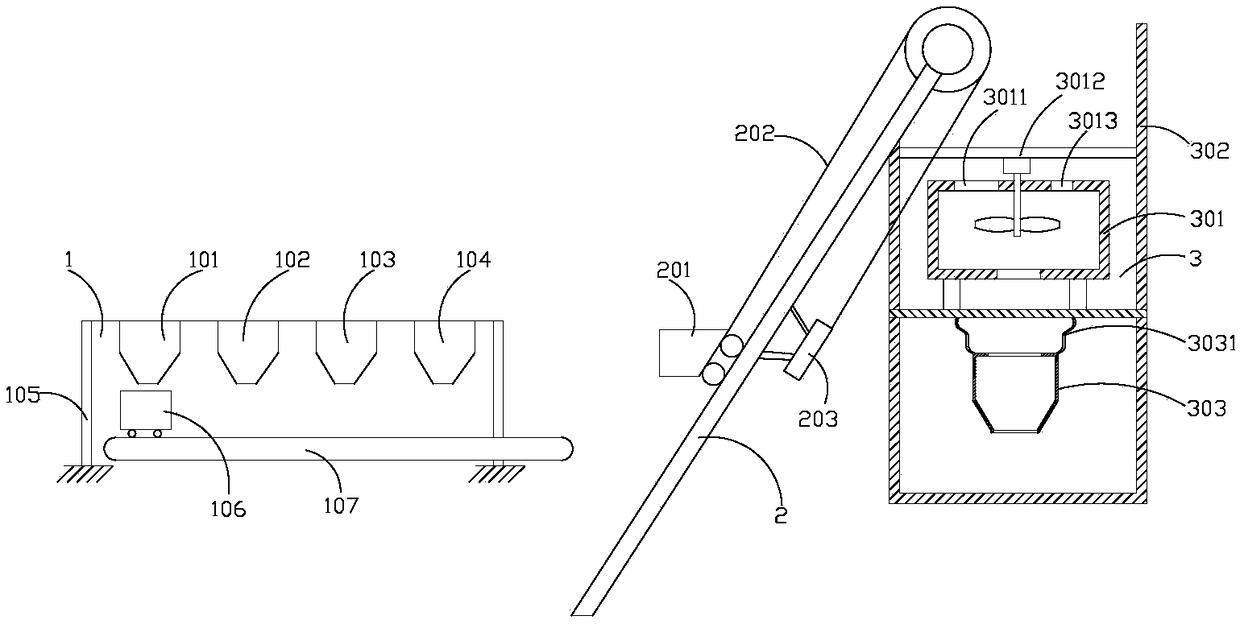

Ore distributing and mixing system based on ports

PendingCN108946205ARealize automatic batchingIncrease productivityLoading/unloadingStack machineGround plane

The invention discloses an ore distributing and mixing system based on ports. The system is characterized in that a feeding system and a stacking system are arranged on the ground, and a distributingsystem is arranged below the ground; the feeding system comprises a belt conveyor feeding system and / or an automobile feeding system; the belt conveyor feeding system and / or the automobile feeding system is connected with an iron ore raw material storage system of the ports; the distributing system comprises a plurality of distributing bins, a belt conveyor and a PLC, wherein the plurality of distributing bins are located below the ground plane, each distributing bin is provided with a feeding machine and an electronic belt scale, the feeding machines are arranged below the distributing bins,the feeding ports of the feeding machines are connected with the discharging ports of the distributing bins, the electronic belt scales are arranged below the discharge ports of the feeding machines,the belt conveyor is arranged below the discharging ends of all the electronic belt scales, and the feeding machines, the electronic belt scales are electrically connected with the PCL correspondingly; and the stacking system comprises a stacking machine, and the receiving end of the stacking machine is connected with the discharging end of the belt conveying conveyor in the distributing system.

Owner:上海慧安科技股份有限公司

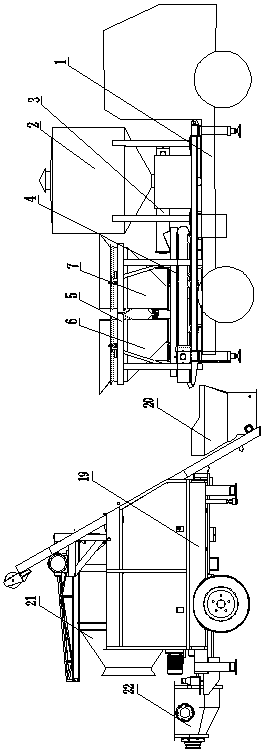

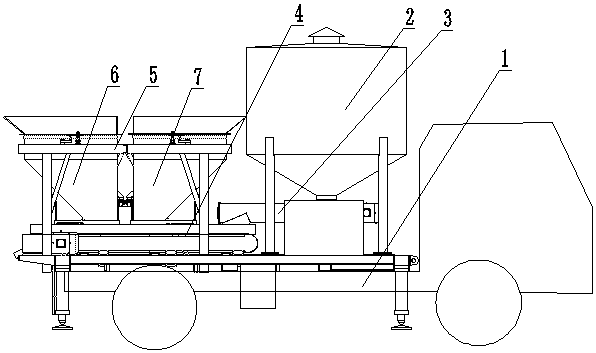

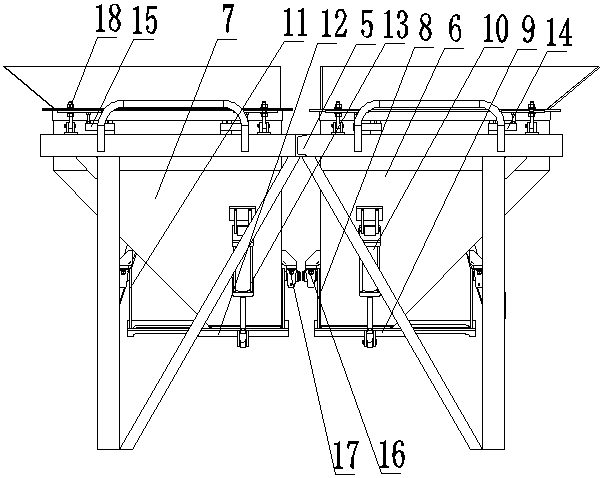

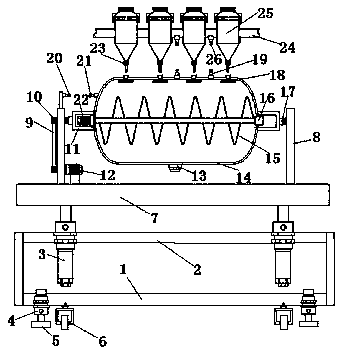

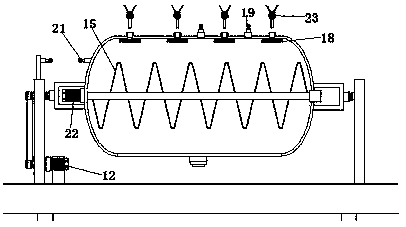

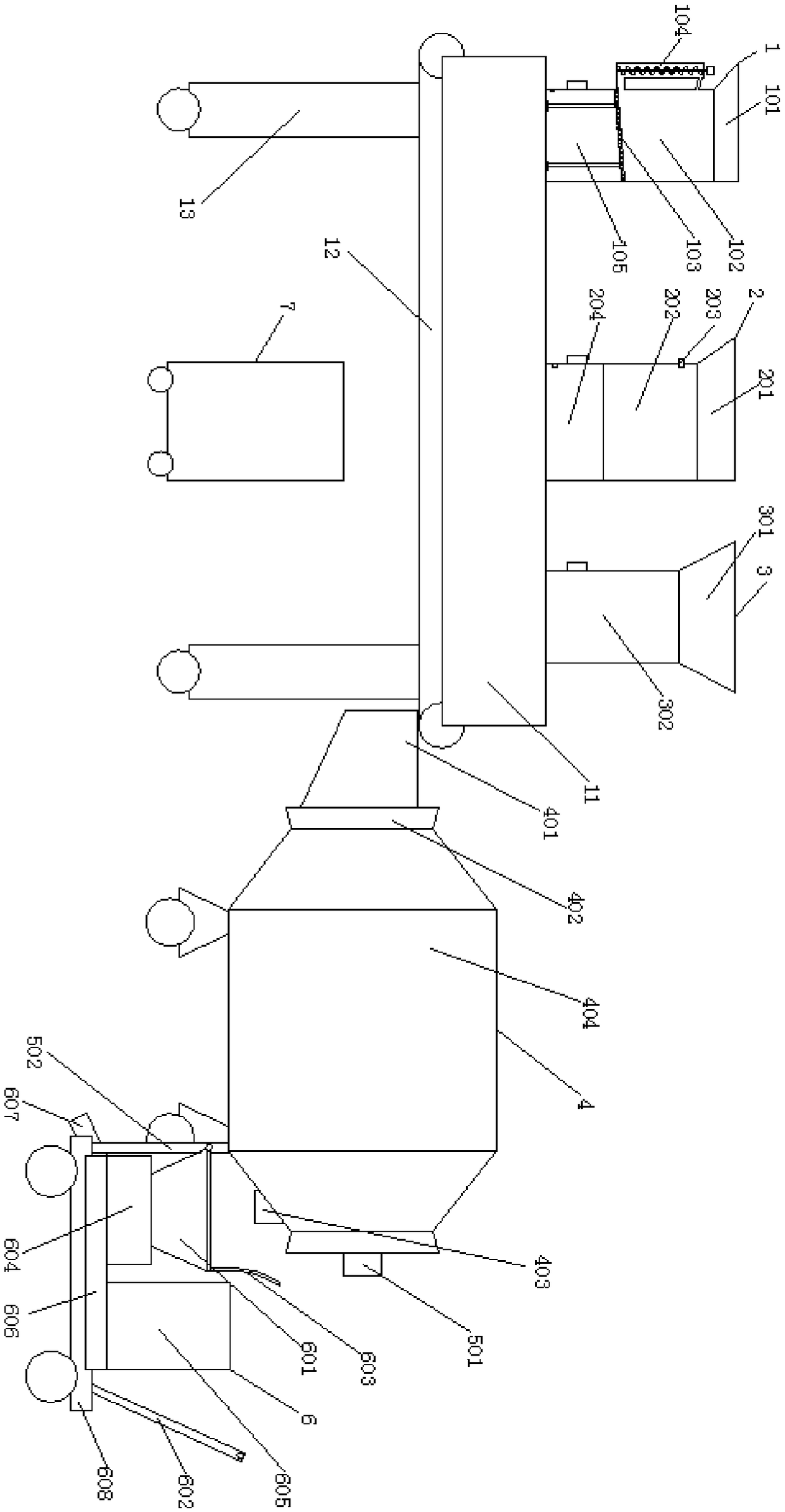

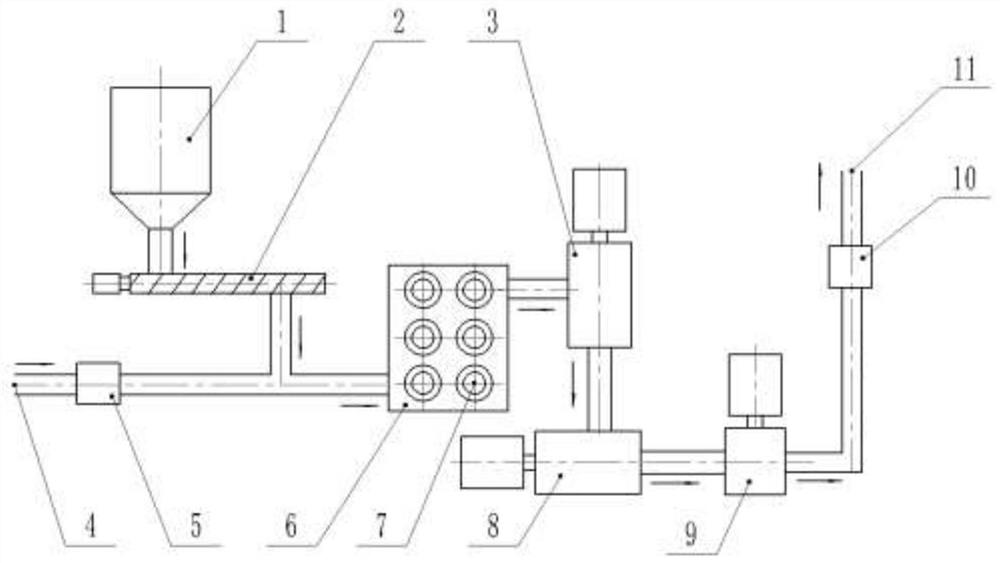

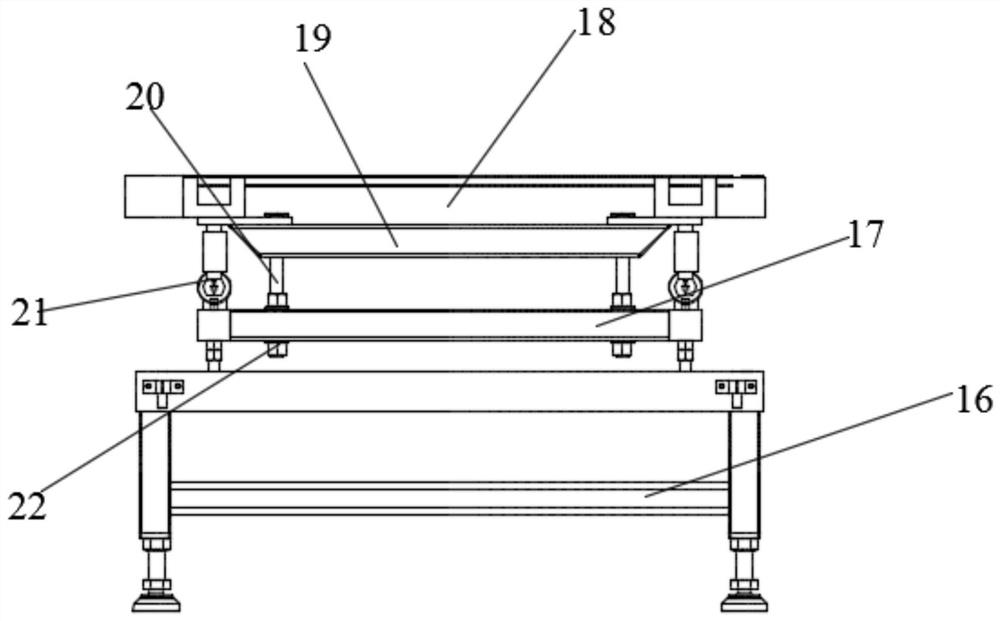

Concrete batching, stirring and conveying system and control method thereof

ActiveCN109352821AImprove stabilityQuality improvementMixing operation control apparatusCement mixing apparatusEngineeringControl valves

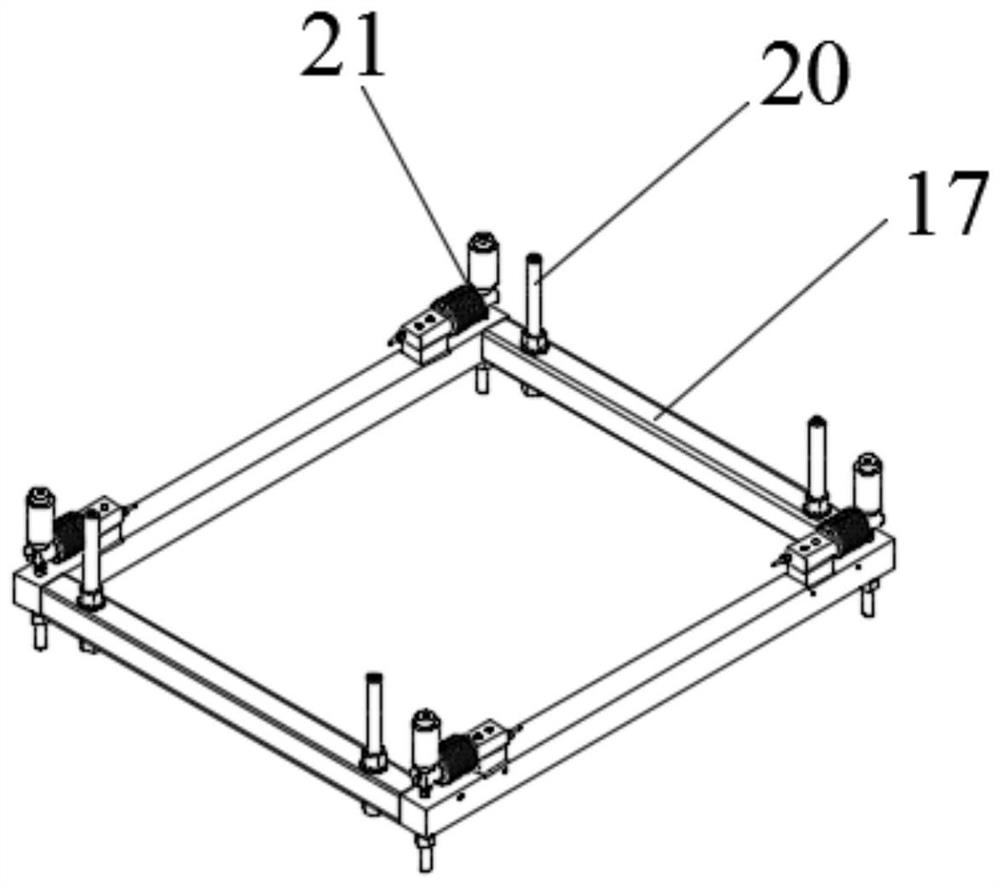

The invention discloses a concrete batching, stirring and conveying system and a control method thereof. The system comprises a batching device and a stirring and conveying device. The batching devicecomprises a loading vehicle (1), a cement bin (2), a screw feeder (3), a belt conveyor (4), a stone bin (6), a sand bin (7), a stone bin discharge valve (9), a first telescopic mechanism (10), a sandbin discharge valve (12), a second telescopic mechanism (13), a first weighing induction device (14) and a second weighing induction device (15). The stirring and conveying device comprises a loadingplatform (19), a hopper (20), a hopper lifting mechanism, a stirring mechanism (21), a water adding pipeline, a water adding control valve and a pumping mechanism (22). The batching device controls the discharge amounts of the cement bin (2), the stone bin (6) and the sand bin (7). The belt conveyor (4) conveys batched materials into the hopper, and the hopper unloads the materials into the stirring mechanism (21); and the stirring mechanism (21) delivers well-stirred concrete to the pumping mechanism (22).

