A kind of automatic batching method

An automatic batching and material technology, applied in non-electric variable control, multiple fluid ratio control, instruments, etc., can solve the problems of waste, low production efficiency, and operator's ratio troubles, so as to reduce waste and ensure production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

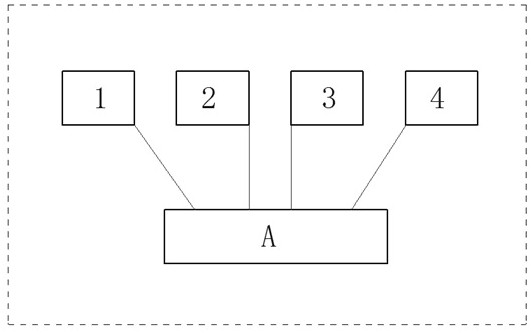

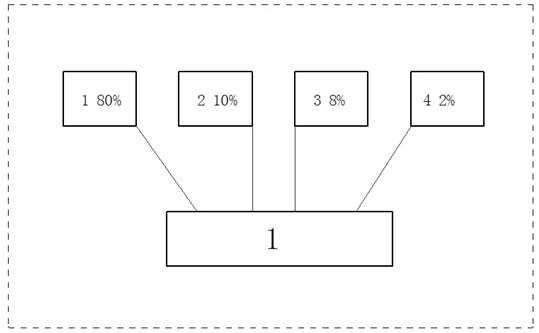

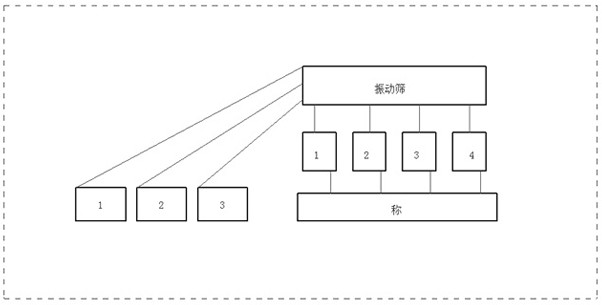

[0016] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0017] A kind of automatic batching method of the present invention comprises the following steps,

[0018] S1. Let the original material be N' 1 , N' 2 ,...,N' n , the weight of the target mixture N to be dosed is M, and the target mixture N consists of n kinds of materials N 1 , N 2 ,...,N n Composition, the ratio of each material is M 1 :M 2 :...:M n ; among them, M 1 , M 2 ,...,M n Respectively the weight of each material in the target mixture N, M=M 1 +M 2 +...+M n ;

[0019] S2. Calculation of the proportion of each material in the original material: since the original material is N' 1 , N' 2 ,...,N' n The purity of the product does not meet the specification, that is, the original material N' 1 , N' 2 ,...,N' n Both may be made of material N 1 , N 2 ,...,N n One or more components, so when batching the target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com