Blending and feeding integrated automatic feeding equipment for livestock rearing

An integrated, animal husbandry technology, applied in the field of machinery, can solve the problems of inconvenient batching and feeding, and achieve the effects of reducing labor intensity, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

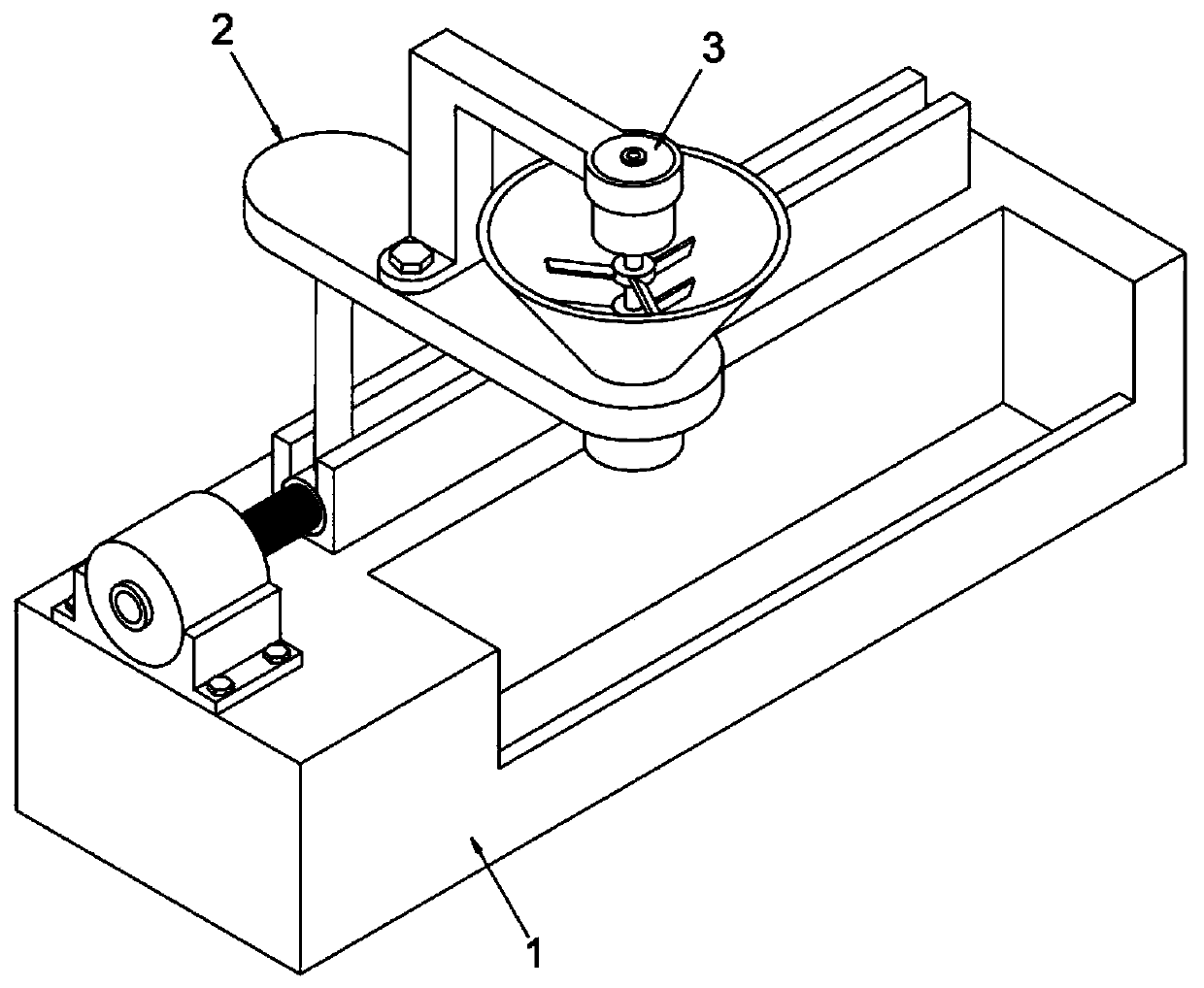

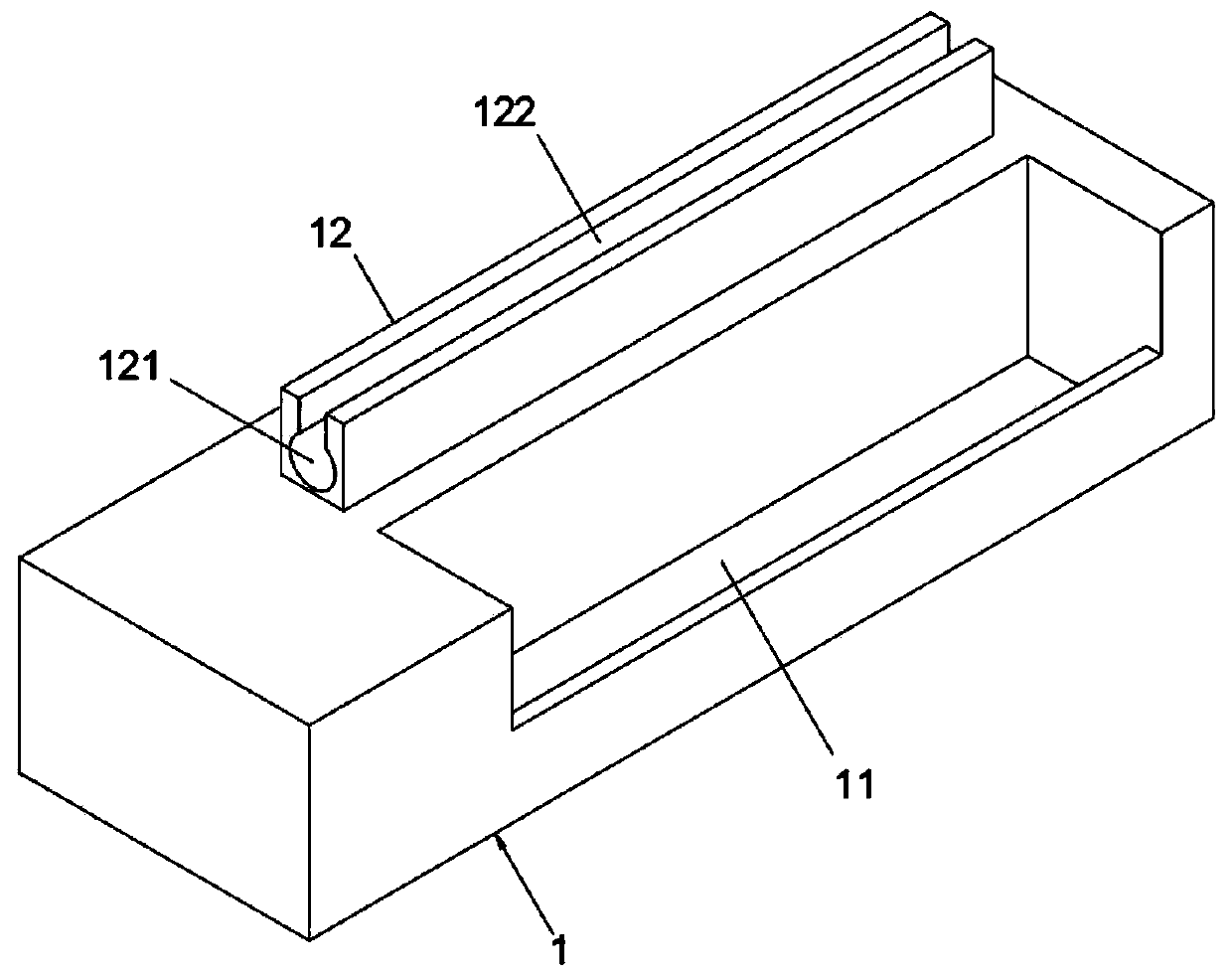

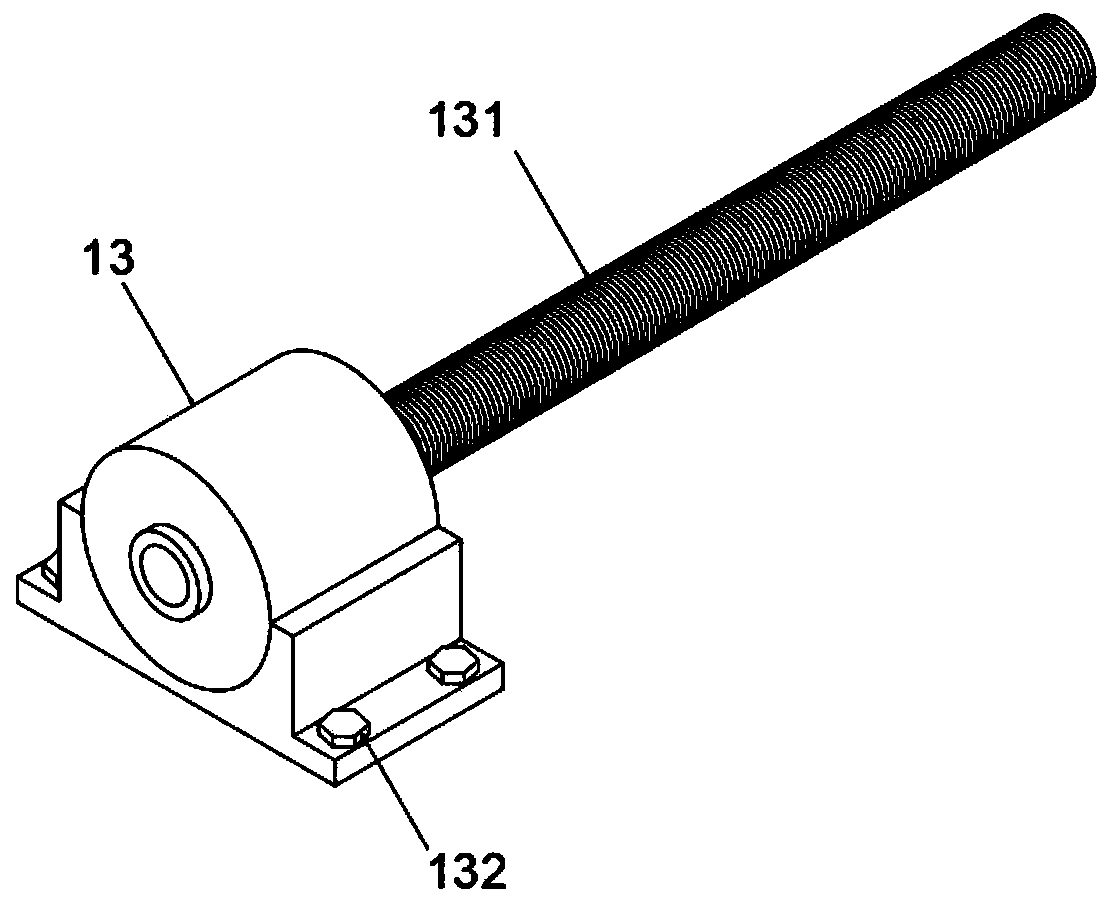

[0032] A batching and feeding integrated automatic feeding equipment for livestock, such as Figure 1-8 As shown, it includes a feeding platform 1, the front surface of the feeding platform 1 is provided with a feeding trough 11, and the upper surface of the feeding platform 1 is located at the side of the opening at the top of the feeding trough 11. The limit block 12 is tightly welded, and the limit block 12 is provided with the through hole 121 that is set horizontally, and the upper surface of limiting block 12 is provided with chute 122, and chute 