Owner:CHANGSHA TOWER MACHINERY ENG

Automatic batching device

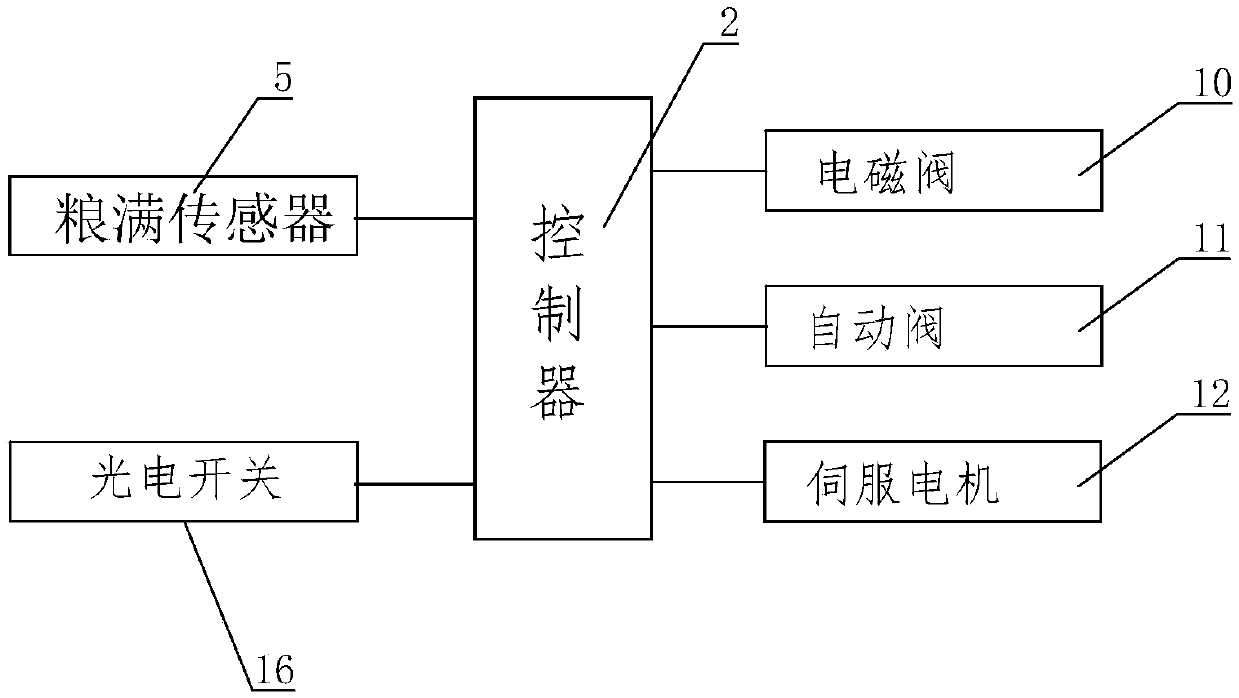

InactiveCN110711533ARealize automatic batchingIncrease productivityTransportation and packagingMixer accessoriesPhotoswitchControl engineering

The invention discloses an automatic batching device, which comprises a rack and a controller, wherein a leakage hopper is arranged above the rack, a stirrer is arranged in the leakage hopper, a quantitative batching barrel is arranged below the leakage hopper, and a grain fullness sensor is arranged in the quantitative batching barrel; a blocking plate is arranged between the lower end of the material leaking hopper and the quantitative batching barrel, an air cylinder is arranged on one side of the blocking plate, and the end of the blocking plate is fixedly connected with a telescopic rod of the air cylinder; a funnel-shaped bottom plate is arranged at the lower end of the quantitative batching cylinder in a blocking manner, a discharge port is formed in the bottom plate and connected with a discharge pipe, an automatic valve is arranged at the position, close to the discharge port, of the discharge pipe, and a photoelectric switch is arranged at the discharge port; a servo motor isarranged below the quantitative batching barrel, an output shaft of the servo motor is fixedly connected with a lead screw, the lead screw extends upwards to the upper end of the quantitative batching barrel, the lead screw is in threaded connection with a sliding block, and the discharging pipe penetrates through the sliding block and is fixedly connected with the sliding block. The device can automatically and quantitatively prepare materials and is high in production efficiency.

Owner:宁国市中英橡胶有限公司

Automatic feed blending system with alarm function

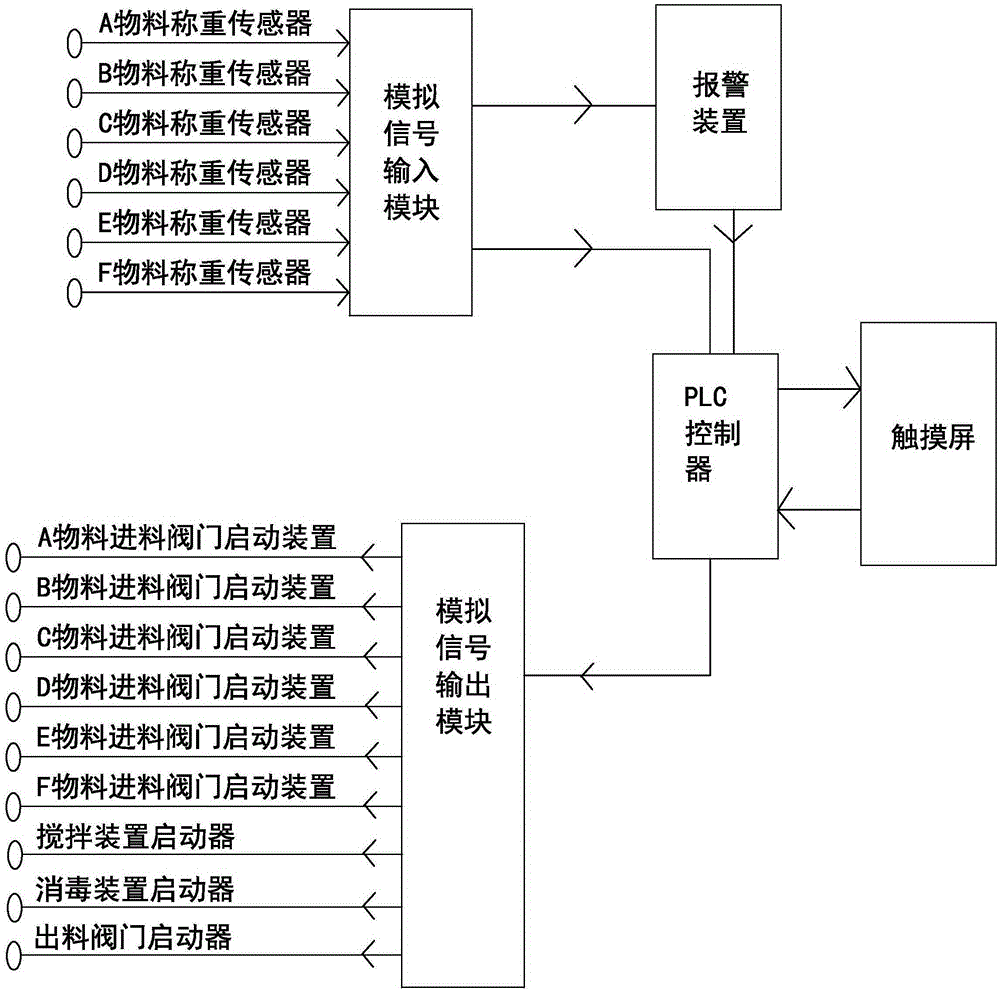

InactiveCN106665390AImprove work efficiencyGuarantee ingredient quality and safetyAnimal feeding devicesFeed processingEngineering

The invention relates to an automatic feed blending system with an alarm function, and belongs to the technical field of feed processing. The automatic feed blending system comprises an analog signal input module, a controller, an analog signal output module, a display screen and an alarm device. The analog signal input module is connected with a material A weighing sensor, a material B weighing sensor, a material C weighing sensor, a material D weighing sensor, a material E weighing sensor and a material F weighing sensor, and the analog signal output module is connected with a material A feeding valve starting device, a material B feeding valve starting device, a material C feeding valve starting device, a material D feeding valve starting device, a material E feeding valve starting device, a material F feeding valve starting device, a stirring device starter, a disinfection device starter and a discharging valve starter. The automatic feed blending system has the advantages that feed can be automatically blended, mixed, stirred and disinfected, the automatic feed blending system has the alarm function, and accordingly the blending quality and safety can be guaranteed.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

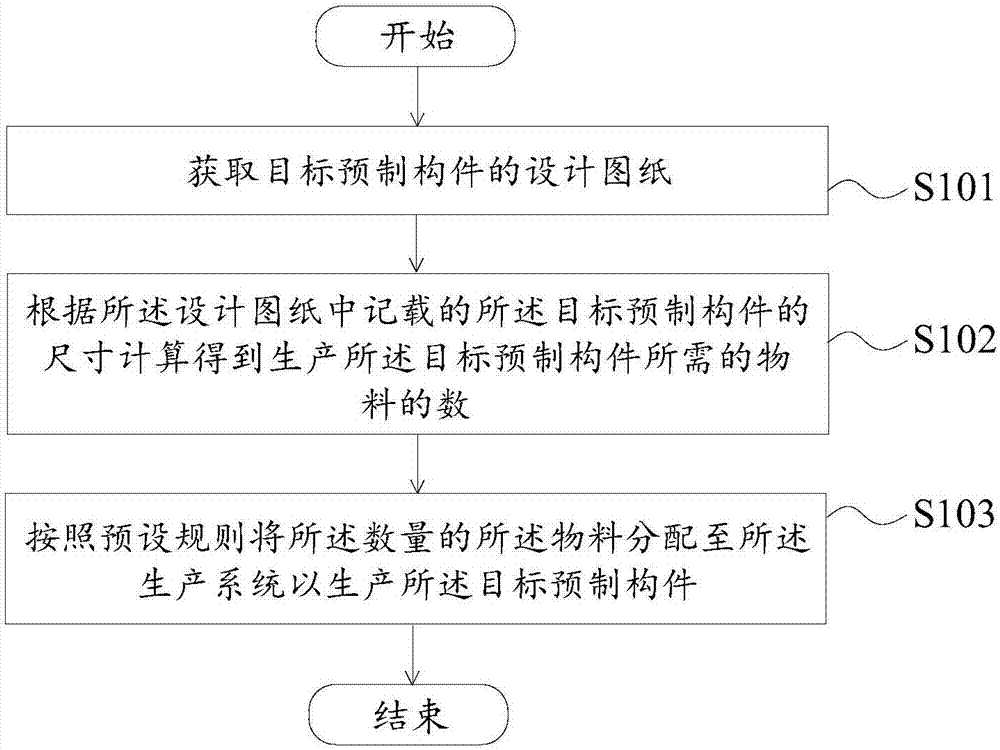

Automatic batching method and device

InactiveCN107443556AImprove batching efficiencyImprove accuracyFeeding arrangmentsManufacturing engineering

The invention provides an automatic batching method and device. The automatic batching method and device are applied to a production system for producing prefabricated parts. The prefabricated parts are used for assembling of a prefabricated building. The automatic batching method comprises the steps that a design drawing of a target prefabricated part is obtained; the number of materials required by production of the target prefabricated part is obtained through calculation according to the size, recorded in the design drawing, of the target prefabricated part; the quantitative materials are distributed to the production system according to the preset rule so as to produce the target prefabricated part. By means of the design, automatic batching of the production system can be achieved, the production efficiency is improved, and the batching error rate is reduced.

Owner:HEZHOU UNIV

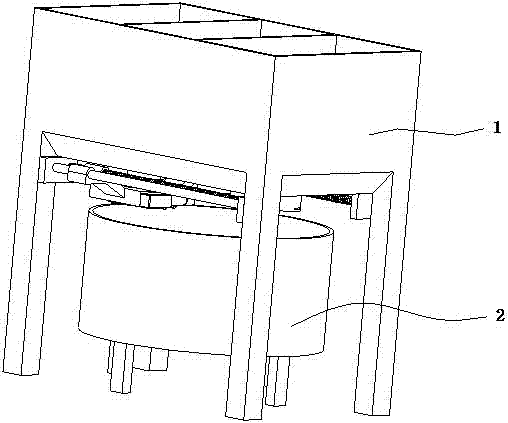

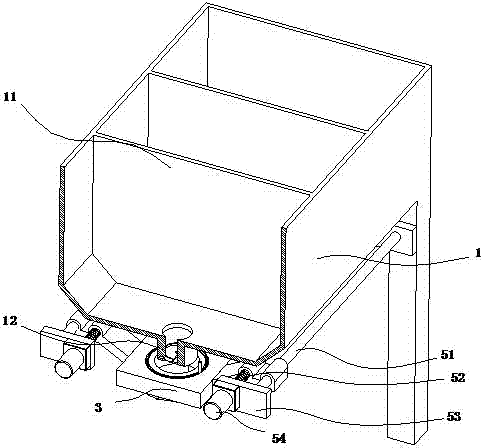

Dispensing and mixing device for organic fertilizer manufacturing

PendingCN108970494AFully automatedRealize mass productionRotating receptacle mixersTransportation and packagingEngineeringOrganic fertilizer

The invention discloses a dispensing and mixing device for organic fertilizer manufacturing. When the dispensing is performed, a rotary dispensing driving assembly drives a feed port of a mixing tankto correspond to the position of a blanking cylinder, and then a lifting assembly drives the mixing tank to rise, so that the blanking cylinder extends into the mixing tank, and a blanking control assembly controls the blanking of each storage assembly; after the blanking is completed, the lifting assembly falls, an elastic cover assembly closes the feed port, and the rotary mixing driving assembly drives the mixing tank to rotate, thereby realizing the automatic dispensing and mixing of an organic fertilizer. The dispensing and mixing device for organic fertilizer manufacturing disclosed by the invention can well realize the automatic dispensing, and adopts a spiral stirring and rotating method when mixing at the same time, thereby greatly improving the efficiency of mixing and the uniformity of mixing; the mass production of organic fertilizer can be effectively realized, and the requirements of automation can be met.

