A corn stalk crushing device

A crushing device and technology of corn stalks, which are applied to mixers with rotating stirring devices, transportation and packaging, agricultural machinery and implements, etc., can solve the problems of inability to mix straw powder, increase feed process, waste time, etc., and save manpower , realize automatic batching, and increase the effect of comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

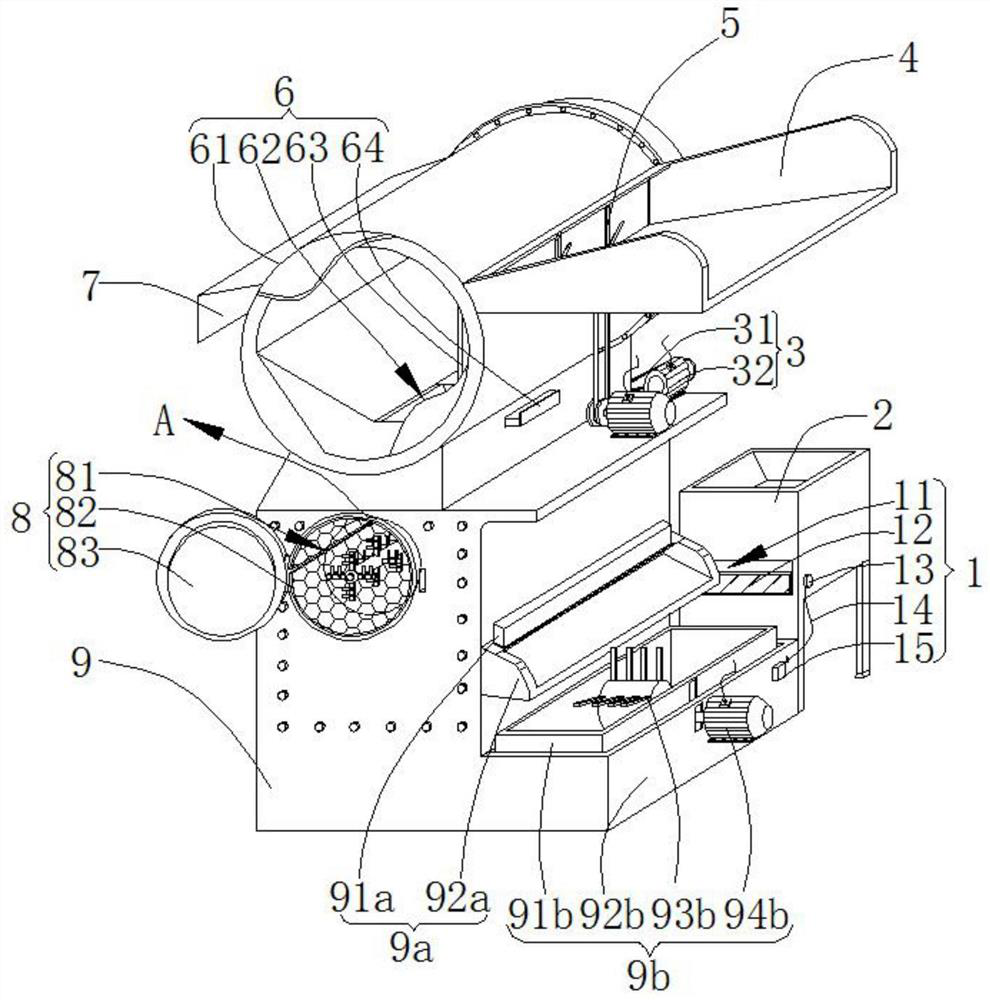

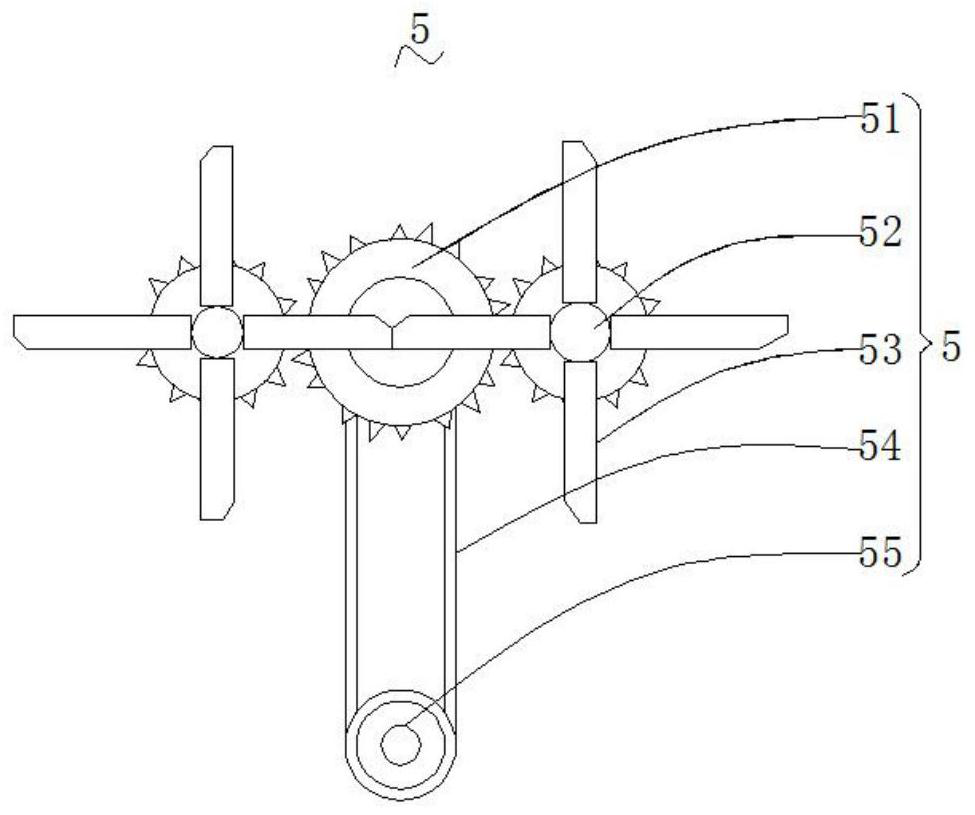

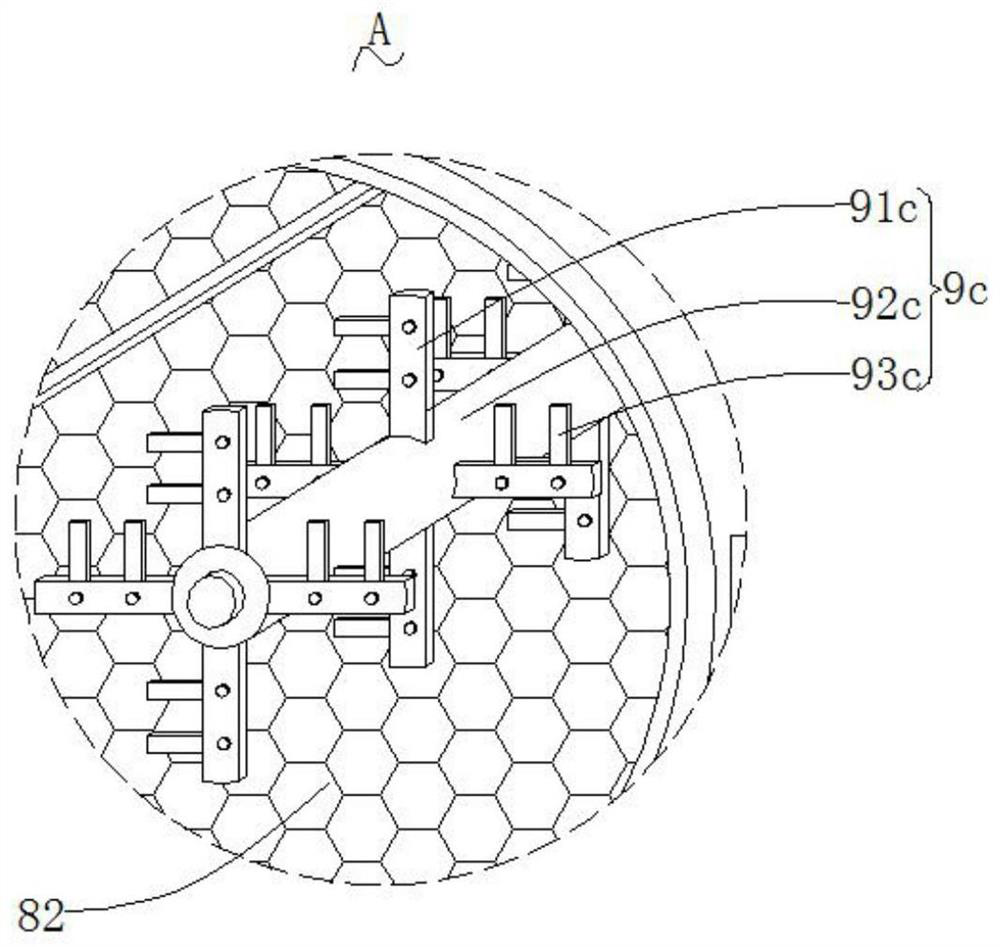

[0028] like figure 1 and Figure 4As shown, a corn stalk crushing device according to the present invention includes a control mechanism 1, a feed bin 2, a driving mechanism 3, a feeding hopper 4, a first crushing mechanism 5, a first feeding mechanism 6, and an ash hopper 7 , a sealing mechanism 8, a body 9, a second feeding mechanism 9a, a stirring mechanism 9b, a second pulverizing mechanism 9c, and a connecting mechanism 9d; the side wall of the first feeding mechanism 6 is obliquely provided with the feed hopper 4, The side wall of the first unloading mechanism 6 is provided with the ash hopper 7 for discharging dust generated by crushing straw, and the first pulverizer for preliminary crushing of straw is installed inside the first unloadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com