122 communicates with through hole 121, and the upper surface of feeding platform 1 is positioned at the side of limiting block 12 and is provided with the first A motor 13, the output end of the first motor 13 is tightly welded with a screw rod 131;

[0033] A baffle plate 2 is arranged above the limit block 12, a pillar 21 is tightly welded to the lower surface of one end of the baffle plate 2, and a threaded pipe 211 is tight...

Embodiment 2

[0045] As the second preferred embodiment of the present invention, both sides of the first motor 13 are provided with mounting bolts 132, the first motor 13 is fixedly connected with the upper surface of the feeding table 1 by the mounting bolts 132, and the feeding table 1 A screw hole matching the mounting bolt 132 is provided on the upper surface, so that the mounting bolt 132 is screwed into the screw hole, so that the first motor 13 can be installed and fixed on the upper surface of the feeding platform 1 .

Embodiment 3

[0047] As the third preferred embodiment of the present invention, both sides of the vertical end of the L-shaped support rod 23 are provided with limit bolts 232, and the vertical end of the L-shaped support rod 23 connects with the upper end of the baffle plate 2 through the limit bolt 232. The surface is fixedly connected, and the upper surface of the baffle plate 2 is provided with a screw hole suitable for the limit bolt 232, so that the limit bolt 232 is threaded with the screw hole, which is convenient for installing and fixing the L-shaped support rod 23 on the bottom of the baffle plate 2. upper surface.

[0048] When the batching and feeding integrated animal husbandry automatic feeding equipment of the present invention is in use, a feeding trough 11 is provided on the feeding table 1, and a limit block 12 is welded on the upper surface of the feeding table 1, and a limit block 12 is provided on the limit block 12. A through hole 121 and a chute 122, and the chute 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com