Owner:ANHUI SCI & TECH UNIV

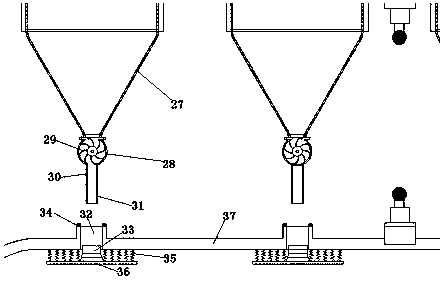

Batching device of asphalt cold paving materials

InactiveCN108193579AReduce configuration costsAvoid quality problemsRoads maintainenceAsphaltConveyor belt

At present, asphalt cold paving materials are manually configured, the labor intensity is high, and the quality control is difficult. The invention provides a batching device of the asphalt cold paving materials. The batching device of the asphalt cold paving materials comprises a batching part and a transport part which are connected with each other, and further comprises a control device; the batching part comprises a material rest, and silos are arranged above the material rest; the lower part of each of the silos is provided with a blanking opening and a blanking baffle for controlling theopening and closing of the blanking opening, and a conveying device is arranged below the material rest; the conveying device comprises a conveying motor and a conveyor belt which are connected witheach other, and the upper part of the conveyor belt is provided with a collecting hopper; the transport part is provided with a transporting material rest, and a slide rail is arranged above the transporting material rest; the slide rail is internally provided with a tackle, and the tackle and the slide rail are slidably arranged; the automatic batching is realized by the mutually connected batching part and transport part, the batching cost of the asphalt cold paving materials is reduced, and the quality problem caused by the manual work is further avoided.

Owner:重庆岚海扬帆科技有限公司

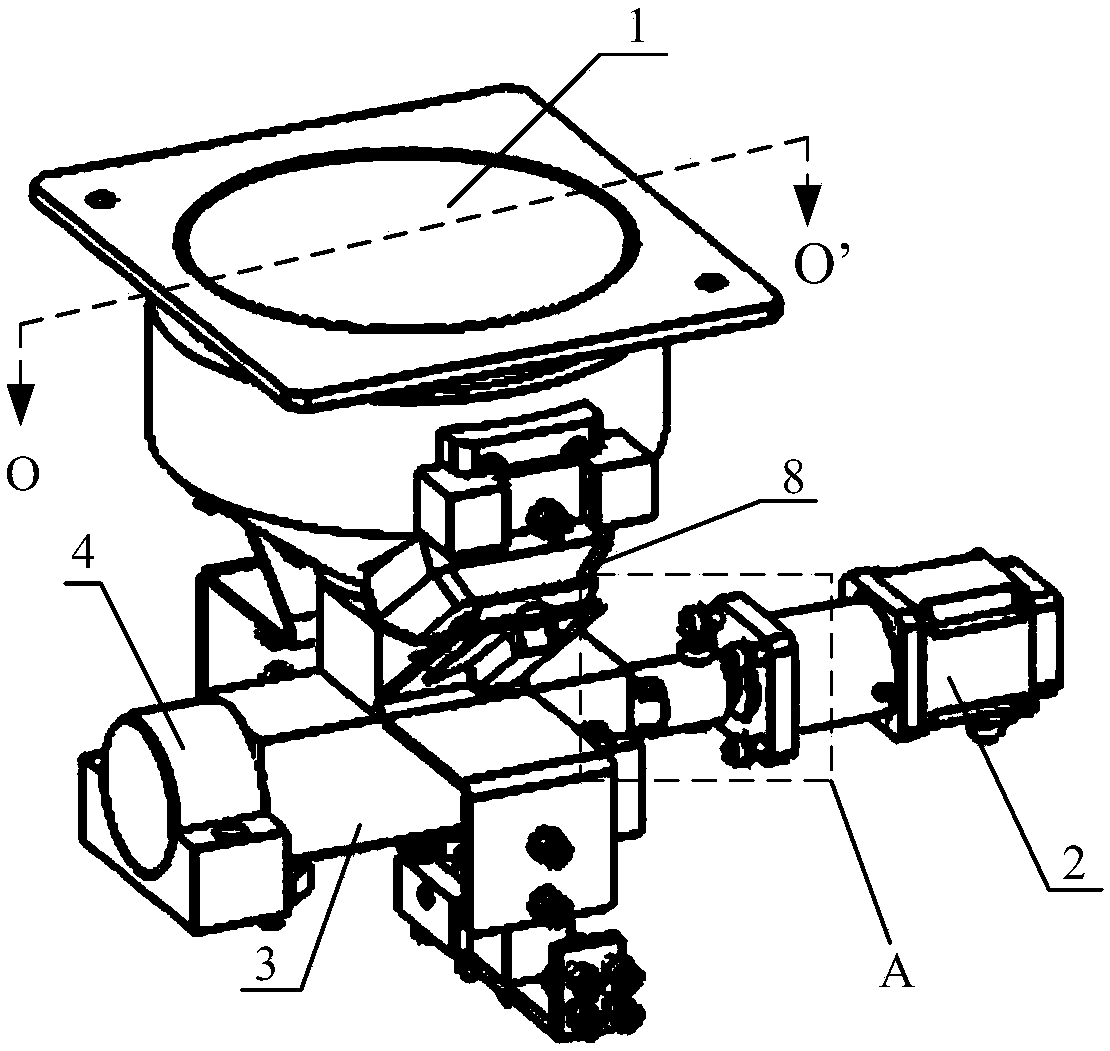

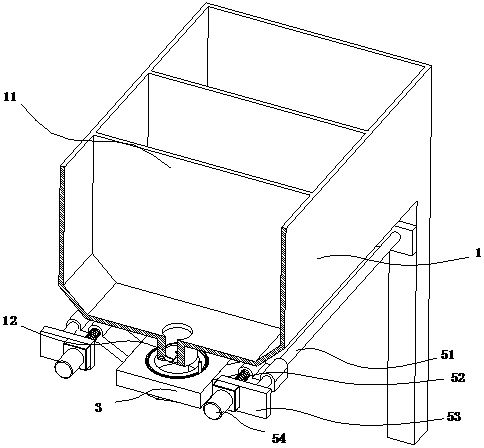

Automatic material blending device

PendingCN108651836AAdd precise and efficientRealize automatic batchingFood scienceElectric machineryEngineering

The present invention discloses an automatic material blending device and relates to the technical field of catering automation. The automatic material blending device is used for accurately and efficiently completing addition of seasoning materials in noodle cooking. The automatic material blending device comprises a material storing tank, a controller and a material conveying mechanism arrangedunder the material storing tank; wherein the material conveying mechanism comprises a driving motor and a material conveying cylinder; the material conveying cylinder is internally sleeved with a screw rod; the screw rod is connected with a rotating shaft of the driving motor; screw thread of the screw rod is in clearance fit with the inner wall of the material conveying cylinder; an upper material inlet is arranged on the side wall of the material conveying cylinder and at one side close to the driving motor; a lower material outlet is arranged on the side wall of the material conveying cylinder and at one side far away from the driving motor; a base table for placing of a material receiving container is arranged under the lower material outlet; the upper material inlet communicates withthe bottom end of the material storing tank; and the controller is connected with the driving motor. The automatic material blending device is applied in adding seasoning materials to cooked noodles at restaurants.

Owner:北京快端科技有限公司

Automatic proportioning device of sand mixer

InactiveCN107159838AQuality improvementRealize automatic batchingMould handling/dressing devicesEngineeringRaw material

The invention relates to the field of sand mixers, in particular to an automatic proportioning device of a sand mixer. The automatic proportioning device comprises a storage tank. A plurality of vertical partition plates are arranged in the storage tank. The space of the storage tank is divided into a plurality of storage spaces through the multiple vertical partition plates. A discharging pipe is arranged in the position, corresponding to each storage space, of the bottom of the storage tank. A semicircular opening is formed in the bottom of each discharging pipe, and a closable blocking plate is arranged at each opening. Feeding assemblies for opening the blocking plates are arranged in the positions, corresponding to the multiple discharging pipes, of the bottom of the storage tank. The sand mixer is arranged at the bottoms of the feeding assemblies. According to the automatic proportioning device, different required raw materials are poured into the different storage spaces, then the feeding assemblies at the bottom of the storage tank can open the blocking plates at the bottoms of the discharging pipes according to a set program, quantitative conveying of the raw materials is controlled according to the opening time of the blocking plates, thus, automatic proportioning is achieved, and the quality of finished products is improved. In addition, the invention further provides the sand mixer.

Owner:HEZE UNIV

Concrete batching system

InactiveCN108466369AQuality improvementAvoid wastingMixing operation control apparatusPretreatment controlEngineeringSprayer

The invention provides a concrete batching system comprising a batching device, a transporting device, a concrete mixer, a concrete sprayer, flow controllers and a control cabinet. The batching devicecomprises a gravel batching device body, a cement batching device body and an accelerator storage device body; the flow controllers are arranged at the bottoms of the batching device bodies correspondingly; the transporting device is located below the batching device; a helical conveying shaft is arranged in the concrete mixer in a penetrating mode; a pump body is arranged at one end of the helical conveying shaft; and a discharging outlet is formed in the bottom of the end, close to the pump body, of the concrete mixer, and the concrete sprayer is arranged below the discharging outlet and comprises a feeding cylinder, a concrete storage device, an electric control box, a spraying mechanism and a bottom plate. Integrated work from raw materials to spraying of concrete is achieved, it is guaranteed that material lacking in the midway is avoided, the labor cost is reduced, and the product quality and the concrete production efficiency are improved.

Owner:HUZHOU ZHONGCHEN CONSTR

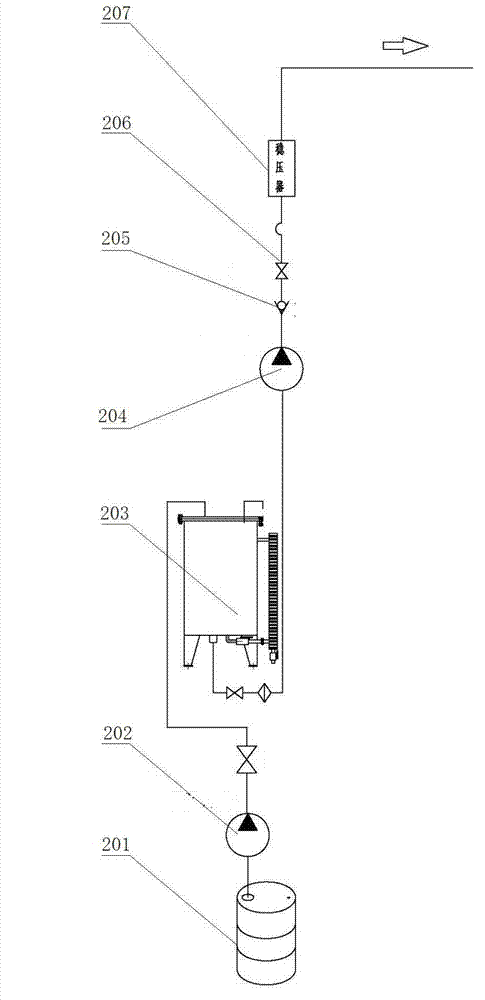

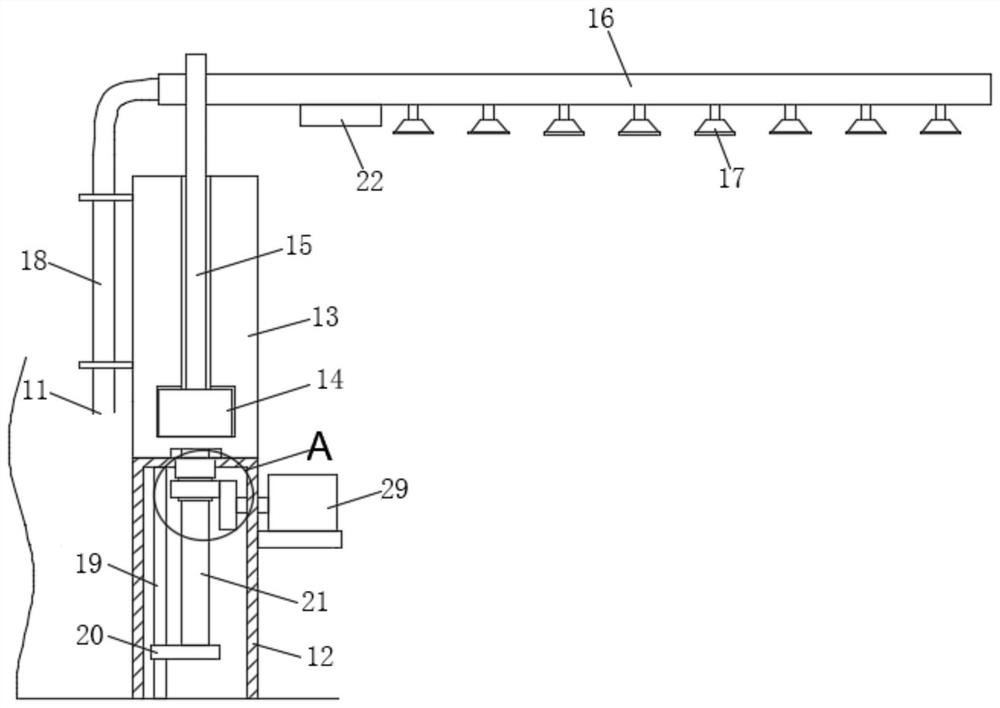

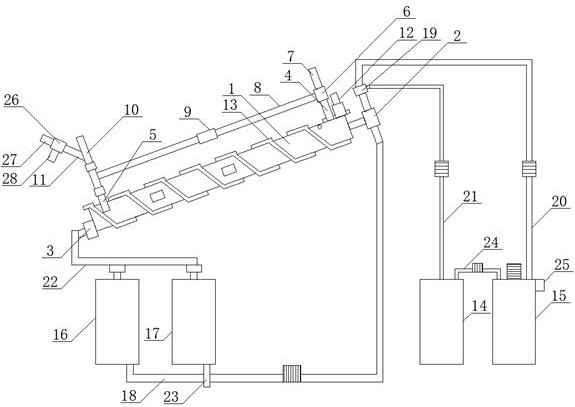

Instant stirring and spraying device for dust suppressant for railway coal transportation

PendingCN112221764ARealize automatic batchingAchieving stirringLiquid spraying apparatusProcess engineeringScrew conveyor

The invention discloses an instant stirring and spraying device for a dust suppressant for railway coal transportation. The instant stirring and spraying device comprises an instant stirring device body and a spraying device body; the stirring device body comprises a powder bin and a spiral conveyor, wherein the powder bin is arranged on the device body, and the spiral conveyor is arranged at thebottom of the powder bin; and the spraying device body comprises a stand column, a connecting base, a feeding pipe and a liquid spraying rod, wherein the stand column is internally provided with a lifting mechanism and is connected to the connecting base, the connecting base is arranged at the top of the stand column and is connected with the liquid spraying rod, the feeding pipe is arranged on one side of the stand column and / or the connecting base, and the liquid spraying rod is connected to a rotating rod. Compared with the prior art, the instant stirring and spraying device has the advantages that a traditional storage stirring tank can be removed, storage is not needed, spraying is conducted while stirring is conducted, and instant spraying is realized; and the whole liquid spraying rod can be controlled to ascend, descend and rotate through a computer, the required amount of water and solvent can be rapidly calculated, liquid preparation can be automatically conducted, and therefore the operation procedure is simplified, the labor intensity and the labor cost are lowered, and the device is more intelligent and more convenient to use.

Owner:神木市锦界安顺煤矿机电修造有限公司

Blending and feeding integrated automatic feeding equipment for livestock rearing

InactiveCN110419456ARealize the operationRealize automatic batchingRotary stirring mixersTransportation and packagingThreaded pipeEngineering

The invention relates to the technical field of machinery, in particular to blending and feeding integrated automatic feeding equipment for livestock rearing. The equipment comprises a feeding platform, a feeding tank is arranged on the front surface of the feeding platform, a limiting block is arranged on the upper surface of the feeding platform, a first motor is arranged on one side of the limiting block, a retaining plate is arranged above the limiting block, a round ring is arranged at the horizontal end of an L-shaped supporting rod on the retaining plate, and a second motor is mounted on the inner circle of the round ring. When a rotating shaft at the output end of the second motor rotates, multiple stirring paddles are driven to uniformly stir feed to realize blending operation; when a screw at the output end of the first motor rotates, a threaded pipe drives the retaining plate to move horizontally, in this way, a discharging bucket uniformly spreads the feed into the feedingtank, so that automatic blending and feeding functions of the feeding equipment are realized, labor intensity is lowered, and the problem that existing automatic feeding equipment is inconvenient forblending and feeding at the same time is solved.

