Automatic batching device for synthetic leather processing

An automatic batching and synthetic leather technology, applied in mixers, mixer accessories, dissolution, etc., can solve problems affecting product quality, complicated pipeline layout, and increased batching costs, so as to avoid complicated pipeline layout, reduce costs, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

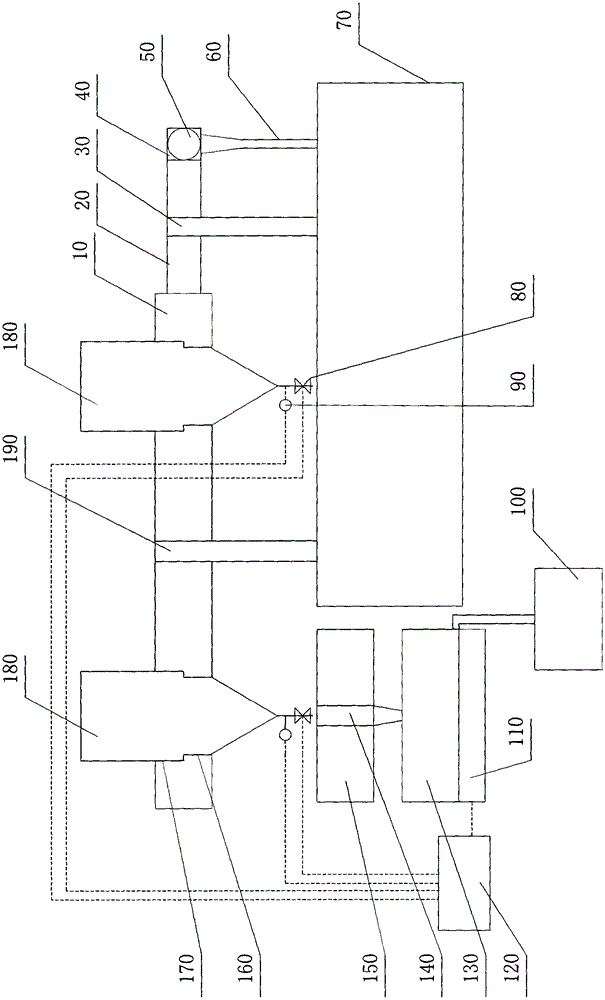

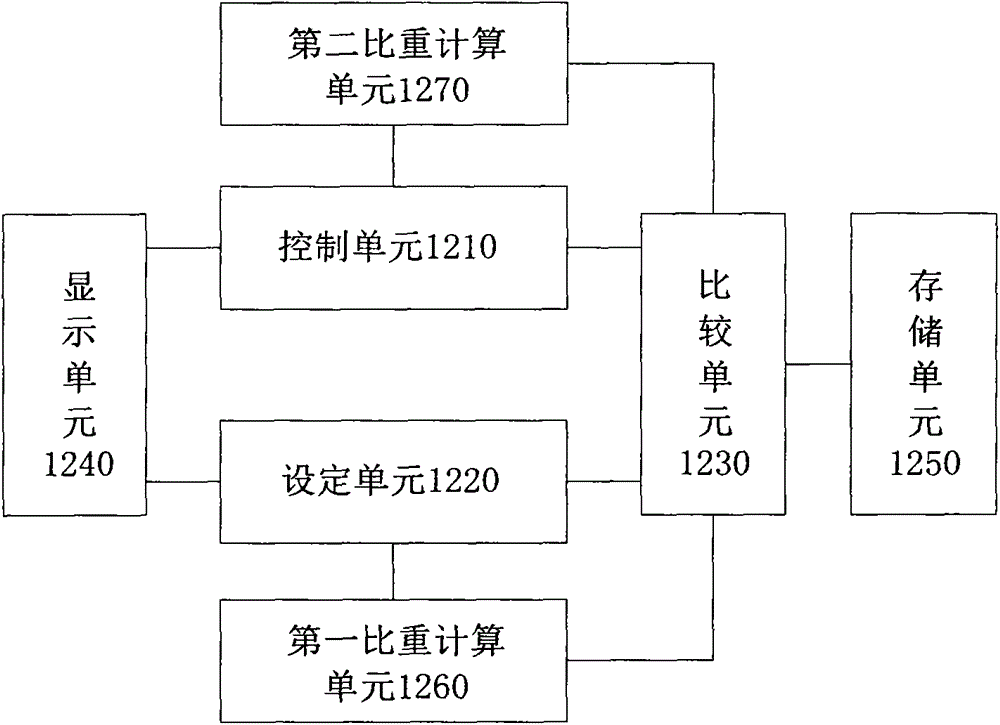

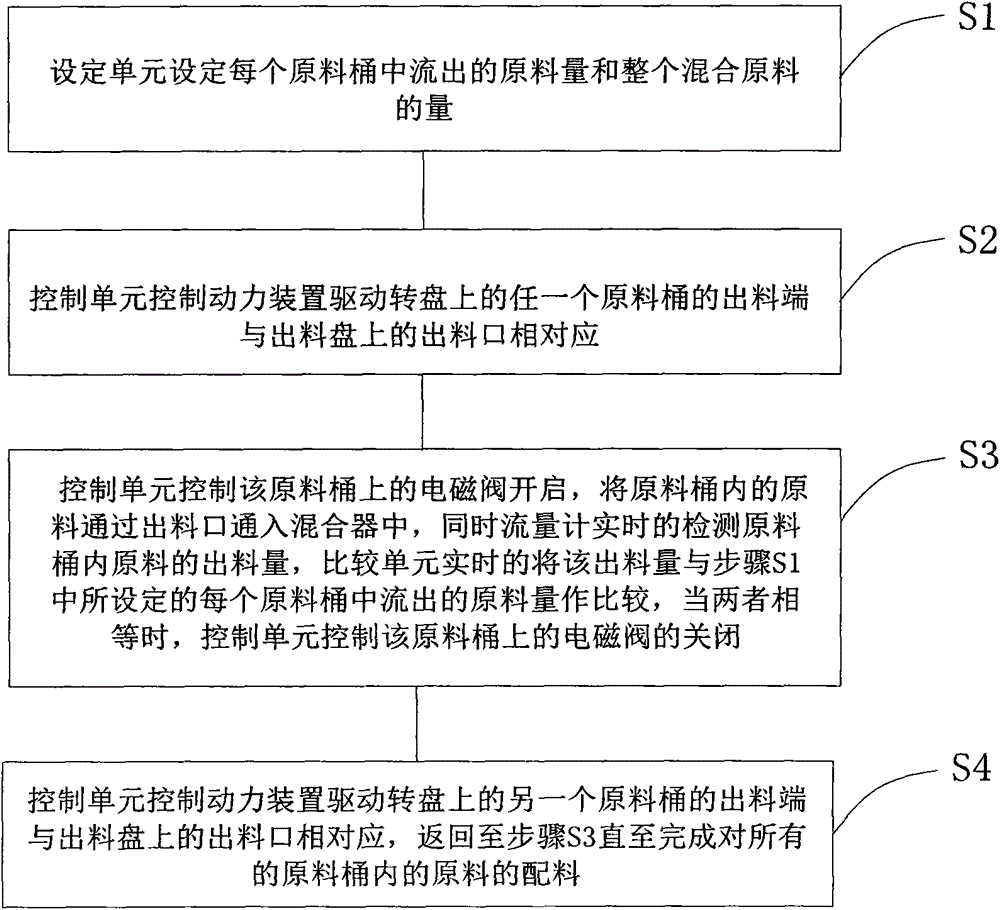

[0027] refer to figure 1 As shown, the automatic batching device for synthetic leather processing provided in this embodiment includes a rotatable turntable 10, a power device for driving the turntable 10 to rotate, and a plurality of raw material barrels 180 installed in the circumferential direction of the turntable 10, which are arranged on each The solenoid valve 80 and the flow meter 90 of the discharge end of each raw material bucket 180 are located at the discharge tray 150 below the turntable 10, and are located on the discharge tray 150 and are corresponding to the discharge port 140 of the discharge end of the raw material barrel 180, The mixer 130 that is located at the lower end of the discharge tray 150 is used to install the electronic scale 110 of the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com