An automatic batching device for a sand mixer

An automatic batching and sand mixer technology, which is applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., can solve the problems of heavy labor, difficult to grasp the proportion of ingredients, and affecting the quality of finished products, etc. , to improve the quality of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

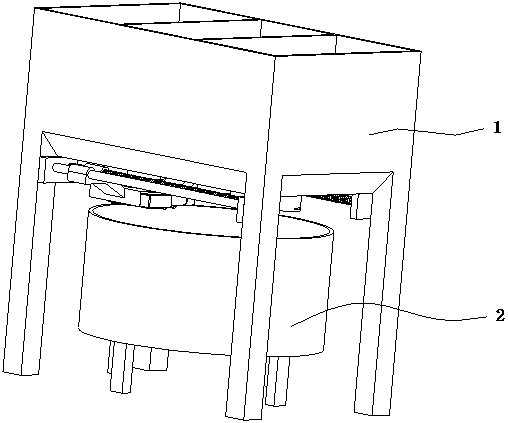

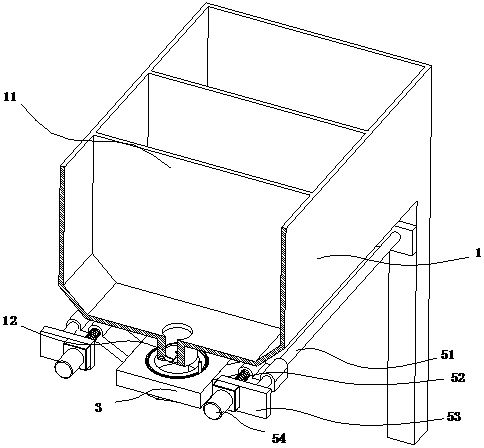

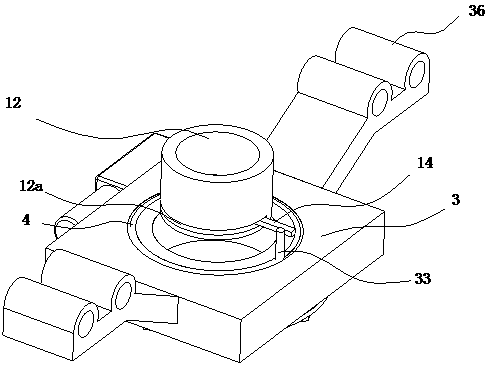

[0024] according to Figure 1 to Figure 7 The automatic batching device of a kind of sand mixer shown, comprises stock tank 1, and described stock tank 1 is provided with a plurality of vertical clapboards 11, and described multiple vertical clapboards 11 store material The space of the tank 1 is divided into a plurality of storage spaces, and the bottom of the storage tank 1 is provided with a discharge pipe 12 corresponding to each storage space, and the bottom of the discharge pipe 12 is provided with a semicircular opening 12b, The opening 12b is provided with a closable baffle plate 13, and the bottom of the storage tank 1 is provided with a feed assembly for opening the material baffle plate 13 corresponding to a plurality of discharge pipes 12, and the bottom of the feed assembly is A sand mixer 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com