Owner:紫云德康生猪养殖有限公司

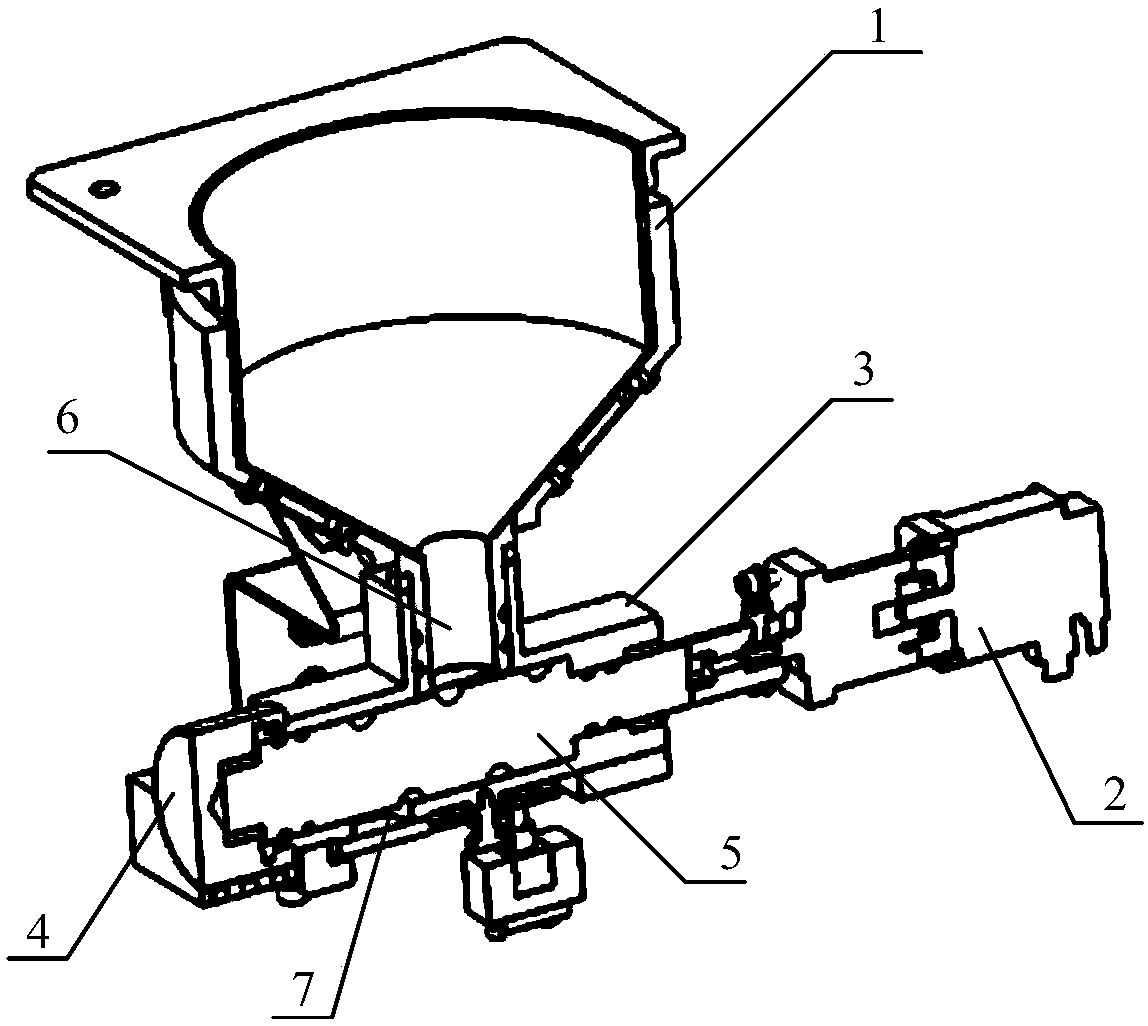

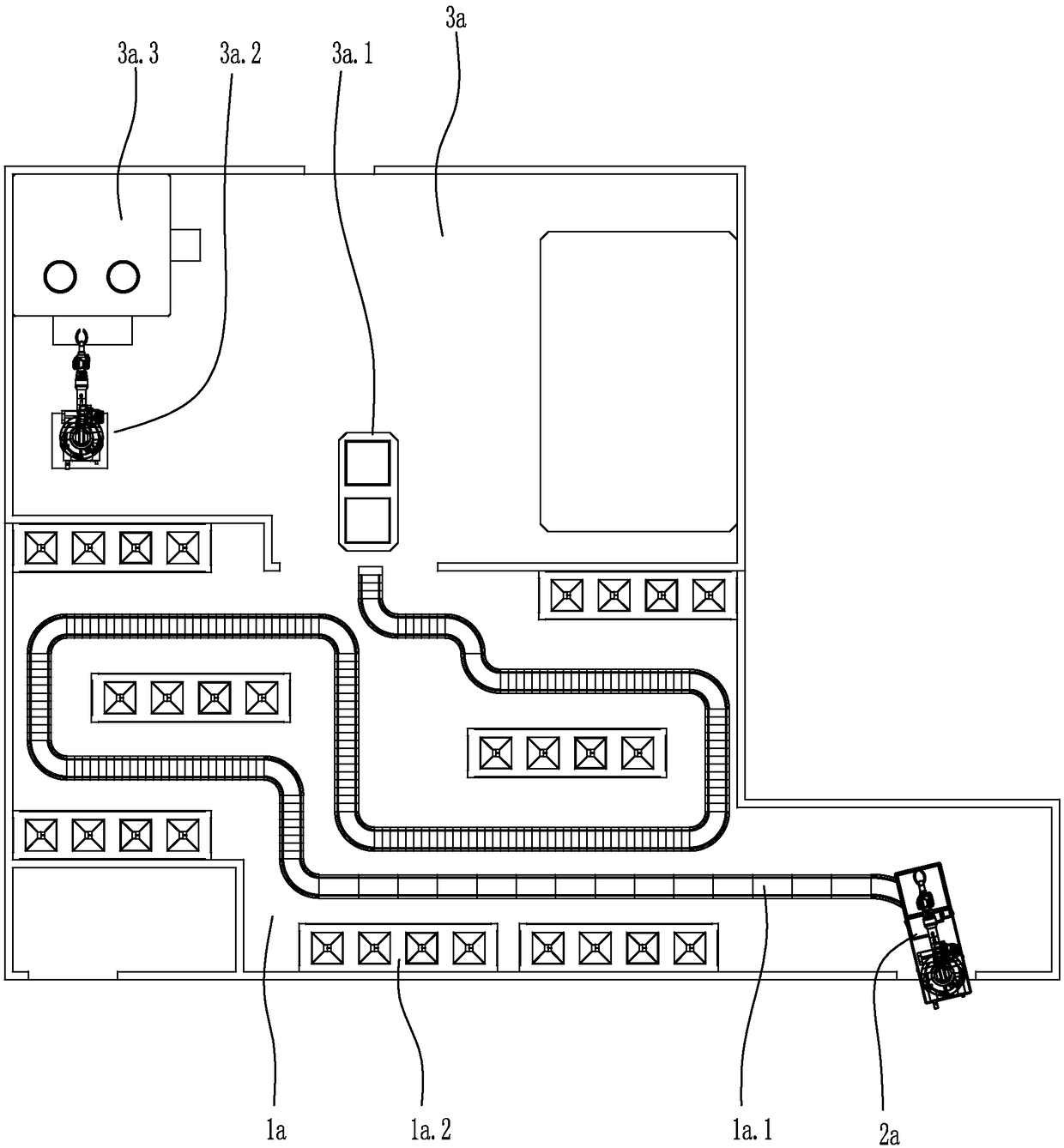

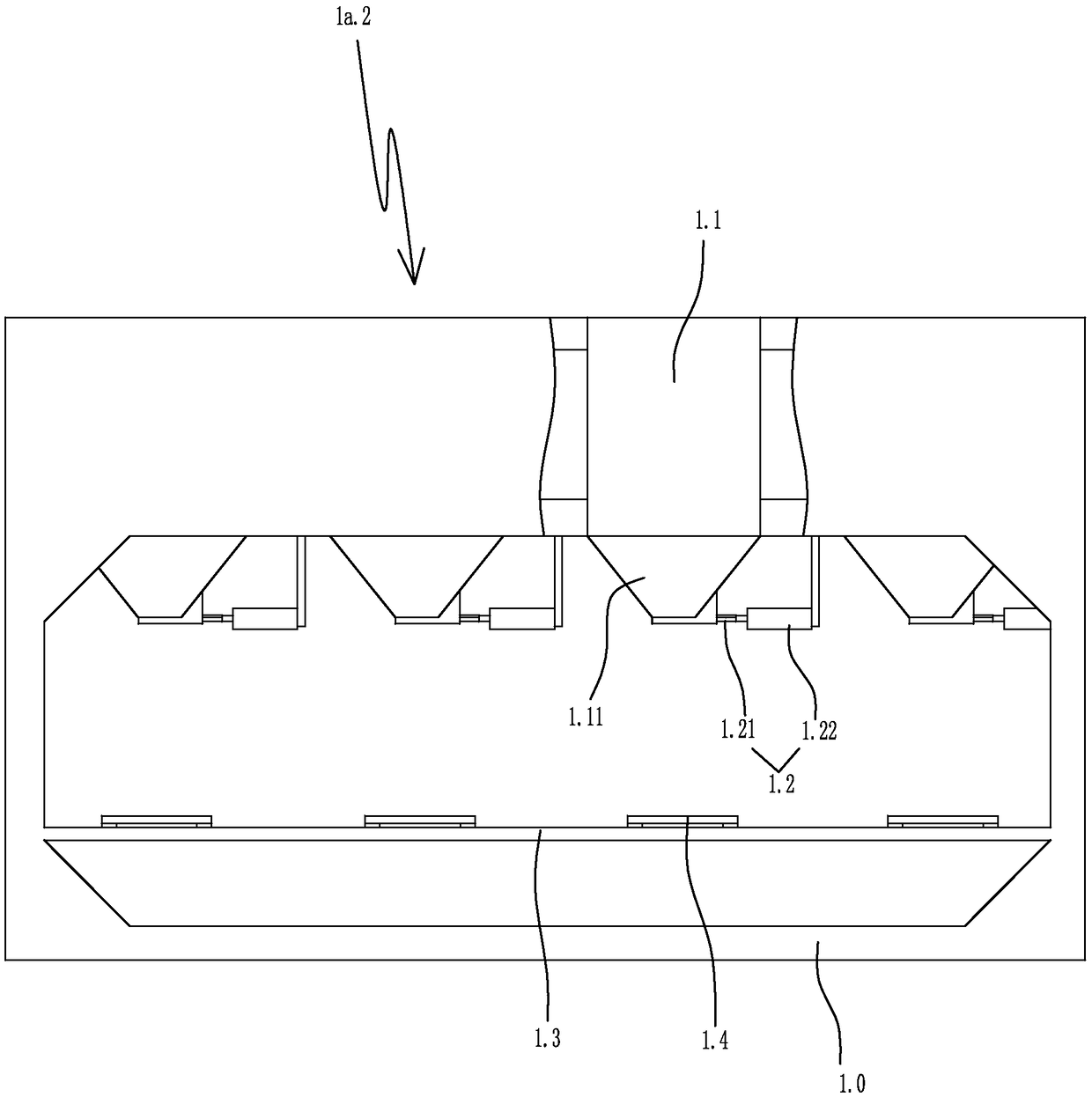

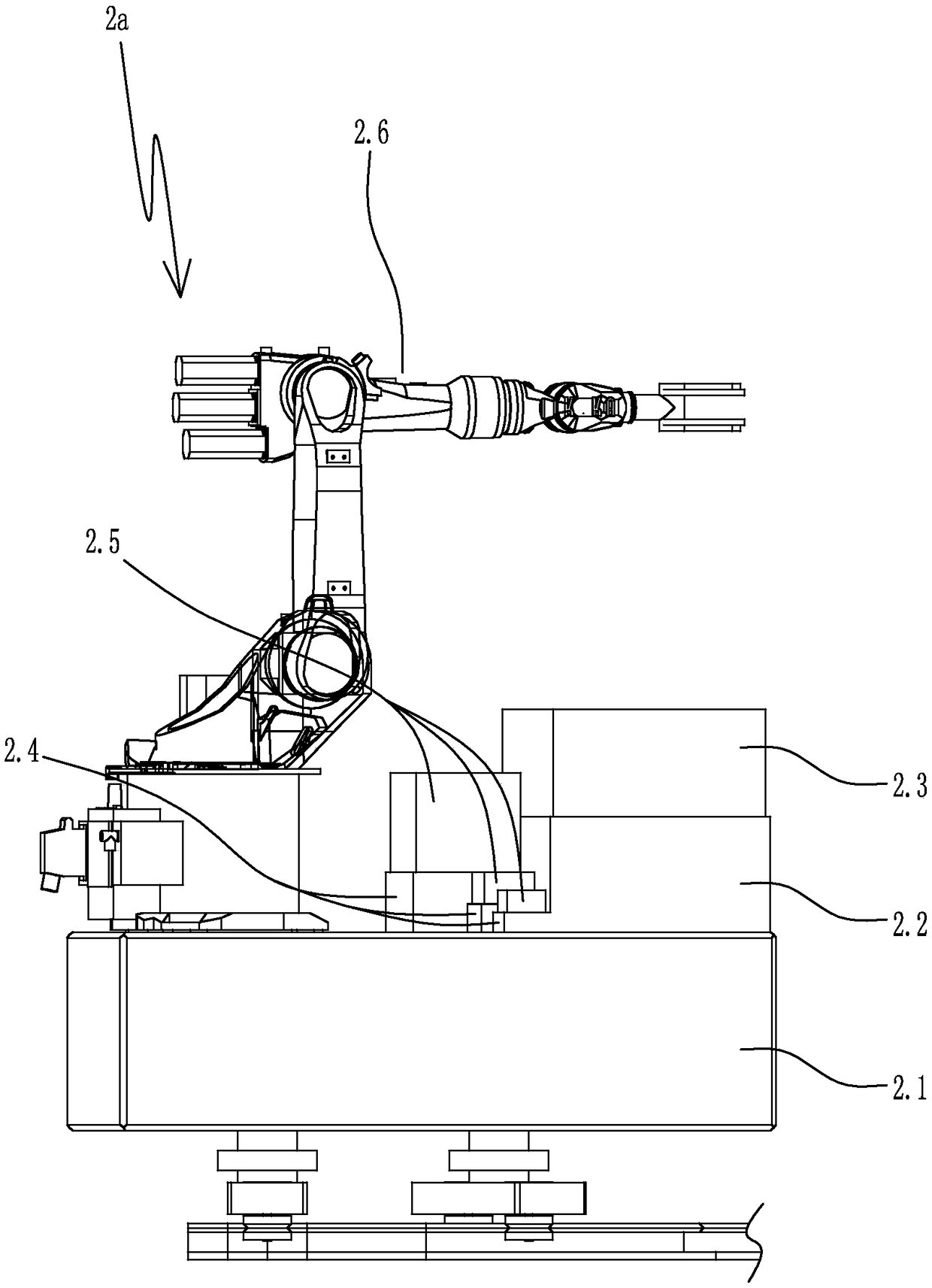

Automatic batching system for laboratory

InactiveCN109178747AWell mixedRealize automatic batchingMixer accessoriesStorage devicesAutomatic testingLaboratory facility

The invention discloses an automatic batching system for a laboratory, and aims to provide the automatic batching system for the laboratory to assist laboratory staff in automatic completion of selection and weighing of materials during batching, uniformly mix the selected materials and therefore realize the automatic batching. The system comprises a material storage area, a batching and conveyingtrolley and a batching area, wherein a walking track and a plurality of material storage racks arranged along the walking track are arranged in the material storage area; the batching and conveying trolley comprises a trolley body which walks along the walking track, a material storage box supporting platform arranged on the trolley body, a material storage box supported on the upper surface of the material storage box supporting platform, at least two metering box supporting platforms arranged on the trolley body, metering boxes and a trolley mechanical arm, wherein the metering boxes are supported on the metering box supporting platforms in a one-to-one correspondence mode, and the trolley mechanical arm is arranged on the trolley body; and a mixer and a batching mechanical arm are arranged in the batching area.

