A sizing preparation system for producing continuous basalt fibers

A technology of basalt fiber and sizing agent, which is applied in the field of sizing agent preparation system for producing continuous basalt fiber, can solve the problems of manpower consumption, reduced production efficiency of basalt fiber, complicated preparation operation, etc., and achieves the effect of improving production efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

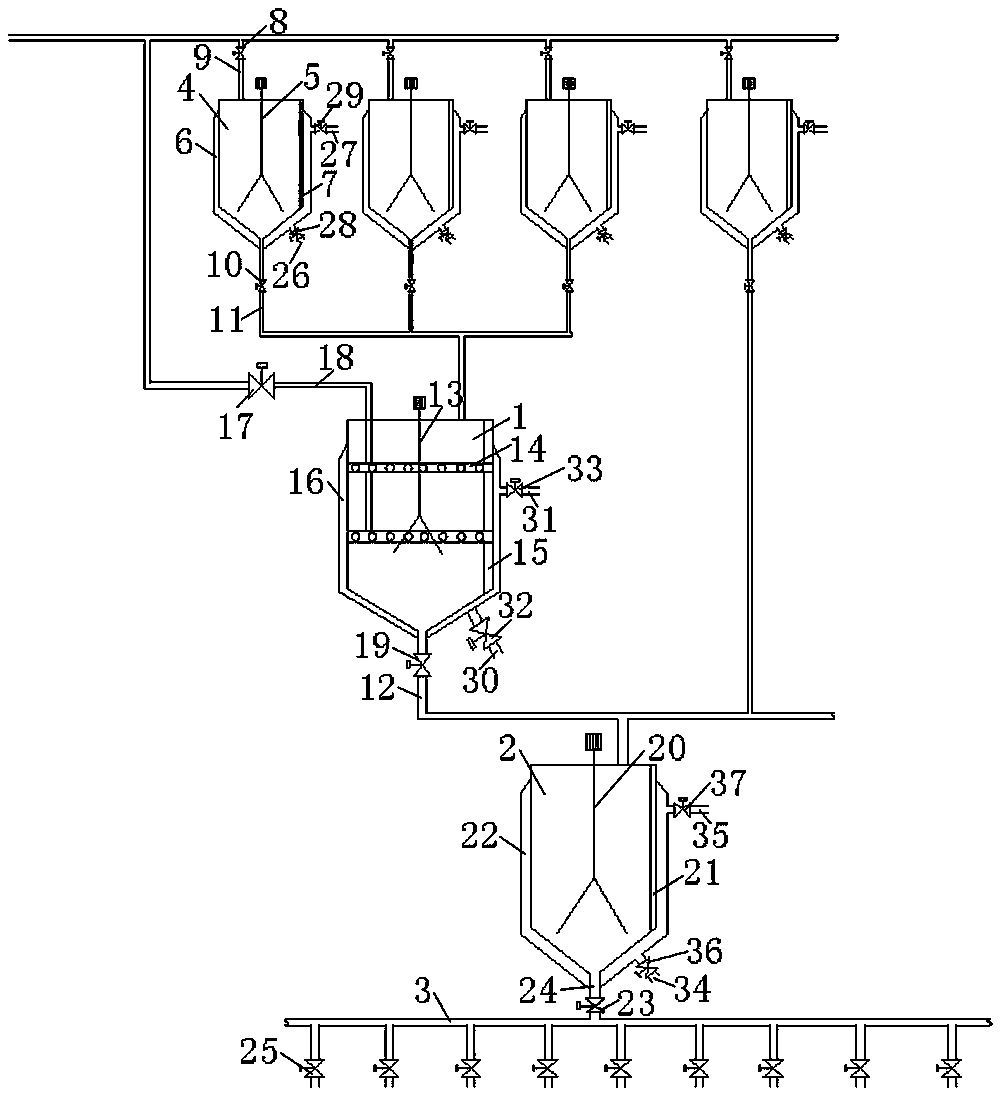

[0018] Such as figure 1 As shown, a sizing preparation system for producing continuous basalt fibers, from top to bottom is a feeding system, a reaction tank 1, a mixing tank 2 and a distribution pipe 3, and the feeding system is composed of a feeding tank 4, which is arranged on Stirring device Ⅰ5 in the feeding tank, heating jacket Ⅰ6 arranged outside the feeding tank, liquid level sensor Ⅰ7 installed in the feeding tank, water inlet pipe Ⅰ9 with valve Ⅰ8 installed on the feeding tank and discharge with valve Ⅱ10 The discharge pipe I11 of the n feeding tanks merges at the feed port of the reaction tank 1, n is an integer greater than or equal to 2, and the discharge pipe I11 of the remaining feeding tank 4 is connected with the discharge pipe of the reaction tank 1 Ⅱ12 meets at the feed port of the mixing tank. The inside of the reaction tank 1 is provided with a stirring device Ⅱ13, the air blowing ring 14 and the liquid level sensor Ⅱ15. The outside of the reaction tank 1 ...

Embodiment 2

[0028] Such as figure 1 As shown, a sizing preparation system for producing continuous basalt fibers, from top to bottom is a feeding system, a reaction tank 1, a mixing tank 2 and a distribution pipe 3, and the feeding system is composed of a feeding tank 4, which is arranged on Stirring device Ⅰ5 in the feeding tank, heating jacket Ⅰ6 arranged outside the feeding tank, liquid level sensor Ⅰ7 installed in the feeding tank, water inlet pipe Ⅰ9 with valve Ⅰ8 installed on the feeding tank and discharge with valve Ⅱ10 The outlet pipe I11 of the three feeding tanks is connected at the feed port of the reaction tank 1, and the outlet pipe I11 of the remaining one feeding tank 4 and the outlet pipe II12 of the reaction tank 1 are connected in the mixing tank. Confluence at the feed inlet, the inside of the reaction tank 1 is equipped with a stirring device Ⅱ13, the blowing ring 14 and the liquid level sensor Ⅱ15, the outside of the reaction tank 1 is provided with a heating jacket Ⅱ...

Embodiment 3

[0038] Such as figure 1 As shown, a sizing preparation system for producing continuous basalt fibers, from top to bottom is a feeding system, a reaction tank 1, a mixing tank 2 and a distribution pipe 3, and the feeding system is composed of a feeding tank 4, which is arranged on Stirring device Ⅰ5 in the feeding tank, heating jacket Ⅰ6 arranged outside the feeding tank, liquid level sensor Ⅰ7 installed in the feeding tank, water inlet pipe Ⅰ9 with valve Ⅰ8 installed on the feeding tank and discharge with valve Ⅱ10 The discharge pipe I11 of the three feeding tanks is connected at the feed port of the reaction tank 1, and the discharge pipe I11 of the remaining two feeding tanks 4 and the discharge pipe II12 of the reaction tank 1 are connected at the feed port of the mixing tank. Confluence at the feed inlet, the inside of the reaction tank 1 is equipped with a stirring device Ⅱ13, the blowing ring 14 and the liquid level sensor Ⅱ15, the outside of the reaction tank 1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com