Batching device of asphalt cold paving materials

A technology for cold feeding and asphalt, applied in the field of cold feeding asphalt, can solve the problems of difficult quality control and high configuration cost of cold feeding asphalt, and achieve the effects of easy control of batching quality, reduction of configuration costs, and avoidance of quality problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

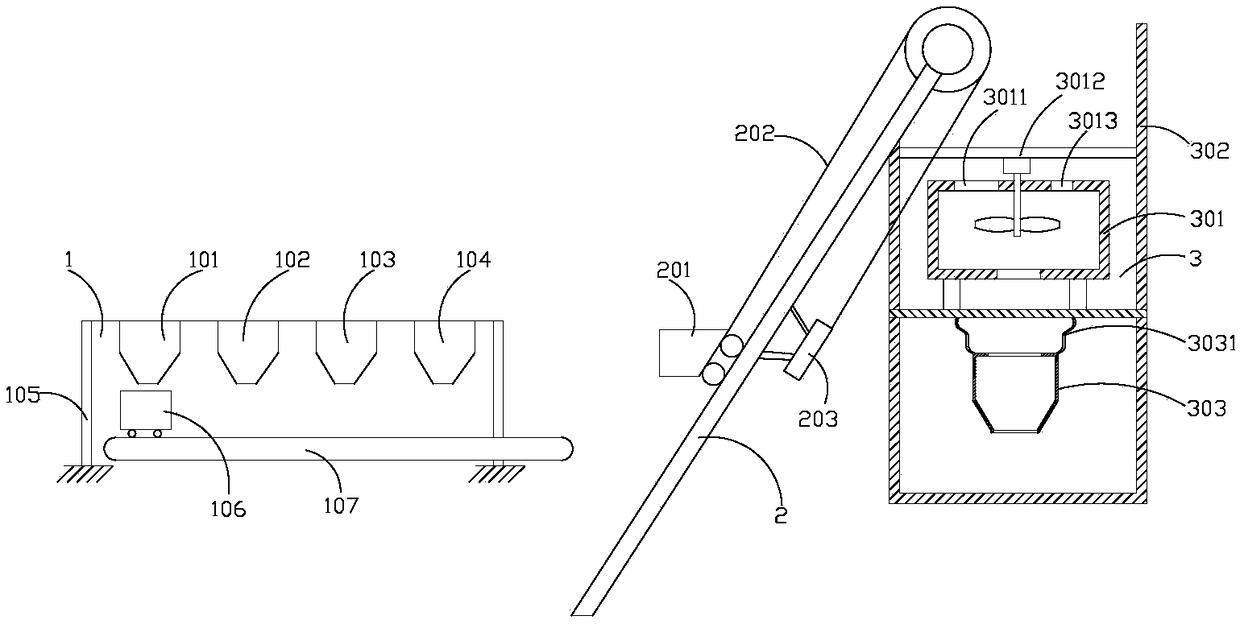

[0022] As shown in the figure, in this embodiment, an asphalt cold patch batching device includes a batching part 1, a transportation part 2 and a mixing part 3 connected to each other, and also includes a control device; After the equipment is completed, the stone is transported to the mixing unit 3 through the transportation unit 2, and the mixing is completed in the mixing unit 3 to form the final cold patching material. During the whole process, the batching, transportation and mixing are connected with the control device. Can be controlled remotely via the control unit.

[0023] In this embodiment, the batching part 1 includes a material rack 105, which is used to support the material bins arranged above the material rack 105, and each material bin is provided with a blanking port and a blanking baffle for controlling the opening and closing of the blanking port. When the blanking plate is opened, the stones in the silo will be discharged from the discharge port. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com