Owner:哈工大机器人义乌人工智能研究院

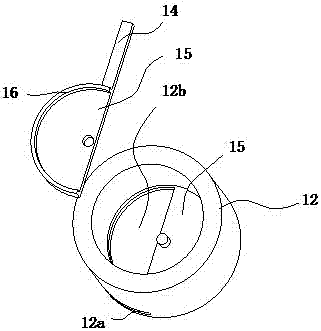

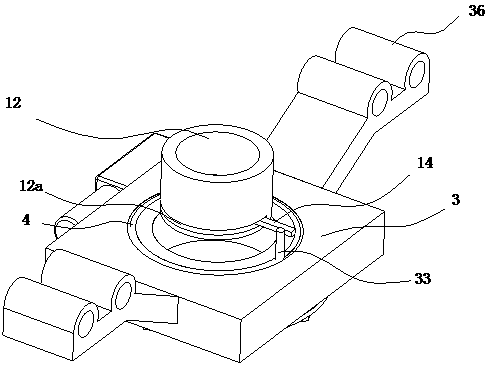

Automatic batching device for synthetic leather processing

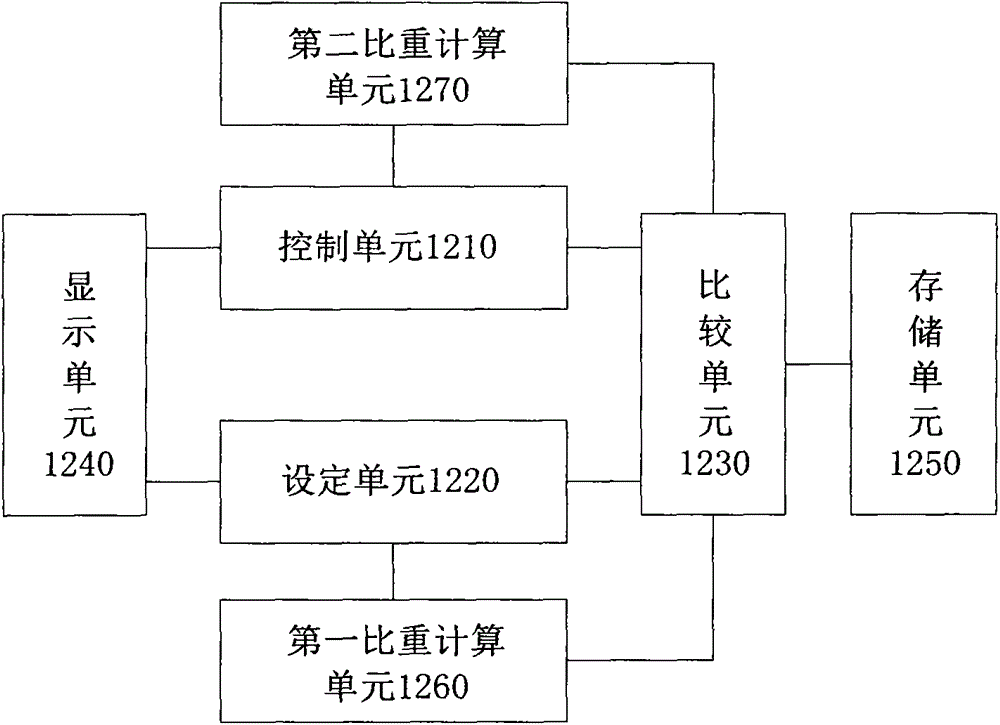

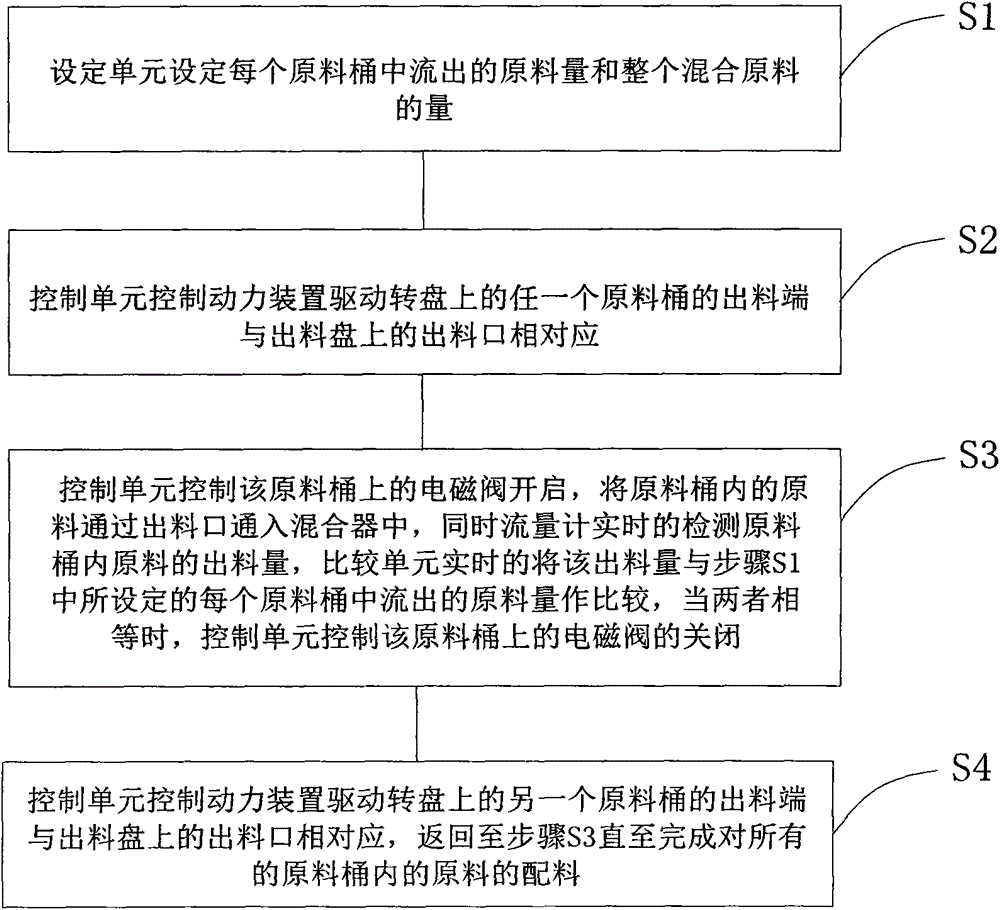

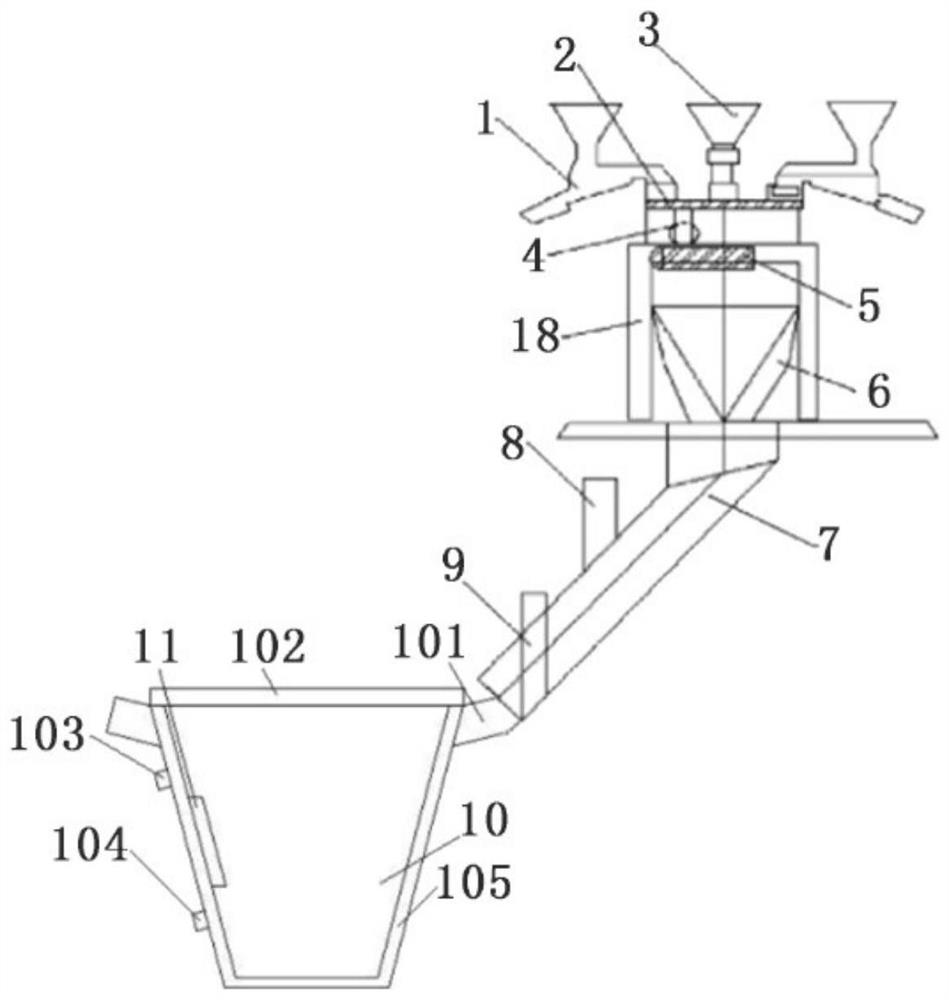

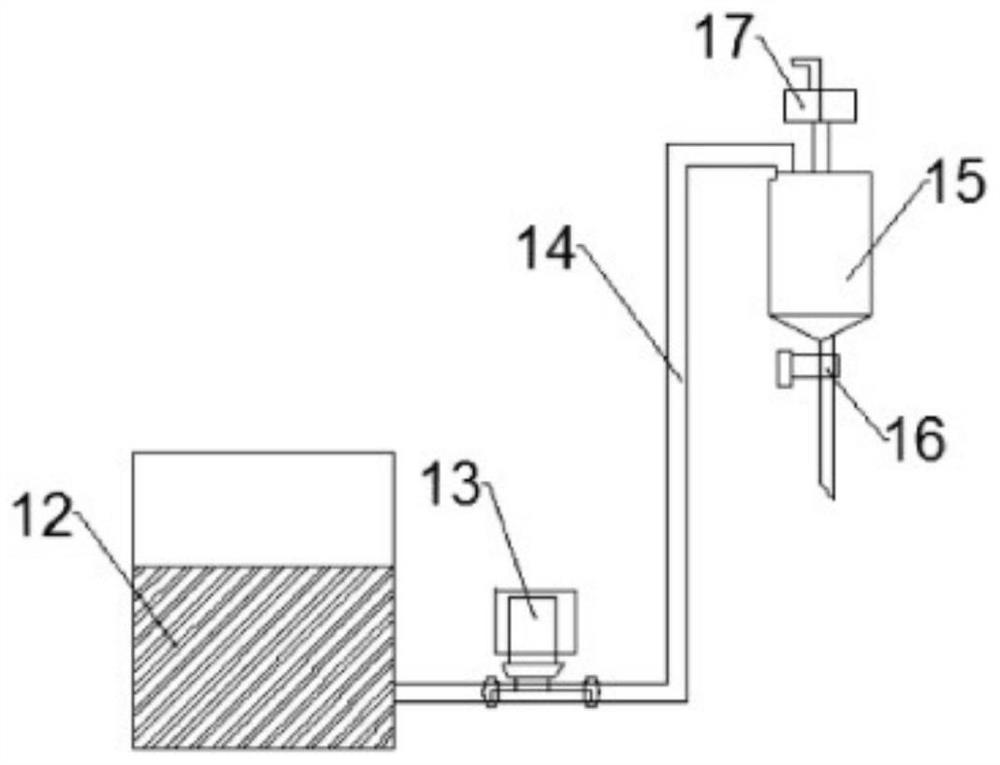

The invention relates to the technical field of automatic synthetic leather material matching, and discloses an automatic material matching apparatus and a method for synthetic leather processing. The apparatus comprises a rotatable rotation disk, a power device for driving the rotation disk to rotate, a plurality of raw material barrels arranged in the circumferential direction of the rotation disk, electromagnetic valves and flow meters arranged on the material outlet ends of each raw material barrel, a material outlet disk arranged below the rotation disk, a material outlet arranged on the material outlet disk and corresponding to the material outlet end of the raw material barrel, a mixer arranged on the lower end of the material outlet disk, an electronic scale for installing the mixer, a material matching barrel communicated with the mixer, and a controller connected with the electromagnetic valves, the flow meters, the electronic scale and the power device. The automatic material matching apparatus has advantages of high material matching efficiency, low error and low cost.

Owner:ZHEJIANG M&F CHEM

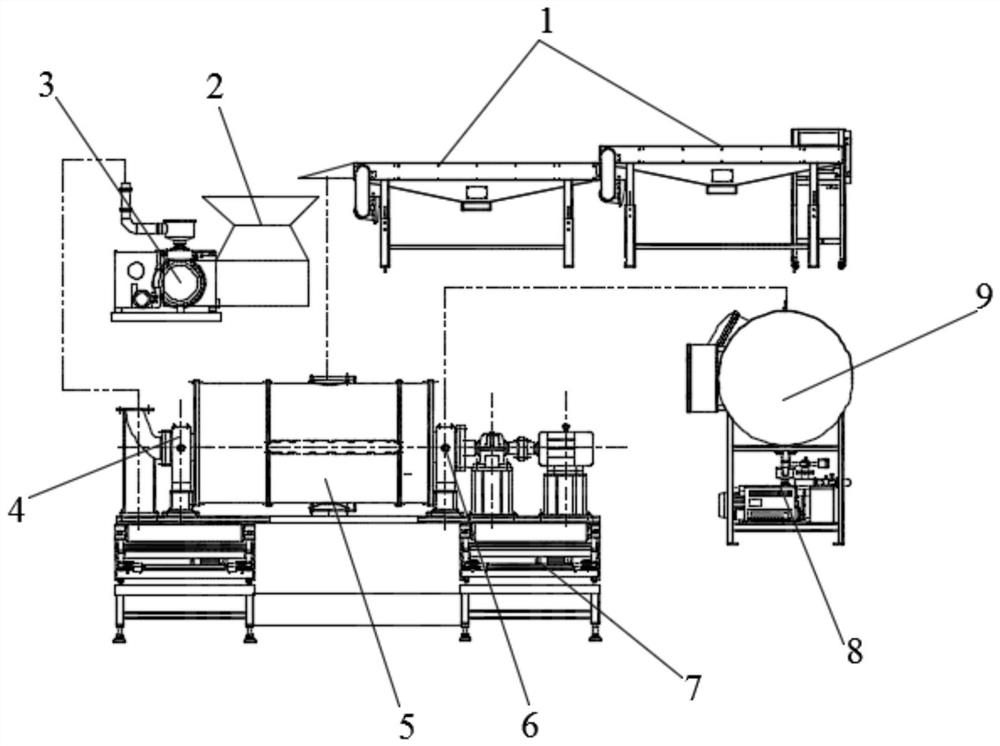

Production method of prefabricated members for prefabricated buildings

InactiveCN110978247ARealize automatic batchingImprove batching efficiencyCeramic shaping plantsConstruction engineeringStructural engineering

The invention discloses a production method of prefabricated members for prefabricated buildings. The method comprises the following steps: 1, a design drawing of a target prefabricated member is obtained, wherein materials required for producing the target prefabricated member are recorded in the design drawing; 2, the quantity of the materials required for producing the target prefabricated member is further calculated according to the size of the target prefabricated member recorded in the design drawing; 3, the materials of the quantity are further distributed to the production system according to a preset rule to produce the target prefabricated member, so that the target prefabricated member is produced, the quantity of the materials required for producing the target prefabricated member is calculated on the basis of the size of the target prefabricated member recorded in the design drawing, the materials of the quantity are distributed to a production system according to the preset rule, and the target prefabricated member is produced. Automatic batching of the production system can be achieved, and batching efficiency is improved on the basis of improvement of batching efficiency.

Owner:HUBEI HUBEI GUANGSHENG CONSTR GRP CO LTD

Batching method, batching machine and storage medium

ActiveCN114749095AImprove experienceRealize automatic batchingTransportation and packagingMixer accessoriesBatch operationProcess engineering

The invention discloses a batching method, a batching machine and a storage medium, relates to the field of intelligent control, and mainly aims to improve the batching efficiency of a seasoning combination during dining, guarantee the overall taste of seasonings after batching and enhance the user experience, and the method comprises the following steps: obtaining a to-be-executed seasoning combination and a corresponding blending proportion thereof; according to the blending proportion, the seasoning category which is executed or set firstly in the seasoning combination and the corresponding discharging amount, the remaining seasoning categories in the seasoning combination and the corresponding discharging amount are determined; and according to the seasoning category which is firstly executed or firstly set, the corresponding blanking amount of the seasoning category, the residual seasoning category and the corresponding blanking amount of the residual seasoning category, executing the batching operation of the seasoning combination. The device is suitable for automatically preparing the seasoning combination during dining.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

Batching method, batching machine and storage medium

ActiveCN112493897ASatisfy special taste needsImprove experienceData processing applicationsCooking vesselsBatch operationProcess engineering

The invention discloses a batching method, a batching machine and a storage medium, relates to the field of intelligent control, and mainly aims to improve the batching efficiency of seasoning combination, ensure that batched dishes meet the special taste requirements of users and enhance the user experience. The method comprises the following steps: acquiring a basic seasoning combination and anadditional seasoning combination to be executed, and a first blending proportion between the basic seasoning combination and the additional seasoning combination; determining the actual blanking amount corresponding to the seasoning combination which is firstly executed or firstly set in the basic seasoning combination or the additional seasoning combination; according to the first blending proportion and the actual blanking amount, determining the blanking amount of the other seasoning combination in the basic seasoning combination and the additional seasoning combination; and according to the blanking amount corresponding to each seasoning combination, respectively executing the blanking operation of the basic seasoning combination and the additional seasoning combination. The method issuitable for batching operation of the basic seasoning combination and the additional seasoning combination.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

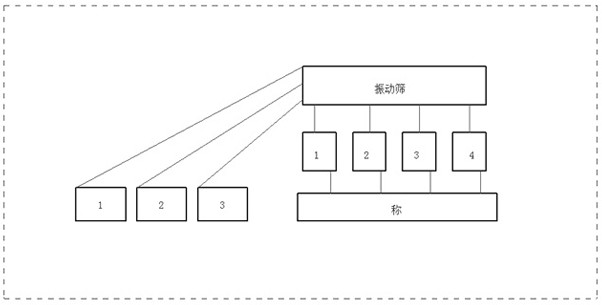

Feed dispensing equipment for culture

The invention discloses feed dispensing equipment for culture. The feed dispensing equipment comprises vibratory feeder, a limiting device and a feed dispensing box, wherein feed bins are fixedly mounted on upper surfaces of the vibratory feeders, loading plates are further fixedly mounted at lower ends of the vibratory feeders, an additive storage tank is arranged inside the limiting device, theright end of the additive storage tank is connected with a pipeline pump through a conduit, the right end of the conduit is connected with a weighing hopper, a weighing sensor is further arranged on the upper surface of the weighing hopper, and a charging opening is formed in one side of the feed dispensing box and is butted with one end of a discharge tube. According to the feed dispensing equipment, feed grains are uniformly stirred through the vibratory feeders, and uniform filtering is ensured through arranging a wide part inside the discharge tube; and meanwhile, through monitoring a temperature of the feed dispensing box, influence on quality of materials caused by a too high or too low temperature is avoided, the quality of feeding is improved, and the practicability is high.

Owner:湖南竟成农业有限公司

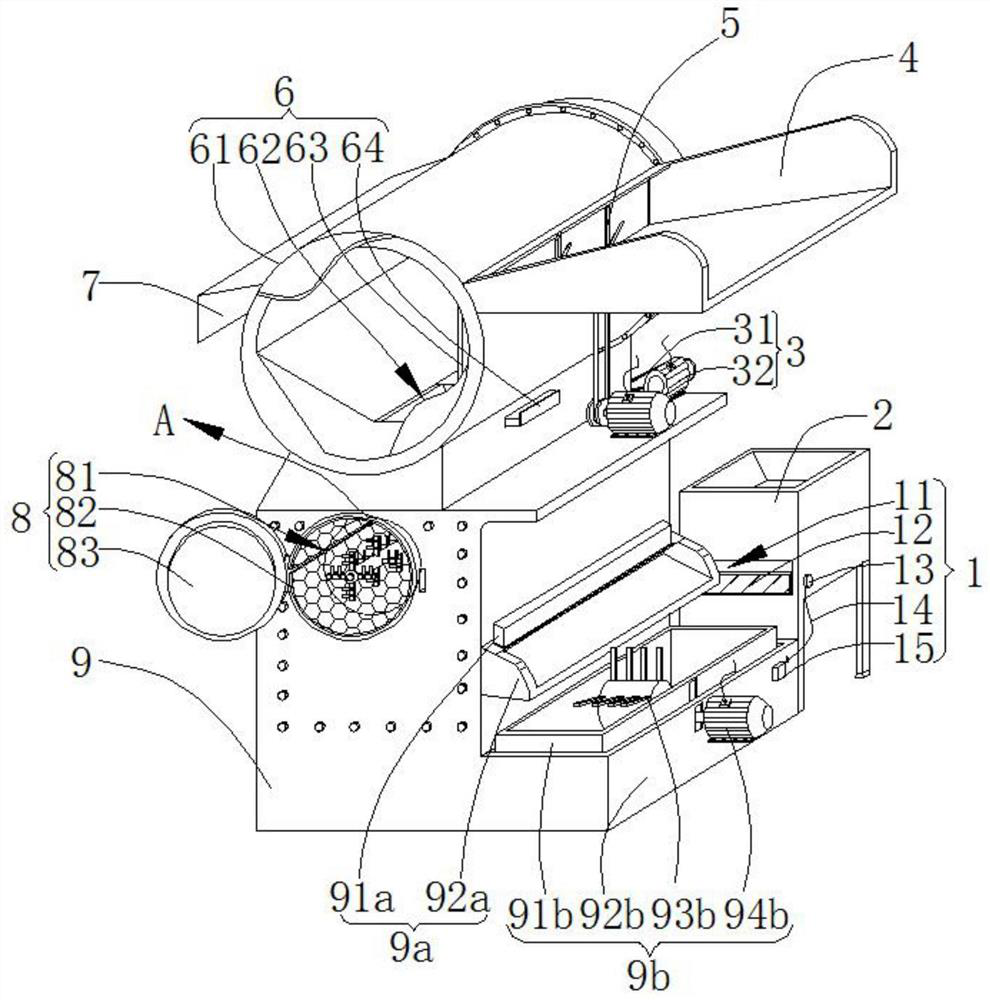

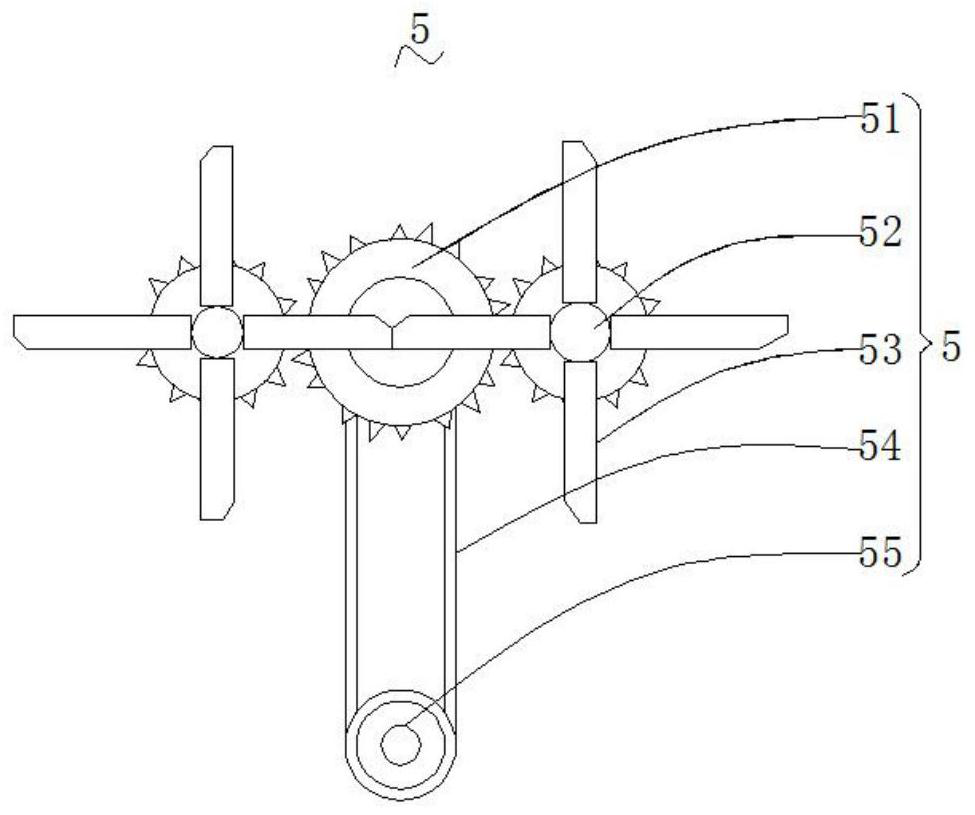

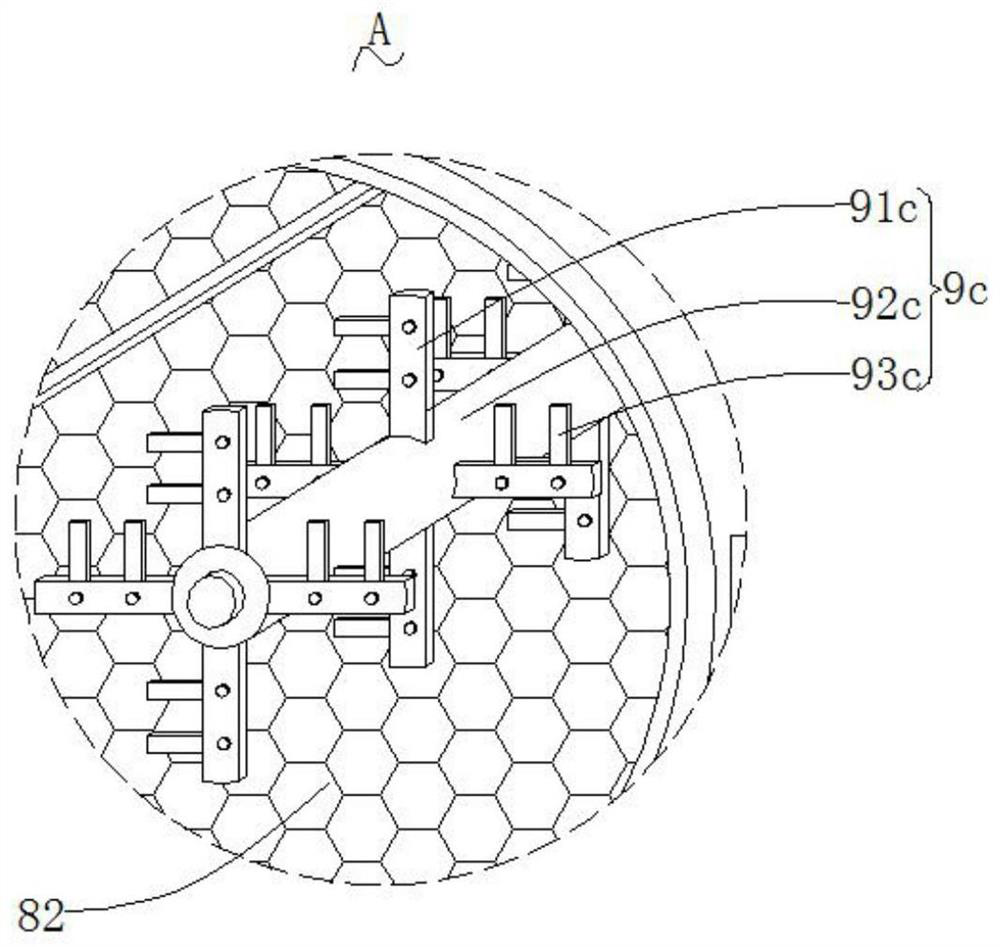

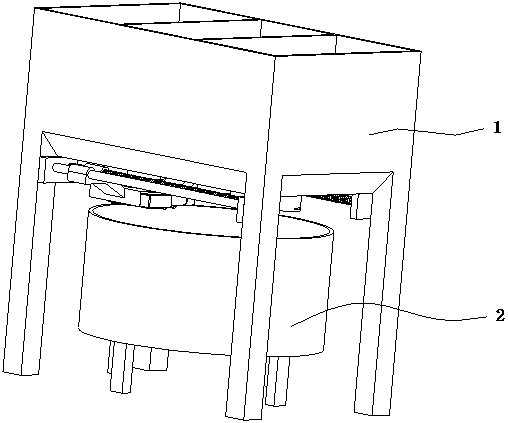

A corn stalk crushing device

ActiveCN108834584BIncrease diversityImprove crushing effectTransportation and packagingRotary stirring mixersGear wheelAgricultural engineering

The present invention relates to the field of straw crushing, specifically a corn straw crushing device, including a control mechanism, a feed bin, a driving mechanism, a feeding hopper, a first crushing mechanism, a first feeding mechanism, an ash hopper, a sealing mechanism, The body, the second feeding mechanism, the stirring mechanism, the second crushing mechanism and the connecting mechanism; the side wall of the leaning plate is rotated to connect two second gears, and the two second gears are meshed by the first gear, which increases the preliminary crushing of straw The comprehensiveness improves the crushing speed. The inclined feeding hopper is convenient for feeding and saves manpower. The inside of the crushing barrel is equipped with a material leakage port, and the initially crushed straw falls into the crushing box and is secondarily crushed. The crushing mechanism increases the effect of crushing and comprehensive crushing. After the second crushing, the straw powder flows from the second feeding mechanism to the inside of the mixing barrel and reaches a certain amount. After the internal spring of the connecting mechanism shrinks, the two copper pieces Electrical connection realizes automatic batching and saves manpower.

Owner:许美凤

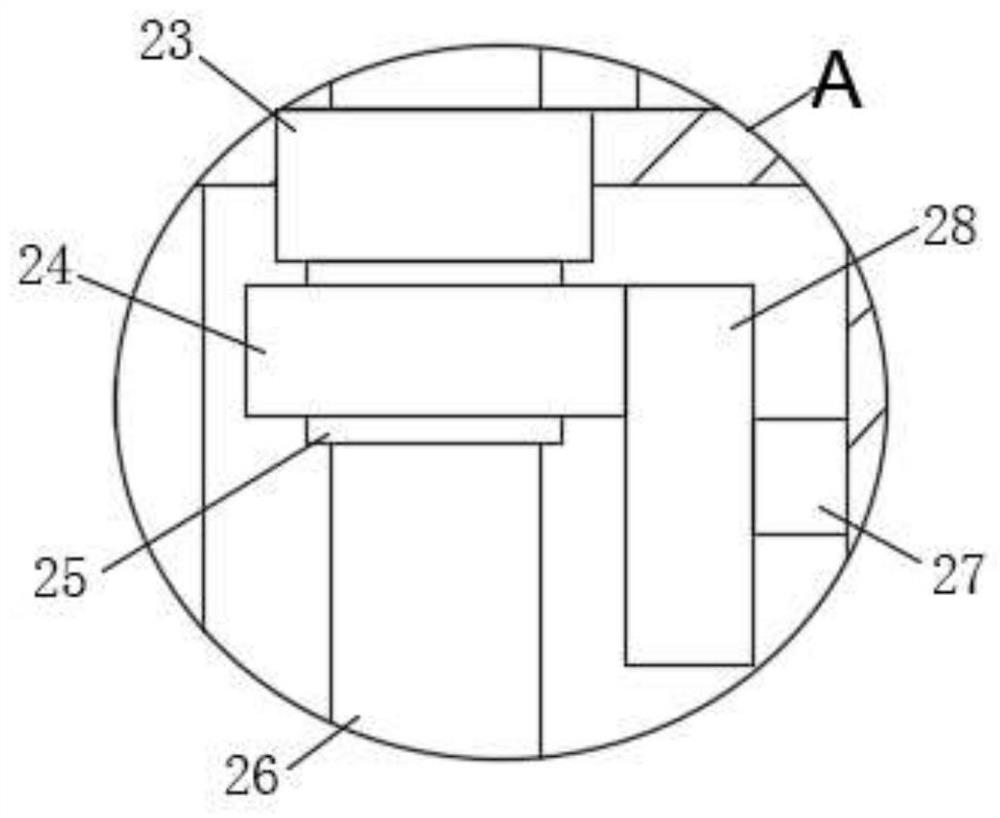

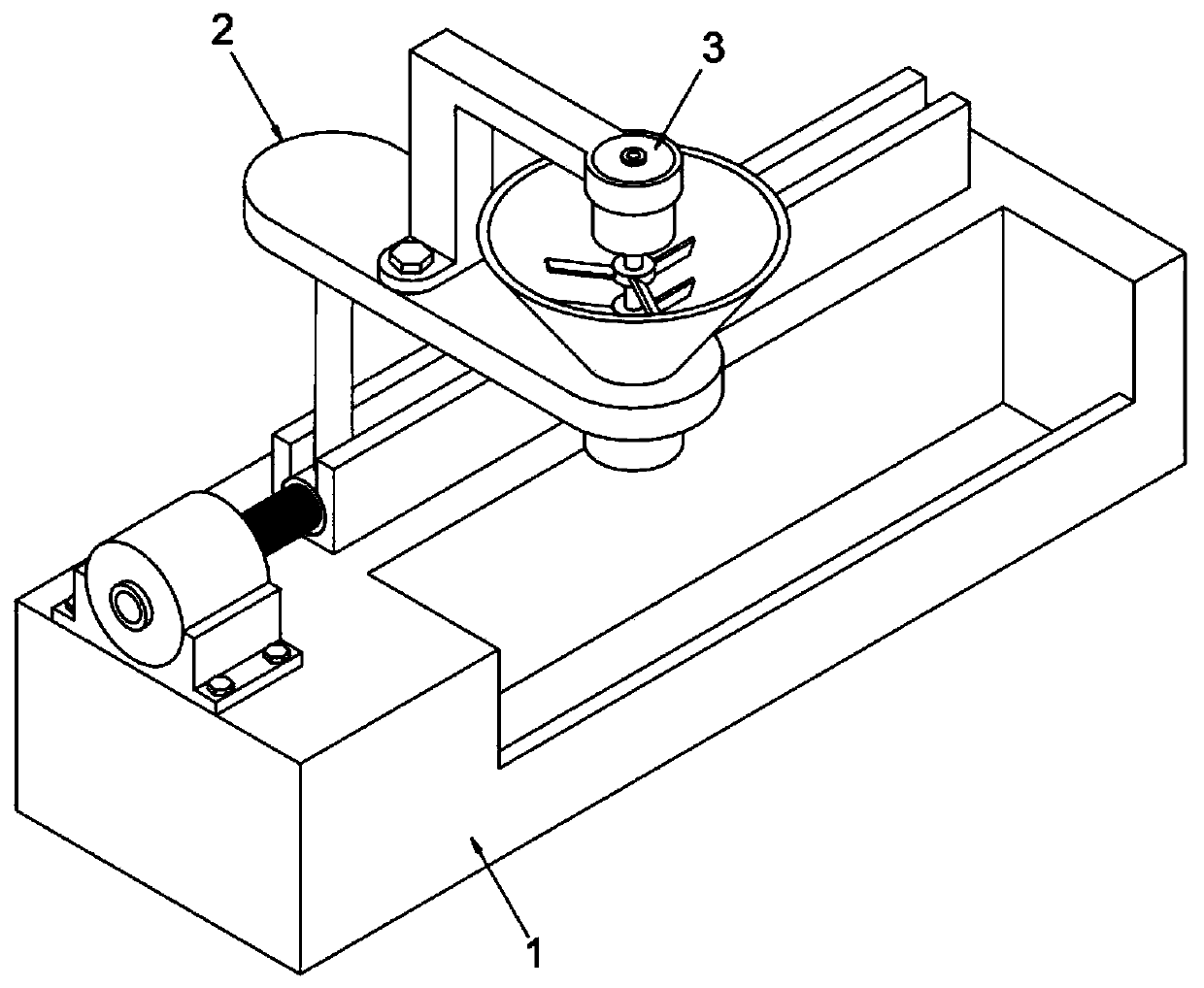

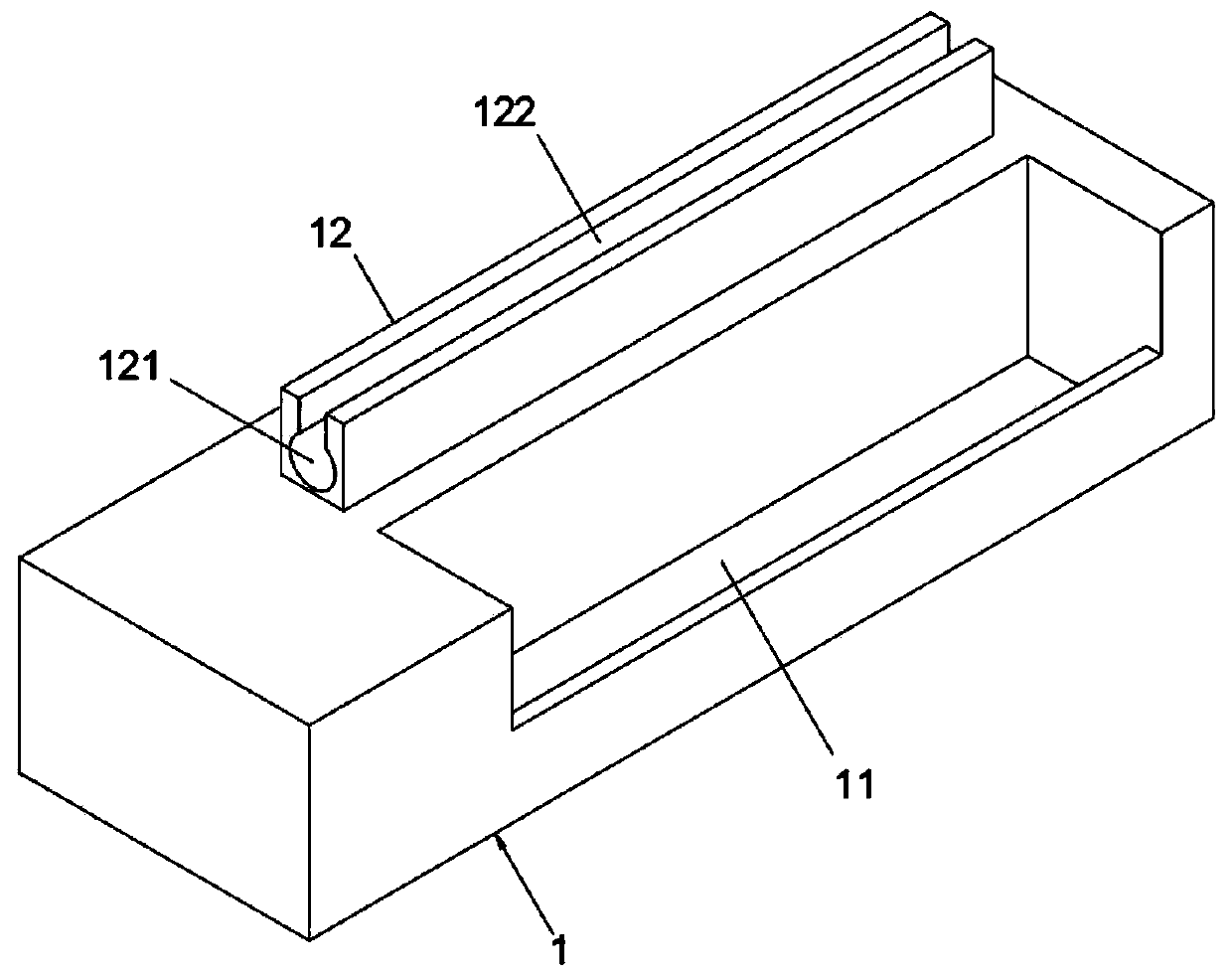

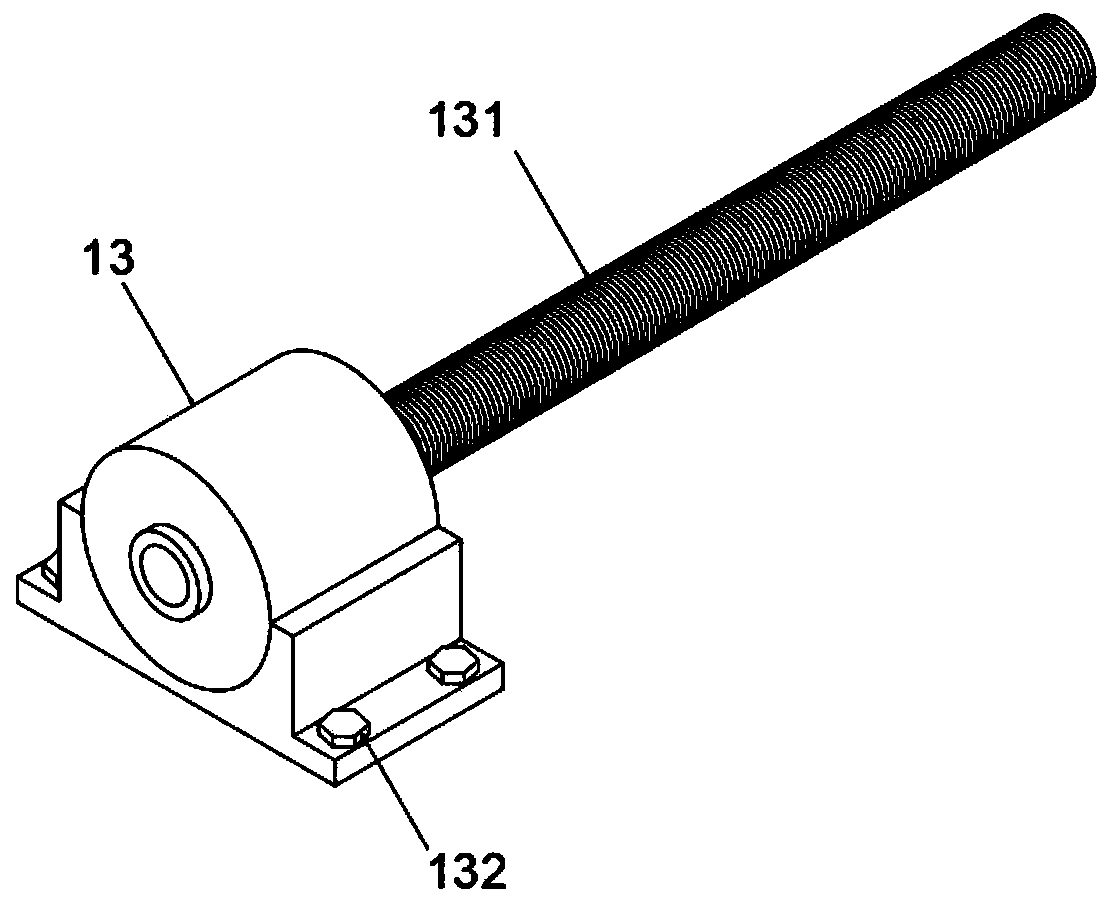

An automatic batching device for a sand mixer

InactiveCN107159838BQuality improvementRealize automatic batchingMould handling/dressing devicesStorage tankRaw material

The invention relates to the field of sand mixers, in particular to an automatic proportioning device of a sand mixer. The automatic proportioning device comprises a storage tank. A plurality of vertical partition plates are arranged in the storage tank. The space of the storage tank is divided into a plurality of storage spaces through the multiple vertical partition plates. A discharging pipe is arranged in the position, corresponding to each storage space, of the bottom of the storage tank. A semicircular opening is formed in the bottom of each discharging pipe, and a closable blocking plate is arranged at each opening. Feeding assemblies for opening the blocking plates are arranged in the positions, corresponding to the multiple discharging pipes, of the bottom of the storage tank. The sand mixer is arranged at the bottoms of the feeding assemblies. According to the automatic proportioning device, different required raw materials are poured into the different storage spaces, then the feeding assemblies at the bottom of the storage tank can open the blocking plates at the bottoms of the discharging pipes according to a set program, quantitative conveying of the raw materials is controlled according to the opening time of the blocking plates, thus, automatic proportioning is achieved, and the quality of finished products is improved. In addition, the invention further provides the sand mixer.

Owner:HEZE UNIV

Concrete production and preparation device for civil engineering

PendingCN113246309ARealize automatic batchingImprove automationMixing operation control apparatusIngredients proportioning apparatusConstruction engineeringStructural engineering

The invention discloses a concrete production and preparation device for civil engineering. Weighing of materials can be realized by arranging a weighing assembly, during preparation, the proportion control can be realized only by gradually controlling the adding amounts of a gravel conveying mechanism, a cement pumping mechanism and a slurry conveying mechanism according to a certain amount in sequence and according to a certain sequence, and automatic and accuracy of preparation are improved; and the weighing assembly is connected with a controller, the controller can control the conveying conditions of the gravel conveying mechanism, the cement pumping mechanism and the slurry conveying mechanism according to the weight change condition detected by the weighing assembly, and automatic batching is achieved.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

A kind of automatic batching method

ActiveCN108153340BReduce wasteGuaranteed productivity efficiencyControlling ratio of multiple fluid flowsProcess engineeringIndustrial engineering

The invention relates to an automatic batching method. Firstly, the original material is screened and weighed through a vibrating sieve, and the matching situation of each material contained in the original material is judged, and then according to the matching situation of each material contained in the original material, the amount of each material that the original material can provide in unit time and unit speed is calculated. The weight of the material, and finally, according to the material ratio of the target mixture to be proportioned, calculate the feeding speed and the overall transportation time required to transport each original material. The invention can realize automatic batching, and will not cause excess or shortage of certain materials in the target mixture due to the fact that the purity of the original material does not meet the specifications. The invention greatly reduces the possible waste caused by the mixing equipment , to ensure the production efficiency of the mixing equipment.

Owner:FUJIAN QUANCHENG MACHINERY

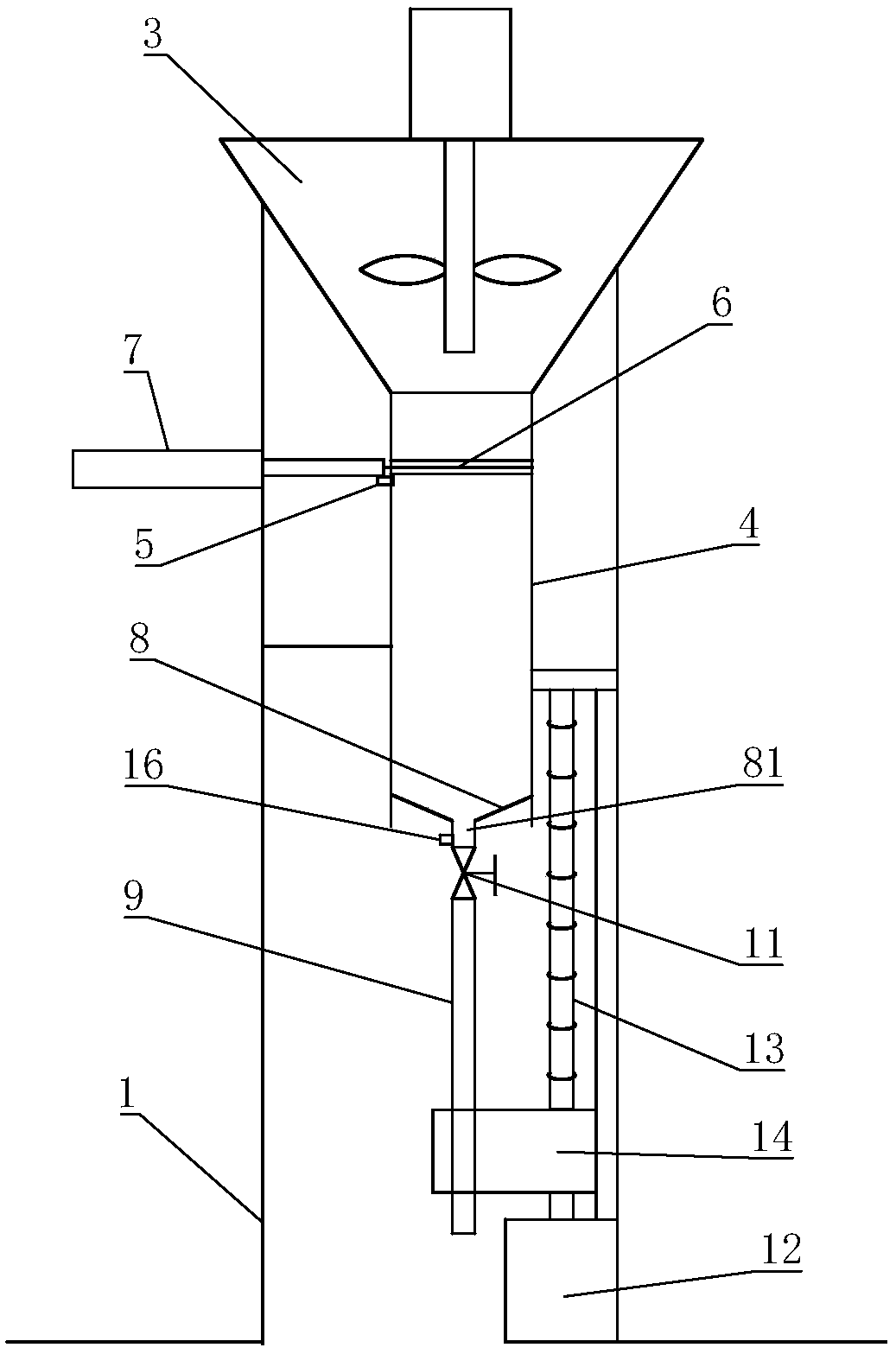

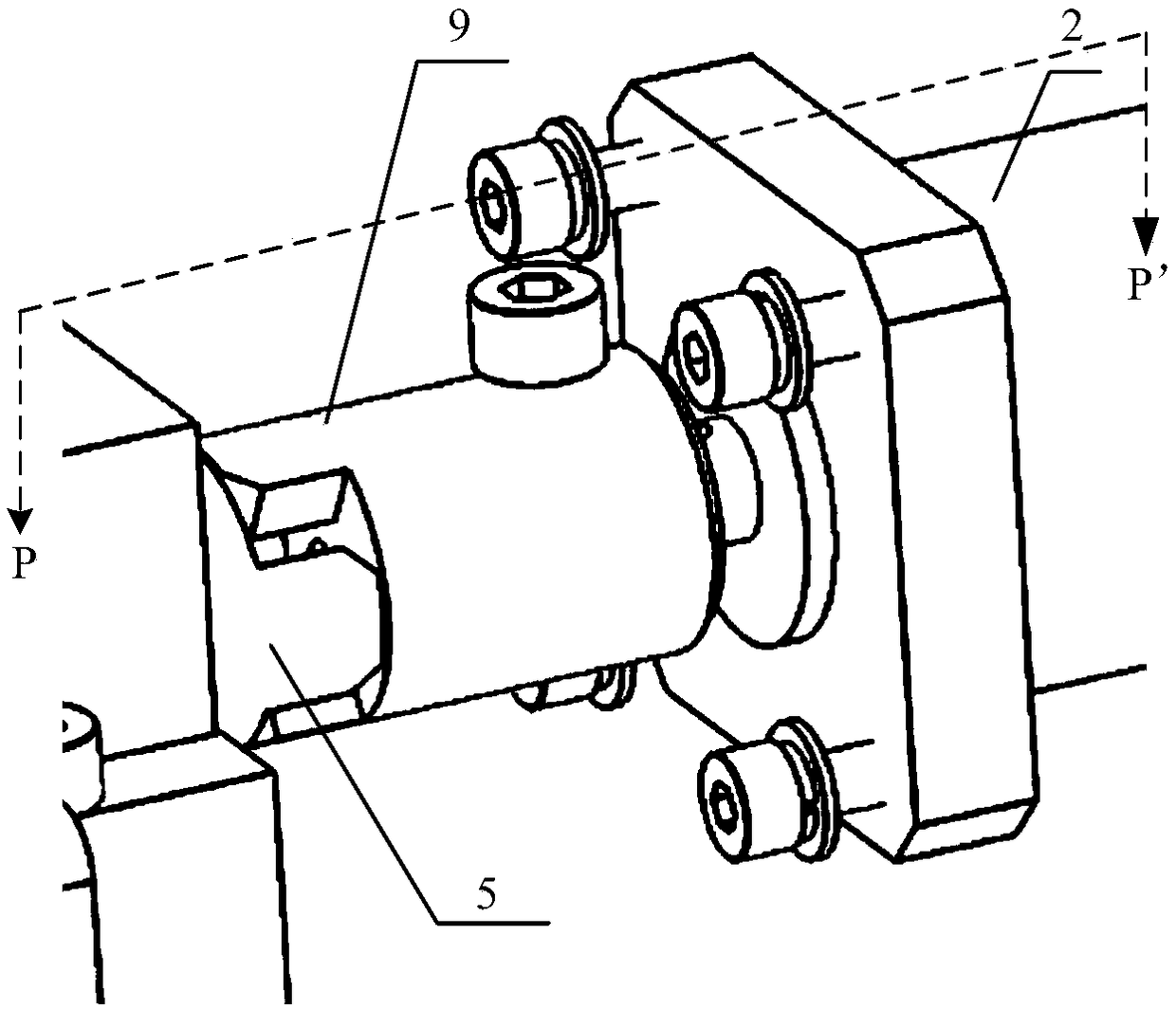

Accurate dosing and feeding device used for anchoring and shotcreting work

InactiveCN107542485ARealize automatic batchingSimple push principleUnderground chambersTunnel liningShotcreteTransverse groove

The invention discloses an accurate dosing and feeding device used for anchoring and shotcreting work. The device comprises a device body, a cavity is formed in the device body, the upper end of the cavity is communicated with the lower end of a transverse groove, the transverse groove is located in the upper end of the device body, two guiding plates are arranged on the left end of the transversegroove, two guiding plates are arranged on the right end of the transverse groove, the number of the guiding plates is four, one end of each guiding plate is fixedly connected to the top of the transverse groove, one side of the other end of each guiding plate is connected with one end of a guiding shaft through a first bearing, the middle of the outer side of each guiding shaft is sleeved with abelt pulley, the number of the belt pulleys is four, the two belt pulleys at the left end of the transverse groove are connected in a wound mode through a belt, and the two belt pulleys at the rightend of the transverse groove are connected in a wound mode through a belt. The belts drive containing grooves to move to achieve the feeding effect for the cavity; a user controls the feeding quantityaccording to a stirring progress, and therefore the mass of materials is increased; under the condition that no machines are additionally arranged, dosing and feeding are made matched each time, anddosing and feeding quantity is accurate.

Owner:童小芬

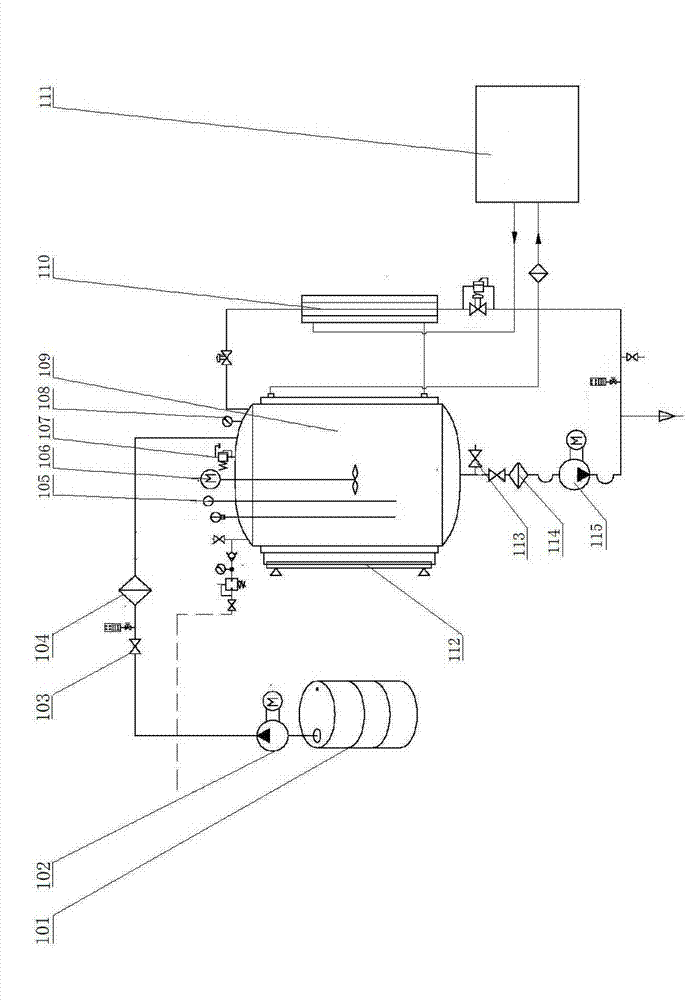

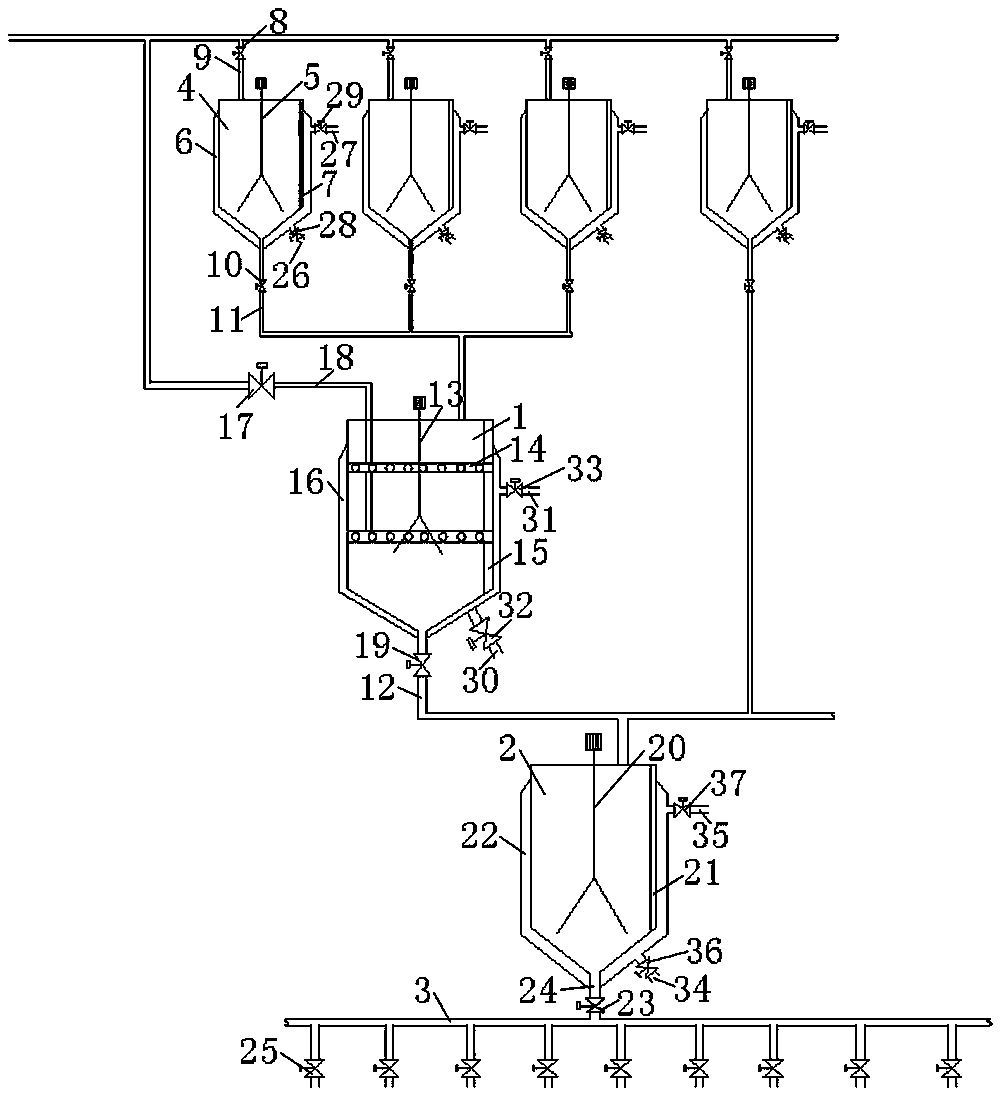

A sizing preparation system for producing continuous basalt fibers

The invention discloses an impregnating compound preparing system for producing continuous basalt fibers and relates to the field of inorganic nonmetallic material processing. The impregnating compound preparing system sequentially comprises a feeding system, a reaction tank, a mixing tank and a distribution pipe from top to bottom, wherein the feeding system comprises feeding tanks, stirring devices I, heating sleeves I, liquid level sensors I, water inlet pipes I and discharge pipes I, part of the discharge pipes I converges at the feed inlet of the reaction tank, and the rest of the discharge pipes I and a discharge pipe II converge at the feed inlet of the mixing tank; the reaction tank is provided with a stirring device II, a blowing ring, a liquid level sensor II, a heating sleeve II, a water inlet pipe II and the discharge pipe II; the mixing tank is provided with a stirring device III, a liquid level sensor III, a heating sleeve III and a discharge pipe III, and liquid level sensors and valves are connected with a PLC. The impregnating compound preparing system has the advantages that optimal dissolving and reaction temperature is provided for an impregnating compound, the impregnating compound is directly conveyed into a draw bench, automatic preparation is achieved, and the production efficiency and quality of the basalt fibers are increased.

Owner:郑州登电玄武石纤有限公司

Batching method, batching machine and storage medium

ActiveCN112493897BSatisfy special taste needsImprove experienceData processing applicationsCooking vesselsBatch operationProcess engineering

The invention discloses a batching method, a batching machine and a storage medium, and relates to the field of intelligent control, mainly aiming at improving the batching efficiency of seasoning combinations, ensuring that the dishes after batching meet the special taste requirements of users, and enhancing user experience. The method includes: obtaining the basic seasoning combination and the additional seasoning combination to be executed, and the first blending ratio between the basic seasoning combination and the additional seasoning combination; determining the most basic seasoning combination or the additional seasoning combination The actual cutting amount corresponding to the first-executed or first-set seasoning combination; according to the first deployment ratio and the actual cutting amount, determine the basic seasoning combination and the other seasoning combination in the additional seasoning combination Amount of feeding: according to the amount of feeding corresponding to each of the seasoning combinations, the feeding operations of the basic seasoning combination and the additional seasoning combination are respectively performed. The invention is suitable for batching operation of basic seasoning combination and additional seasoning combination.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

A method and system for the synergistic preparation of nickel sulfate by ammonia-enhanced laterite ore reduction calcined pulp method for desulfurization and nitric acid

ActiveCN111187921BPromote absorptionRealize desulfurization and denitrificationProcess efficiency improvementReaction rateSulfate

The invention discloses a method and a system for synergistically preparing nickel sulfate through ammonia-enhanced laterite ore reduction calcined pulp method for desulfurization and nitric acid. The method comprises the steps of pulp preparation, complexation leaching, solid-liquid separation of pulp and preparation of nickel sulfate. The invention adopts ammonia-enhanced laterite ore reduction calcined ore pulp method to desulfurize and nitricate synergistically to prepare nickel sulfate, convert sulfur dioxide in waste gas into ammonium sulfate solution to leach laterite nickel ore, and the leached solution can complex and adsorb nitrogen compounds to achieve denitrification The whole process couples multiple processes to achieve the effect of multi-objective realization, which has the advantages of high leaching rate, reduced energy consumption and labor intensity, high resource utilization rate, and good economic benefits. The reaction chamber of the system of the present invention can effectively improve the reaction rate; the system of the present invention can realize automatic batching, feeding and discharging functions, and can automatically perform leaching treatment and subsequent precipitation treatment, and the operation is very convenient.

Owner:KUNMING UNIV OF SCI & TECH

Bottle internally provided with ingredients

PendingCN109775123AAvoid manual processingImprovement ingredientsBottlesClosure with auxillary devicesAdditive ingredientBottle neck

The invention provides a bottle internally provided with ingredients and relates to the technical field of storing bottles mainly in order to solve the technical problem that a common bottle cannot beused for automatic material matching. The bottle neck inner side of the bottle internally provided with the ingredients is provided with an annular clamping groove and an ingredient bin connected with the clamping groove and internally provided with the ingredients; the bottom of the ingredient bin is provided with a hanging part and an easy-to-tear portion which comprises a tearing and pulling strip and a tearing and pulling line; the tearing and pulling wire extends from the edge of the tearing and pulling strip to the other edge of the tearing and pulling strip, and therefore the tearing and pulling strip is divided into at least two areas; the hanging part is located on the outer side of the easy-to-tear portion; one end of the hanging part is connected with the clamping groove, and the other end of the hanging part is connected with the tearing and pulling strip; by pulling the hanging part, the easy-to-tear portion bears force, the tearing and pulling strip is driven to break the tearing and pulling line in a pulling manner; all or part of the areas of the tearing and pulling strip disengage from the ingredient bin so that the lower portion of the ingredient bin can be completely or partially opened. The bottle with the ingredients is provided.

Owner:康福永

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com